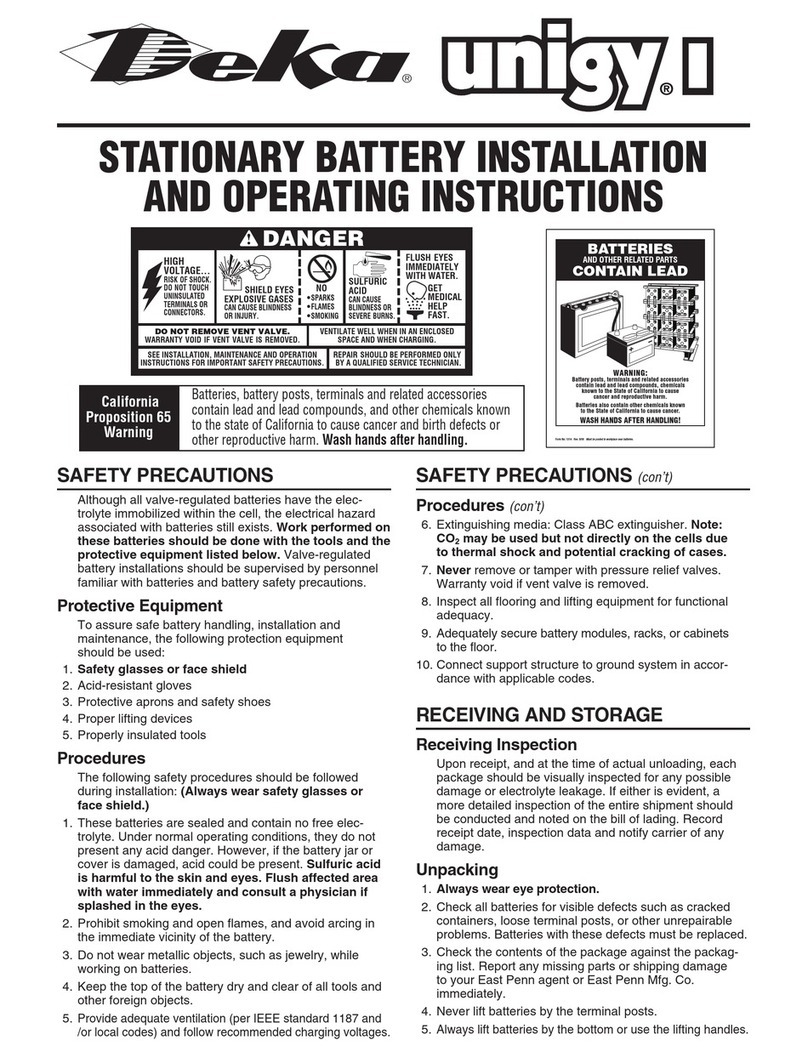

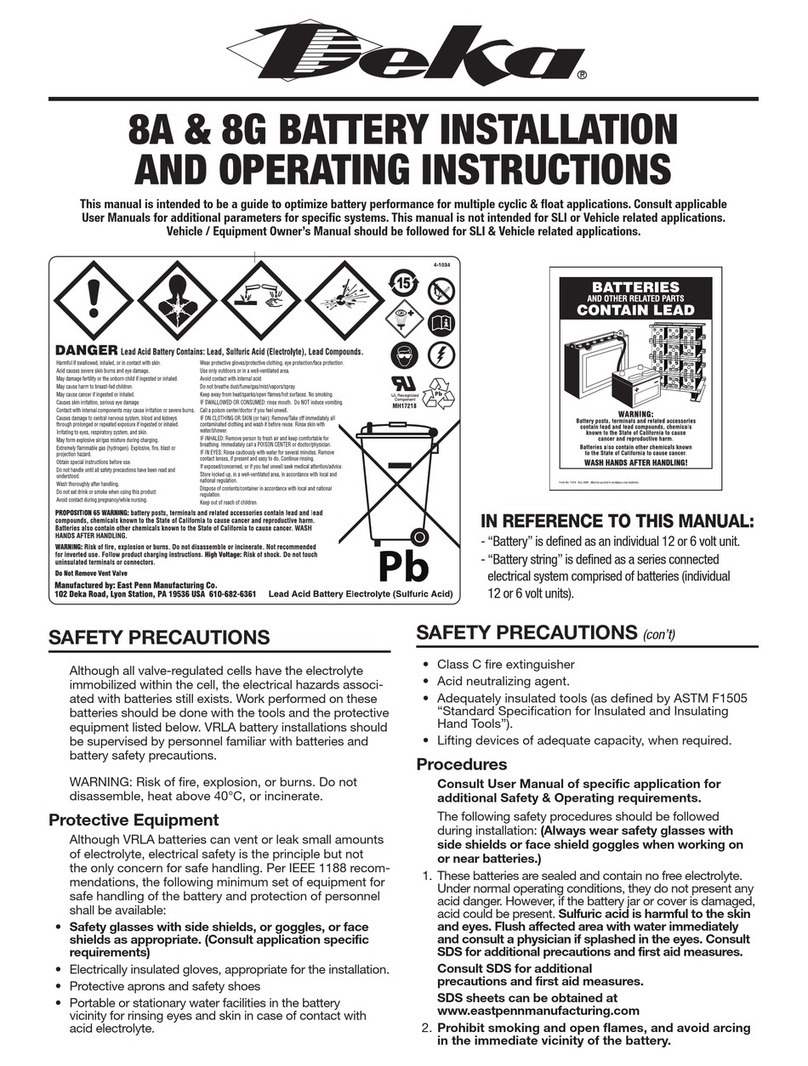

SAFETY PRECAUTIONS

Although all valve-regulated batteries have the elec-

trolyte immobilized within the cell, the electrical hazard

associated with batteries still exists. Work performed

on these batteries should be done with the tools

and the protective equipment listed below. Valve-

regulated battery installations should be supervised by

personnel familiar with batteries and battery safety

precautions.

Protective Equipment

To assure safe battery handling, installation and main-

tenance, the following protective equipment should be

used.

1. Safety glasses or face shield

2. Acid-resistant gloves

3. Protective aprons

4. Proper lifting devices

5. Tools with insulated handles

Procedures

(Always wear safety glasses or face shield when

working on or near batteries. Refer to Fig. 1-1 on

pg. 2.)

The following safety procedures should be followed

during installation:

