Deka unigy User manual

HIGH RATE SERIES

STATIONARY BATTERY INSTALLATION

AND OPERATING INSTRUCTIONS

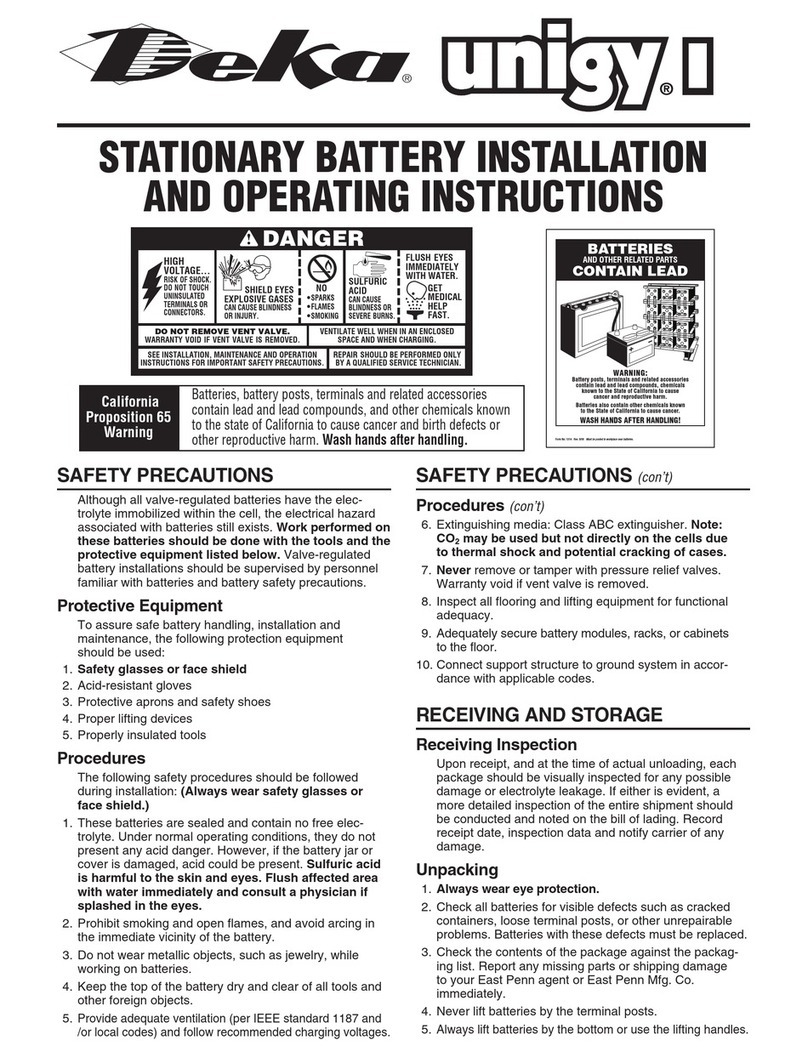

DANGER

!

SHIELD EYES

EXPLOSIVE GASES

CAN CAUSE BLINDNESS

OR INJURY.

NO.

•

SPARKS

•

FLAMES

•

SMOKING

SULFURIC

ACID

CAN CAUSE

BLINDNESS OR

SEVERE BURNS.

FLUSH EYES

IMMEDIATELY

WITH WATER.

GET

MEDICAL

HELP

FAST.

HIGH

VOLTAGE...

RISK OF SHOCK.

DO NOT TOUCH

UNINSULATED

TERMINALS OR

CONNECTORS.

DO NOT REMOVE VENT VALVE.

WARRANTY VOID IF VENT VALVE IS REMOVED.

VENTILATE WELL WHEN IN AN ENCLOSED

SPACE AND WHEN CHARGING.

REPAIR SHOULD BE PERFORMED ONLY

.BY A QUALIFIED SERVICE TECHNICIAN.

SEE INSTALLATION, MAINTENANCE AND OPERATION

INSTRUCTIONS FOR IMPORTANT SAFETY PRECAUTIONS.

