1

MPI-300 Installation & Operations Manual

SECTION 1 GENERAL

INFORMATION

1A. Description

The MPI-300 is available in three different

configurations, MPI-300, MPI-300WM, and MPI-

300M. The MPI-300 is the base model system

designed for general, in place surface sanitation

applications including equipment sanitation of

conveyors, slicers, saws, etc. as well as direct

contact on food. The MPI-300WM (wall-mounted)

and MPI-300M (mobile) are designed as manually-

operated surface sanitation systems utilizing the

included ozone delivery hose and spray wand.

The systems flow ozonated water at approximately

3.3 GPM with an applied ozone dose of 3-3.5 PPM.

Average dissolved ozone concentration at the

spray nozzle is 2.0 PPM with clean, potable source

water free of chemicals and minerals. The MPI-

300 provides a final sanitizing rinse, leaving no

residual.

The MPI-300 is designed to sanitize wettable

surfaces and equipment including converyors,

containers, saws, slicers, walls and floors, in

addition to certain foods. Compatible materials

include stainless steel, plastics, wood, concrete,

cement, cement block, painted and unpainted. The

MPI-300 uses interchangeable attachments for

spray applications.

1B. Specifications

Ozone Output:

Ozone output (+10%): 2.5 g/hr

Applied Ozone Dose: 3.3 PPM

Gas flow rate (max): 3.0 SCFH

% weight O3: 3.0%

Power Requirements:

Domestic: 115VAC, 60 Hz, 1Ø, 7.0 A

Water Flow Rate (Approx): 3.3 gpm

NOTE: Accessories installed on the system must

have these flow parameters or the system will

not operate. Only DEL attachments may be used

(see Figure 1, page 2). Please call DEL if further

explanation is required.

Supply Water Requirements:

Temperature: 40°F - 80°F (greater than 80°F

will damage the MPI-300)

Pressure: 40 psi (min.)

Flow: 4.0 GPM (min.)

Weights & Dimensions: 25.5”H x 24.5”W x11”D.

100 lbs.

Ambient Temp: 40°F - 90°F (not to

exceed 90°F)

