214077 vii Revision A

3.18.6 Using Chemical Drying Agents .................................................................................................94

3.19 Transporting the Header ...................................................................................................................95

Chapter 4: Maintenance and Servicing ........................................................................................... 97

4.1 Preparing Machine for Servicing..........................................................................................................97

4.2 Recommended Safety Procedures ......................................................................................................98

4.3 Maintenance Requirements ..............................................................................................................100

4.3.1 Maintenance Schedule/Record ................................................................................................101

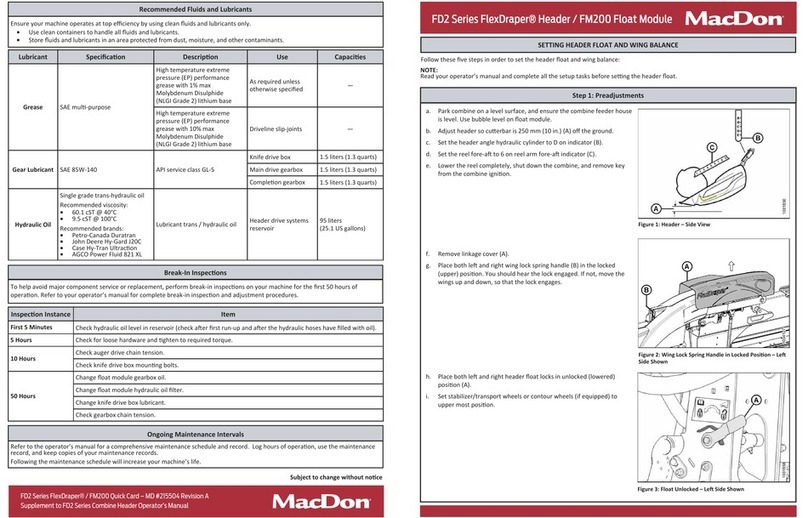

4.3.2 Break-In Inspections................................................................................................................103

4.3.3 Preseason Servicing ...............................................................................................................104

4.3.4 End-of-Season Servicing .........................................................................................................104

4.4 Lubrication ...................................................................................................................................... 105

4.4.1 Greasing Procedure ................................................................................................................105

4.4.2 Service Intervals .....................................................................................................................106

First 25 Hours ........................................................................................................................106

Every 25 Hours ......................................................................................................................107

First 50 Hours ........................................................................................................................108

Every 100 Hours or Annually ...................................................................................................109

First 150 Hours....................................................................................................................... 110

Every 250 Hours..................................................................................................................... 111

4.5 Cutterbar......................................................................................................................................... 112

4.5.1 Cutterbar Discs ....................................................................................................................... 112

Inspecting Cutterbar Discs ...................................................................................................... 112

Removing Cutterbar Discs....................................................................................................... 113

Installing Cutterbar Discs ........................................................................................................ 114

4.5.2 Cutterbar Spindles .................................................................................................................. 116

Removing Cutterbar Spindles .................................................................................................. 116

Installing Cutterbar Spindles.................................................................................................... 119

4.5.3 Cutterbar Crop Stream Configuration........................................................................................124

Changing 13-Foot Cutterbar Crop Stream Configuration............................................................125

4.5.4 Discblades..............................................................................................................................125

Inspecting Discblades .............................................................................................................126

Inspecting Discblade Hardware ...............................................................................................127

Removing Discblades .............................................................................................................129

Installing Discblades ...............................................................................................................130

4.5.5 Accelerators ...........................................................................................................................131

Inspecting Accelerators...........................................................................................................132

Removing Accelerators ...........................................................................................................132

Installing Accelerators.............................................................................................................133

4.5.6 Rock Guards...........................................................................................................................134

Inspecting Rock Guards..........................................................................................................134

Removing Rock Guards ..........................................................................................................135

Installing Rock Guards ............................................................................................................136

4.5.7 Drums .................................................................................................................................... 136

Inspecting Drums ...................................................................................................................136

Removing Driven Drums and Driveline .....................................................................................138

Installing Driven Drums and Driveline.......................................................................................141

Removing Non-Driven Drums ..................................................................................................145

TABLE OF CONTENTS