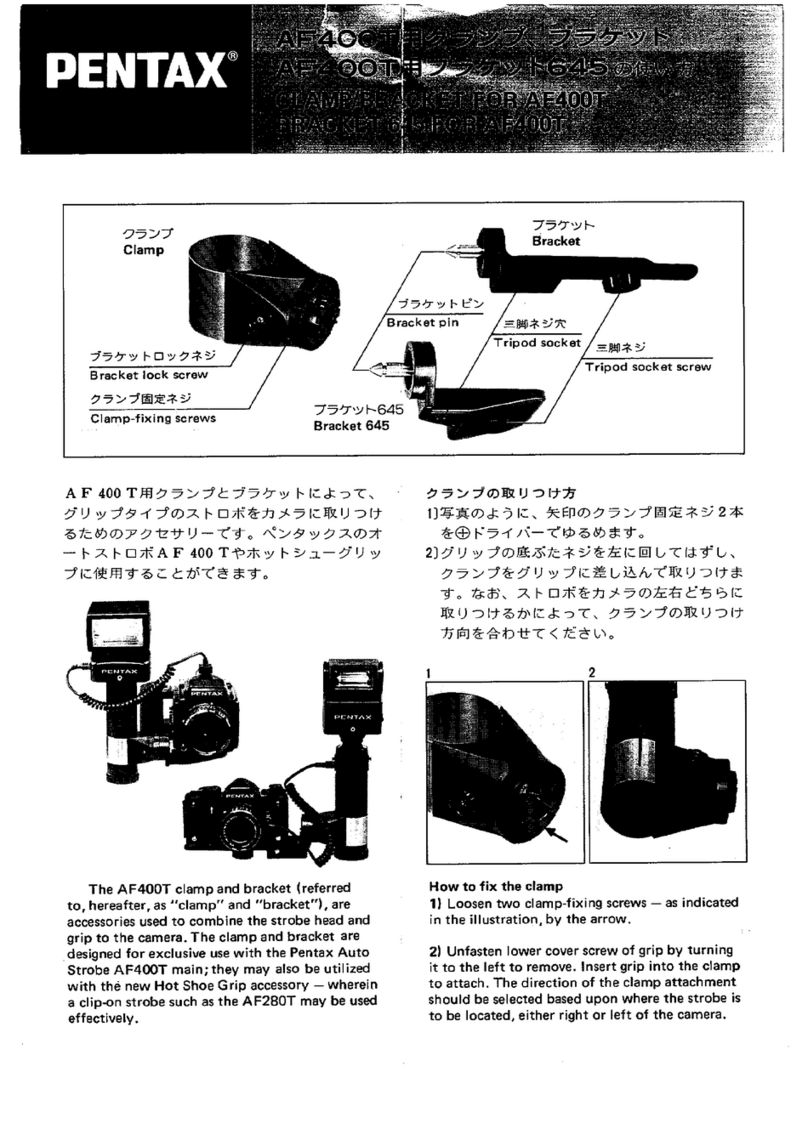

Deka SOLAR Monoblock VRLA System Installation instructions

Monoblock VRLA System

Installation & Operating Manual

System Design ................................................1

Battery Operation

Temperature ....................................................1

Depth of Discharge (DoD) ..............................1

Charging ..........................................................1

Inverter/Charge Controller Settings..............1

Bulk............................................................2

Absorption..................................................2

Float ..........................................................2

Equalize ....................................................3

Maintenance ....................................................3

Battery Location

Space ..............................................................3

Floor Preparation ............................................3

Battery Racking System ..................................3

Ventilation ........................................................3

Environment ....................................................3

Operating Equipment ......................................4

Series/Parallel Wiring ......................................4

Sa ety Precautions

Procedures ......................................................

Receiving & Storage

Receiving Inspection ......................................

Unpacking........................................................

Storage ............................................................

Installation

General............................................................

Grounding........................................................

System Operation

Charging ..........................................................

Charging Parameters ....................................

Charge Current..............................................

State of Charge ..............................................

Record Keeping

Maintenance

Annual Inspection ............................................

Rectifier Ripple ................................................

Capacity Testing ..............................................

Glossary

Appendix A – Renewable Energy Worksheet..

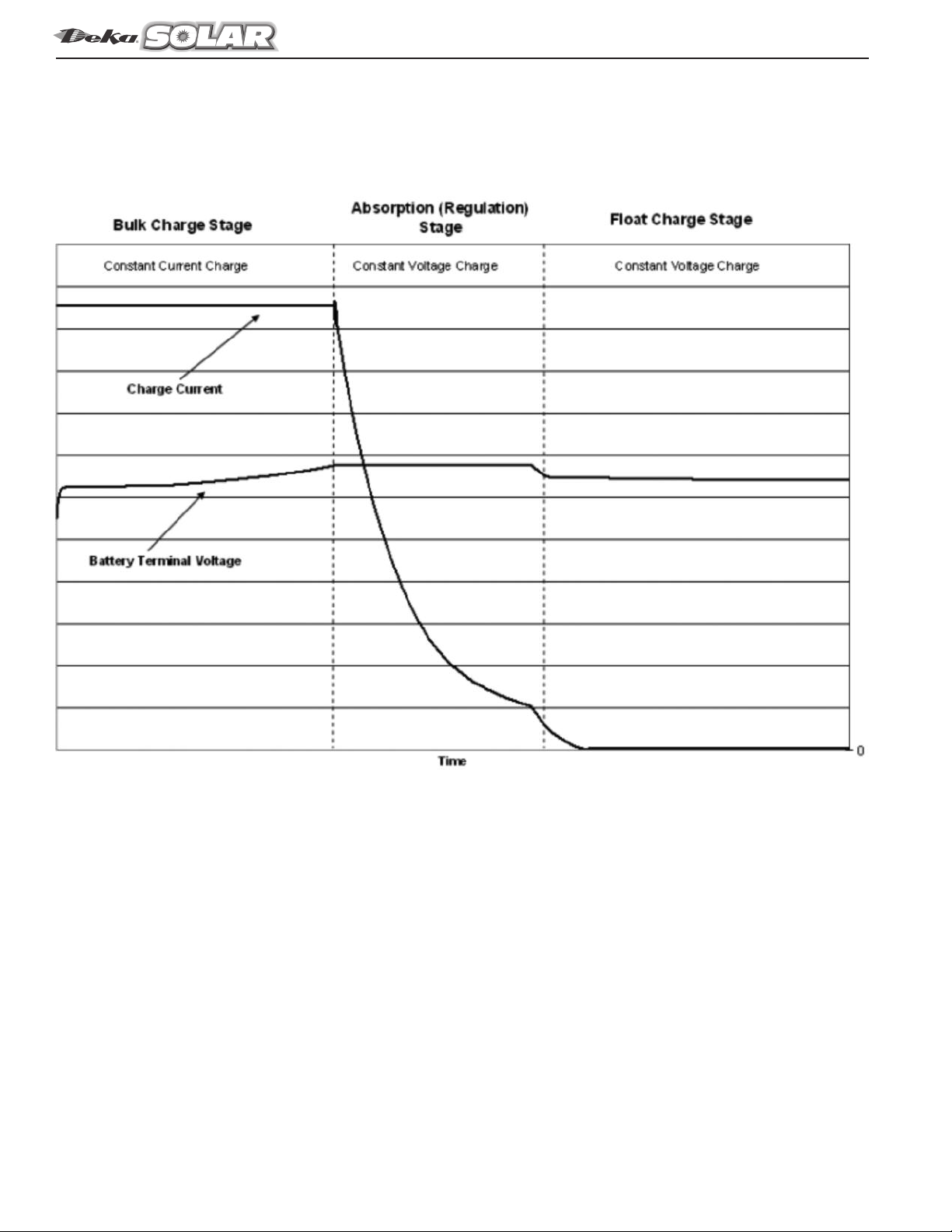

Appendix B – Example of Typical 3 Stage

Charger..............................................................

Appendix C – Depth of Discharge vs. Freezing

Point

Appendix D – Capacity vs. Temperature..........

Appendix E – Voltage Compensation Chart ....

Appendix F

Charging Current vs. Charging Time Chart ..

Discharge Voltage Curve ..............................

Appendix G – Battery Maintenance Report ........

