DeLaval VMS 2008 User manual

Instruction Book

DeLaval voluntary milking system

VMS model 2008

2007-12-18 - 0712 - 94897201.pdf

94897201.pdf2007-12-18

Table of contents

DeLaval voluntary milking system VMS.................................................................................................. 3

Safety precautions.................................................................................................................... 3

Warnings and cautions .............................................................................................. 3

Safety during operation.............................................................................................. 4

Laser radiation............................................................................................. 9

Safety during maintenance and service................................................................... 11

Position of warning stickers ....................................................................... 18

General description ................................................................................................................ 21

Introduction .............................................................................................................. 21

Multi-purpose arm...................................................................................... 22

Camera unit ............................................................................................... 23

Magazine ................................................................................................... 24

Milking module........................................................................................... 24

Teat preparation module ........................................................................... 29

Stall and gates........................................................................................... 30

Hydraulic pump unit................................................................................... 32

Cleaning unit.............................................................................................. 33

Power box.................................................................................................. 34

Electrical box ............................................................................................. 34

Feeding module......................................................................................... 34

Service switch............................................................................................ 35

Management and supervision.................................................................................. 35

Data communication and the VMS management software ....................... 35

Multiple systems ........................................................................................ 36

Establishing communication ...................................................................... 36

Integration with ALPRO WE ...................................................................... 37

Error detection and remote accessing....................................................... 37

Database management ............................................................................. 38

Operation................................................................................................................................ 39

General advice for operating VMS........................................................................... 39

Starting, restarting and shutting off the milking station.............................. 39

94897201.pdf2007-12-18

Restarting the milking station after an emergency stop............................. 40

Switching between automatic and manual mode ...................................... 41

Fetch and start positions ........................................................................... 42

Achieving successful teatcup attachment.................................................. 43

Working in manual mode........................................................................... 45

Common manual tasks ............................................................................................ 47

Starting the milking station for automatic operation................................... 47

Shutting off the milking station................................................................... 48

Restarting the milking station .................................................................... 49

Switching from manual to automatic mode................................................ 49

Switching from automatic to manual mode................................................ 49

Stopping the multi-purpose arm ................................................................ 50

Miscellaneous tasks................................................................................................. 51

Parking the multi-purpose arm .................................................................. 51

Setting the multi-purpose arm to service mode ......................................... 51

Restarting the milking station after a power failure.................................... 52

Starting the hydraulic pump unit after oil temperature, oil level or motor

protection alarms ....................................................................................... 52

Shutting down the hydraulic pump unit...................................................... 54

Depressurising the hydraulic system......................................................... 54

Resetting motor protection and control fuse.............................................. 54

A complete manual milking procedure..................................................................... 56

Stall and feeding functions....................................................................................... 59

Manual identification ................................................................................................ 60

Change of destination................................................................................ 60

Attaching teatcups by hand...................................................................................... 63

Attaching one cup at a time ....................................................................... 63

Attaching two cups at a time...................................................................... 64

Support of milk tubes ............................................................................................... 65

Emptying the receiver and purging the milk lines .................................................... 66

Shutting off the compressed-air to the gates ........................................................... 67

Tank emptying ......................................................................................................... 67

94897201.pdf2007-12-18

Tank emptying process Flow controlled cooling (FCC) ............................. 68

Options ...................................................................................................... 68

Tank emptying FCC: milk delivery to tank is stopped immediately ........... 69

Tank emptying FCC: milk delivery to tank is delayed................................ 71

Tank emptying: tank systems from other manufacturers........................... 73

Tank emptying process: VMS/IN cooling systems .................................... 75

Tank emptying: DeLaval storage tanks ..................................................... 76

Tank emptying: storage tanks from other manufacturers .......................... 77

Determining cup and start positions......................................................................... 79

General principle ....................................................................................... 79

Determining the positions of all teatcups at the same time ....................... 82

Determining positions of individual teatcups ............................................. 84

Determining the position of the teat preparation cup................................. 85

Determining the position of the camera cleaner (sponge)......................... 85

Determining all teat positions at the same time......................................... 86

Determining individual teat positions ......................................................... 89

Automatic determining/determination of all teat positions ......................... 90

Verification of determined positions ......................................................................... 92

Verifying the positions of the teatcups....................................................... 93

Verifying the position of the teat preparation cup ...................................... 93

Verifying the teat positions ........................................................................ 93

Searching for teats .................................................................................... 94

VMS cleaning........................................................................................................................................ 95

Operation................................................................................................................................ 95

Contents................................................................................................................... 95

General advice for achieving good cleaning results ................................................ 95

Water quality.............................................................................................. 95

Detergent consumption and concentration................................................ 96

Water temperature..................................................................................... 96

Hot water supply........................................................................................ 97

Detergents and detergent dosing............................................................................. 97

94897201.pdf2007-12-18

Alkaline dominant cleaning scheme .......................................................... 97

Alternating acid and alkaline detergent ..................................................... 98

Shelf life of detergents............................................................................... 99

Dosing parameters................................................................................................... 99

Maintenance and calibration .................................................................................... 99

Starting cleaning or rinsing from the touch screen................................................. 100

Starting cleaning and rinsing manually.................................................... 100

Viewing the progress of a cleaning process .......................................................... 101

DeLaval voluntary milking system VMS.............................................................................................. 103

Maintenance......................................................................................................................... 103

Introduction ............................................................................................................ 103

Daily checklist ........................................................................................................ 103

Overall performance ................................................................................ 104

Management software ............................................................................. 106

Vacuum pump ......................................................................................... 107

Atlas Copco SF4 Full-feature compressor............................................... 107

Hydraulic pump unit................................................................................. 108

Cleaning detergent .................................................................................. 109

Daily maintenance ................................................................................................. 109

Cleaning equipment................................................................................. 109

Preparations for working safely ............................................................... 109

Cleaning of magazine, teatcups and milk tubes ...................................... 111

Cleaning of teat preparation cup ............................................................. 112

Cleaning of end effector .......................................................................... 112

Cleaning of camera window .................................................................... 113

Cleaning of feeding module..................................................................... 115

Cleaning of stall and floor ........................................................................ 117

Change of filter sock................................................................................ 118

Weekly maintenance.............................................................................................. 120

Milk filter unit: cleaning interior parts ....................................................... 120

Cleaning of cow-detection sensors.......................................................... 121