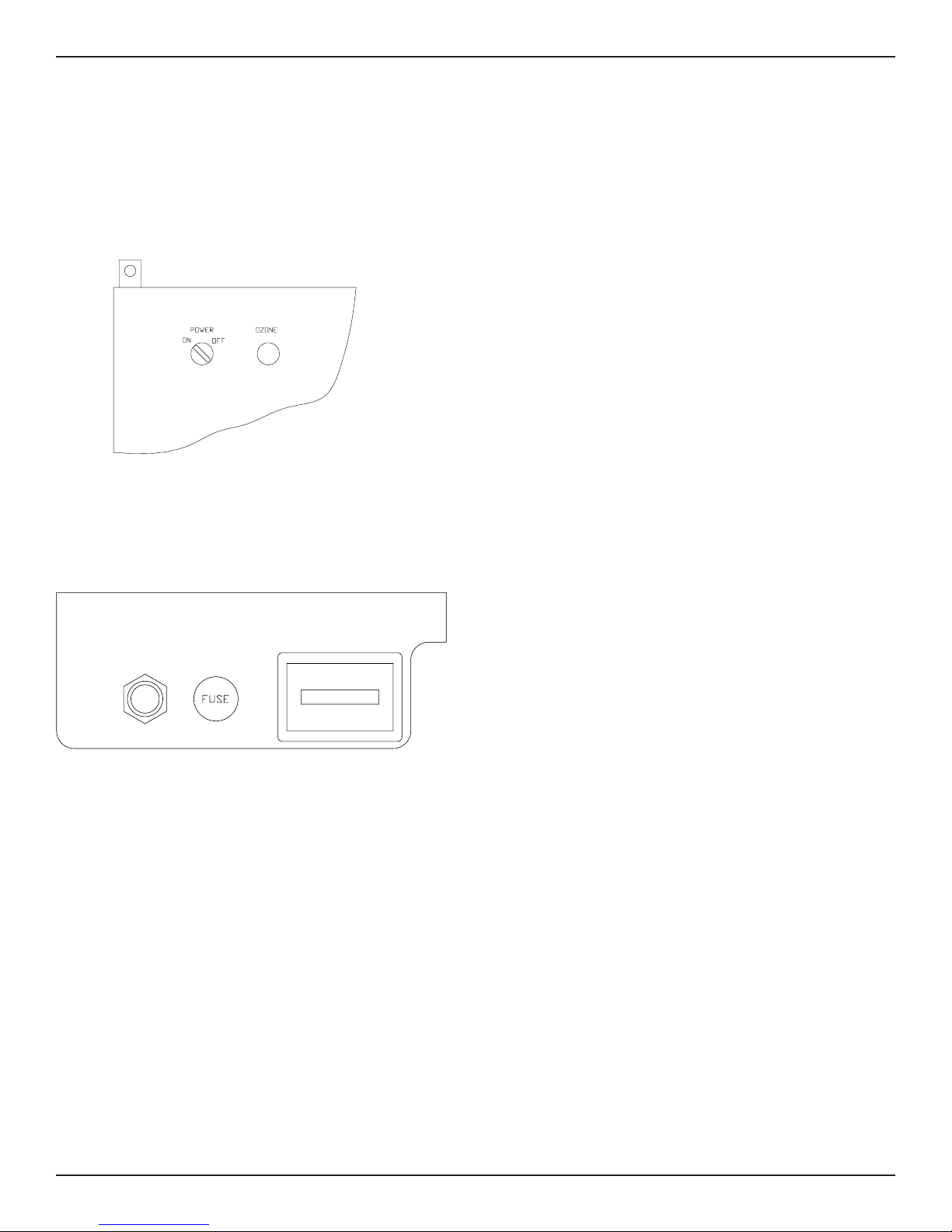

1C. Layout & Accessories

The MPI-300 is a low pressure, ozone enriched

cold water surface sanitizer. Internally it is

separated into two basic sections – dry and wet –

as discussed below and shown in Figure 1, page 2.

1C1. Dry Section - Ozone Generation:

• Air Compressor: oilless, piston air compressor

pumps ambient air at 2.5 CFM into the oxygen

concentrator

• Oxygen Concentrator: the oxygen concentrator

uses a PSA (pressure swing absorption) molec-

ular sieve to remove dirt, moisture, nitrogen and

other trace gases, producing oxygen at greater

than 85% purity and less than -60° C dewpoint.

Concentrated oxygen feed-gas enables ozone

generation at 2-6% (by weight) concentration.

• Ozone Generation Cell: the corona discharge

ozone generation cell consists of an aluminum

housing (ground, two end housings, and fasten-

ers), gaskets, high voltage stainless steel elec-

trode, ceramic dielectric, oxygen inlet fitting, and

ozone outlet fitting. Concentrated oxygen gas is

pulled into the ozone generation cell under vac-

uum. The oxygen molecules are split into atomic

oxygen which then recombine to form ozone gas.

1C2. Wet Section - Ozone Dissolution in Water:

• Ozone Injector: Inlet water flows through

the ozone injector, creating vacuum that pulls

ozone gas from the ozone generation module

and injects the ozone into the water flow. The

injector is sized and factory preset to dissolve a

minimum of 90% of the ozone gas into the water

flow continuously.

• Ozone Degas Chamber: ozone-enriched water

from the ozone injector flows into the degas

chamber where the counter-current design forc-

es any undissolved ozone gas through the float

valve-protected top vent to the Ozone Destruct.

• Ozone Destruct: undissolved ozone gas pass-

es through the heated catalytic ozone destruct

which is made of non-consumable manganese

dioxide (heat protected from moisture fouling).