TABLE OF CONTENTS

1

SYSTEM DESIGN

Systems Design is the process of defining the architecture,

components, modules, interfaces, and load data for a system

to satisfy specified requirements. For a solar system these

components are the PV modules, inverter/charge controller

& batteries, as well as the different interfaces of those

components.

To properly size a battery/battery bank for a renewable energy

system the following parameters are required:

Load – Amount of DC current (Amps, Ah) or power (Watts,

Wh) a battery is required to supply to a DC load or AC loads

through an inverter.

Time – expressed in hours the battery will be required to

provide the load.

System Voltage – DC system operating voltage

Ambient Temperature – Average temperature of battery

room or enclosure.

Depth of Discharge (DoD) – The proportion of energy that

has been removed from a battery; typically in a 24hr period

Example: 100% DoD is removing all

of the energy from a battery.

Autonomy – Length of time PV system can provide energy to

load without energy from PV array

Design Margin - Factor (typically expressed as a percentage)

to allow for future load additions.

A Renewable Energy Worksheet is provided in Appendix A

listing the above requirements along with additional information

requirements

BATTERY OPERATION

There are several factors that affect the operation of the battery

concerning its ability to deliver capacity and life expectancy.

Temperature

Many chemical reactions are effected by temperature, and

this is true of the reaction that occurs in a storage battery.

The chemical reaction of a lead-acid battery is slowed down

by a lowering of the electrolyte temperature that results in

less capacity. A battery that will deliver 100% of rated

capacity at 77° F will only deliver approximately 65% of

rated capacity at 32°F.

At temperatures below 32°F (0°C) a battery can freeze

dependent on the DoD (Depth of Discharge). The higher the

DoD, the closer to 32°F (0°C) before the battery will freeze.

The graph in Appendix C should be consulted to verify the

DoD of the battery / battery bank at the end of the discharge

will not be susceptible to freezing in a particular application.

If the electrolyte would freeze, the internal damage would be

irreversible requiring the battery to be replaced.

xcessive heat will increase the natural corrosion factors of a

lead-acid battery. This increase corrosion of the positive plates

contributes greatly to reducing the overall life of the battery.

Depth o Discharge (DoD)

Depth of discharge is a function of design. The deeper the

discharge per cycle, the shorter the life of the battery. A

cycle is a discharge and its subsequent recharge regardless

of depth of discharge.

Systems should be designed for shallow discharges. The

result of shallower discharges is typically a larger capacity

battery at prolonged battery life.

A Cycle vs. DoD chart should be consulted to determine the

number of cycles at a specific DoD and the projected life in

years the battery / battery system will provide prior to need-

ing replacement.

Charging

Majority of battery capacity/life issues can be traced to

improper charging. Improper charging settings may lead to

an overcharging or undercharging condition.

Typical Inverters/Charge Controllers charging lead-acid

batteries use 3 stage charging: Bulk, Absorption and Float

with an optional equalize stage. See Appendix B for an

example of a typical 3-stage charging curve.

Inverter/Charge Controller Settings

Proper Inverter/Charge Controller settings are necessary

to ensure peak battery performance and life. All bulk,

absorption, float and equalize settings should be verified they

are within the battery manufacturers settings. These settings

are included but not limited to; voltage, current and time.

Consult individual battery Installation & Operating manuals

for inverter/charge controller setting recommendations.

Default settings should not be presumed to be correct.

For battery systems located in an uncontrolled temperature

environment, temperature compensation must be used.

Bulk

Current is applied to the batteries at the maximum safe rate

they will accept until voltage rises to near (80-85%) full charge

level. The battery voltage rises because the charging current

that is provided by the battery charger is replenishing its

internal charge capacity. The charger current is flat (constant)

and the battery voltage is rising.

Maximum allowable charge voltage & current allowed by

the battery manufacturer should be used to ensure the most

energy is returned within the bulk stage.

Renewable nergy applications that depend on battery power as part of the system operation must be at

maximum performance at all times. To ensure this high rate of performance is achieved, the battery charging

system must be set properly. A battery/battery bank that is undercharged or overcharged will affect the

battery system performance & life, as well as the performance of the entire system.

Key factors that affect a batteries ability to provide the capacity and long life that is expected are: System

Design, Storage, Temperature, Depth of Discharge (DoD), Charging and Maintenance.

2

Bulk continued

Bulk Charge Stage Time Calculation:

Max Time ( r) = (Ahr x 1.2)/Avg. Current (A)

Ahr = Amp hours removed during discharge.

1.2 = Recharge multiplier

Avg. Current = Average current available

to battery from charger.

Note: Avg. current should be < maximum current limits

for installed battery. Charge current limits available

from your East Penn representative.

Max Time ( r) – Maximum charge time for battery to

reach 80% - 85% state of charge

Absorption

The charger will attempt to hold its output voltage constant

while the battery continues to absorb charge (draw charging

current) from the charger. The rate at which the battery con-

tinues to absorb charge in this mode gradually slows down.

The amplitude of the charger current is gradually decreasing.

The charge current is falling and the battery voltage is flat

(constant).

Some Inverter/Charge Controllers can either use time or

current to determine the length of the absorption stage.

Time regulated absorption is based on a predetermined time

after the battery has completed the bulk stage (charge voltage

has reached its maximum set point). A lead-acid battery is said

to be at 80% to 85% SOC (State of Charge) when the voltage

set point is met and the current starts to taper; considered the

start of absorption. The remaining time required to reach

100% SOC is based on ever changing factors: solar isolation

(summer vs. winter), ambient temperature, battery type

(flooded, VRLA), and battery age.

Absorption stage time should be set to optimize the available

sun hours during the winter and/or cloudy months. If improp-

erly set, there is a risk of undercharging the battery system.

It is recommended to set the absorption time to the maxi-

mum time setting possible to take advantage of all available

charging light regardless of time of year or weather issues.

Using this method, the sun availability will determine the

absorption time. Following this recommendation, there is no

risk of overcharging if the battery charge voltage is set within

the recommended settings.

The amount of available power (current) to the batteries is

important for getting a battery charged. Available power

(current) to the batteries is the remaining power (current) after

connected loads are satisfied. Maximum charge voltage and

current allowed by the battery manufacturer should be used to

ensure the most energy is returned to the batteries.

The below calculation will assist in identifying the necessary

maximum charge current for the system. If the calculation

shows the absorption time is greater than the minimum

average peak sun hours for the installation location, the

amount of available current to the batteries should be

increased, which could be accomplished by a larger array

or a secondary power source such as a generator.

Charge Current Verification:

FLOODED

C20 x 0.44/charge current available

Example:

Maximum Charge Current

Battery Rating: 1186 (C20)

2374A – Charge current (maximum)

1186Ah x 0.44/237 = 2.20 hrs

Minimum Charge Current

Battery Rating: 1186Ah (C20)

118A – Charge Current (minimum)

1186Ah x 0.44 / 118A = 4.42 hrs

VRLA (AGM & GEL)

C20 x 0.39 / charge current available

Maximum Charge Current

Battery Rating: 183Ah (C20)

55A – Charge current (maximum)

183Ah x 0.39 / 55A = 1.30 hrs

Minimum Charge Current

Battery Rating: 183Ah (C20)

18.3A – Charge Current (minimum)

183Ah x 0.39 / 18.3A = 3.90 hrs

Current regulated absorption is using the charge current to

determine battery state of charge, which eliminates a majori-

ty of the variables previously mentioned with time based

absorption (solar isolation, ambient temperature, battery

type). Charging in constant voltage, when a battery / battery

system reaches the absorption voltage setting, the current

will start to taper. The point at which the current stops taper-

ing or declining is referred to as the stabilizing current. This

is an indication that the battery is fully charged and the cur-

rent the battery / battery system is drawing is only needed to

keep the battery at the set voltage. This minimum or stabiliz-

ing current will change based on the charge voltage setting.

Battery manufacturer should be consulted for current set-

tings.

An additional option for determining the SOC of a battery is

monitoring the Ah (amp hour) removed from a battery dur-

ing a discharge and the amount of Ah returned during

charge; similar to a gas gauge in a car. The Ah in and out

should be monitored on a continuous basis to keep track of

the overall SOC not just from day to day.

Float

The voltage at which the battery is maintained after being

charged to 100% SOC (State of Charge) to maintain capacity

by compensating for self-discharge of the battery.