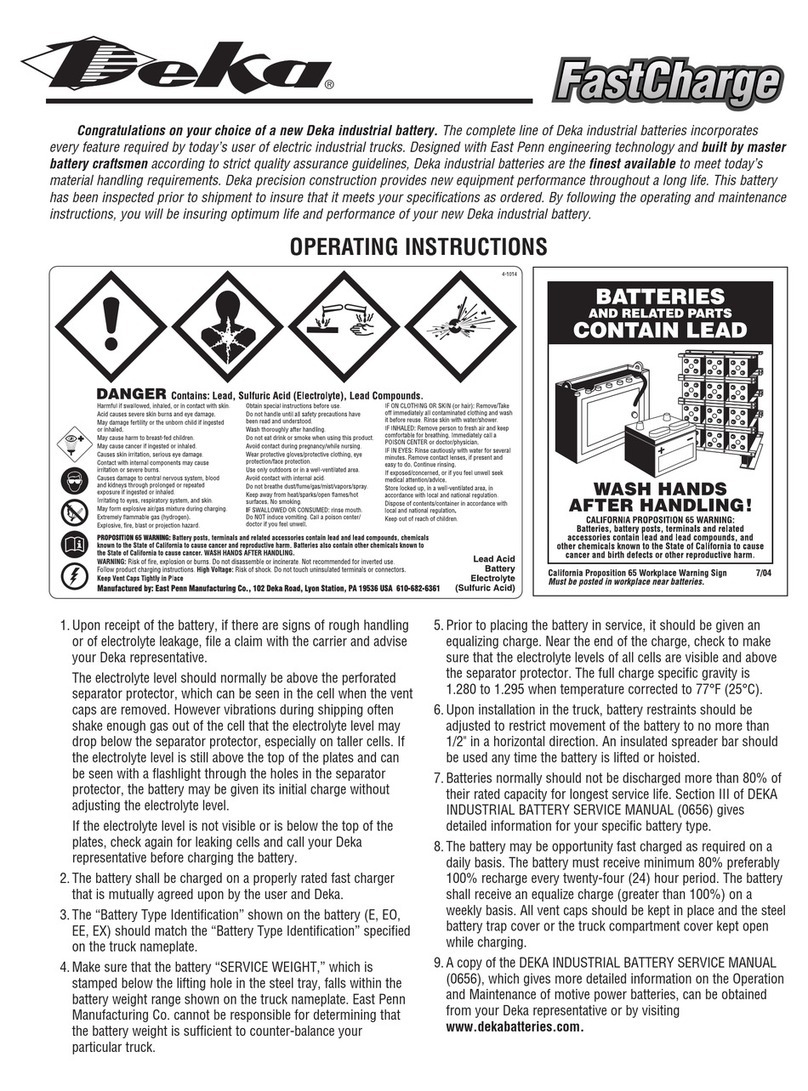

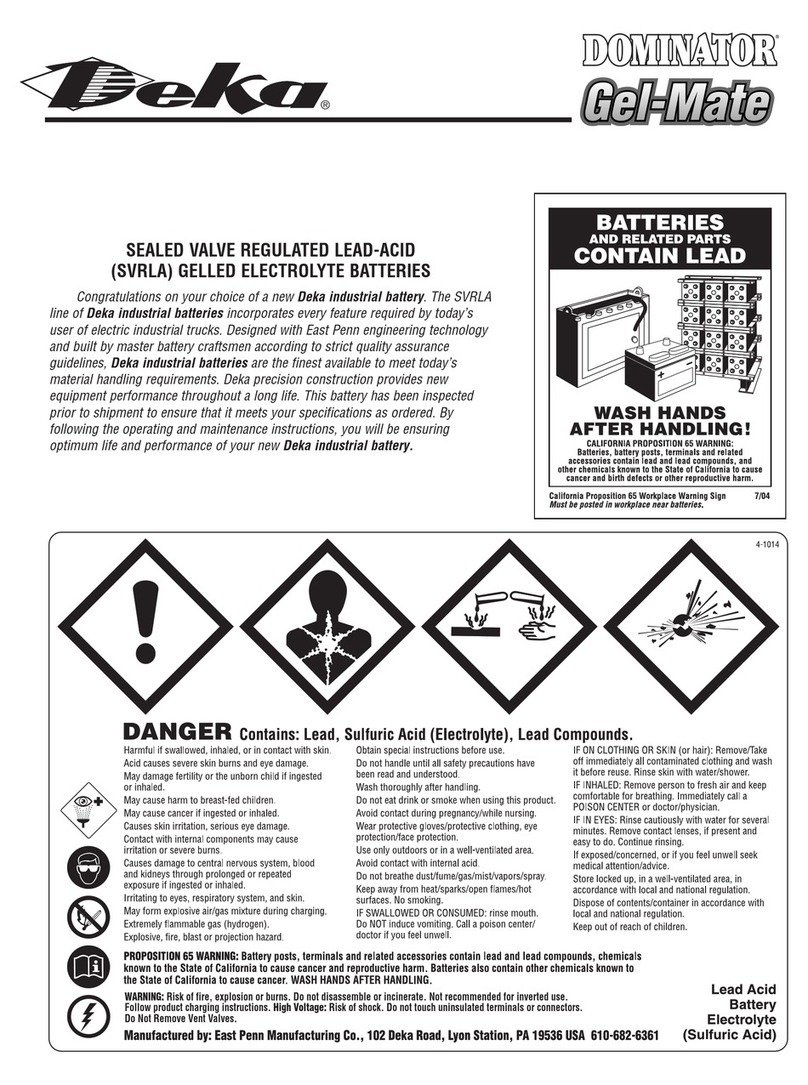

1.These batteries are sealed and contain no free

electrolyte. Under normal operating conditions, they

do not present any acid danger. However, if the

battery jar or cover is damaged, acid could be

present. Sulfuric acid is harmful to the skin and

eyes. Flush affected area with water immedi-

ately and consult a physician if splashed in the

eyes.

2. Prohibit smoking and open flames, and avoid

arcing in the immediate vicinity of the battery.

3. Do not wear metallic objects, such as jewelry,

while working on batteries.

4. Keep the top of the battery dry and clear of tools

and other foreign objects.

5. Provide adequate ventilation and follow recom-

mended charging voltages.

