East Penn Manufacturing Co. Lyon Station, PA 19536-0147 Phone: 610-682-6361 Fax: 610-682-4781 www.dekabatte ies.com

E.P. . Form No. 0720 2/16 © 2016 by EP Printed in U.S.A.

All data subject to change without notice. No part of this document may be copied or

reproduced, electronically or mechanically, without written permission from the company.

MAINTENANCE

1. Once each week the electrolyte level should be checked in

every cell. It may be necessary to add water to the battery on a

weekly to a monthly basis, depending on the type of battery

and the type of service for which it is used.

2. Only distilled, deionized or approved water should be added to

the battery. Water should be added only near the end of the

charge to raise the electrolyte level to the bottom of the vent

well. Water should be stored in a clean non-metallic container

as impurities, even in small amounts, may be harmful to

battery life.

3. It will be necessary to give the battery an equalizing charge

every week.

4. Specific gravity readings should be recorded for all cells once

each month immediately after an equalizing charge. If the

readings average below 1.265 the charger output should be

checked. If two successive monthly readings indicate more

than 20 points deviation in any cell from the average specific

gravity, you should contact your Deka representative.

5. The top of the battery should be kept clean and dry at all times.

When required, the top of the battery should be neutralized,

after removing the shrouds, with a non-corrosive water based

neutralizing solution. ake sure vent caps are securely in place

to prevent any solution from entering cells. After the battery

has been neutralized, rinse thoroughly with clear water, dry

and then reinstall the cleaned shrouds.

6. The cables and connectors should be inspected monthly for

exposed copper wires, fraying or cracked insulation, loose

connections, or pitted contacts, and repaired as required.

7. Be especially careful to keep metallic objects off the top of the

battery, as any metal touching two or more connectors may

cause a short circuit resulting in an arc or spark which could

ignite battery gasses explosively.