94897201.pdf2007-12-18

Check of teat preparation module ........................................................... 122

Check of Oil recirculation system (ORS) ................................................. 122

Maintenance every third week ............................................................................... 123

Change of liners ...................................................................................... 123

Check of Oil recirculation system (ORS) ................................................. 128

Monthly maintenance............................................................................................. 128

Change of flexible double-tubes .............................................................. 128

Check of multi-purpose arm .................................................................... 130

Check of Atlas Copco SF4 Full-feature compressor ............................... 130

Vacuum pump: DeLaval DVP-F .............................................................. 131

Bi-monthly activities ............................................................................................... 131

Removing hair from udders ..................................................................... 131

Yearly maintenance ............................................................................................... 131

Change of hydraulic pump unit oil filter ................................................... 131

Lubrication of hinges on the gates........................................................... 132

Milk refrigeration .................................................................................................... 133

Maintenance schedule: a summary ....................................................................... 134

Milk sampler........................................................................................................................................ 137

Operation.............................................................................................................................. 137

About collecting milk samples................................................................................ 137

Collecting milk samples ......................................................................................... 137

Connecting the milk sampler ................................................................... 137

Starting a sampling sequence ................................................................. 139

Stopping a sampling sequence ............................................................... 140

Maintenance......................................................................................................................... 141

About carrying out maintenance ............................................................................ 141

Manual cleaning ...................................................................................... 141

Additional maintenance.......................................................................................... 143

Changing hoses....................................................................................... 143

DeLaval online cell counter OCC........................................................................................................ 147

Operation.............................................................................................................................. 147

94897201.pdf2007-12-18

Introduction ............................................................................................................ 147

Connections............................................................................................. 147

User interface......................................................................................................... 147

Management software ............................................................................. 148

Touch screen........................................................................................... 148

Maintenance......................................................................................................................... 149

DeLaval voluntary milking system VMS.............................................................................................. 153

Troubleshooting.................................................................................................................... 153

Introduction ............................................................................................................ 153

Alarms.................................................................................................................... 153

Error codes .............................................................................................. 153

Types of alarms ....................................................................................... 154

Meaning and actions ............................................................................... 155

94897201.pdf2007-12-18

EC Declaration of ConformityEC Declaration of Conformity

Name of product: DeLaval voluntary milking system VMSName of product: DeLaval voluntary milking system VMS

Type: VMS milking station, left: 94765080 through 82Type: VMS milking station, left: 94765080 through 82

VMS milking station, right: 94765180 through 82VMS milking station, right: 94765180 through 82

The product complies with requirements of the following directives:The product complies with requirements of the following directives:

73/23/EEC, 93/68/EEC (Low Voltage Directive)73/23/EEC, 93/68/EEC (Low Voltage Directive)

89/336/EEC (Electro Magnetic Compatibility)89/336/EEC (Electro Magnetic Compatibility)

98/37/EG (Machine Directive)98/37/EG (Machine Directive)

Harmonized standards which have been used:Harmonized standards which have been used:

EN 60204 - 1 :2006, (LVD)EN 60204 - 1 :2006, (LVD)

EN 61000(2002)+A1(2002), EN 55011(1998)+A1(1999)+A2(2002), (EMC)EN 61000(2002)+A1(2002), EN 55011(1998)+A1(1999)+A2(2002), (EMC)

EN ISO 218-1:2006, EN775:1992, (MD)EN ISO 218-1:2006, EN775:1992, (MD)

National technical standards and specifications which have been used:National technical standards and specifications which have been used:

VMS0612-001 (test report EMC from Delta)VMS0612-001 (test report EMC from Delta)

VMS0612-002 (test report LVD from Semko)VMS0612-002 (test report LVD from Semko)

VMS0612-003 (test report MD from Semko)VMS0612-003 (test report MD from Semko)

VMS0612-004 (Technical construction file VMS)VMS0612-004 (Technical construction file VMS)

Other identifying data:Other identifying data:

The product is CE-marked.The product is CE-marked.

Date: 2007-12-11 Signed:Date: 2007-12-11 Signed:

Name: Andrew TurnerName: Andrew Turner

Position: Vice PresidentPosition: Vice President

Business Unit: PA Milking SystemsBusiness Unit: PA Milking Systems

Name and address of manufacturer: Name and address of agent:Name and address of manufacturer: Name and address of agent:

DeLaval International ABDeLaval International AB

P.O. Box 39P.O. Box 39

SE-147 21 Tumba, SwedenSE-147 21 Tumba, Sweden

1(198)