E ualize

A charge, at a level higher than the normal float voltage,

applied for a limited period of time, to correct inequalities of

voltage, specific gravity, or state of charge that may have

developed between the cells during service.

Note: Equalize charging not required on VRLA (AGM/Gel)

as part of a daily charge setup. Based on PV applications,

unpredictable recharge availability, periodic equalize may

be required.

3

E ualize continued

Charge Controller/Inverter charge setting recommendations

are detailed in System Operation section of this manual. A

voltage range is provided because of equipment setting

availability/limitations, however for optimal charge per-

formance all setting should be at the highest setting of the

battery range that the charge controller/inverter can handle.

Maintenance

I (Institute of lectrical and lectronics ngineers) suggests

batteries be checked on a monthly, quarterly and yearly basis.

ach time period requires different checks. A maintenance log

should be initiated at the time of installation.

Typical checks consist of voltage, specific gravity (not

required for VRLA) and visual inspections. Periodic verifica-

tion of voltages will ensure battery is being fully charged and

operating properly. If any conditions are found that are out of

specifications, corrections should be made.

A good battery maintenance program is necessary to protect

life expectancy and capacity of the battery. Reference IEEE

450 for Flooded batteries and IEEE 1188 for VRLA (Valve

Regulated Lead-Acid) batteries.

BATTERY LOCATION

When planning a battery system the following requirements

should be considered:

• Space

• Floor Preparation

• Battery Racking System

• Ventilation

• Environment

• Operating Equipment

Space

It is recommended that aisle space be provided in front of all

battery racks be a minimum of 36.0" (915mm). The design

should meet all applicable local, state and federal codes and

regulations.

Floor Preparation

It is recommended to consult with a structural engineer to

determine if the existing floor will withstand the weight of the

battery and the battery racking system. The floors in which the

battery will be located should have an acid-resistant coating.

Any battery spills should be neutralized with non-corrosive,

water based neutralizing chemical (ex: baking soda/water

solution) that is user safe and environmentally compliant.

The area should always be washed with clean water to remove

any acid neutralizing chemical residue.

Battery Racking System

The battery should not be installed directly on a floor. There

should be some type of barrier/racking between the floor and

the batteries. This barrier/racking should be sufficient to handle

the weight of the battery. The battery racking system must be

suitably insulated to prevent sparking and eliminate any

grounding paths.

Battery Racking System continued

Adequate space and accessibility for taking individual battery or

cell voltage, hydrometer readings and adding water should be

considered. If installed in an earthquake seismic zone, battery

racking system must be of sufficient strength and adequately

anchored to the floor. Battery rack design and anchoring should

be reviewed by a structural engineer.

Ventilation

It is the responsibility of the installer to provide detailed

methods or engineering design required by Federal, State

and local regulations to maintain safe levels of hydrogen in

battery rooms/enclosures.

The rate of hydrogen evolution is highest when the battery is

on charge. xplosive mixtures of hydrogen in air are present

when the hydrogen concentration is greater than or equal to

4% by volume. To provide a margin of safety, battery

room/enclosure must be ventilated to limit the accumulation of

hydrogen gas under all anticipated conditions. This margin of

safety is regulated by Federal, State and Local codes and is

typically limited to 1% to 2% by volume of the battery

room/enclosure.

Consult all applicable codes to determine specific margin of

safety. Hydrogen gas calculations can be determined by using

proper formulas.

Hydrogen gas is lighter than air and will accumulate, creating

pockets of gas in the ceiling. The ventilation system should be

designed to account for and eliminate this situation. Ventilation

system must be designed to vent to the outside atmosphere by

either natural or mechanical means in order to eliminate the

hydrogen from the battery room/enclosure.

Environment

Batteries should be located in a clean, cool and dry place and

isolated from outside elements. The selected area should be free

of any water, oil and dirt from accumulating on the batteries.

Operating Equipment

Battery systems are sized based on a specific load (Amps

or Watts) for a specific run time to a specific end voltage.

Battery performance is based on these values, as measured

at the battery terminals.

For proper operation of the battery system the following should

be considered:

• Distance between battery system and operating systems

should be kept at the shortest distant possible

• Cables are to be of proper gauge to handle system loads

and minimize voltage drops.

• All cable lengths from battery system to operating system

should be of the same wire gauge and length.

The above is to ensure the battery cable used will be able to

carry the charge/discharge current & minimize the voltage drop

between equipment.

lectrical equipment should not be installed above the batteries,

because of the possibility of corrosive fumes being released

from the battery(s).

4

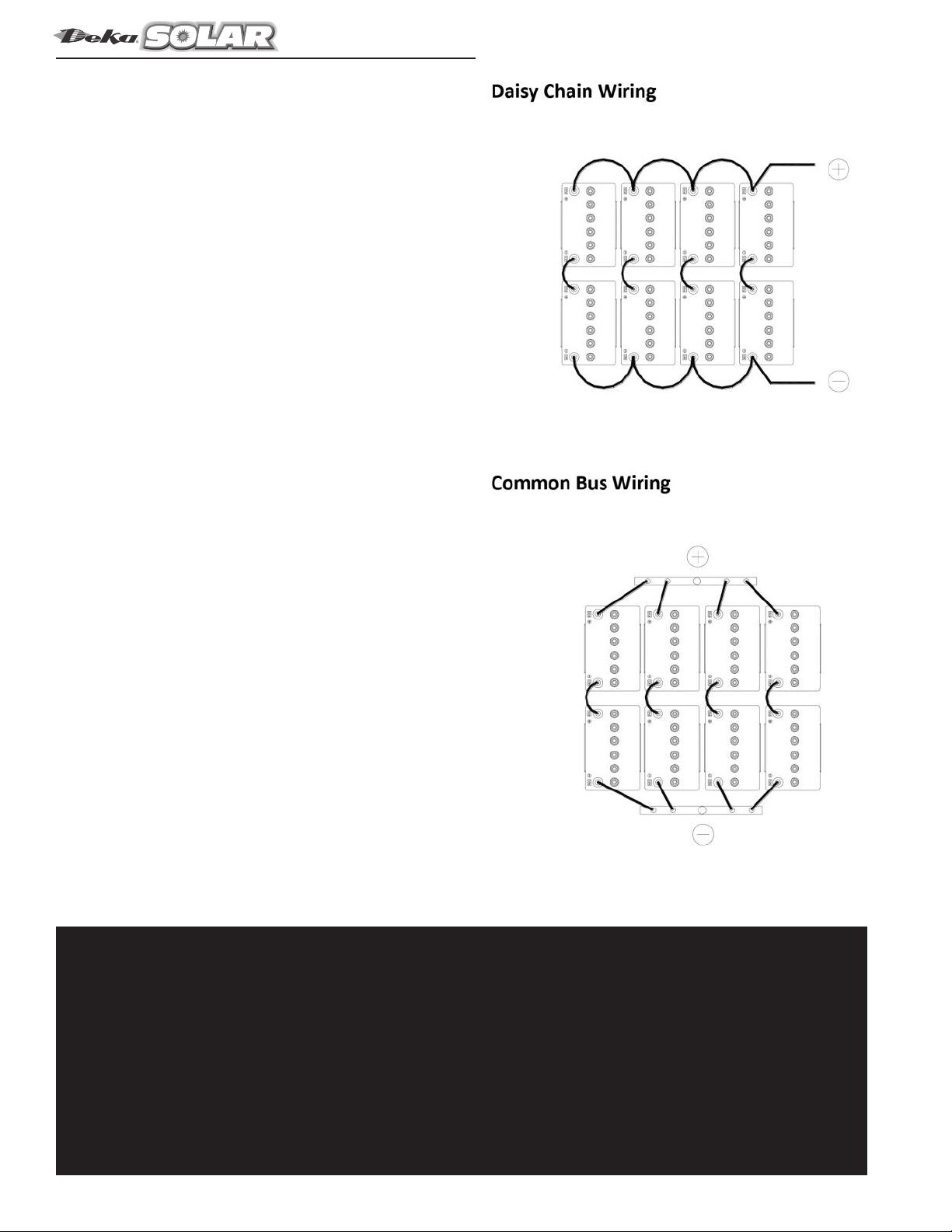

Series/Parallel Wiring

Series and parallel wiring of batteries as well as battery to

inverter/charge controller wiring should be designed to

minimize voltage drop. Wire gauge, wire length as well as

interbattery connection layout are all variables in reducing volt-

age drop as well as providing battery balance between parallel

battery strings.

