Deka 8A User manual

8A & 8G BATTERY INSTALLATION

AND OPERATING INSTRUCTIONS

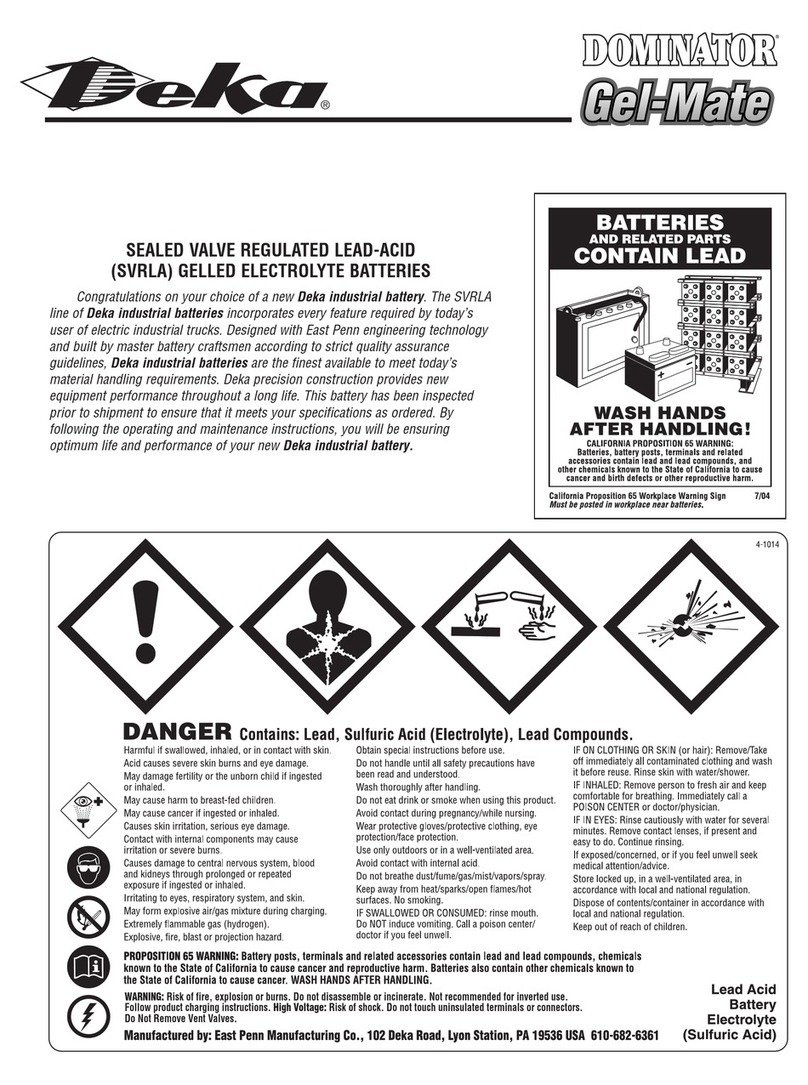

SAFETY PRECAUTIONS

Although all valve-regulated cells have the electrolyte

immobilized within the cell, the electrical hazards associ-

ated with batteries still exists. Work performed on these

batteries should be done with the tools and the protective

equipment listed below. VRLA battery installations should

be supervised by personnel familiar with batteries and

battery safety precautions.

WARNING: Risk of fire, explosion, or burns. Do not

disassemble, heat above 40°C, or incinerate.

Protective Equipment

Although VRLA batteries can vent or leak small amounts

of electrolyte, electrical safety is the principle but not

the only concern for safe handling. Per IEEE 1188 recom-

mendations, the following minimum set of equipment for

safe handling of the battery and protection of personnel

shall be available:

• Safety glasses with side shields, or goggles, or face

shields as appropriate. (Consult application specific

requirements)

• Electrically insulated gloves, appropriate for the installation.

• Protective aprons and safety shoes

• Portable or stationary water facilities in the battery

vicinity for rinsing eyes and skin in case of contact with

acid electrolyte.

SAFETY PRECAUTIONS (con’t)

• Class C fire extinguisher

• Acid neutralizing agent.

• Adequately insulated tools (as defined by ASTM F1505

“Standard Specification for Insulated and Insulating

Hand Tools”).

• Lifting devices of adequate capacity, when required.

Procedures

Consult User Manual of specific application for

additional Safety & Operating requirements.

The following safety procedures should be followed

during installation: (Always wear safety glasses with

side shields or face shield goggles when working on

or near batteries.)