94897201.pdf2007-12-18 2(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

DeLaval voluntary

milking system VMS

Safety precautions

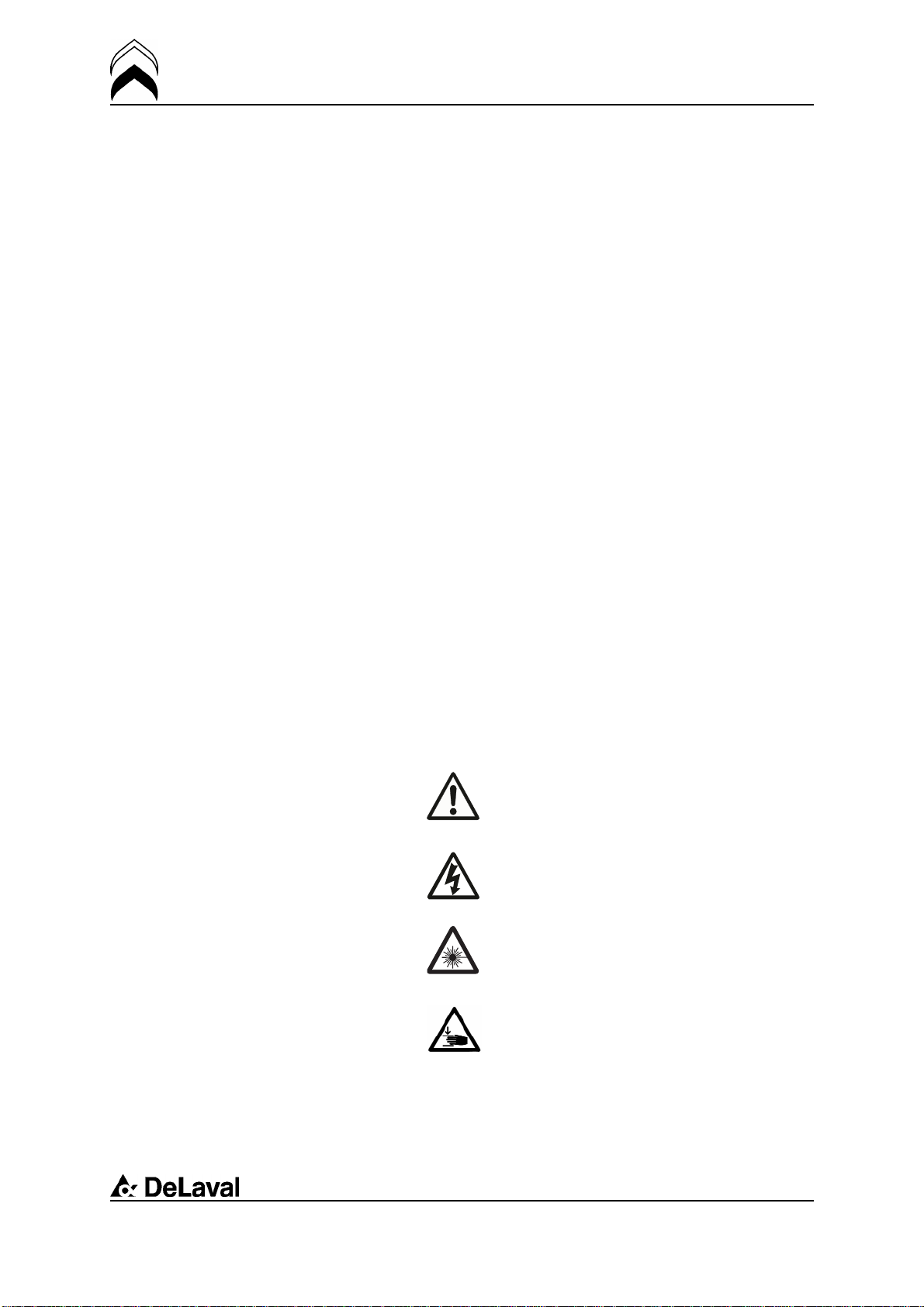

Warnings and cautions

Warnings and cautions provide important

information that is intended to prevent

incorrect or hazardous use of equipment,

machinery or software.

The following list defines the different types

used in this manual:

Danger: Refers to imminent and severe

risk. Failure to comply with instruction will

result in serious injury or death.

Warning: Refers to a potential but severe

risk. Failure to comply with instruction could

result in injury or death.

Caution: Refers to a limited risk. Failure to

comply with instruction could result in minor

injury or product damage.

Note: Is intended to draw attention to

specific points of importance in the text.

The following signs are used in this manual:

•Risk of danger

•Risk of damage to the equipment

•Risk of electric shock

•Risk of laser radiation

•Risk of pinching

3(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

•Risk of hot surface

•Risk of squeezing/crushing

•Risk for corrosive chemicals

•Risk of slipping on the floor

•Risk of falling into pit

————————————————————

Note: To ensure a safe and correct use of

the VMS, read the manual before you start

to to use the VMS.

————————————————————

Safety during operation

————————————————————

Prohibited: Minors and unauthorized

personnel are not allowed within the milking

room, unless accompanied by a responsible

adult with adequate knowledge.

————————————————————

————————————————————

Warning: The VMS system should only be

operated by personnel trained by DeLaval.

This concerns all parts of the system.