Proceeding are examples of common wiring layouts with

narrative of the advantages and / or disadvantages of each.

Daisy Chain Wi ing a wiring scheme in which multiple

devices are wired together in sequence. All interconnecting

wiring should be of same length to minimize voltage drop.

Disadvantages:

• The interunit cables are required to increase in gauge

size to accommodate the increase in current of each

connected string.

• Maintenance and battery diagnostics require the entire

battery system to be disconnected from the renewable

energy system, leaving no back up energy source.

• Wiring connection assessment difficult to follow with

multiple wirings connected to same battery terminal,

increasing chance of re-connection wiring errors.

Common Bus Wi ing a wiring scheme in which same polarity

terminals are connected to a single termination point. All inter-

connecting wiring should be of same length to minimize volt-

age drop.

Advantages:

• Cables can be of same gauge.

• Maintenance and battery diagnostics can be performed

on a single string while maintaining a level of back up

energy source from the other strings staying connected

to the renewable energy system.

• Wiring connection assessment simplified by single

ONLY TRAINED AND AUTHORIZED PERSONNEL SHOULD

INSTALL, REPAIR OR CHARGE BATTERIES.

When used properly, a lead-acid renewable energy battery is a safe, dependable source of electrical

power. However, if proper care and safety precautions aren’t exercised when handling a battery, it can

be an extremely dangerous piece of equipment.

There are four hazardous elements in a lead-acid battery: sulfuric acid, explosive gases, electricity, and

weight.

5

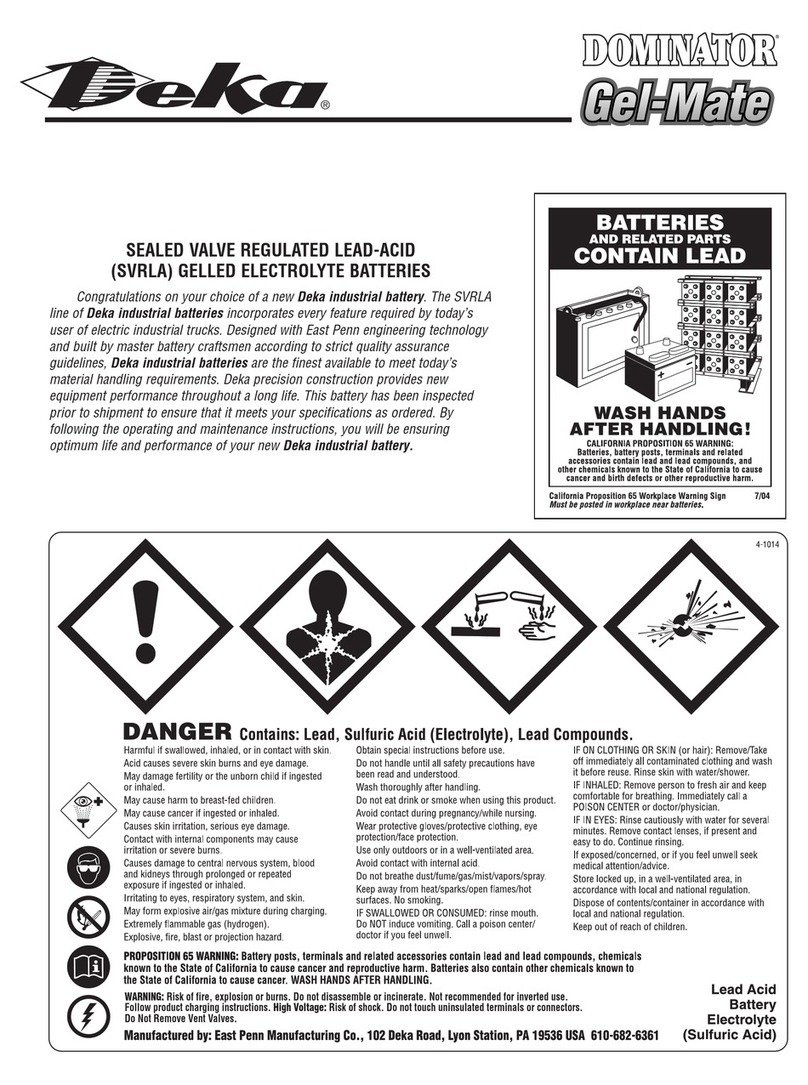

SAFETY PRECAUTIONS

Although all valve-regulated batteries have the electrolyte

immobilized within the battery, the electrical hazard associated

with batteries still exists. Work performed on these batteries

should be done with the tools and the protective equip-

ment listed below. Valve-Regulated battery installations

should be supervised by personnel familiar with batteries and

battery safety precautions.

WARNING: Risk of fire, explosion or burns. Do not

disassemble, heat above 40°C, or incinerate.

Protective E uipment

Although VRLA batteries can vent or leak small amounts of

electrolyte, electrical safety is the principle but not the only

concern for safe handling. Per I 1188 recommendations,

the following minimum set of equipment for safe handling of

the batteries and protection of personnel shall be available:

1. Safety glasses with side shields, or goggles, or face

shields as appropriate. (Consult application specific

requirements)

2. lectrically insulated gloves, appropriate for the installation.

3. Protective aprons and safety shoes.

4. Portable or stationary water facilities in the battery vicinity

for rinsing eyes and skin in case of contact with acid elec-

trolyte.

5. Class C fire extinguisher.

6. Acid neutralizing agent.

7. Adequately insulated tools (as defined by ASTM F1505

“Standard Specification for Insulated and Insulating Hand

Tools).

8. Lifting devices of adequate capacity, when required.

Procedures

The following safety procedures should be followed during

installation:

(Always wear safety glasses or face shield when working on

or near batteries.)

1. These batteries are sealed and contain no free electrolyte.

Under normal operating conditions, they do not present

any acid danger. However, if the cell jar or cover is dam-

aged, acid could be present. Sulfuric acid is harmful to

the skin and eyes.

Flush affected area with water immediately and consult a

physician if splashed in the eyes.

Consult SDS fo additional p ecautions and fi st aid measu es.

SDS sheets can be obtained at

.eastpennmanufacturing.com

2. Prohibit smoking and open flames, and avoid arcing in the

immediate vicinity of the battery.

3. Do not wear metallic objects, such as jewelry, while work-

ing on cells. Do not store un-insulated tools in pockets or

tool belt while working in vicinity of battery. Keep the top

of the battery string dry and clear of tools and other for-

eign objects.

4. Provide adequate ventilation (per IEEE standard 1187

and/or local codes) and follow recommended charging

voltages.

5. Never remove or tamper with the pressure relief valves,

except for cell replacement. Warranty void if vent valve is

removed.

6. Inspect flooring and lifting equipment for functional

adequacy.

7. Adequately secure cell modules, racks, or cabinets to the

floor.

8. Connect support structures to ground system in

accordance with applicable codes.

RECEIVING & STORAGE

Receiving Inspection

Upon receipt, and at the time of actual unloading, each pack-

age should be visually inspected for any possible damage or

electrolyte leakage. If either is evident, a more detailed inspec-

tion of the entire shipment should be conducted and noted on

the bill of lading. Record receipt date, inspection data and

notify carrier of any damage.

Unpacking

1. Always wear eye protection.

2. Check all batteries for visible defects such as cracked

containers, loose terminal posts, or other unrepairable

problems. Cells with these defects must be replaced.

3. Check the contents of the packages against the packaging

list. Report any missing parts or shipping damage to your

ast Penn agent or ast Penn Mfg. Co. immediately.

4. Never lift batteries by the terminal posts.

Storage

1. Cells should be stored indoors in a clean, level, dry, cool

location. Recommended storage temperature is 0°F to

90°F (–18°C to 32°C).

2. Stored lead-acid batteries self discharge and must be

given a boost charge to prevent permanent performance

degradation.

0°F to 77°F (-18°C to 25°C) storage:

Batteries should be recharged six months from date of

manufacture.