1. These batteries are sealed and contain no free electrolyte.

Under normal operating conditions, they do not present any

acid danger. However, if the battery jar or cover is damaged,

acid could be present. Sulfuric acid is harmful to the skin

and eyes. Flush affected area with water immediately

and consult a physician if splashed in the eyes. Consult

SDS for additional precautions and first aid measures.

Consult SDS for additional

precautions and first aid measures.

SDS sheets can be obtained at

www.eastpennmanufacturing.com

2. Prohibit smoking and open flames, and avoid arcing

in the immediate vicinity of the battery.

®

This manual is intended to be a guide to optimize battery performance for multiple cyclic & float applications. Consult applicable

User Manuals for additional parameters for specific systems. This manual is not intended for SLI or Vehicle related applications.

Vehicle / Equipment Owner’s Manual should be followed for SLI & Vehicle related applications.

IN REFERENCE TO THIS MANUAL:

- “Battery” is defined as an individual 12 or 6 volt unit.

- “Battery string” is defined as a series connected

electrical system comprised of batteries (individual

12 or 6 volt units).

EAST PENN MFG. CO., INC. – Proprietary. No part of this document may be copied, reproduced or disclosed electronically or

mechanically, without written permission from the company. All data subject to change without notice.

EAST PENN MFG. CO., INC. – Proprietary. No part of this document may be copied, reproduced or disclosed electronically or

mechanically, without written permission from the company. All data subject to change without notice.

2

SAFETY PRECAUTIONS (con’t)

3. Do not wear metallic objects, such as jewelry, while

working on batteries. Do not store un-insulated tools in

pockets or tool belt while working in vicinity of battery.

4. Keep the top of the battery dry and clear of all tools and

other foreign objects.

5. Provide adequate ventilation (per IEEE standard 1187

and / or as regulated by Federal, State and Local

codes) and follow recommended charging voltages.

6. Never remove or tamper with pressure relief valves.

Warranty void if vent valve is removed.

7. Inspect all flooring and lifting equipment for functional

adequacy.

8. Adequately secure battery, racks or cabinets to the floor.

9. Connect support structures to ground system in accor-

dance with applicable codes.

STORAGE / REFRESH

Batteries should be installed, and float charged upon de-

livery. If batteries are to be stored, the below requirements

shall be followed.

1. Batteries shall be stored indoors in a clean, level, dry, cool

location.

2. Store, charge, and ship in vertical position only.

3. Recommended storage temperature is 50°F (10°C) to

77°F (25°C). Acceptable storage temperature is 0°F

(-18°C) to 90°F (32°C).

4. The batteries shall be given a refresh charge at regular

intervals as detailed below:

0°F(-18°C) to 77°F (25°C)

Batteries shall be charged by the “battery charge date”

marked on pallet.

Successive recharges shall be performed every 6 months.

78°F (26°C) to 90°F (32°C)

Battery voltage readings shall be taken monthly. Batteries

must be given a refresh charge within 3 months from date

of receipt or if any battery voltage falls below 12.72 volts

per battery (6.36V of 6V battery), whichever occurs first.

Successive refresh charges shall be performed every 3

months.

STORAGE / REFRESH (con’t)

5. Whenever a refresh charge is required, it’s important that

all batteries to be installed in the same series string re-

ceive a charge at the same time to ensure continuity once

placed in their intended application.

6. Each battery shall be charged for 24 hours at a constant

voltage equal to 14.40 volts per battery (7.20V for 6V

battery). To ensure the batteries are fully charged within

24hrs, the charger used for this refresh charge must have

the capacity to provide at least the minimum charge cur-

rent specification and not exceed the maximum charge

current for the given battery type (model), as called out in

Appendix D.

7. All requested information on “Refresh Record Form” in

Appendix A should be completed for each refresh charge.

8. Batteries shall not be stored beyond 12 months. Storing

beyond 12 months will affect warranty.

9. If the storage / refresh requirements cannot be met, con-

tact East Penn Reserve Power’s Product Support group

for alternate instructions.

INSTALLATIONS

General

Caution should be taken when installing batteries to

insure no damage occurs. The battery string cabinet,

tray, rack, etc. shall be inspected for sharp edges that

could cause damage to the battery casing. Batteries

shall not be dropped, slid, placed on rough or uneven

surfaces such as tray lips or grated flooring. Mishandling

of batteries could result in equipment damage or human

injury. East Penn will not be liable for damage or injury

as a result of mishandling or misuse of the product.