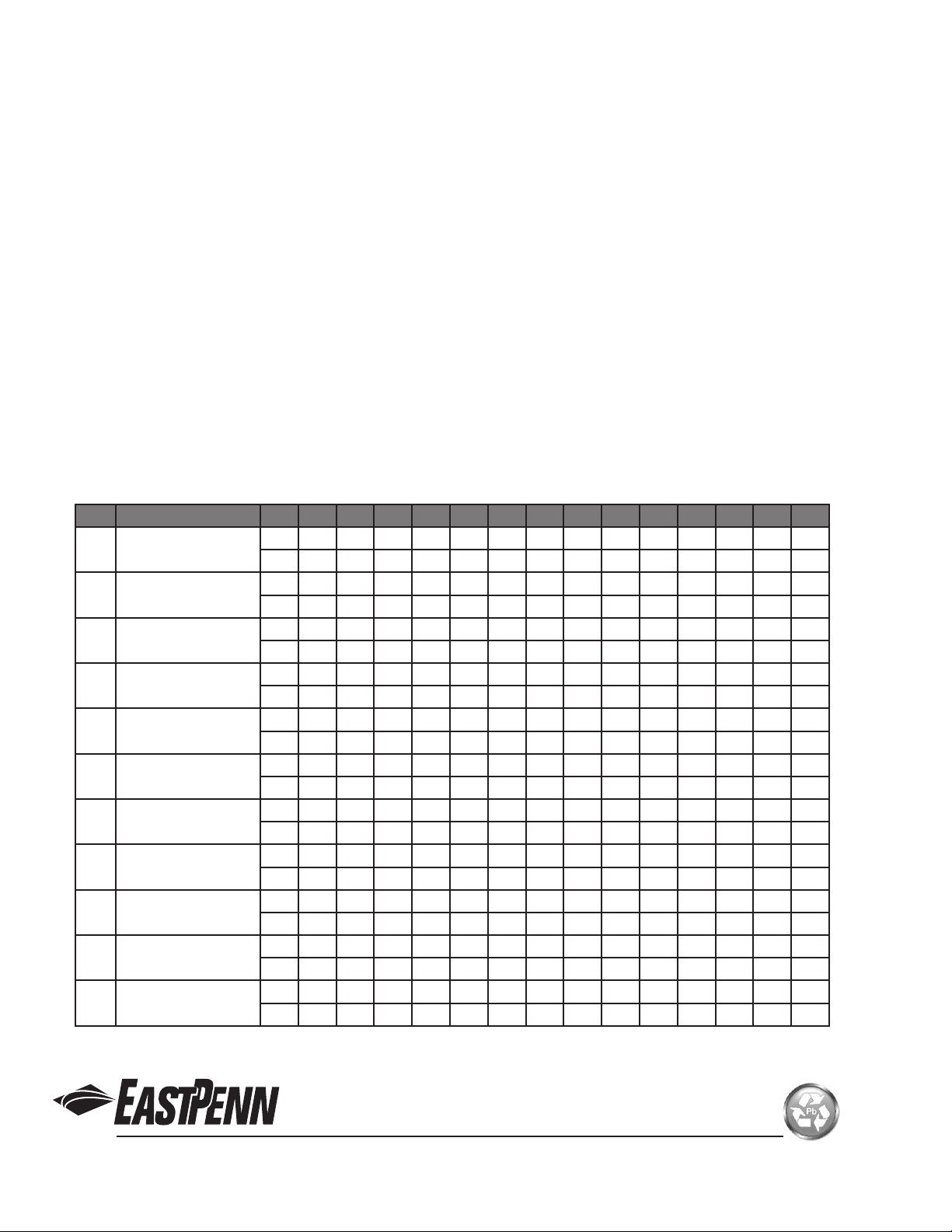

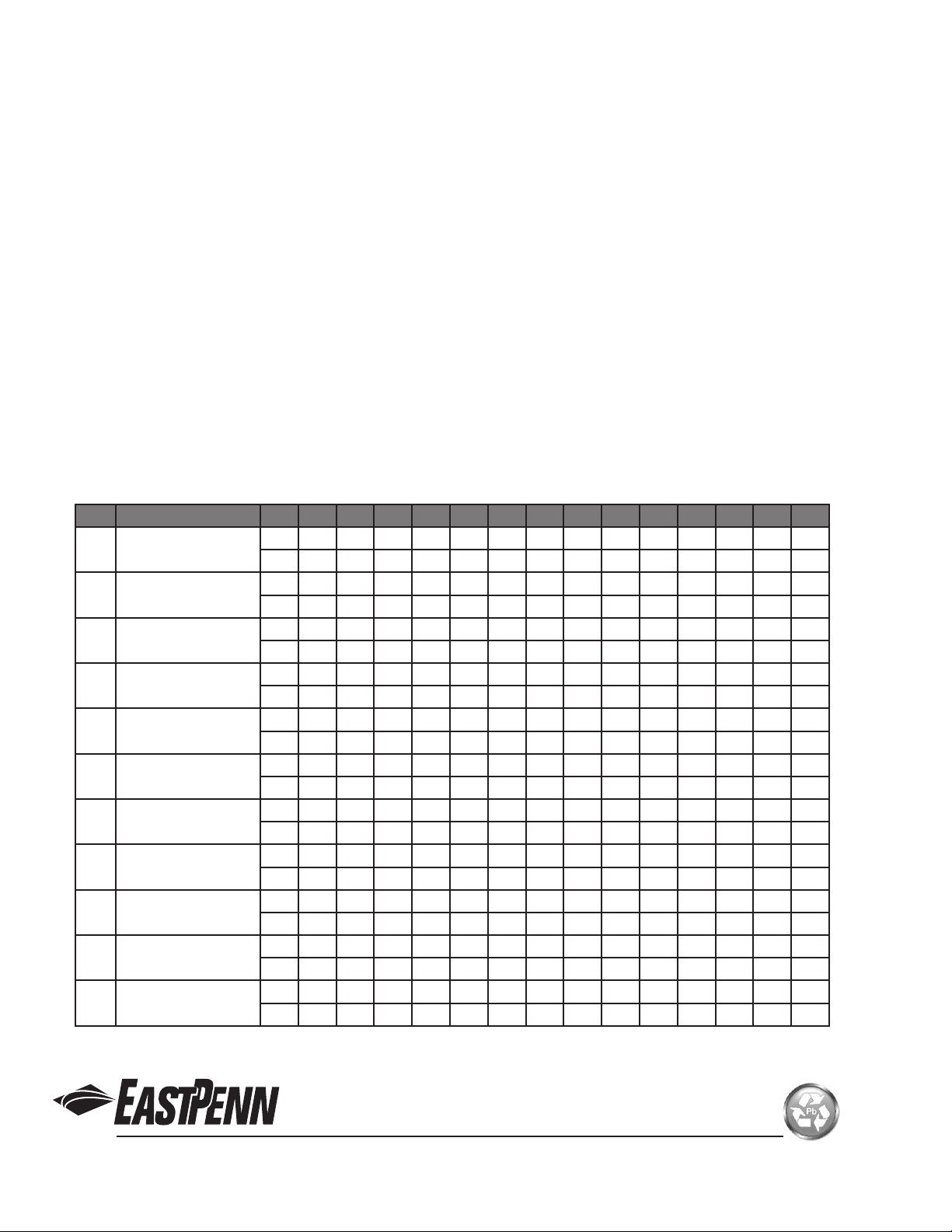

8. The output rate of the charger should be checked periodically.

The starting rate should correspond to the starting rate shown

on the charger nameplate. The following chart shows the

ampere hour capacity at the six-hour rate, as well as the Deka

F-Series manufactured by East Penn anufacturing Co.

TYPE PLATES PER CELL 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33

F35 6 HR. A.H. RATING

FINISH RATE—A PS

70 105 140 175 210 245 280 315 350 385 420 455 490 525 560

4 5 7 9 10 12 14 16 18 19 21 23 24 26 28

F45 6 HR. A.H. RATING

FINISH RATE—A PS

90 135 180 225 270 315 360 405 450 495 540 585 630 675 720

4 7 9 11 14 16 18 20 22 25 27 29 32 34 36

F55 6 HR. A.H. RATING

FINISH RATE—A PS

110 165 220 275 330 385 440 495 550 605 660 715 770 825 880

6 8 11 14 16 19 22 25 28 30 33 36 38 41 44

F65 6 HR. A.H. RATING

FINISH RATE—A PS

130 195 260 325 390 455 520 585 650 715 780 845 910 975 1040