SAFETY PRECAUTIONS

Although all valve-regulated batteries have the elec-

trolyte immobilized within the cell, the electrical hazard

associated with batteries still exists. Work performed on

these batteries should be done with the tools and the

protective equipment listed below. Valve-regulated

battery installations should be supervised by personnel

familiar with batteries and battery safety precautions.

Protective Equipment

To assure safe battery handling, installation and

maintenance, the following protective equipment

should be available:

1. Safety glasses or face shields

2. Acid-resistant gloves

3. Protective aprons

4. Lifting devices

5. Use only insulated tools.

Procedures

The following safety procedures should be followed

during installation: (Always wear safety glasses or

face shield.)

1. Adequately secure battery racks or cabinet

enclosures to the floor.

2. Connect support structures to ground system in

accordance with applicable codes.

3. Inspect all flooring and lifting equipment for functional

adequacy. Specifically review floor loading capacity.

4 Prohibit smoking and open flames, and avoid

arcing in the immediate vicinity of the battery.

5. Keep the top of the battery clear of all tools

and other foreign objects.

6. Provide adequate ventilation and follow

recommended charging voltages.

7. Avoid wearing metallic objects such as

jewelry while working on the battery.

8. Never remove or tamper with the pressure relief valves.

9. These batteries are sealed and contain no free

electrolyte. Under normal operating conditions they

do not present any acid danger. However, if the

battery case or cover is damaged, acid could be

present. Sulfuric acid is harmful to the skin and

eyes. Flush affected area with water immediately

and consult a physician if splashed in the eyes.

10. Extinguishing media: Class ABC extinguisher.

Note: CO2 may be used. The thermal shock may

cause the case to crack.

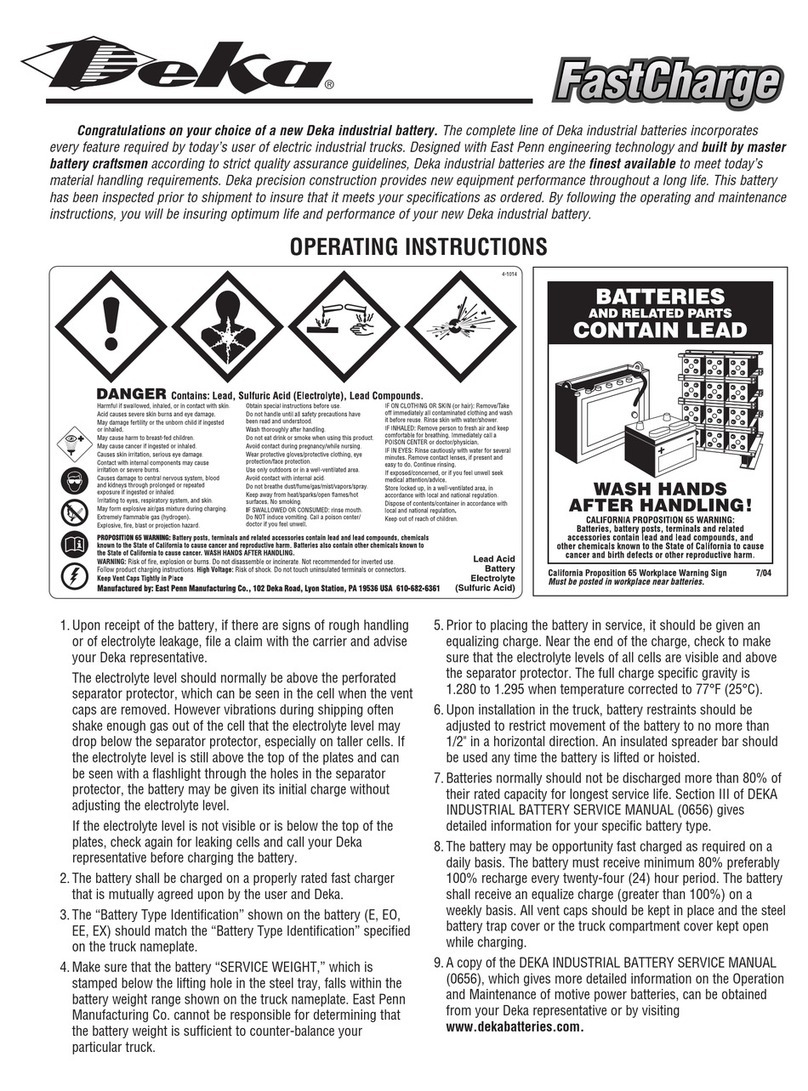

Battery posts, terminals and related

accessories contain lead and lead

compounds, and other chemicals

known to the state of California to

cause cancer and birth defects or

other reproductive harm.