————————————————————

4(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

————————————————————

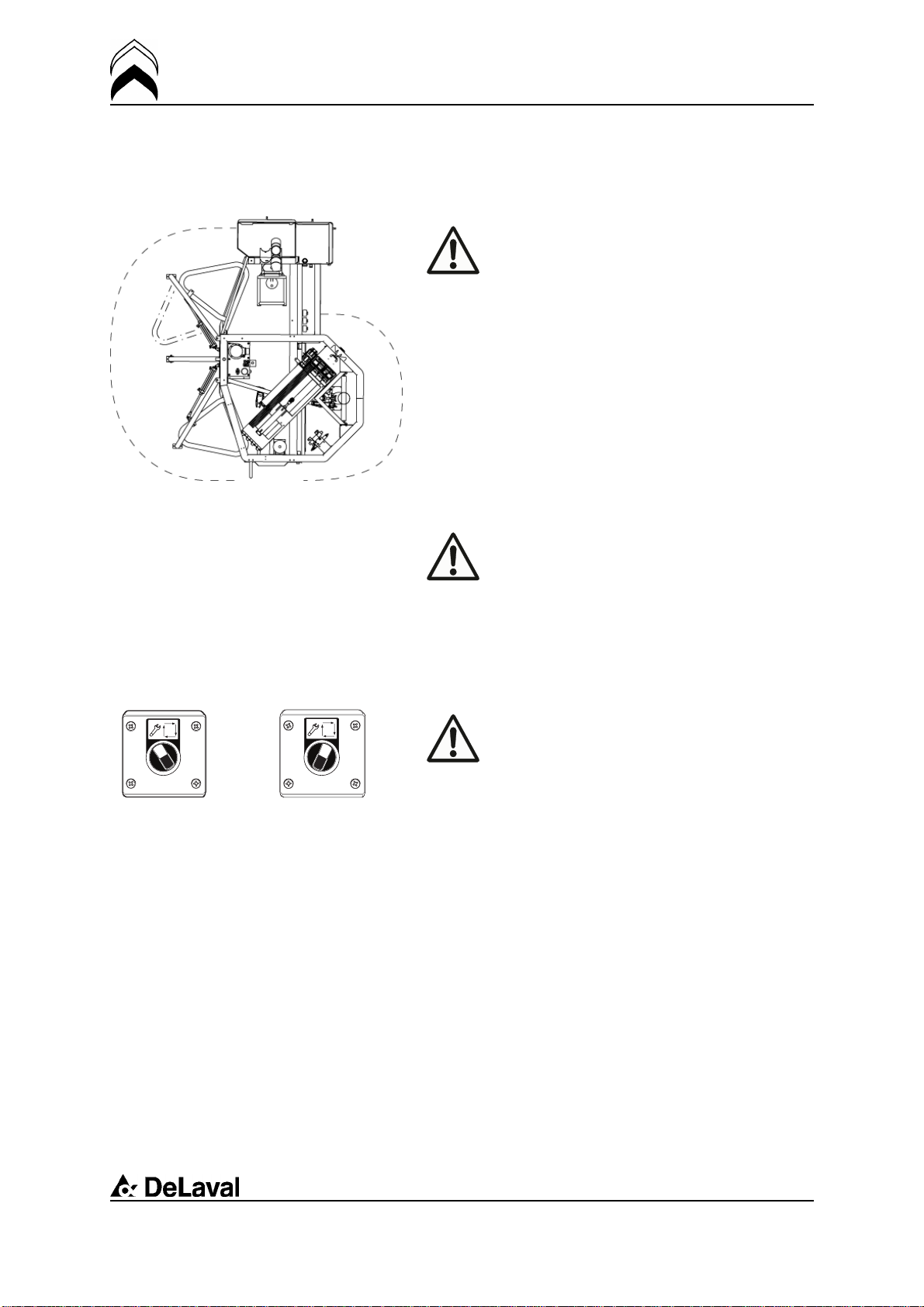

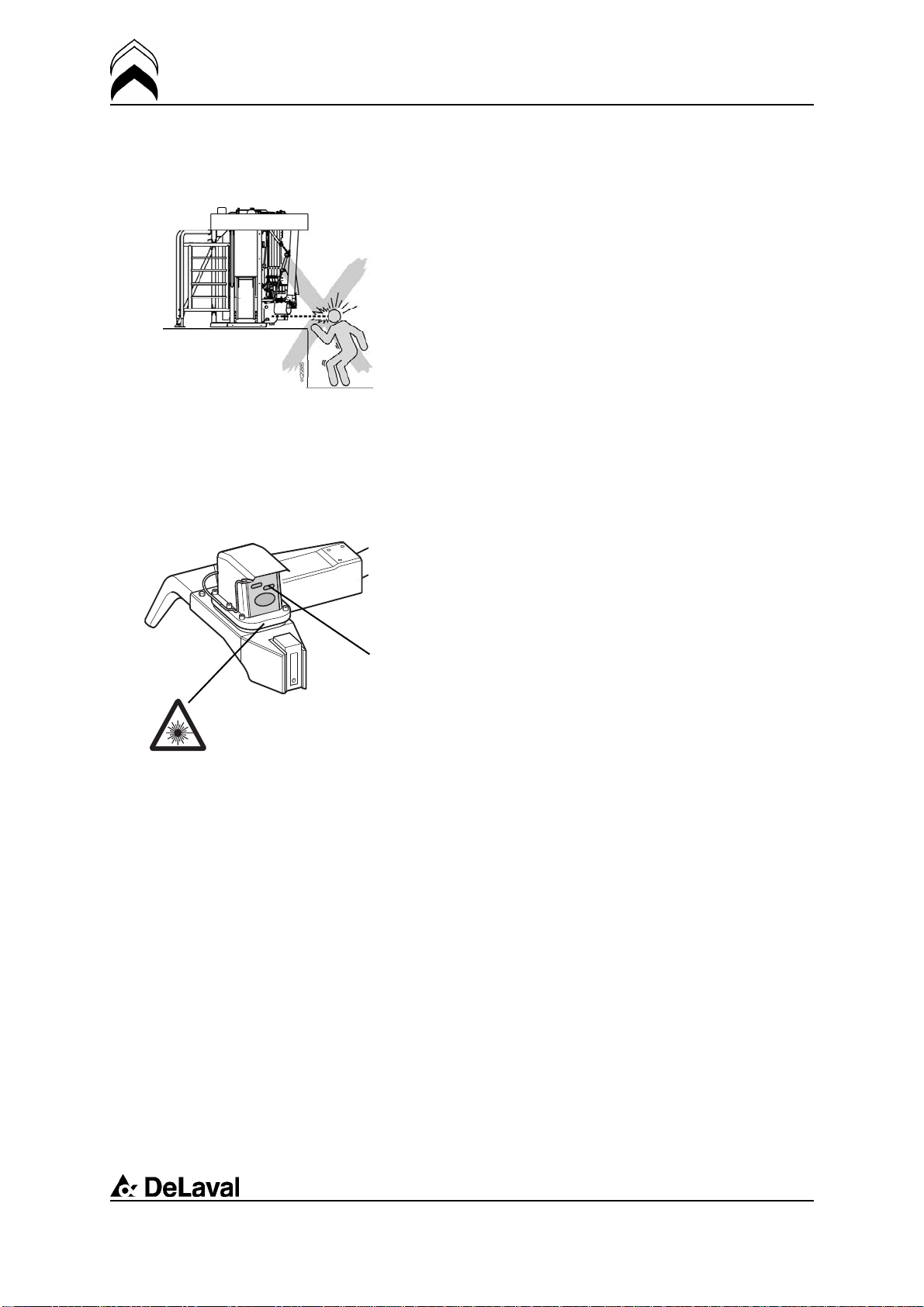

Warning: The area within the dotted lines is

the working range for the milking station.

This area is not safe when the milking

station is in operation, especially in

automatic mode. Do not stay in this area

longer than necessary.

————————————————————

Note: Floor markings indicates the working

range of the multi-purpose arm.

————————————————————

Warning: When pressing the emergency

stop, the inertial energy in the multi-purpose

arm will allow it to continue to move up to

one meter. The multi-purpose arm will be

totally stopped within approximately one

second.

————————————————————

————————————————————

FG

Service mode Working mode

FG

Warning: To avoid the risk of being injured

by moving parts on the milking station,

always set the service switch to service

mode before entering the working range of

the milking station.