>77°F (25°C) storage:

Use the chart below for recharge intervals. Voltage readings

should be taken on a monthly basis. Batteries that reach

12.60V per 12V battery (6.30 per 6V battery) or less should

be recharged regardless of scheduled interval. Record dates

and conditions for all charges during storage.

3. If a boost charge is required; the recommended charge is

24 hours at a constant voltage equal to 14.40V per 12V

battery (7.20V per 6V battery).

4. Do not store beyond 12 months.

INSTALLATION

General

Caution should be taken when installing batteries to ensure

no damage occurs. Batteries shall not be dropped, slid, or

placed on rough or uneven surfaces such as tray lips or

grated flooring. Mishandling of batteries could result in

equipment damage or human injury. ast Penn will not be

liable for damage or injury as a result of mishandling or

misuse of the product.

6

Charging Parameters

Charge Voltage

Bulk Charge:

Current limited to 30% of C20 or 6 times I20.

Absorption Charge:

12.10V to 14.40V per 12V battery

Float Charge:

13.44V to 13.56V per 12V battery

Equalize:

14.40V to 14.60V per 12V battery

Note: Divide values in half for 6-volt battery.

Temperature Compensation

Battery voltage should be adjusted for ambient temperature

variations.

3mV per °C (1.8°F) per cell

18mV per 12V battery

9mV per 6V battery

For temperatures above 77°F (25°C) subtract and for temper-

atures below 77°F (25°C) add.

Consult Voltage Compensation Chart in Appendix D for

temperature compensation voltage maximum and minimum

limits.

The average battery operating temperature should not exceed

95°F (35°C) and should never exceed 105°F (40.5°C) for more

than an eight-hour period. Operating at temperatures greater

than 77°F (25°C) will reduce the operating life of the battery. If

operating temperatures are expected to be in excess of

95°F (35°C), contact East Penn for recommendations.

Discharging at temperatures less than 77°F (25°C) will reduce

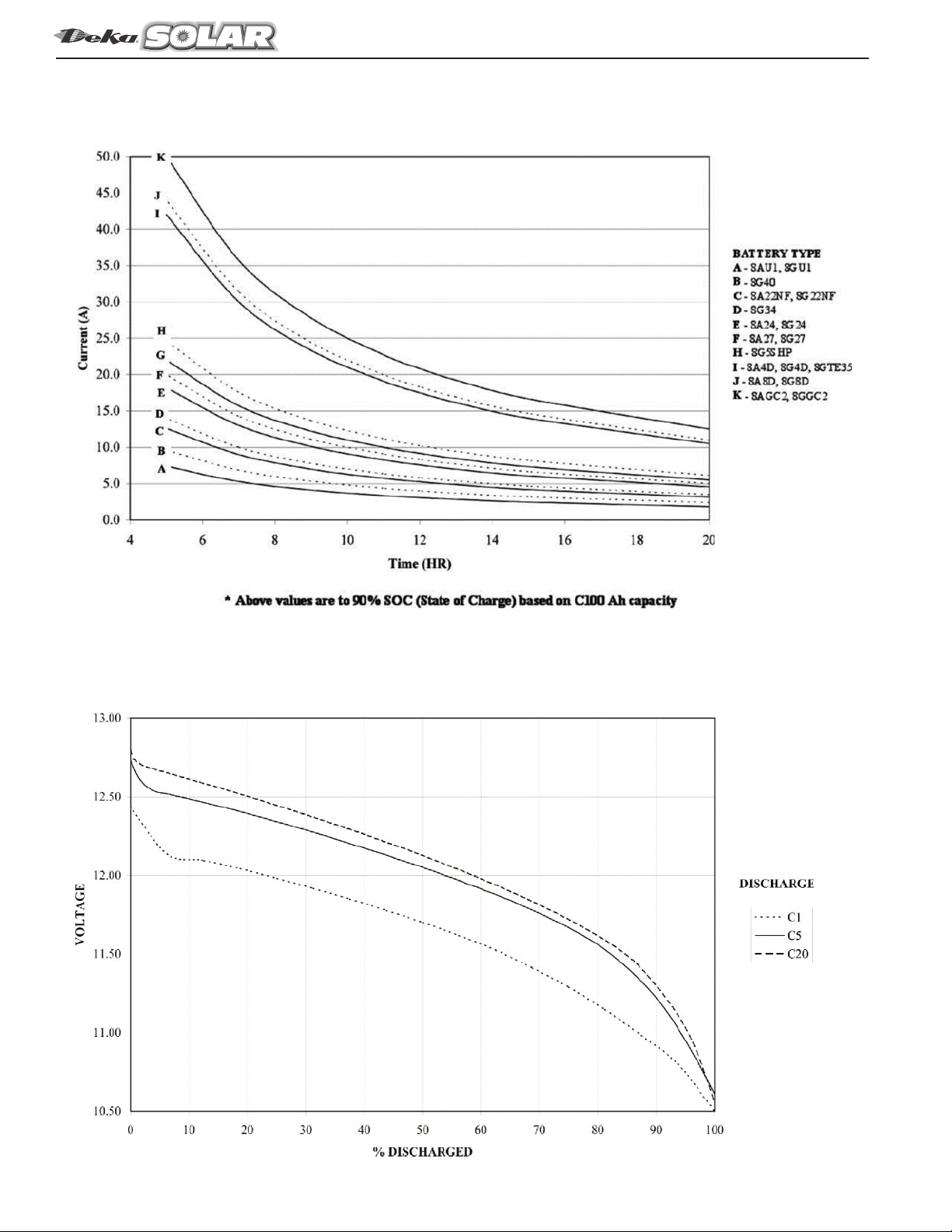

the capacity of the battery.

Charge Current

To properly determine the amount of charge current required

the following variables are to be considered:

• DoD (Depth of Discharge)

• Temperature

• Size & efficiency of the charger

• Age and condition of battery(ies)

Maximum charge current should be limited to 30% of the C20

Ah rate for the battery(ies) being used in the system.

Example: 8G24 C20 rate – 73.6Ah

Max. recharge rate: 73.6Ah x 0.3 = 22.1A

Consult Charging Current vs Charging Time chart in

Appendix E as a guide line to determine recharge time from

0% to 90% state of charge at an initial charge current.

Discharge Voltage Curve

To estimate battery voltage during a constant current dis-

charge at various DoD (Depth of Discharge) consult chart

Discharge Voltage Curve in Appendix E.

NOTE: Battery voltage can vary depending on tempera-

ture, age, and condition of battery.

Grounding

When grounding the battery system, proper techniques should

be applied per electrical standards, such as N C and/or local

codes, as well as User Manual of specific application.

BATTERY ASSEMBLY

(Always wear eye protection.)

1. Set up the batteries so that the positive post (+) of one

battery is connected to the negative post (–) of the next

battery for all series connections.

2. All battery electrical contact surfaces shall be cleaned by

rubbing gently with a non-metallic brush or pad before

installing connectors. No-Ox-ID grease can be used but is

not required.

3. Install all electrical connectors / cables and bolting

hard¬ware loosely to allow for final alignment of batteries.

Torque to manufacturer recommendations.

4. After torquing, read the voltage of the battery string to

ensure the individual batteries are connected correctly. The

total voltage should be approximately equal to the number

of batteries times the measured voltage of one battery

(when connected in series). If the measurement is less,

recheck the connections for proper voltage and polarity.

5. Read and record connection resistance and note the

method of measurement. This helps determine a satisfac-

tory initial installation and can be used as a reference

for future maintenance requirements. See Appendix B,

recording forms, in the back of the manual. Clean, remake

and re-measure any connection having a resistance meas-

urement greater than 10% of the average of all the same

type of connections.

6. Battery performance is based on the output at the battery

terminals. Therefore, the shortest electrical connections

between the battery system and the operating equipment

results in maximum total system performance.

7. Cable size selection should be determined by current

carrying requirements as well as providing a minimum

voltage drop between battery system and operation

equipment. Proper techniques should be applied per

electrical standards, such as N C and/or local codes.

Note: xcess voltage drop will reduce the support time

of the battery system.

SYSTEM OPERATION

There are several factors that affect the operation of the battery

system concerning its ability to deliver capacity and life

expectancy. Many chemical reactions are affected by tempera-

ture, and this is true of the reaction that occurs in a storage

battery. The chemical reac¬tion of a lead-acid battery is slowed

down by a lowering of the electrolyte temperature that result in

less capacity. A battery that will deliver 100% of rated capacity

at 77° F (25°C) will only deliver 65% of rated capacity at 32°F

(0°C).