Wash hands after handling.

California

Proposition 65 Warning

RECEIVING

AND STORAGE

Receiving Inspection

Upon receipt, and at the time of actual unloading,

each package should be visually inspected for any

possible damage or electrolyte leakage. If either is

evident, a more detailed inspection of the entire

shipment should be conducted and noted on the

bill of lading. Record receipt date, inspection data

and notify carrier of any damage.

Unpacking

(Always wear eye protection.)

1. Never lift batteries by the terminal posts. Always lift

batteries by the bottom or use the lifting handle.

2. Check all batteries for visible defects such as

cracked containers, loose terminal posts, or other

unrepairable problems. Batteries with these defects

must be replaced.

Storage

1. Cells should be stored indoors in a clean, level, dry

and cool location. Recommended storage tempera-

tures are 0°F to 90°F (–18°C to 32°C).

2. Lead acid batteries self-discharge and must be given

a boost charge periodically to prevent permanent

performance degradation. Batteries should not be

stored for more than 180 days without applying a

boost charge of 13.8 volts ± .06 volts per battery

until the current stabilizes. Record dates and condi-

tions for all charges during storage.

INSTALLATIONS

Cabinets

Cabinet systems come factory assembled and

prewired. Do not tip or turn cabinets on their sides

when positioning them in their intended installation

area. Cabinets must be used in an upright position.

These systems are preconnected. Only inter-shelf,

inter-cabinet and connections to the load are

required. See the connection diagram inside the

cabinet. Inter-cabinet and load connection cables

are not included.

Racks

Assemble racks in accordance with the intended

arrangement, align with a level and bolt to the floor.

See rack assembly instructions.

BATTERY

ASSEMBLY

(Always wear eye protection.)

1. Set up the batteries so that the positive post (+) of one battery

is connected to the negative post (–) of the next battery for

all series connections. Make sure they match the connection

diagram. For parallel or parallel/series combinations, check

the connection diagram.

2. The intercell connection contact surfaces should be cleaned

by rubbing gently with a non-metallic brush or pad before

installing connectors.

3. Install all intercell connections loosely to allow for final

alignment of batteries, then torque to 60± 5 inch pounds.

General

1. Install the lockwasher and torque the terminal bolts or nuts

to 60 ± 5 inch pounds. DO NOT OVERTORQUE. Some

batteries have cable harnesses (torque value is 60 ± 5).

2. Clean all outside surfaces of batteries, cabinets and

racks with soapy water only. DO NOT USE SOLVENTS.

3. For future identification of all racked batteries, apply

individual battery numbers in sequence beginning with

number one at the positive end of the first battery.

4. After torquing the connections on racked batteries, read the

voltage of the battery string to assure that individual batteries are

connected correctly. The total voltage should be approximately

equal to the number of batteries times the measured voltage of

one battery (when connected in series). If the measurement is

less, recheck the connections for proper voltage and polarity.

5. Read and record intercell connection resistance and note

the method of measurement. This helps determine a

satisfactory initial installation and can be used as a reference

for future maintenance requirements. See Appendix A,

recording forms, in the back of the manual. Clean, remake

and remeasure any connection having a resistance

measurement greater than 10% of the average of all the

same type of connections (intercell, inter-tier or shelf,

inter-rack or inter-cabinet).

6. Battery performance is based on the output at the battery

terminals. Therefore, the shortest electrical connections

between the battery system and the operating equipment r

result in maximum total system performance.

Do not select cable size on current carrying capabilities

only Cable size should not provide a greater voltage drop

between the battery system and operating equipment than

specified. Excess voltage drop will reduce the desired

support time of the battery system. Cables are not

recommended for connecting parallel battery strings.