————————————————————

5(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

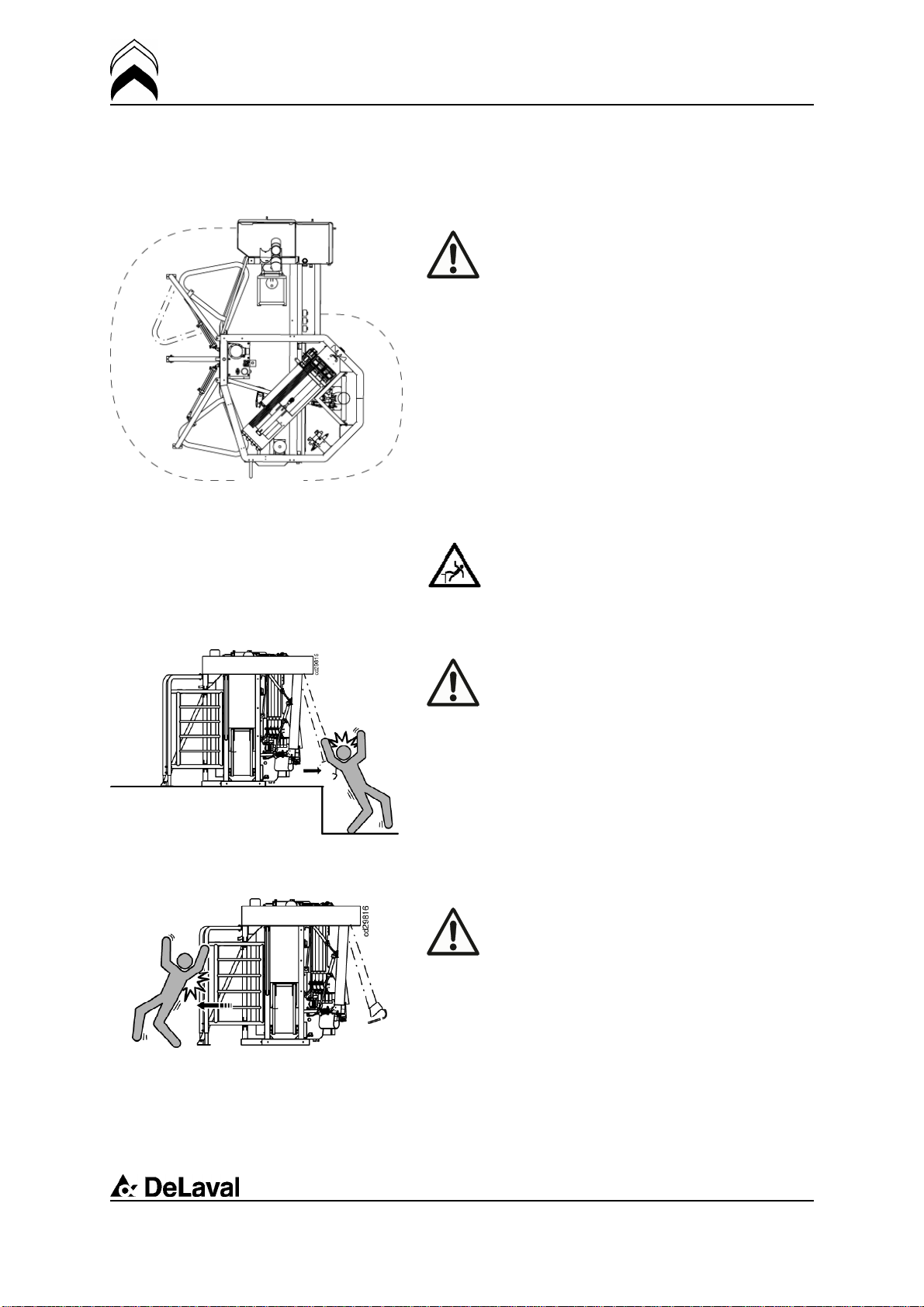

————————————————————

Warning: Do not allow unauthorized

personnel and children to be close to the

VMS system.

————————————————————

————————————————————

Warning: Risk of falling into pit (if present).

————————————————————

————————————————————

Warning: Do not stay within working range

of the multi-purpose arm longer than

necessary. If you need to carry out tasks

within the working range of the arm, for

example attaching teatcups by hand or

checking udder health, always set the

service switch to service mode, then park

the arm. Deactivating the multi-purpose arm

provides additional safety.

————————————————————

————————————————————

Warning: Do not stay within the working

range of the gates. They can move without

warning and there is a risk of being hit or

squeezed. Always set the service switch to

service mode if you need to work near the

gates.

————————————————————

6(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

————————————————————

Warning: Never put any part of your body

between the multi-purpose arm and the

magazine when the milking station is in

operation. You may become seriously

injured.

————————————————————

————————————————————

FG

B

A

Warning: Keep away from the

multi-purpose arm. Risk of pinching at the

junction between the lower arm (A) and the

cylinder (B). Your hand or fingers may

become caught and crushed.

————————————————————

————————————————————

Warning: Keep away from the cleaning

shelf area. During backflush and cleaning,

the cleaning shelf tilts upwards and your

hands or fingers may become seriously

injured.