Charging

Consult Charger User Manual of specific application for

Safety and Operating requirements.

For cyclic applications it is important that the battery system

be charged fully after each discharge. It is recommended that

108% to 115% of the Ah (Amp Hour) capacity removed from

the battery system be replaced after each discharge. This addi-

tional Ah is to compensate for any efficiency losses between

the battery charger and the battery system.

7

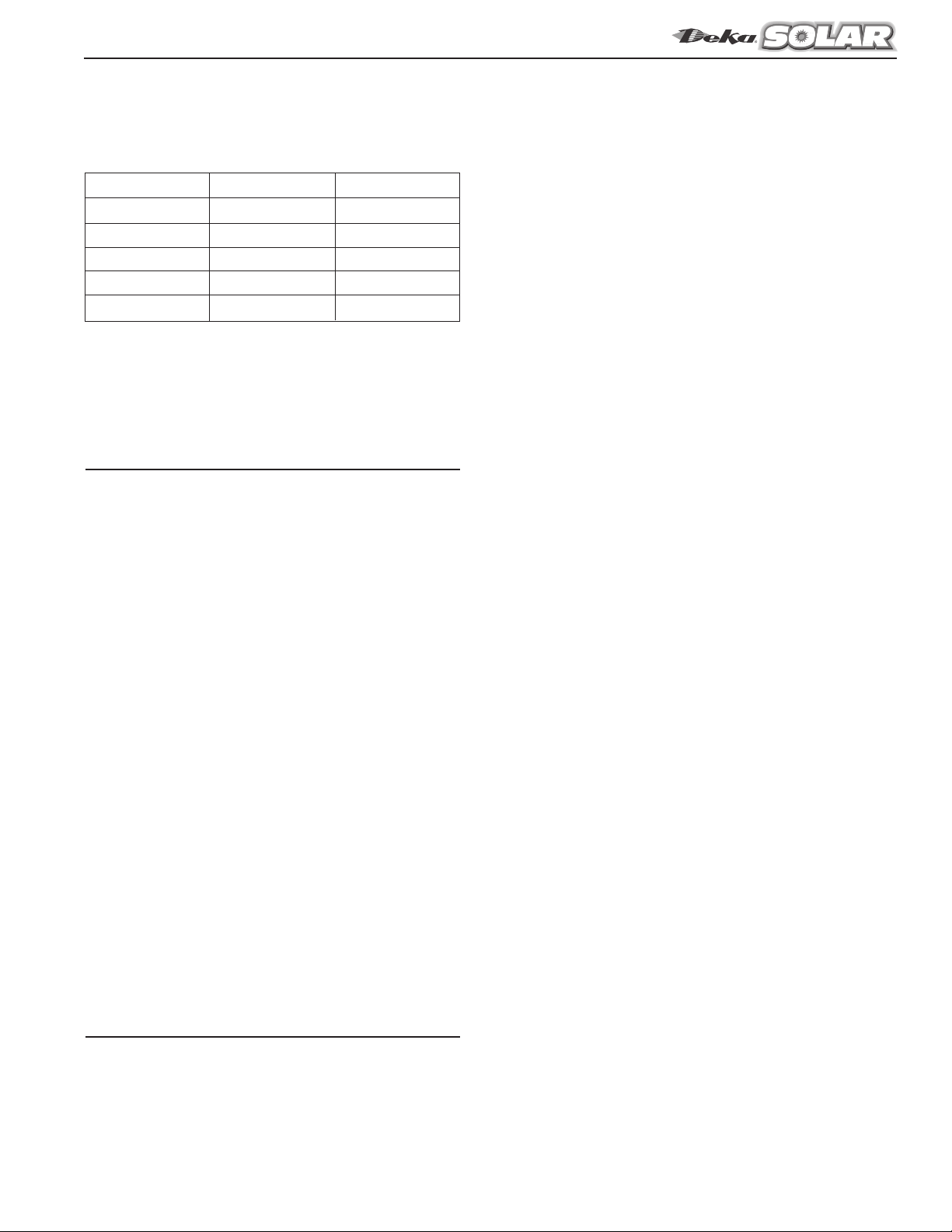

State of Charge

Battery state of charge can be determined by measuring the

open circuit voltage. Consult the below table.

State of Charge vs. Open Circuit Voltage*

NOTE: Divide values in half for 6-volt battery(ies)

*The “true” O.C.V. of a battery can only be determined after the

battery has been removed from the load (charge / discharge)

for 24 hours.

RECORD KEEPING

Voltages, Temperatures & Ohmic Readings

Consult User Manual of specific application for additional

Safety & Operating requirements.

Record keeping is an important part of battery mainte-nance

and warranty coverage. This information will help in establish-

ing a life history of the battery and inform the user if and when

corrective action needs to be taken. (Refer to Appendix B,

Battery Maintenance Report).

After installation and the batteries are at a fully charged

condition, the following data should be recorded:

Depending on application, some of the following recommen-

dations may not apply.

• Battery and/or string terminal voltage

• Charger voltage

• Individual battery float / charge voltages

• Individual battery ohmic readings**

• Ambient temperatures

• Terminal connections should be checked to verify all

connections are properly torques. Micro-ohm readings

should be taken across every connection. Refer to meter

manufacturer’s instructions for proper placement of

probes. If any reading differs by more than 20% from its

initial installation value, re-torque the connections. If the

reading still remains high, clean contact surfaces

according to installation portion of this manual.

** Note: To provide accurate consistent values, battery sys-

tems must be fully charged, at same temperature and probes

placed at same location each time readings are taken.

MAINTENANCE

Always wear eye protection when working on or near batteries.

Keep sparks and open flames away from batteries at all times.

Consult User Manual of specific application for additional

Safety & Operating requirements.

Annual Inspection

Depending on the application, some of the following recom-

mendations may not apply.

1. Conduct a visual inspection of the battery(ies).

2. Record battery and /or string voltage. The accuracy of the

DMM (Digital Multimeter) must be 0.05% (on dc scale) or

better. The DMM must be calibrated to NIST traceable

standards. Because voltage readings are affected by dis-

charge and recharges, for cyclic applica¬tions, the

battery(ies) must be in a fully charged condition prior to

taking readings. Batteries should be within ± 0.30 volts (+

0.15 volts for 6V) of the average battery float voltage.

3. Record charger voltage.

4. Record the ambient temperature.

5. Record individual battery ohmic readings.***

6. Record all interunit and terminal connection resistances.

Micro-ohm readings should be taken during this

inspec¬tion. If any reading is greater than 20% from initial

readings, retorque the connection. Recheck the micro-ohm

reading. If the reading remains high, clean contact surface

according to installation portion of this manual.

*** Note: To provide accurate / consistent values, battery(ies)

must be fully charged, at same temperature and probes placed

at same location each time readings are taken.

Rectifier Ripple Voltage

FREQUENCY

Ripple that has a frequency greater than 667Hz (duration less

than 1.5ms) is acceptable, unless it is causing additional battery

heating.

Ripple that has a frequency less than 667Hz (duration greater

than1.5ms), must meet the following voltage specification to

be acceptable.

VOLTAGE

Ripple voltage shall be less than .5% peak to peak of the

manufacturer’s recommended string voltage.

Battery Cleaning

Batteries, cabinets, racks, and modules should be cleaned with

clean water. If neutralizing is required, use a mixture of baking

soda and water. Use clean water to remove baking soda

residue. Never use solvents to clean the battery(ies).

Capacity Testing

Capacity tests should not be run unless the battery’s operation

is questionable. Do not discharge the battery(ies) beyond the

specified final voltage. When discharging at higher rates, extra

connectors may be required to prevent excessive voltage drop.

When performing capacity testing and recording data use

applicable standard and/or User Manual.

Should it be determined any individual battery(ies) or cell(s)

need to be replaced, contact your nearest ast Penn agent or

ast Penn Mfg. Co.

To determine if a battery can deliver its rated capacity, a test

discharge, or capacity test, can be performed. This test helps

determine the “health” of a battery and whether or not it

should be replaced.