6. Refer to Material Safety Data Sheet for proper extin-

guishing mehod (See Appendix B, Sect. 4, pg 15.).

7. Never remove or tamper with the pressure relief

valves.Warranty void if vent valve is removed.

8. Inspect all flooring and lifting equipment for func-

tional adequacy. Specifically review floor-loading

capacity.

9. Adequately secure battery modules to the floor.

10. Connect support structures to ground system in

accordance with applicable codes.

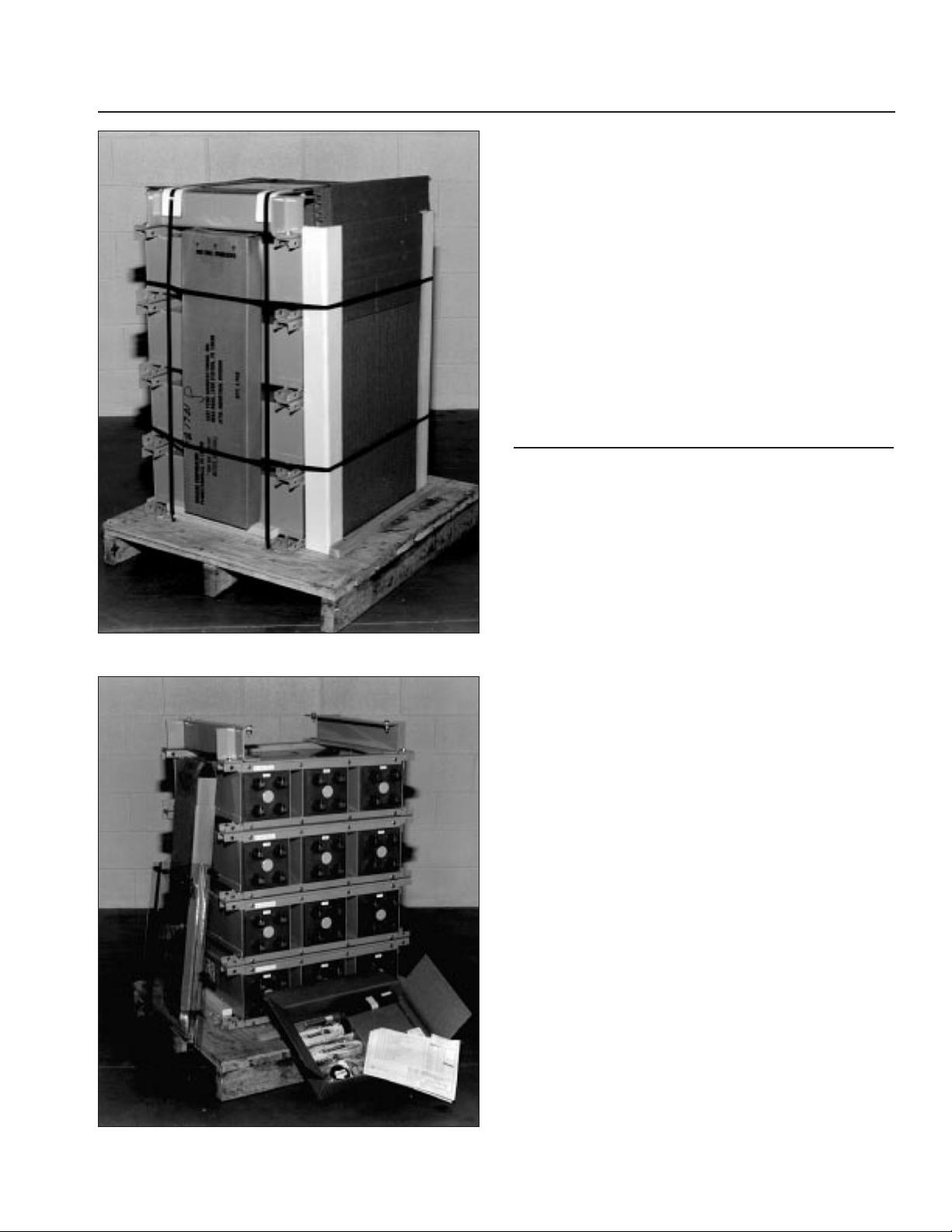

RECEIVING & STORAGE

Receiving Inspection

Upon receipt of the battery and at the time of unload-

ing, each package should be visually inspected for

damage. If damage is evident, a more detailed inspec-

tion of the entire shipment should be conducted and

noted on the bill of lading. Record receipt date and

inspection data, and notify the carrier of any damage.