————————————————————

7(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

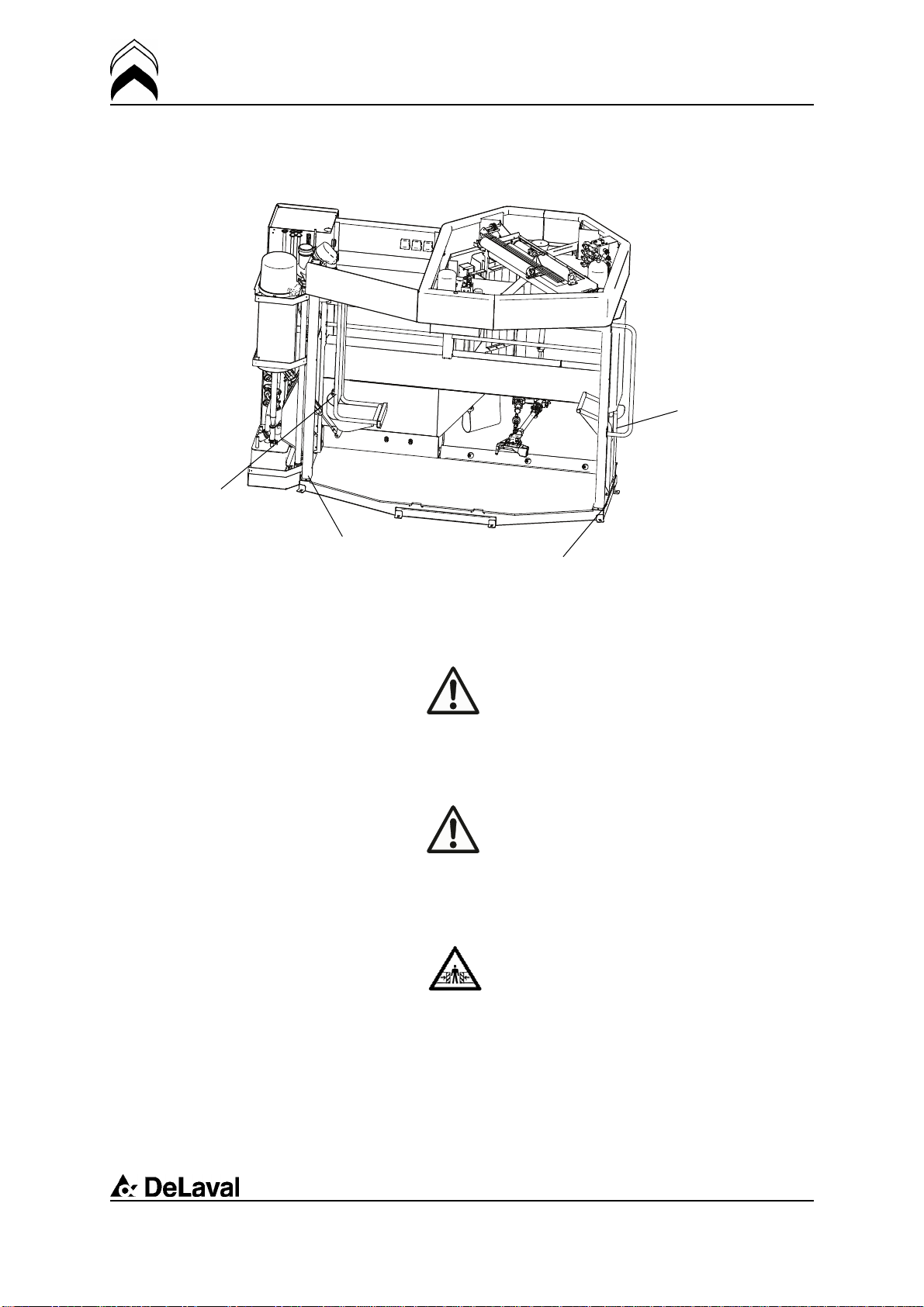

cd29900

Rear plate

Rear gable

Manger

support

Front gable

————————————————————

Warning: Never put any part of your body

between the rear plate and the rear gable,

between the manger support and the front

gable. You may become seriously injured.

————————————————————

————————————————————

Warning: Never put any part of your body

inside the milking station when cow is in the

milking station. You might be seriously

injured.

————————————————————

————————————————————

Warning: The gates are automatically

operated. Never enter the milking station

without setting the service switch in service

mode.

————————————————————

8(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

————————————————————

Caution: Be careful not to hit your head on

the structure overhead, when working in the

milking station.

————————————————————

————————————————————

Warning: Always keep the floor around the

milking station clean. A slippery floor poses

a safety hazard.

————————————————————

————————————————————

Warning: Make sure that every cow is

given the time she needs to become

accustomed to the milking station. A forced

time schedule might make a cow panic

during a milking session, which could result

in injuries.

————————————————————

————————————————————

Caution: The sound pressure overrides

83dB(A) during teat cleaning.

————————————————————

Laser radiation

————————————————————

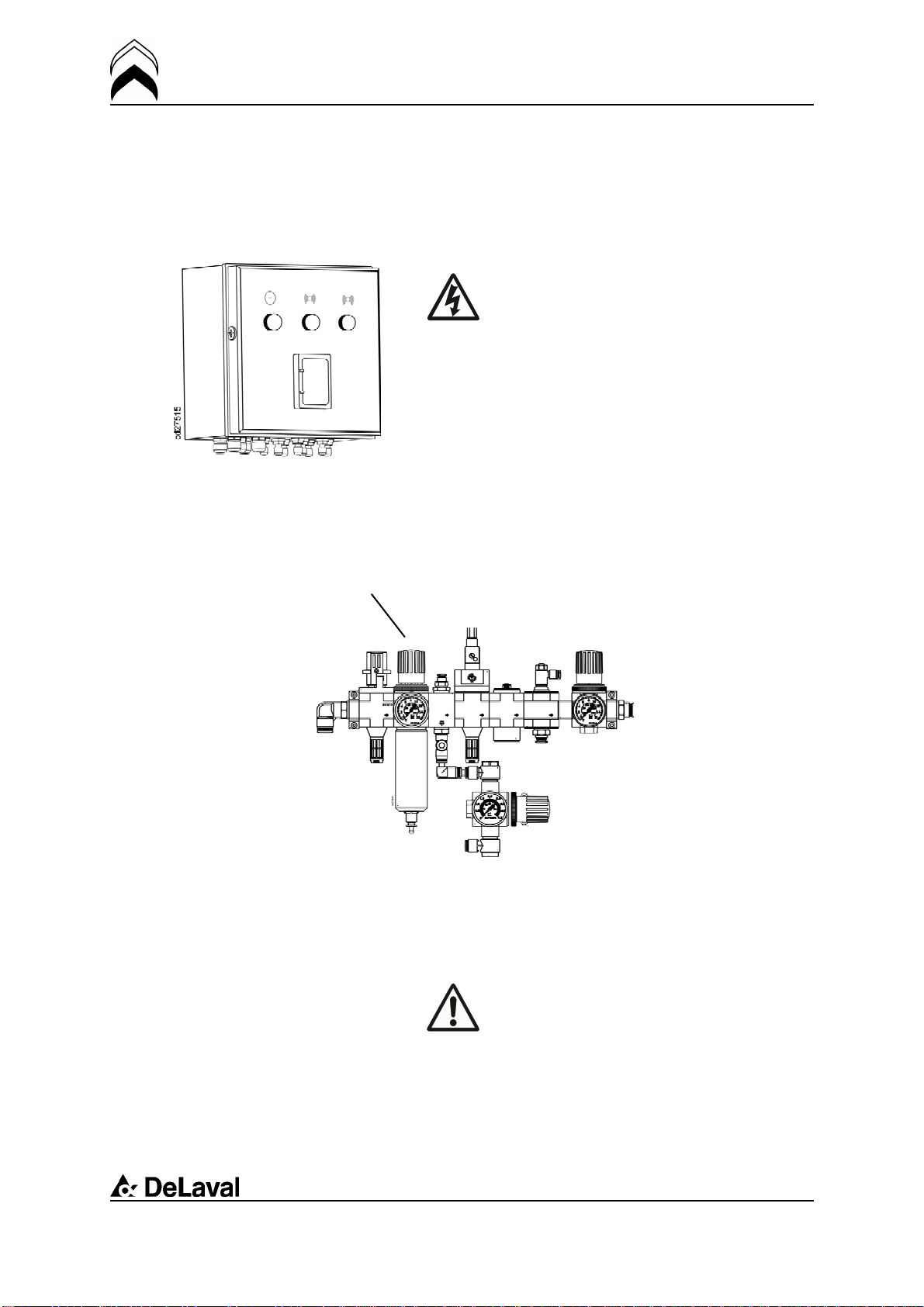

Caution: Laser radiation. Do not stare into

the beam.