6 10 13 16 20 23 26 29 32 36 39 42 46 49 52

F75 6 HR. A.H. RATING

FINISH RATE—A PS

150 225 300 375 450 525 600 675 750 825 900 975 1050 1125 1200

8 1 15 19 22 26 30 34 38 41 45 49 52 56 60

F85 6 HR. A.H. RATING

FINISH RATE—A PS

170 255 340 425 510 595 680 765 850 935 1020 1105 1190 1275 1360

8 13 17 21 26 30 34 38 42 47 51 55 60 64 68

F100 6 HR. A.H. RATING

FINISH RATE—A PS

200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

F110 6 HR. A.H. RATING

FINISH RATE—A PS

220 330 440 550 660 770 880 990 1100 1210 1320 1430 1540 1650 1760

11 16 22 28 33 38 44 50 55 60 66 72 77 82 88

F125 6 HR. A.H. RATING

FINISH RATE—A PS

250 375 500 625 750 875 1000 1125 1250 1375 1500 1625 1750 1875 2000

12 19 25 31 38 44 50 56 62 69 75 81 88 94 100

F150 6 HR. A.H. RATING

FINISH RATE—A PS

600 750 900 1050 1200 1350 1500

30 38 45 52 60 68 75

F160 6 HR. A.H. RATING

FINISH RATE—A PS

640 800 960 1120 1280 1440 1600

32 40 48 56 64 72 80