Unpacking

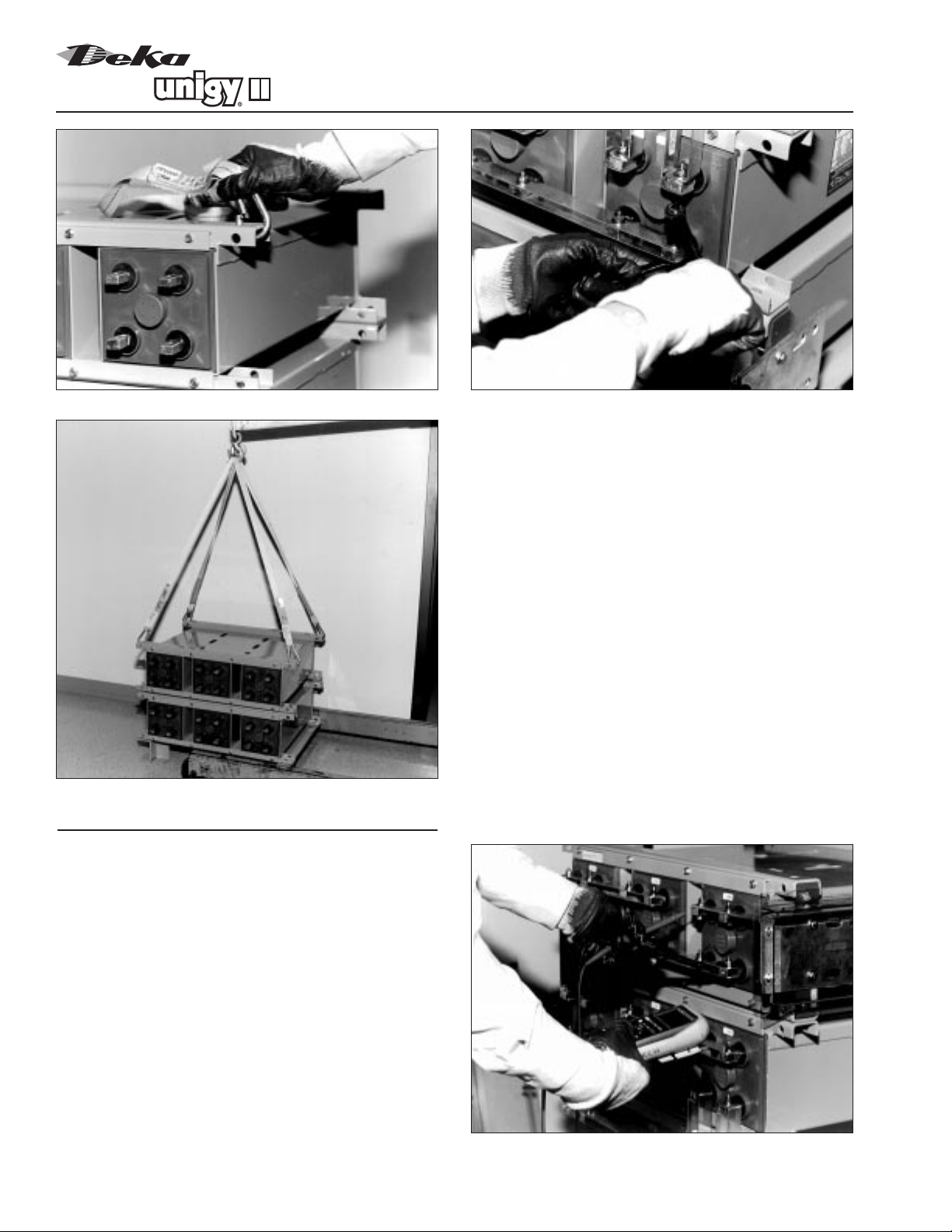

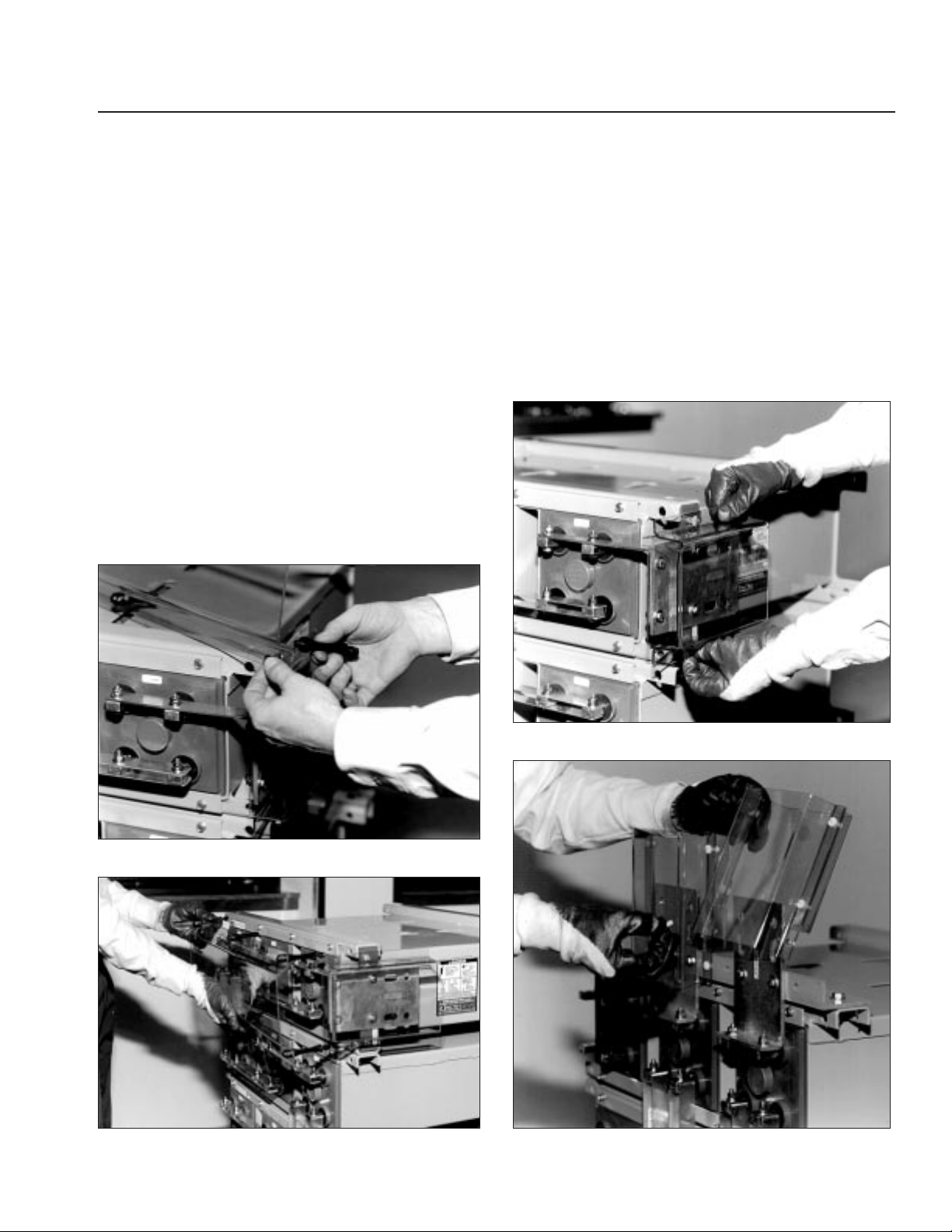

1. Always wear eye protection.

2. Check for visible defects.

3. Check the contents of the package against the

packing list. Report any missing parts or shipping

damage to your East Penn agent or East Penn Mfg.

Co. immediately. (See Fig. 2-1 and 2-2 on pg. 3.)

4. Never lift the batteries by the terminal posts. Always

lift batteries by the module mounting holes with the

lifting straps provided. (See Fig. 3-2, pg. 8.)

5.When lifting batteries, the proper equipment is

needed such as a forklift or a portable crane.

Always check the lifting capacities of the equipment

being used and never lift more than one module at

a time by the module mounting holes.

EYES.

CONNECTORS.