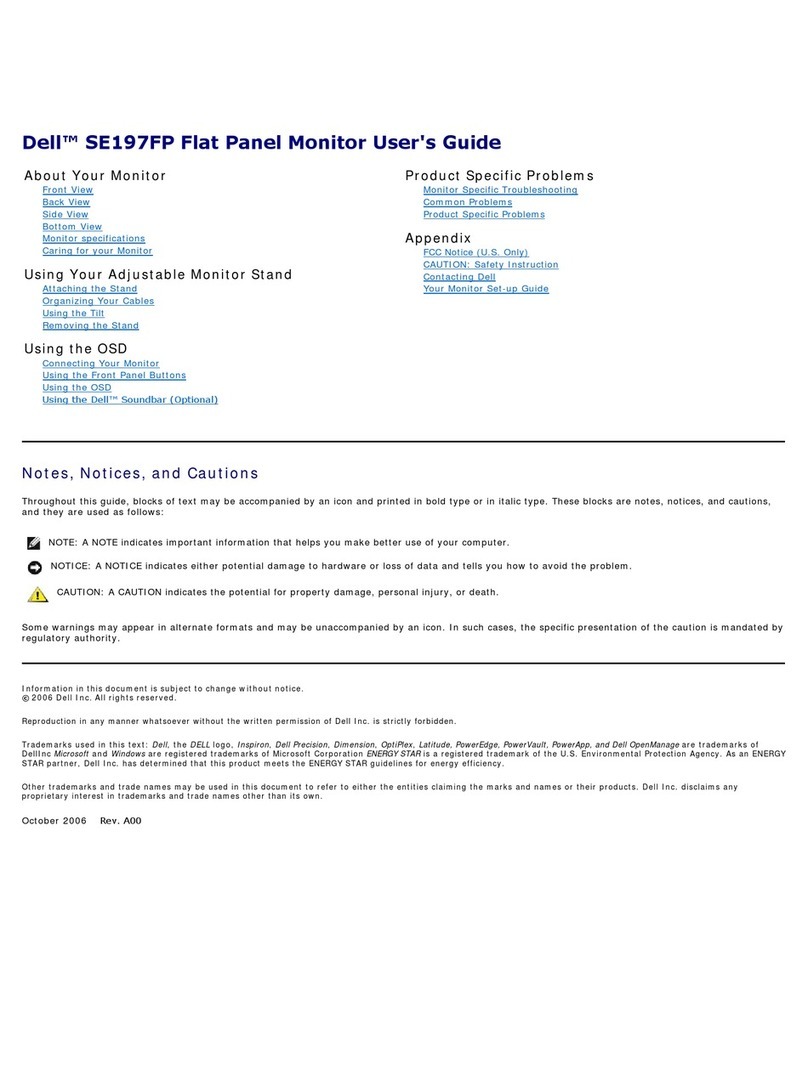

Table of Contents

CHAPTER 1- PRECAUTIONS & SAFETY NOTICES................................................................................................

SAFETY PRECAUTIONS................................................................................................................................

................................

PRODUCT SAFETY NOTICE................................................................................................................................

.............................

SERVICE NOTES ................................................................................................................................

................................

CHAPTER 2- SERVICE TOOLS & EQUIPMENT REQUIRED................................................................

................................

CHAPTER 3- CIRCUIT THEORY................................................................................................................................

1.BLOCK DIAGRAM ................................................................................................................................

................................

2.ELECTRONIC CIRCUIT THEORY................................................................................................................................

...........................

3. FACTORYPRESETTIMING TABLE ................................................................................................

................................

4. POWER ON/OFF SEQUENCY ................................................................................................................................

.............................

5. D-SUB CONNECTOR PIN ASSIGNMENT................................................................................................

................................

6.AC OUTLET PIN ASSIGNMENT ................................................................................................................................

.........................

7. INNER CONNECTOR PIN ASSIGNMENT................................................................................................

................................

8. KEY PARTS PIN ASSIGNMENTS................................................................................................................................

.........................