Grounding

When grounding the battery string, proper techniques

should be applied per electrical standards, such as

NEC and/or local codes, as well as User Manual of

specific application.

®

FOR ANY OTHER INSTALLATION ORIENTATION, THE PRODUCT WILL NOT BE WARRANTED.

DEKA 8A & 8G BATTERIES ARE TESTED AND APPROVED TO BE

INSTALLED AND OPERATED IN THEIR UPRIGHT POSITION.

Terminals – Upright Position Terminals – Upright / Front Position

TOP TERMINAL BATTERY FRONT TERMINAL BATTERY

3

BATTERY ASSEMBLY

(Always wear eye protection.)

1. Set up the batteries so that the positive post (+) of one

battery is connected to the negative post (–) of the next

battery for all series connections.

2. For future identification, individual batteries should be

numbered in electrical connection sequence, beginning

with number one (1) at the positive end of the battery

string.

3. All battery electrical contact surfaces shall be cleaned

by rubbing gently with a non-metallic brush or pad be-

fore installing connectors. Oxide inhibitor grease can be

used but is not required. Only approved oxide inhibitor:

No-Ox-ID “A” from Sanchem, Inc. should be used on ter-

minals and connectors.

4. Install all electrical connectors / cables and bolting

hardware loosely to allow for final alignment of batteries.

Torque to manufacturer recommendations.

5. After torquing, read the voltage of the battery string to

ensure the individual batteries are connected correctly.

The total voltage should be approximately equal to the

number of batteries times the measured voltage of one

battery (when connected in series). If the measurement

is less, recheck the connections for proper voltage and

polarity.

6. Read and record connection resistance and note the

method of measurement. This helps determine a satis-

factory initial installation and can be used as a reference

for future maintenance requirements. See Appendix E,

recording forms, in the back of the manual. Clean,

remake and remeasure any connection having a resis-

tance measurement greater than 10% of the average

of all the same type of connections.

7. Battery string performance is based on the output at the

battery terminals. Therefore, the shortest electrical con-

nections between the battery string and the operating

equipment results in maximum total system performance.

Do not select cable size on current carrying capability

only. Cable size should not provide a greater voltage

drop between the battery string and operating equip-

ment than specified. Excess voltage drop will reduce the

desired support time of the battery string.

SYSTEM OPERATION

State of Charge

Battery state of charge can be determined by measuring

the open circuit voltage. Consult the below table.

®

SYSTEM OPERATION (con’t)

Charging

Consult Charger User Manual of specific application

for Safety and Operating requirements.

For cyclic applications it is important that the bat-

tery(ies) be charged fully after each discharge. It is

recommended that 108% to 115% of the Ah (Amp

Hour) capacity removed from the battery(ies) be re-

placed after each

discharge. This additional Ah is to compensate for

any efficiency losses between the battery charger and

the battery(ies)

Charge Voltage

For both 8A & 8G batteries the following voltage set-

tings should be followed:

Charge / Absorption / Equalize

13.80V to 14.60V @ 77°F (25°C)

Float / Standby

13.50V +/- .06 @ 77°F (25°C)

The charger must be able to maintain the battery string

voltage within ± 0.5% of the desired level at all times.

Note: Divide values in half for 6-volt battery(ies).

TEMPERATURE COMPENSATION

Battery voltage should be adjusted for ambient

temperature variations.

3mV per °C (1.8°F) per cell

18mV per 12V battery

9mV per 6V battery

For temperatures above 77°F (25°C) subtract and

for temperatures below 77°F (25°C) add.

Consult Voltage Compensation Chart in

Appendix B for temperature compensation voltage

maximum and minimum limits.

The average battery operating temperature should not

exceed 95°F (35°C) and should never exceed 105°F

(40.5°C) for more than an eight-hour period. Operating

at temperatures greater than 77°F (25°C) will reduce the

operating life of the battery. If operating temperatures

are expected to be in excess of 95°F (35°C), contact

East Penn for recommendations.

Discharging at temperatures less than 77°F (25°C) will

reduce the capacity of the battery.

Charge Current

To properly determine the amount of charge current re-

quired the following variables are to be considered:

• DoD (Depth of Discharge)

• Temperature

• Size & efficiency of the charger

• Age and condition of battery(ies)

Maximum charge current should be limited to 30% of the

C20 Ah rate for the battery(ies) being used in the battery

string.