————————————————————

9(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

Lasers

FG

The lasers are used during the procedures

listed below. The controls related to the

procedures are performed on the touch

screen, which are referred to windows and

buttons. The names of the windows are

printed in italics, the names of the buttons in

bold face.

The lasers are used:

•When the multi-purpose arm is attaching

cups. This concerns both automatic and

manual mode. Prepare Cow for Milking:

Clean Teats; Teat Attach and Milking:

Attach Cups Auto. These buttons are

only used in manual mode.

•When determining teat positions. Robot

Teaching: Teach All Teat Positions,

Teach Teat Pos, Auto Teach.

•When verifying teat positions and testing

that the arm can find teats. Robot Control:

Test Start Positions, Attach Without

Cups.

•When testing the lasers. Robot Service:

Main Laser, Teat Laser.

•When testing misc codes 55 (activates

the two laser lines) and 66 (restarts the

Camera unit). Test misc codes: VMS >

Robot Service > Test Misc.

•When using the camera image menu to

provide an image of what the Camera unit

sees. Camera image menu: VMS >

Robot Control > Analyze Camera

Image.

•When starting the milking station by

pressing Start (I) button on the On/Off box

after an emergency stop.

•During maintenance and repair: when

re-connecting the power to the camera

unit.

Note: It is not allowed to dismantle the

lasers.

Note: The lasers may not be adjusted

on-site.

10(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

————————————————————

Warning: Use of controls, adjustments or

performance of procedures other than those

specified herein may result in hazardous

radiation.

————————————————————

Safety during maintenance and

service

————————————————————

Warning: Service should only be carried

out by personnel with the proper training

and authorisation. This concerns all parts of

the system.

————————————————————

————————————————————

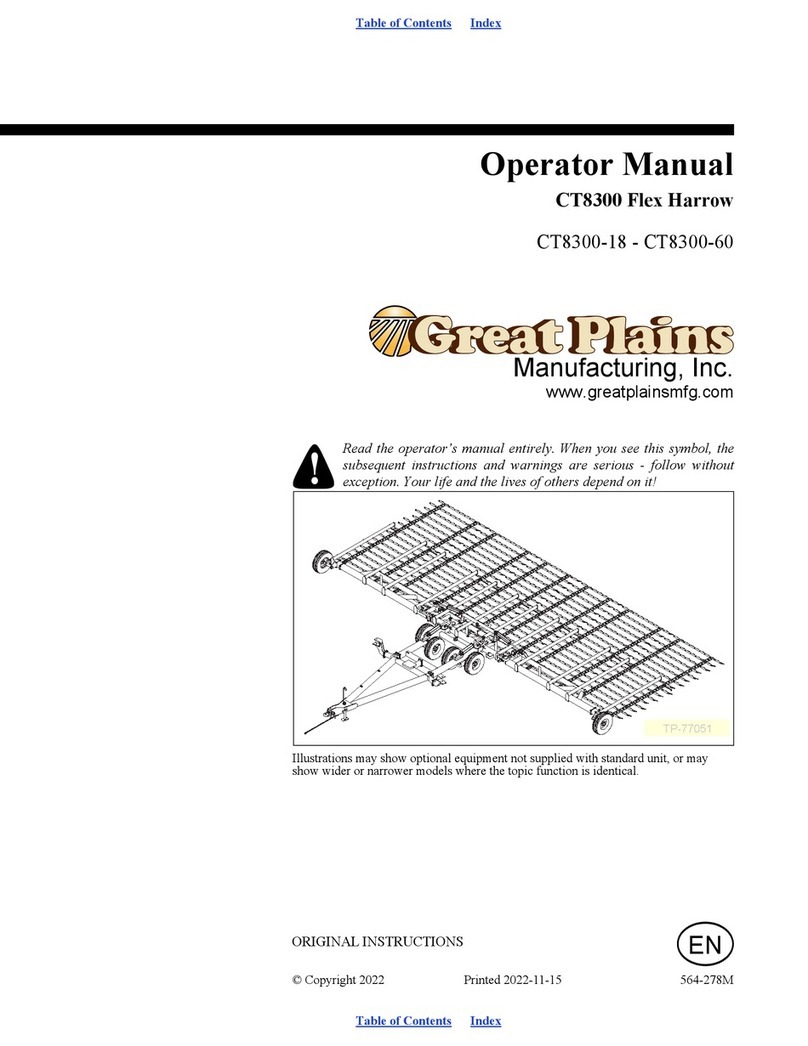

Main

switch

VMS power box

Danger: Always shut down the milking

station and switch off the electrical power

supply (by turning the main switch

anti-clockwise) before service or repair of

the electrical system is carried out. Use

appropriate lockout/tagout procedures to

make sure that the power is not switched on

without your knowledge.

————————————————————

Note: Use the touch screen to shut down

the milking station. The programs executed

in the milking station will then be terminated

properly.

————————————————————

FG

FG

Service mode Working mode

Warning: To avoid the risk of being injured

by moving parts on the milking station,

always set the service switch to service

mode before entering the working range of

the milking station.

————————————————————

11(198)

Safety precautions

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

Guardmaster information is valid for the US

only.

————————————————————

VMS guardmaster box

Danger: Always switch off the electrical

power supply to the VMS guardmaster box

before opening the cover to the

guardmaster box.