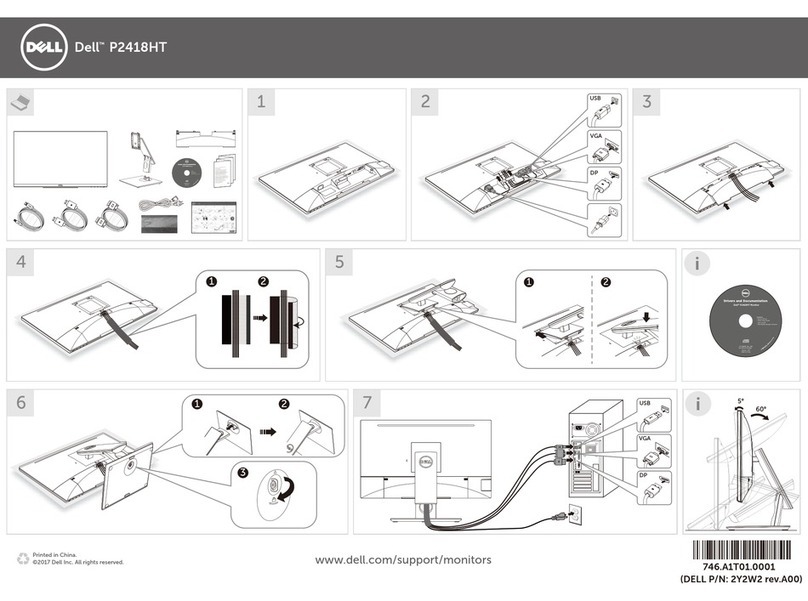

CHAPTER 4- DISASSEMBLY & ASSEMBLY................................................................................................

................................

1. EXPLODED DIAGRAM................................................................................................................................

................................

2. ST2010 DISASSEMBLY BLOCK ................................................................................................................................

3. ST2010ASSEMBLY BLOCK................................................................................................................................

............................

CHAPTER 5- TESTAND ADJUSTMENT................................................................................................

................................

5.1 FUNCTION KEY DEFINITIONS................................................................................................................................

..........................

5.2 OSD CONTROL................................................................................................................................

................................

5.3 OSD MESSAGE ................................................................................................................................

................................

5.4 BURN-IN PATTERN................................................................................................................................

................................

5.5AUTO COLOR BALANCE (AUTOMATICALLY CALIBRATE CHIPADC PARAMETER BY USING CHIP

INTERNAL DAC.)................................................................................................................................................................

5.6 UPGRADE FIRMWARE TO SERIAL VIA FLASH CABLE BY ISP_TOOLV4.100.EXE ................................

................................

CHAPTER 6- TROUBLE SHOOTING................................................................................................

................................

1. COMMON ACKNOWLEDGE ................................................................................................................................

...............................

2. NO POWER SUPPLY ................................................................................................................................

................................

3. POWER (INCLUDE IF +5VAND +3.3V) SUPPLY NORMAL BUT LED OFF AND NO DISPLAY ................................

................................

4. POWER (INCLUDE IF +5VAND +3.3V) SUPPLYAND DISPLAY NORMAL ONLY LED OFF................................

................................

5. POWER (INCLUDE IF +5VAND +3.3V) SUPPLY NORMAL BUT LEDAMBER ................................................................

6. POWER (INCLUDE IF +5VAND +3.3V) SUPPLY NORMAL ,KEY FUNCTION OK,BUT BACKLIGHT CAN’T

BE TURNED ON................................................................................................................................................................

7. BACKLIGHT ON,KEY FUNCTION AND LEDACCURATE INDICATION OK BUT NO PICTURE................................

................................

8. AT 32-GRAY SCALE PATTERN,COLOR LOST IN SOME SCALE................................................................

................................

CHAPTER 7- RECOMMENDED PART LIST................................................................................................

................................

ATTACHMENT 1- BILL OF MATERIAL ................................................................................................

................................

ATTACHMENT 2- SCHEMATIC................................................................................................................................

ATTACHMENT 3- PCB LAYOUT................................................................................................................................