Only experienced battery technicians should be allowed to

prepare a battery for discharge testing and to conduct the

actual discharge test.

% Charge Gel AGM

100 12.85 or higher 12.80 or higher

75 12.65 12.60

50 12.35 12.30

25 12.00 12.00

0 11.80 11.80

8

Capacity Testing continued

The test is conducted by discharging a fully charged battery at

a specific rate until the battery voltage drops to a

predeter¬mined volts per battery, times the number of batter-

ies in the battery system. By noting the time elapsed between

when the battery was put on discharge and when the final volt-

age was reached, you can determine whether the battery is

delivering its rated capacity:

1. Give the battery an equalizing charge until the current has

stabilized. Start the test and record the starting time.

2. Record individual battery voltages and overall battery sys-

tem voltages during the first hour at 10 minutes, 30 min-

utes and then 60 minutes. After the first hour, take hourly

readings until the first battery voltage reaches 10.80 volts

per battery. From this point on, record the voltage of the

batteries every 5 minutes. monitor the voltage of the low

batteries and as the voltage of each battery drops below

the predetermined final voltage, record the time.

3. When the majority of the batteries reach termination value,

stop the test. Don’t let any battery go into reversal.

For example, if the test was run at the 360 minute rate was ter-

minated after 336 minutes; the capacity percentage would be

93%

4. If the battery system delivers 50% or more of its rated

capacity, it can be returned to service. If the test indicates

less than 50% of the battery’s rated capacity is being deliv-

ered, the battery system should be either repaired or

replaced, depending upon its age and overall condition.

For more detailed information on capacity testing, contact

East Penn Manufacturing Company or your local authorized

East Penn Representative.

GLOSSARY:

AGM – Absorbed Glass Mat – A class of VRLA (Valve

Regulated Lead-Acid) battery in which the electrolyte is

absorbed into a glass mat.

Ambient Temperature – The average temperature of the

battery room. Temperatures below 77°F (25°C) will reduce

battery capacity. Temperatures above 77°F (25°C) will

reduce battery service life.

Amp our (Ah) – Amps times Hours

Battery fficiency – The amount of Ah return required to

achieve full SOC vs. the amount of Ah removed during dis-

charge. Require 110% to 115% Ah return

Capacity – The capacity of a battery is specified as the

number of Amp-Hrs that the battery will deliver at a specific

discharge rate and temperature. The capacity of a battery is

not a constant value and is seen to decrease with increasing

discharge rate.

C20 –Battery capacity measured in Ah (amp hour) at the

20hr rate.

End Voltage – The minimum voltage at which a DC system

will operate.

Flooded – A battery in which the products of electrolysis

and evaporation are allowed to escape to the atmosphere

as they are generated. lectrolyte is free flowing throughout

the battery.

Gel – A class of VRLA (Valve Regulated Leda-Acid) battery

in which the electrolyte is immobilized in a gel form (sulfuric

acid mixed with silica)

Parallel – A circuit that provides more than one path for the

flow of current. A parallel arrangement of batteries (usually

of like voltages and capacities) has all positive terminals

connected to a conductor and all negative terminals con-

nected to another conductor. If two 12-volt batteries of 50

ampere-hour capacity each are connected in parallel, the

circuit voltage is 12 volts, and the ampere-hour capacity of

the combination is 100 ampere-hours.

Series – A circuit that has only one path for the flow of

current. Batteries arranged in series are connected with

negative of the first to positive of the second, negative of the

second to positive of the third, etc. If two 12-volt batteries of

50 ampere hours capacity each are connected in series, the

circuit voltage is equal to the sum of the two battery volt-

ages, or 24 volts, and the ampere-hour capacity of the com-

bination is 50 ampere-hours.

SOC (State of Charge) – The amount of deliverable

low-rate electrical energy stored in a battery at a given time

expressed as a percentage of the energy when fully charged

and measured under the same discharge conditions. If the

battery is fully charged the “SOC” is said to be 100%.

Temperature Correction – A factor used to compensate for

battery capacity and/or adjust battery voltage at ambient

temperatures greater than or less than 77°F (25°C).

Undercharge (Deficit charge) – Charging a battery with less

ampere-hours (Ah) than is required to return the battery to

its initial state-of-charge. This results in a reduction in the

battery state-of-charge.

VPC – Volts per Cell

VRLA – Valve Regulated Lead Acid – a lead-acid cell/battery

that is sealed with exception of a valve that opens to the

atmosphere when the internal gas pressure exceeds atmos-

pheric pressure by a pre-selected amount. VRLA batteries

provide a means for recombination of internally generated

oxygen and the suppression of hydrogen gas evolution to

limit water consumption

9

APPENDIX A

Completing all parameters ensures accurate battery sizing.

Worksheet to be submitted to sales representative for battery recommendation.