Example: 8G24 C20 rate – 73.6Ah

Max. recharge rate: 73.6Ah x 0.3 = 22.1A

Consult Charging Current vs Charging Time chart

in Appendix C as a guide line to determine recharge

time from 0% to 90% state of charge at an initial

charge current.

State of Charge vs. Open Circuit Voltage*

% Charge Gel AGM

100 12.85 or higher 12.80 or higher

75 12.65 12.60

50 12.35 12.30

25 12.00 12.00

0 11.80 11.80

NOTE: Divide values in half for 6-volt battery(ies)

*The “true” O.C.V. of a battery can only be determined

after the battery has been removed from the load

(charge / discharge) for 24 hours.

4

®

TEMPERATURE COMPENSATION

(con’t)

Discharge Voltage Curve

To estimate battery voltage during a constant current

discharge at various DoD (Depth of Discharge) consult

chart Discharge Voltage Curve in Appendix B.

NOTE: Battery voltage can vary depending on

temperature, age, and condition of battery.

BATTERY OPERATION

Battery operating temperature will effect battery string

capacity and operating life.

Temperatures greater than 77°F (25°C) will reduce the

operating life of the battery. For every 13°F (7°C) in-

crease in operating temperature above 77°F (25°C), the

warranty period will be proportionally reduced by 50%

as shown below:

The average cell operating temperature should not ex-

ceed 95°F (35°C) and should never exceed 105°F (40.5°C)

for more than an eight-hour period. If operating tem-

peratures are expected to be in excess of 95°F (35°C),

contact East Penn for recommendations.

Discharging at temperatures less than 77°F (25°C) will

reduce the capacity of the battery.

Batteries [cells] must not be continuously operated

below 50°F (10°C). If operating temperatures are

expected to be less than 50°F (10°C), contact East

Penn for recommendations.

The battery string must be located in a manner that the in-

dividual cells do not vary by more than 5°F (2.8°C) between

the lowest and highest individual cell temperatures.

RECTIFIER RIPPLE VOLTAGE

Frequency

Ripple that has a frequency greater than 667Hz (dura-

tion less than 1.5ms) is acceptable, unless it is causing

additional battery heating.

Ripple that has a frequency less than 667Hz (duration

greater than1.5ms), must meet the following voltage

specification to be acceptable.

Voltage Specification

Ripple voltage shall be less than .5% peak to peak of

the manufacturer’s recommended string voltage.

Failure to comply can void the warranty.

RECORD KEEPING

Voltages, Temperatures & Ohmic Readings

Record keeping is an important part of battery mainte-

nance and warranty coverage. This information will help

in establishing a life history of the battery string and

inform the user if and when corrective action needs to

be taken. Consult Battery Maintenance Report (Pg.8 –

Appendix E).

While it is acceptable to operate at temperatures less

than 77°F (25°C), it will require longer charging time to

become fully recharged. Also, the capacity will be less

at operating temperatures below 77°F (25°C).

After installation and when the battery string has been

on float charge for one week, the following data should

be recorded:

1. Battery string voltage at battery terminals while battery

is on float charge.

2. Charger voltage at charger panel meter.

3. Individual battery float voltages.

4. Ambient temperatures within area of battery string.

5. Terminal connections should be checked to verify that

the installer did torque all connections are properly

torqued. Micro-ohm readings should be taken across

every

connection. Refer to meter manufacturer’s instructions

for proper placement of probes. If any reading differs

by more than 20% from its initial installation value,

re-torque the connection, to 100 ± 5 in lb

(11.3 ± .5 newton meters) for proper torque values.

If reading remains high, clean contact surfaces ac-

cording to Step 2 under Battery Assembly.

Failure to maintain proper records including

information as detailed above may result in

voiding any applicable warranty.

Acceptance Testing

Each battery should be at 100% State of Charge prior

to performing an acceptance test on the battery system.

To ensure the batteries are fully charged the following

charge schedule should be followed.

Batteries should be charged at the equalization rate

of 14.40 volts per battery (7.20V for 6V battery) for 24

hours. Temperature compensated charging parameters

shall be applied as detailed in “Voltage Compensation

Chart” in Appendix B of this manual.

To ensure the batteries are fully charged within 24hrs;

the charger used for this charge must have the current

equal to the maximum charge current for the given

battery type (model), as called out in Appendix D of

this manual.

If these requirements cannot be met, contact East Penn

Reserve Power’s Product Support group for alternate

instructions.