————————————————————

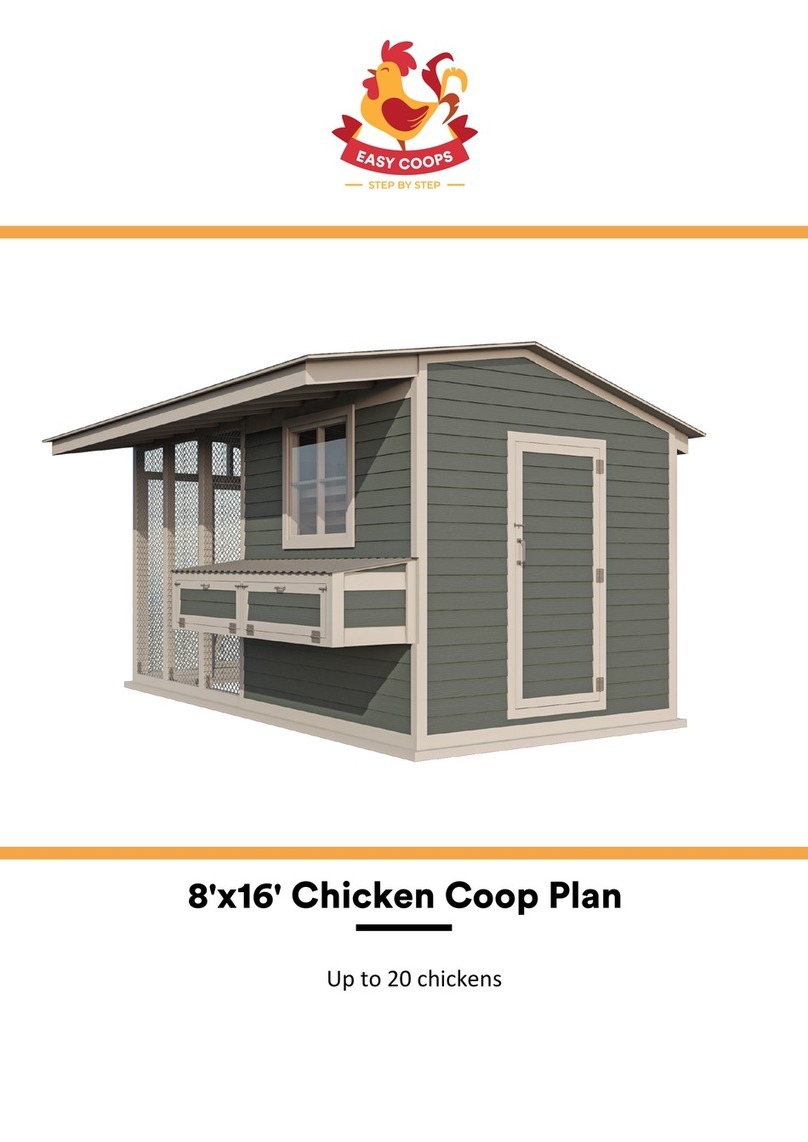

(Part of the upper beam.)

Main valve for compressed-air to the milking station.

————————————————————

Warning: Always shut off the main

compressed-air supply to the milking station

before performing service or making repairs.

————————————————————

Note: Even if the compress-air supply has

been shut off, be aware that the

12(198)

Table of contents

Other DeLaval Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Unverferth

Unverferth CROSS-FOLD ROLLING HARROW 1245 manual

Ovlac

Ovlac MINIVID OPERATING INSTRUCIONS AND SPARE PARTS

GREAT PLAINS

GREAT PLAINS CT8300 Operator's manual

EASY COOPS

EASY COOPS Chicken Coop Plan 8x16 Assembly instructions

Steiner

Steiner TR270 TERRA Operator's & parts manual

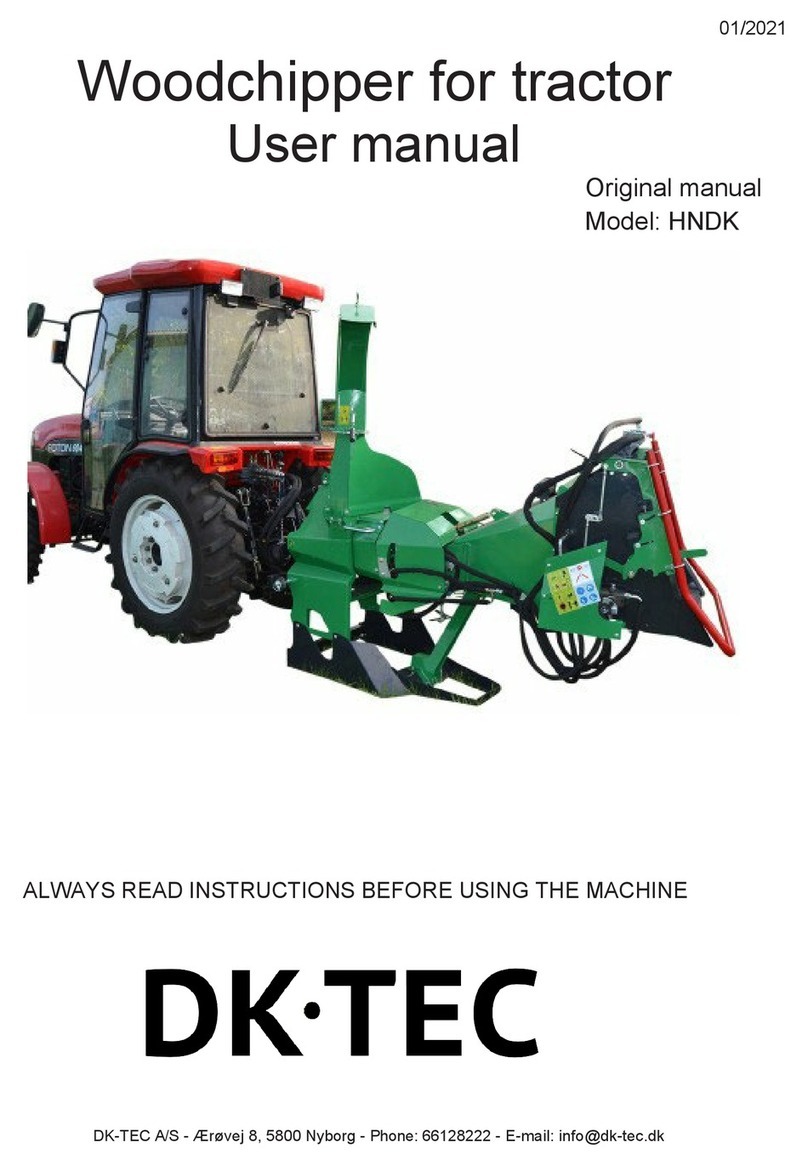

DK-TEC

DK-TEC HNDK user manual