DeLaval VMS 2012 Series User manual

Table of contents

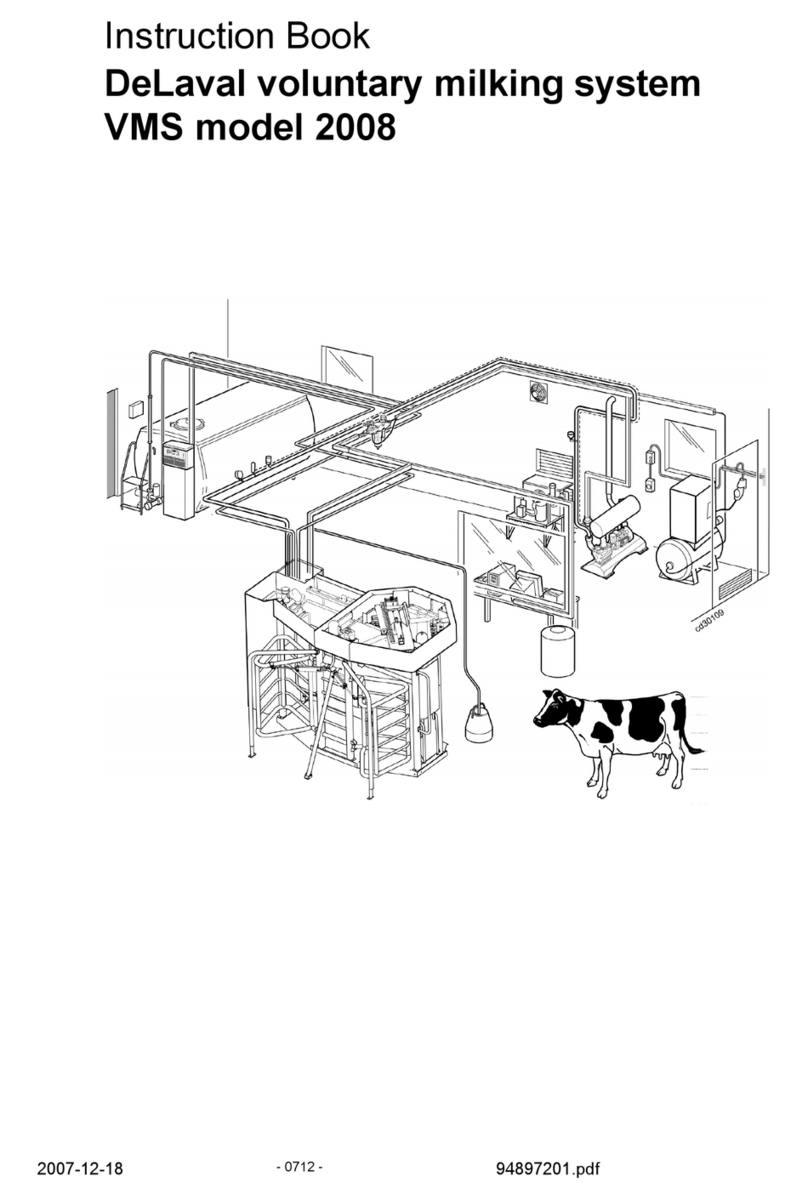

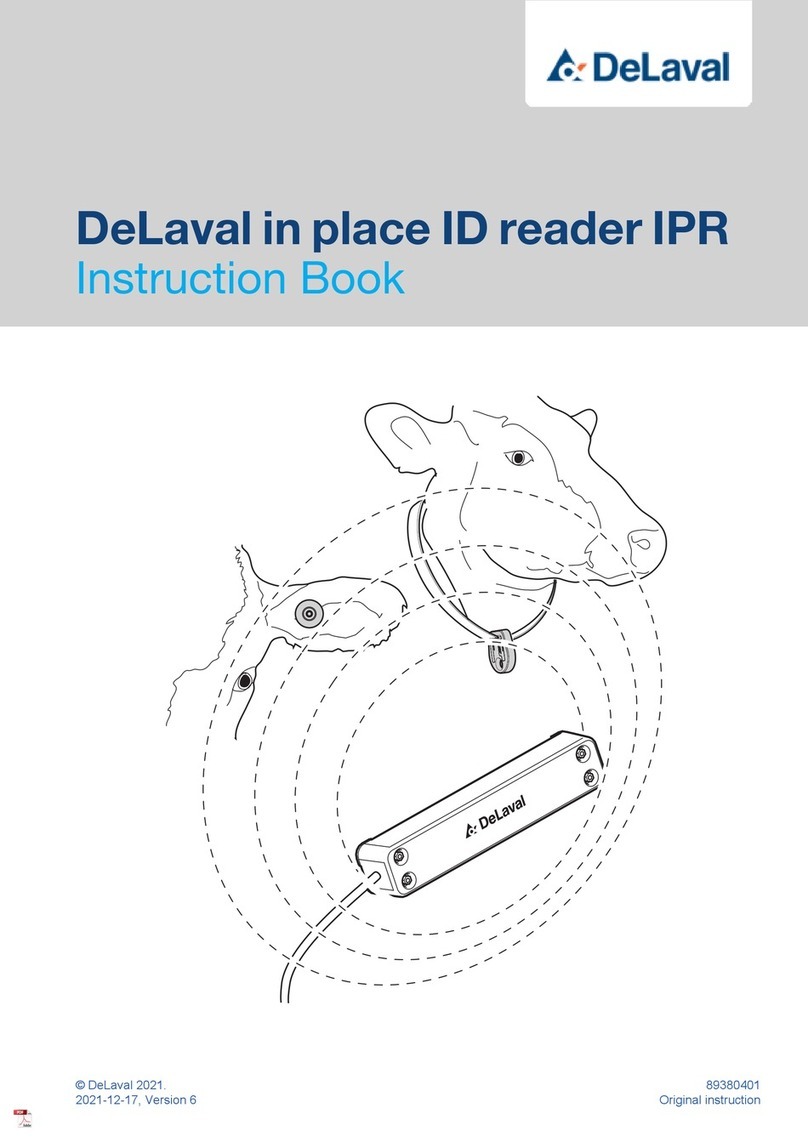

Other DeLaval Farm Equipment manuals

Popular Farm Equipment manuals by other brands

GREMO

GREMO 1050F4 instruction manual

Kongskilde

Kongskilde FCT 1360 Operator's manual

APV

APV ZS 200 M3 Original operating instructions

Redexim

Redexim Core Collector 1200 User manual and parts book

Checchi & Magli

Checchi & Magli WOLF PRO Use and maintenance manual

Chapman

Chapman BT500 Original instructions

Unverferth

Unverferth Perfecta 10 manual

Berthoud

Berthoud BOXER II-1800 manual

MASSEY FERGUSON

MASSEY FERGUSON 2140 - Workshop service manual

Helm Welding

Helm Welding LuckNow BP744 Instruction book

Schmeiser

Schmeiser Till an' Pak Operation and parts manual

HighLine

HighLine NT Rockpicker NT60E Operator's manual

TTI

TTI WeedControl 12VSPT-TTI INSTRUCTIONS FOR ASSEMBLY, OPERATION, SERVICING & STORAGE

Wiesenfield

Wiesenfield WIHE-03201 user manual

FARMTECH

FARMTECH T-DCBM-4 user manual

Krone

Krone EasyCollect 6000 FP operating instructions

GREAT PLAINS

GREAT PLAINS Qualidisc HS2200-13 manual

MacDon

MacDon R113 Operator's manual