Upon completion, the charge voltage should be

lowered to the float voltage of 13.50 volts per battery

(6.75V for 6V battery) for a minimum period of 72 hours.

Reference: IEEE 1188-2005 Section 7.2 for additional

acceptance test requirements.

Operating Temperature Proportional

Percentage (%)

of Life

°F °C

77 25 100%

81 27 80%

87 30 60%

90 32 50%

5

®

Upon completion of the above charge, the desired

acceptance test can be performed.

NOTE: There shall be no discharges of any duration

between the start of the equalization and the comple-

tion of the float period. If a discharge does occur, the

charging regime detailed above shall be repeated.

Upon completion of the acceptance test, the battery

system should be placed on float charge at 13.50 volts

per battery (6.75V for 6V battery) to restore the battery

to its’ rated capacity. Batteries should not require an

equalization charge once they have passed their ini-

tial acceptance test. Consult with East Penn Reserve

Power’s Product Support group before performing

additional equalizing charges on batteries that have

successfully passed their initial acceptance test.

MAINTENANCE

Always wear eye protection when working on or near

batteries. Keep sparks and open flames away from

batteries at all times.

Consult User Manual of specific application for

additional Safety & Operating requirements.

Annual Inspection

Depending on the application, some of the following

recommendations may not apply.

1. Conduct a visual inspection of the battery(ies).

2. Record battery and /or battery string voltage. The ac-

curacy of the DMM (Digital Multimeter) must be 0.05%

(on dc scale) or better. The DMM must be calibrated to

NIST traceable standards. Because voltage readings

are affected by discharge and recharges, for cyclic

applications, the battery(ies) must be in a fully charged

condition prior to taking readings. Batteries should be

within ± 0.30 volts (+ 0.15 volts for 6V) of the average

battery float voltage.

3. Record charger voltage at charger panel meter.

4. Record the ambient temperature.

5. Record the battery string temperature at the negative

terminal

6. Record individual battery ohmic readings.***

7. Record all interunit and terminal connection resis-

tances. Micro-ohm readings should be taken during

this inspection. If any reading is greater than 20% from

initial readings, retorque the connection. Recheck the

micro-ohm reading. If the reading remains high, clean

contact surface according to installation portion of this

manual.

*** Note: To provide accurate / consistent values,

battery(ies) must be fully charged, at same tem-

perature and probes placed at same location each

time readings are taken.

Battery Cleaning

Batteries, cabinets, and racks should be cleaned

with clean water, a mixture of baking soda and water or

East Penn Mfg. supplied battery cleaner (part # 00321

Never use solvents to clean the battery(ies).

Capacity Testing

Capacity testing is used to trend battery aging. The re-

sult of a capacity test is a calculation of the capacity of

the battery. The calculated capacity is also used to de-

termine if the battery requires replacement.

NOTE: When discharging at higher rates, extra con-

nectors may need to be added to prevent excessive

voltage drop and / or excessive temperature rise.

Should it be determined any individual battery(ies) or

cell(s) need to be replaced, contact your nearest East

Penn agent or East Penn Mfg. Co.

APPENDIX A

6

REFRESH RECORD FORM

EPM Order Number* Pallet ID Number Individual Performing Test (Full Name) Date of

Refresh Refresh Duration

Model

Number

Information Prior to Refresh Information within 1 hour of

Refresh Completion

Notes & Comments

Date

Code

Battery

Serial

Number

Open Circuit Voltage

Battery

Voltage

Reading

Charging

Current

Battery

Temperature

Battery 1

Battery 2

Battery 3

Battery 4

Battery 5

Battery 6

Battery 7

Battery 8

Battery 9

Battery 10

Battery 11

Battery 12

Battery 13

Battery 14

Battery 15

Battery 16

Battery 17

Battery 18

Battery 19

Battery 20

Battery 21

Battery 22

Battery 23

Battery 24

ALL FIELDS TO THE RIGHT OF THE CELL NUMBER ABOVE MUST BE COMPLETED

EPM ORDER NUMBER WILL APPEAR ON THE SHIPPING LABEL ON THE CARTON COVERING EACH PALLET OF BATTERIES

TO ENSURE CONTINUATION OF WARRANTY, SUBMIT FORMS TO: East Penn Mfg. Co, Inc.,

APPENDIX B

7

Voltage Compensation Chart

Note: 1. Above values based on 12-volt battery.