10

APPENDIX B

Example of typical 3 stage charger

11

APPENDIX C

Depth of Discharge vs. Freezing Point

12

APPENDIX D

Capacity vs. Operating Temperature

13

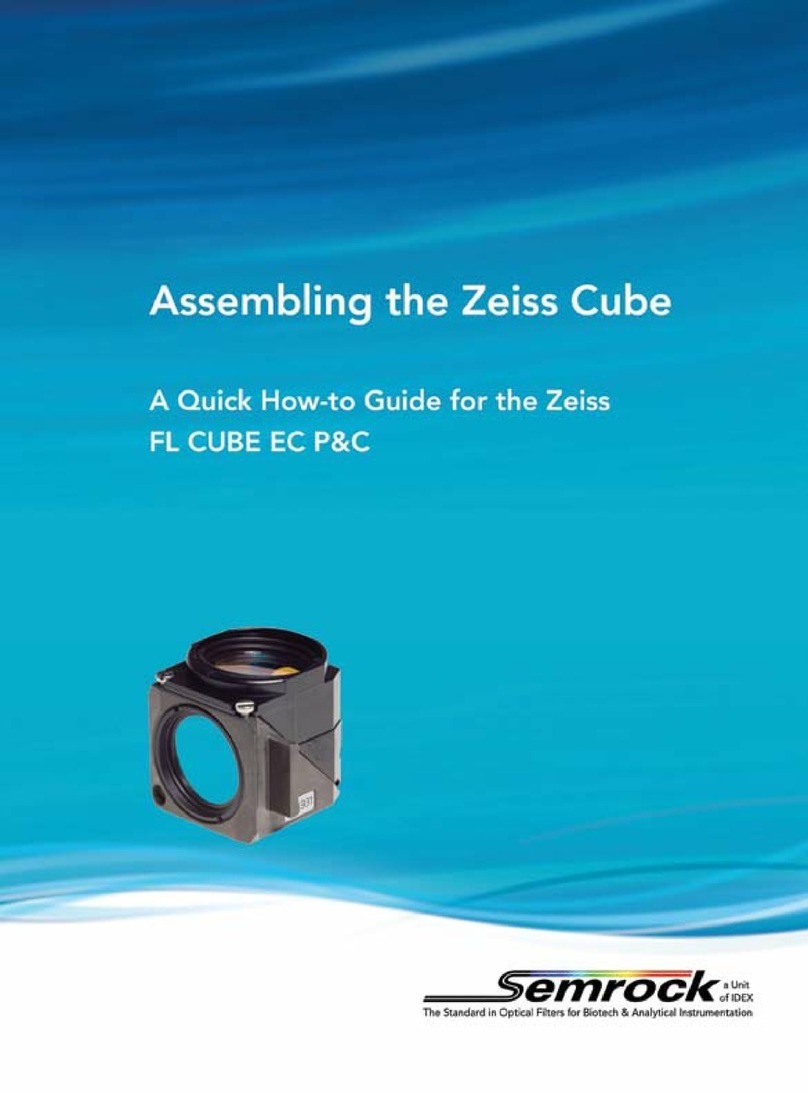

APPENDIX E

Voltage Compensation Chart

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!"#

$%&'(#

")'*+,-./0&*1(2&3#

!$#

4235#

4'65#

≥

!"#

$!%!&#

$!%'&#

$(%()#

≥

*"#

!(#

$!%!(#

$!%'(#

$(%(&#

*!%&#

!!#

$!%!'#

$!%''#

$(%((#

*$%(#

!&#

$!%!+#

$!%'+#

$(%("#

,*%'#

!$#

$!%!*#

$!%'*#

$(%(+#

,+%,#

!)#

$!%($#

$!%+$#

$(%(*#

,'%)#

&*#

$!%(!#

$!%+!#

$(%"$#

,(%&#

&,#

$!%("#

$!%+"#

$(%"!#

,&%(#

&+#

$!%('#

$!%+'#

$(%"(#

,)%'#

&'#

$!%(,#

$!%+,#

$(%"'#

+,%,#

&"#

$!%")#

$!%,)#

$(%",#

++%)#

&(#

$!%"&#

$!%,&#

$(%')#

+"%&#

&!#

$!%"(#

$!%,(#

$(%'&#

+!%(#

&&#

$!%""#

$!%,"#

$(%'!#

+$%'#

&$#

$!%"+#

$!%,+#

$(%'"#

'*%,#

&)#

$!%"*#

$!%,*#

$(%'+#

',%)#

$*#

$!%'$#

$!%*$#

$(%'*#

''%&#

$,#

$!%'!#

$!%*!#

$(%+$#

'(%(#

$+#

$!%'(#

$!%*(#

$(%+&#

'&%'#

$'#

$!%''#

$!%*'#

$(%+(#

')%,#

≤

$"#

$!%',#

$!%*,#

$(%+'#

≤

"*#

Note: 1. Above values based on 12-volt battery

2. Divide above values in half for 6-volt battery.

14

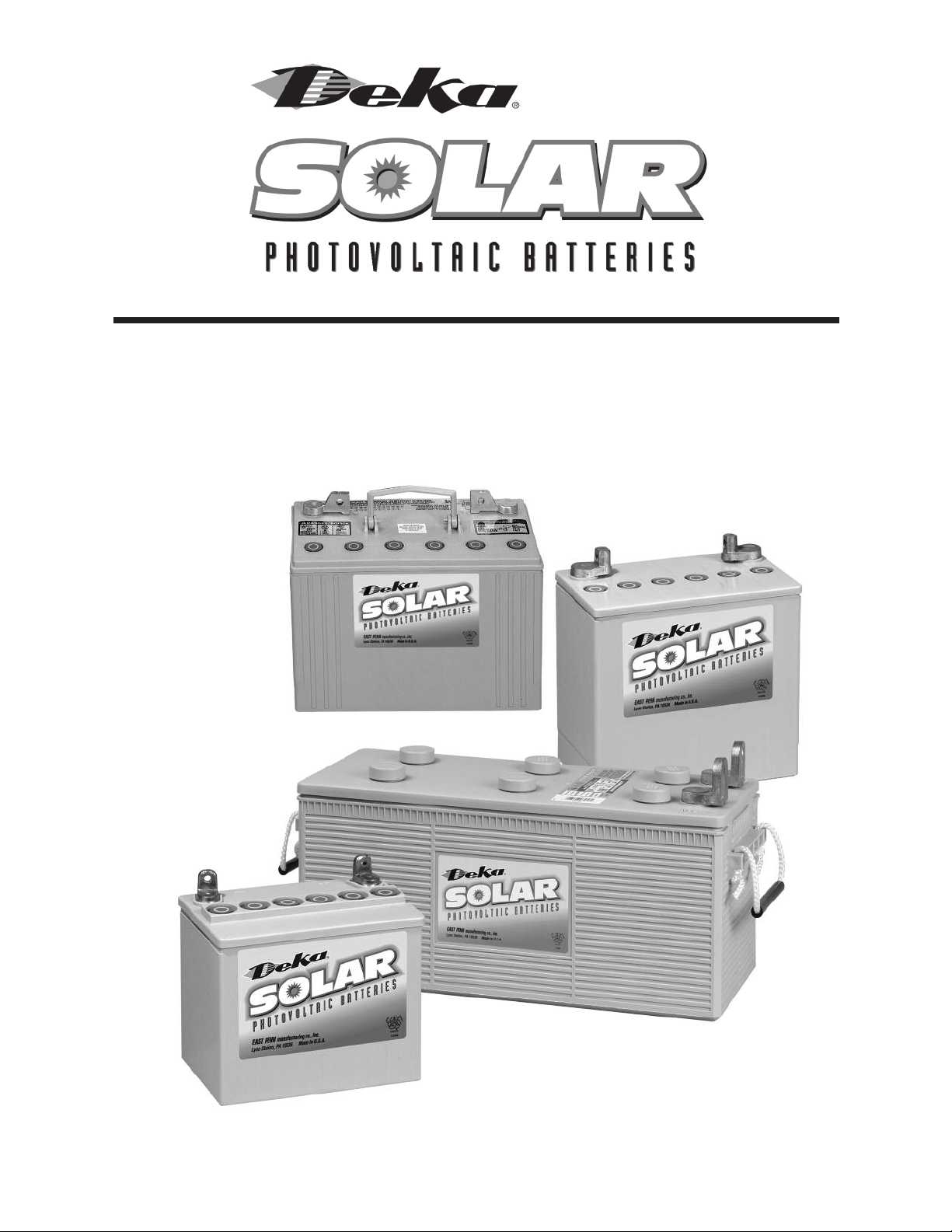

APPENDIX F

Charging Current vs Charging Time chart

Discharge Voltage Curve

!

!

!

!

!

!

!

!

APPENDIX G

Notes:

E.P.M. Form No. 2478. 6/19 © 2019 by EPM Printed in U.S.A.

An East Penn Manufacturing Co. Subsidiary

1-800-372-9253. www.mkbattery.com

e-mail: sales@mkbattery.com

www.dekabatteries.com

All data subject to

change without notice.

No part of this document may

be copied or reproduced,

electronically or mechanically,

without written permission

from the company.

Table of contents

Other Deka Camera Accessories manuals

Deka

Deka Unigy II AVR45 Series User manual

Deka

Deka FastCharge F35 User manual

Deka

Deka Unigy I User manual

Deka

Deka EZ LINK D35 User manual

Deka

Deka 8A User manual

Deka

Deka unigy II SPACESAVER Non-Interlock AVR 45 AH User manual

Deka

Deka unigy I User manual

Deka

Deka unigy User manual

Deka

Deka Unigy II User manual

Deka

Deka Dominator Gel-Mate SVRLA G45 User manual

Popular Camera Accessories manuals by other brands

Logitech

Logitech CIRCLE 2 quick start guide

VADDIO

VADDIO WALLVIEW DVI/HDMI HD-20 Installation and user guide

RODE Microphones

RODE Microphones VideoMic instruction manual

Aigis Mechtronics

Aigis Mechtronics HS9383S-2HP Installation and operating instructions

Axis

Axis A4020-E user manual

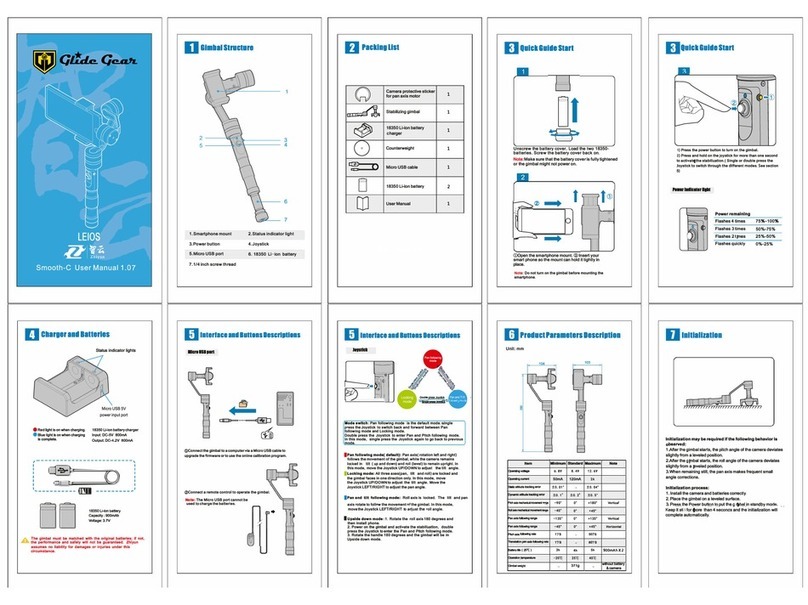

Glide Gear

Glide Gear LEIOS SMOOTH-C user manual