HIGH RATE SERIES

7. When paralleling valve-regulated batteries, the capacity,

arrangement and external circuit length should be

identical for each battery string because a wide variation

in battery circuit resistance can result in unbalanced

charging (i.e., excessive charging currents in some

batteries, and undercharging in others). As a conse-

quence, a single battery failure in one battery string

and the subsequent loss of performance capabilities

of that string, will result in higher loads in the other

parallel string(s), which may exceed the ratings of the

battery connections. This can damage the battery

system and dramatically shorten battery life.

SYSTEM

OPERATION

These batteries are designed for continuous float

application. The charger must be able to sustain the

system voltage within ± .01 volts per cell of the desired

level at all times. The desired float voltage varies with

temperature according to the table below.

Equalizing

Upon installation of the high rate battery series, an

optional boost charge of 13.80 volts ± .06 volts for a

maximum of 24 hours can be applied.

If this is done, be sure to reset the charging equipment

to the proper float voltage. The average battery

operating temperature should not exceed 95°F (35°C)

and should never exceed 105°F (40.5°C) for more than

an eight-hour period.

Operating at temperatures greater than 77°F (25°C)

will reduce the operating life of the battery. If operating

temperatures are expected to be in excess of 95°F

(35°C), contact East Penn for recommendations.

Battery Battery High Rate

Temperature Temperature Per Battery Float Voltage

Degrees F Degrees C ± .06 volts

50° . . . . . . . . 10° . . . . . . . . . . . . . . . . . 13.50

59° . . . . . . . . 15° . . . . . . . . . . . . . . . . . 13.50

68° . . . . . . . . 20° . . . . . . . . . . . . . . . . . 13.50

77° . . . . . . . . 25° . . . . . . . . . . . . . . . . . 13.50

86° . . . . . . . . 30° . . . . . . . . . . . . . . . . . 13.50

95° . . . . . . . . 35° . . . . . . . . . . . . . . . . . 13.38

PERIODIC

MAINTENANCE

(Always wear eye protection;

keep sparks and flames away.)

Annual Inspection

1. Conduct a visual inspection of the battery(ies).

2. Record the battery string voltage.

3. Record the charger voltage.

4. Record the individual battery voltages.

Batteries should be within ± 0.18 volts of float voltage.

5. Record the ambient temperatures.

6. Record all inter-battery and terminal connections.

Micro-ohm readings should be taken during this

inspection. If any reading differs by more than 20%

from the inital reading taken, retorque the connection

to 60 ± 5 inch-pounds. Recheck the micro-ohm reading.

If the reading remains high, clean the contact surfaces

according to Step 2 under Battery Assembly.

Capacity Testing

Capacity tests may be run if operation is questionable.

Do not discharge the batteries beyond the specified

final voltage. Record all findings.

Should it be determined that any individual battery

need be replaced, contact your nearest Unigy I agent

or East Penn Service Center.