2. Divide above values in half for 6-volt battery.

°C Float Absorption / Regulation Equalize /

Maintenance °F

Min. Max.

>35 13.32 13.62 14.22 14.40 >95

34 13.34 13.64 14.24 14.42 93.2

33 13.36 13.66 14.26 14.44 91.4

32 13.37 13.67 14.27 14.45 89.6

31 13.39 13.69 14.29 14.47 87.8

30 13.41 13.71 14.31 14.49 86.0

29 13.43 13.73 14.33 14.51 84.2

28 13.45 13.75 14.35 14.53 82.4

27 13.46 13.76 14.36 14.54 80.6

26 13.48 13.78 14.38 14.56 78.8

25 13.50 13.80 14.40 14.58 77.0

24 13.52 13.82 14.42 14.60 75.2

23 13.54 13.84 14.44 14.62 73.4

22 13.55 13.85 14.45 14.63 71.6

21 13.57 13.87 14.47 14.65 69.8

20 13.59 13.89 14.49 14.67 68.0

19 13.61 13.91 14.51 14.69 66.2

18 13.63 13.93 14.53 14.71 64.4

17 13.64 13.94 14.54 14.72 62.6

16 13.66 13.96 14.56 14.74 60.8

15 13.68 13.98 14.58 14.76 59.0

14 13.70 14.00 14.60 14.78 57.2

13 13.72 14.02 14.62 14.80 55.4

12 13.73 14.03 14.63 14.81 53.6

11 13.75 14.05 14.65 14.83 51.8

<10 13.77 14.07 14.67 14.85 <50

8

APPENDIX C

DISCHARGE VOLTAGE CURVE

CHARGING CURRENT VS. CHARGING TIME*

BATTERY TYPE

A= 8AU1, 8GU1

B= 8G40C

C= 8A22NF, 8G22NF

D= 8G34R

F= 8A27, 8G27

G= 8A31DT, 8G30H,

8G31, 8G31DT

H= 8G5SHP

I= 8A4D, 8G4D, 8GTE35

J= 8A8D, 8G8D

K= 8AGC2, 8GGC2

9

APPENDIX D

Charge Current Limits

8A Series 8G Series

Cell Type Max. Charge

Current (A)

Min. Charge

Current (A)**

8AU1 9.6 2.9

8A22NF 16.5 5.0

8A24 23.7 7.1

8A24HEI 23.7 7.1

8A27 27.6 8.3

8A27EI 27.6 8.3

8A30H 31.5 9.5

8A30HEI 31.5 9.5

8A31DT 31.5 9.5

8AGC2 57.0 17.1

8A4D 59.4 17.8

8A8D 73.5 22.1

** = Using minimum charge current will extend recharge

time and increase risk of battery being undercharged

Cell Type Max. Charge

Current (A)

Min. Charge

Current (A)**

8GU1 31.6 9.5

8G40C 40.0 12.0

8G22NF 51.0 15.3

8G34R 60.0 18.0

8G24 73.6 22.1

8G24SS 73.6 22.1

8G27 88.0 26.4

8G30H 97.6 29.3

8G31 97.6 29.3

8G31DT 97.6 29.3

8GGC2 180 54.0

8G4D 183 54.9

8G4DEI 183 54.9

8G8D 225 67.5

8G8DEI 225 67.5

8G5SHP 115 34.5

8GTE35 196 58.9

10

APPENDIX E

11

Page Intentionally Blank

®

All data subject to change without notice. No part of this document may be copied or

reproduced, electronically or mechanically, without written permission from the company.

E.P.M. Form No. 1833 10/22 © 2022 by EPM Printed in U.S.A.

East Penn Manufacturing Co. Lyon Station, PA 19536-0147 Phone: 610-682-3263 Fax: 610-682-4781 www.dekabatteries.com

This manual suits for next models

1

Table of contents

Other Deka Camera Accessories manuals

Deka

Deka Unigy I User manual

Deka

Deka Dominator Gel-Mate SVRLA G45 User manual

Deka

Deka Unigy II User manual

Deka

Deka FastCharge F35 User manual

Deka

Deka unigy II SPACESAVER Non-Interlock AVR 45 AH User manual

Deka

Deka SOLAR Monoblock VRLA System Installation instructions

Deka

Deka unigy I User manual

Deka

Deka Dominator Gel-Mate SVRLA G105 User manual

Deka

Deka EZ LINK D35 User manual

Deka

Deka Unigy II AVR45 Series User manual