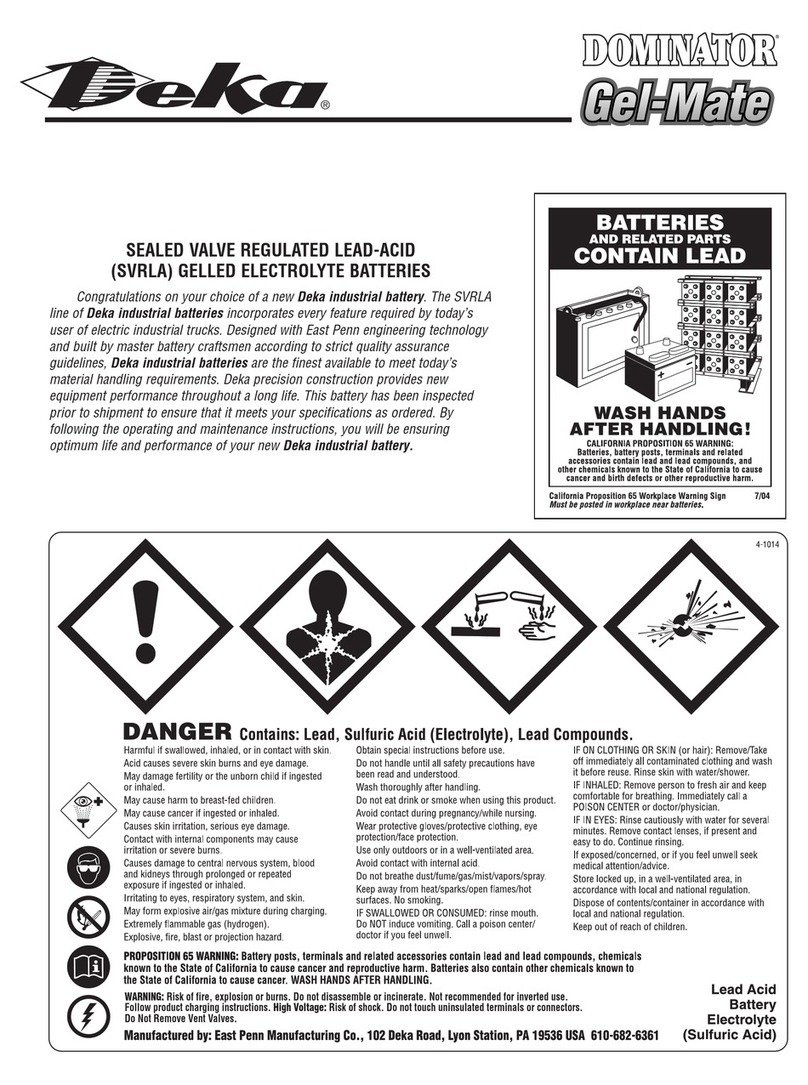

BATTERIES

AND RELATED PARTS

CONTAIN LEAD

California Proposition 65 Workplace Warning Sign 1/99

Must be posted in workplace near batteries.

WASH HANDS

AFTER HANDLING !

CALIFORNIA PROPOSITION 65 WARNING:

Battery posts, terminals and related accessories

contain lead and lead compounds, and other

chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

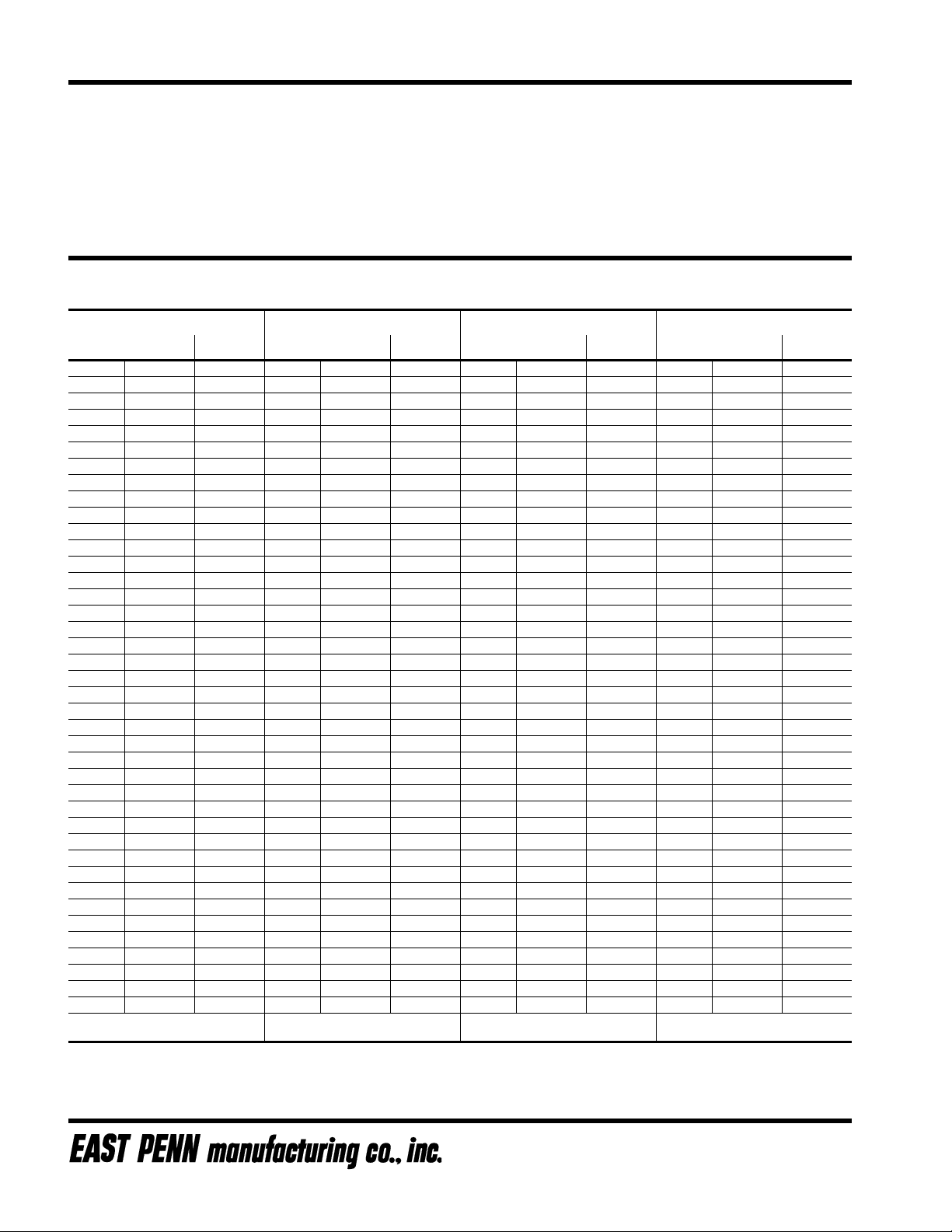

APPENDIX A

Lyon Station, PA 19536-0147 • Phone: 610-682-6361 • Fax: 610-682-4781

Order Department Hotline: 610-682-4231

DISTRIBUTED BY:

E.P.M. Form No. 0970 Rev. 1/02 © 2002 by EPM Printed in U.S.A.

Charger Output ____________________Amp Air Temperature____________________°F

Total Battery String Voltage _______________ Panel Meter Volts ____________________

Year _______________________ Year _______________________ Year _______________________ Year _______________________

Unit Ohms or Unit Ohms or Unit Ohms or Unit Ohms or

Number Volts Mhos Number Volts Mhos Number Volts Mhos Number Volts Mhos

Inspection Date_______________________________________________________________ No. of Units/String _________________

Company ___________________________________________________________________ Type ____________________________

Address ____________________________________________________________________ Date New ________________________

Battery location and/or number __________________________________________________ Date Installed_____________________

Readings Taken By ____________________________ Remarks/Recommendations __________________________________________________________

Readings should be taken at installation and annually thereafter. _________________________________________________________________________________

1111

2222

3333

4444

5555

6666

7777

8888

9999

10 10 10 10

11 11 11 11

12 12 12 12

13 13 13 13

14 14 14 14

15 15 15 15

16 16 16 16

17 17 17 17

18 18 18 18

19 19 19 19

20 20 20 20

21 21 21 21

22 22 22 22

23 23 23 23

24 24 24 24

25 25 25 25

26 26 26 26

27 27 27 27

28 28 28 28

29 29 29 29

30 30 30 30

31 31 31 31

32 32 32 32

33 33 33 33

34 34 34 34

35 35 35 35

36 36 36 36

37 37 37 37

38 38 38 38

39 39 39 39

40 40 40 40

Avg. Voltage Avg. Voltage Avg. Voltage Avg. Voltage

Individual

Battery Readings

BATTERY MAINTENANCE REPORT

Other Deka Camera Accessories manuals

Deka

Deka unigy I User manual

Deka

Deka Unigy I User manual

Deka

Deka Dominator Gel-Mate SVRLA G105 User manual

Deka

Deka unigy II SPACESAVER Non-Interlock AVR 45 AH User manual

Deka

Deka Unigy II User manual

Deka

Deka Unigy II AVR45 Series User manual

Deka

Deka FastCharge F35 User manual

Deka

Deka 8A User manual

Deka

Deka SOLAR Monoblock VRLA System Installation instructions

Deka

Deka Unigy II User manual

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual