dellonda DG5 User manual

Thank you for purchasing a Dellonda product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Original Language Version

Refer to

instruction

manual

PROPANEGASPYRAMIDPATIOHEATERS13KW

MODEL NO: DG5, DG6

1. SAFETY

9Read the installation, operating and maintenance instructions thoroughly before installing or using this equipment.

9 Ifthereisasmellofgas:shutothegastotheappliance,extinguishanyopenames.Ifodourcontinuescontactgassupplier.

8DO NOTstoreorusepetrolorotherammablesubstancesinsidethehousingoftheheater.

8DO NOTstoreorusepetrolorotherammableliquidsorgasesinthevicinityoftheheater.

8DO NOTstoreagascylinderthatisnotconnectedforuseinthevicinityofthisoranyotherappliance.

WARNING! DO NOTuseindoors.Foruseoutdoorsorinamplyventilatedareas.

Anamplyventilatedareaisonethathasaminimumof25%ofthesurfaceareaopen,seeg.1.

(Thesurfaceareaisthesumofthewallsurface.)

WARNING!Notintendedtobeinstalledinrecreationalvehiclesand/orboats.

WARNING!Improperinstallation,adjustment,alteration,serviceormaintenancecancauseinjuryor

propertydamage.

9 Installationandrepairmustbecarriedoutbyaqualiedperson.

8DO NOTattempttoalterinanyway.

9 Wearsafetyglovesduringtheassemblyprocess.

9 Thisproductmustbeinstalledandthegascylinderstoredinaccordancewiththelocalregulationsinforce.

8DO NOTobstructtheventilationholesofthecylinderhousing.

8DO NOTmove/transporttheappliancewheninoperation.Shutothegascylinderattheregulatorbeforemoving.

8DO NOTmove/transporttheheateruntilithascooleddown.

9 Useonlythetypeofgasandthetypeofcylinderspeciedbythemanufacturer.

TheLPcylinderusedwiththepatioheatermustmeetthefollowingsizerequirements:

Diameter31.8cmxheight58cm,15kgmaximumcapacity.

9 Protecttheproductfromstrongwindtopreventtilting.

9 Onlyuseonlevelground,capableofsupportingtheweightoftheheaterandthegascylinder.

8DO NOTconnectthegascylinderdirectlytotheappliancewithoutaregulator.Useonlythetypeofgasspeciedintheinstructions.

9 Thewholegassystem(hose,regulator,pilotorburner)shouldbeinspectedforleaksordamagebeforeuseandatleastannually,bya

suitablyqualiedperson.

9 Allleaktestingshouldbedonewithanappropriategasleakdetection/soapsolution.Neveruseanopenametocheckforleaks,refer

tosection6.2.

8DO NOTusetheheateruntilallconnectionshavebeenleaktested.

9 Turnothegasimmediatelyifagassmellisdetected.TurncylindervalveOFF.Iftheleakisatthehose/regulatorconnectiontighten

theconnectionandperformanotherleaktest.Ifbubblescontinueappearingcontactyoursupplier.Iftheleakisattheregulator/

cylinderconnectiondisconnectfromcylinder,reconnectandperformanotherleakcheck.Ifsoapbubblesarestillseen,cylindervalve

isdefective.Returncylindertoitsplaceofpurchase.

9 Keeptheventilationopeningofthecylinderenclosurefreeandclearofdebris.

8DO NOTpainttheradiantscreen,controlpanelortopcanopyreector.

9 Controlcompartment,burnerandcirculationairpassagewaysoftheheatermustbekeptclean.

9 Turnogaswhilstnotinuse.

9 LPregulator/hoseassemblymustbeaprotectedfromaccidentaldamage.

9 Anyguardremovedforservicing/maintenancemustbereplacedbeforeoperation.

9 Keepsadultsandchildrenawayfromthehightemperaturesurfaces,toavoidburnsandignitionofclothing.

9 Childrenshouldbecarefullysupervisedwhentheyareinthevicinityoftheheater.

8DO NOThangclothingorotherammablematerialsontheheaterorplacethemneartheheater.

2. INTRODUCTION

InnovativedesignofGasFlamePatioHeater.Contemporaryfreestandingpatioheateridealforbothcommercialanddomesticsettings

includingopenworkshops,boatyards,patios,forecourts,gardensandterraces.Standingat2.2mtall,whenlittheheaterproducesareal

ameencompassedbyaglasstubeandheatsthesurroundingarea. Metalreectormakessuretheheatisdirecteddownwardsandoutwards.

Variableheatoutputcontrolsmakeitfullyadjustable.Featuresafullyenclosedgascylinderchamberandsafetytipoverswitch.

g.1

DG5,DG6Issue:6(3,4,5)30/06/2021

Wearsafety

glovesduring

assembly

3. SPECIFICATION

Modelno’s............................................................. DG5,DG6

Fuel...........................................................................Propane

Fuelconsumption....................................................... 945g/hr

Heatedarea.....................................................................8m²

Output........................................................................... 13Kw

Dimensions(WxH)........................................580x2270mm

4. CONTENTS

Original Language Version

PART DESCRIPTION QTY.

A Reector 1

BFlame screen 1

CGlasstube 1

D Uppersupport 4

E Protectiveguard 4

FBlacksiliconering 1

G Sidepanel 3

H Frontpanel 1

IGas hose 1

J Controlboxassembly 1

K Lowersupport 4

L Blockbelt 1

M Wheelassembly 1

N Bottomplate 1

Max.gasbottlesize.......................................... Ø325x700mm

DG5,DG6Issue:6(3,4,5)30/06/2021

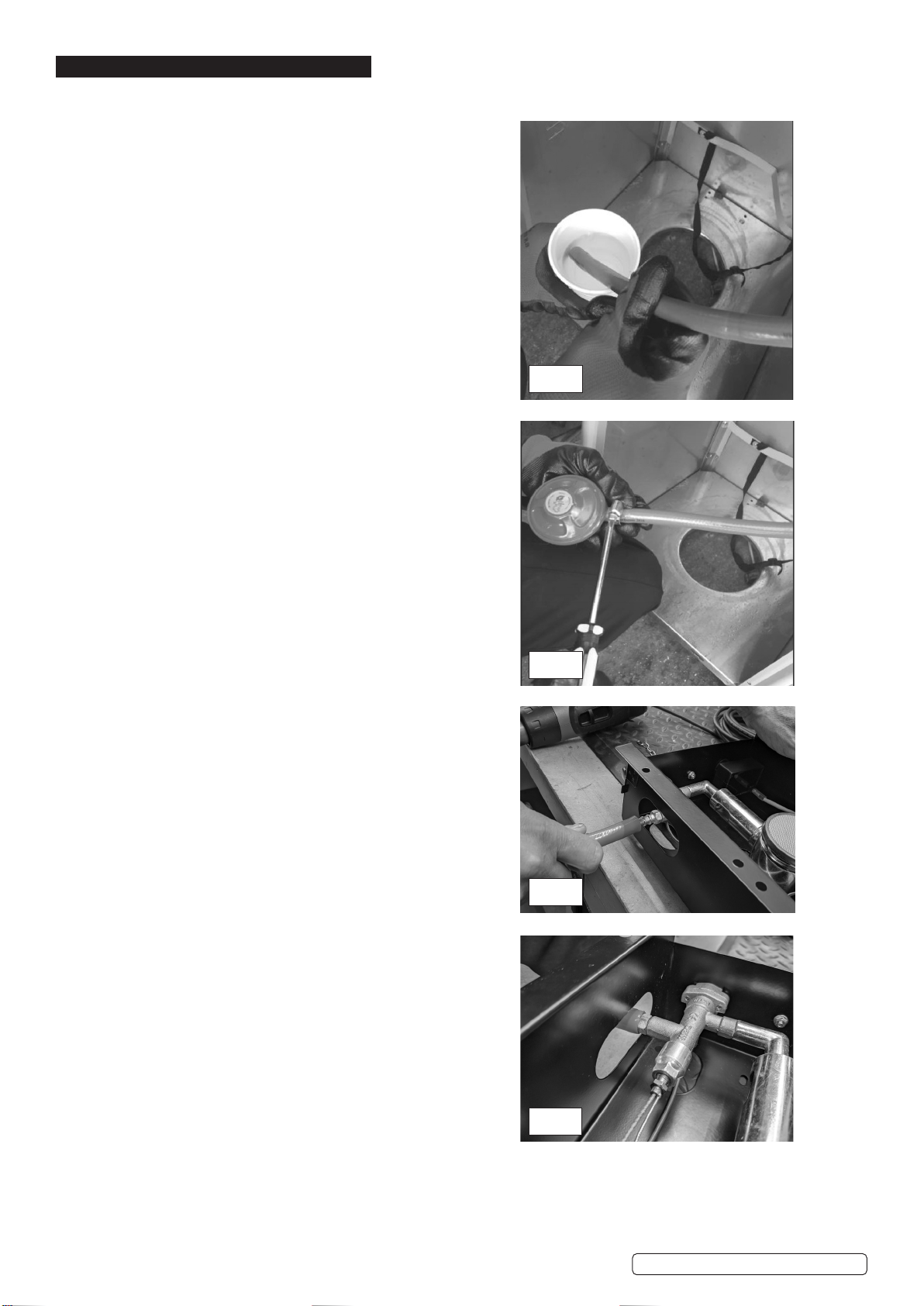

5.2. Toassistconnectingtheregulator,carefullyplacetherubberhoseintoan

insulatedcupofboilinghotwater(Fig.1).Thisallowstherubberhoseto

expand,ensurethehoseclipisslidoverthehoseandthenpushtheopen

hoseendfullyontothegasregulatorinlet.

5.3. Afterconnectingtheregulator,slidethehoseclipbacktoneartheendof

thehoseandtightenwithascrewdriver(Fig.2).

NOTE: Ensure you leak test this joint as directed in Section 6 after

assembly is complete and when you rst connect the gas bottle.

5.4. Now connect the open hose end to the control unit (J) again carefully place

the rubber hose end into an insulated cup of boiling hot water (Fig.1). This

allows the rubber hose to expand, ensure the hose clip is slid over the hose

and then push the open hose end fully onto the gas inlet on the control unit

as shown in Fig. 3.

5.5. Afterconnectingthehoseintothecontrolunit(J)slidethehoseclipbackto

neartheendofthehoseandtightenwithascrewdriver(Fig.2).

NOTE: Ensure you leak test this joint as directed in Section 6 after

assembly is complete and when you rst connect the gas bottle.

WARNING!Ensurefullengagementofhosetoregulatorandcontrol

unit.

WARNING!Checkthatthewormdriveclipsatbothendsofthegashose

arefullytightened.

WARNING! Arrangethegashoseandregulatortoensurethehosedoes

notcomeintocontactwithanyhightemperaturesurfacesasitmaymelt

andcauseare.Afterthecylinderisplacedinsidetheheater,tightly

securethecylinderwiththebelt.

NOTE:Seesection6forLeakCheckprocedure.

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

Fig.1

Fig.2

Fig.3

Fig.4

5. ASSEMBLY

5.1. Itisrecommendedthatyouconnectthegasregulatorhosetotheregulatorandthecontrolunit(J)priortoassemblingtheunit,becareful

nottodamageordislodgecomponentsinthecontrolunit(J).

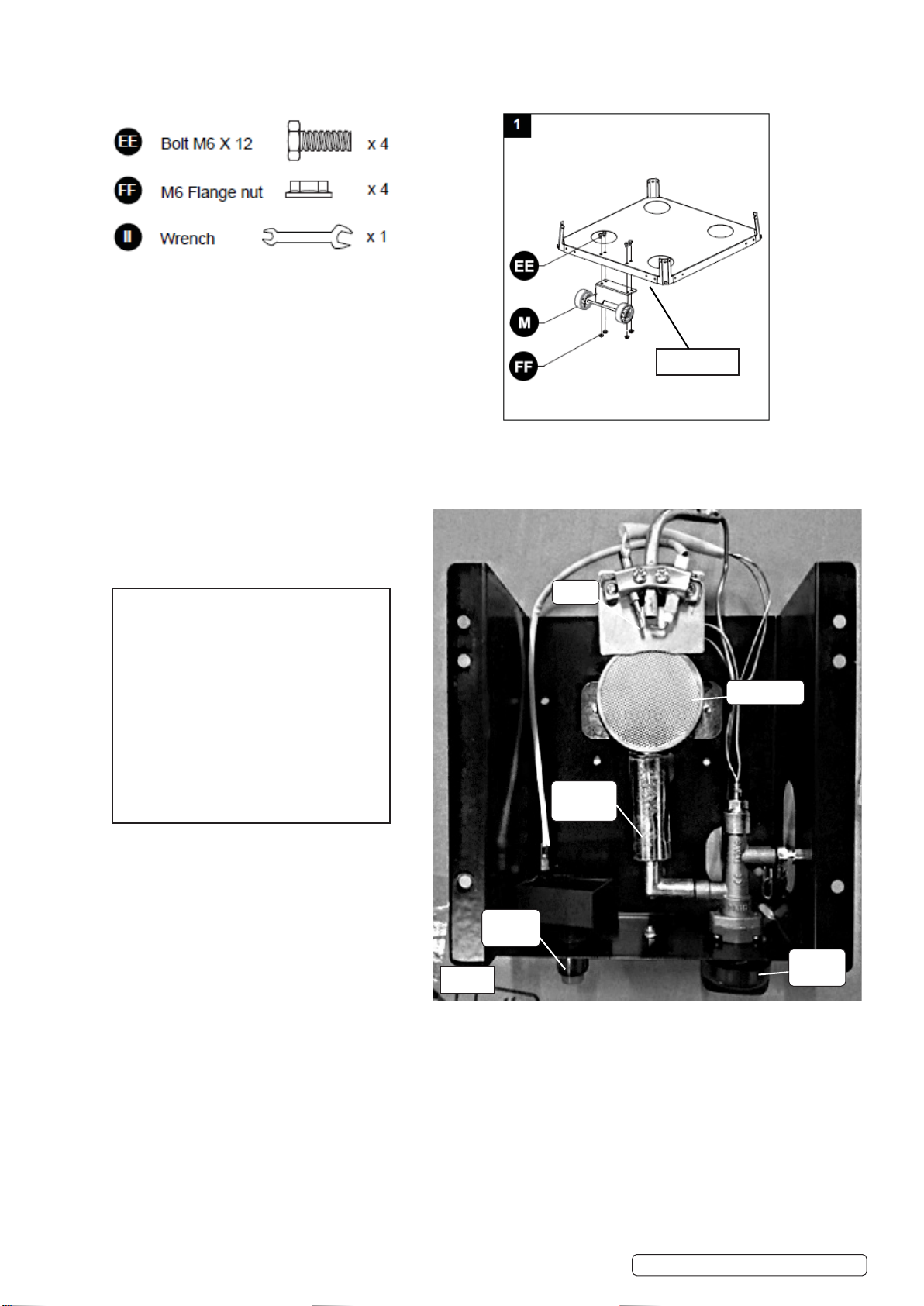

5.6. DIAGRAM 1Fixthewheelassemblytothebottomplate,use4pcsboltM6X12and4pcsangenutM6.

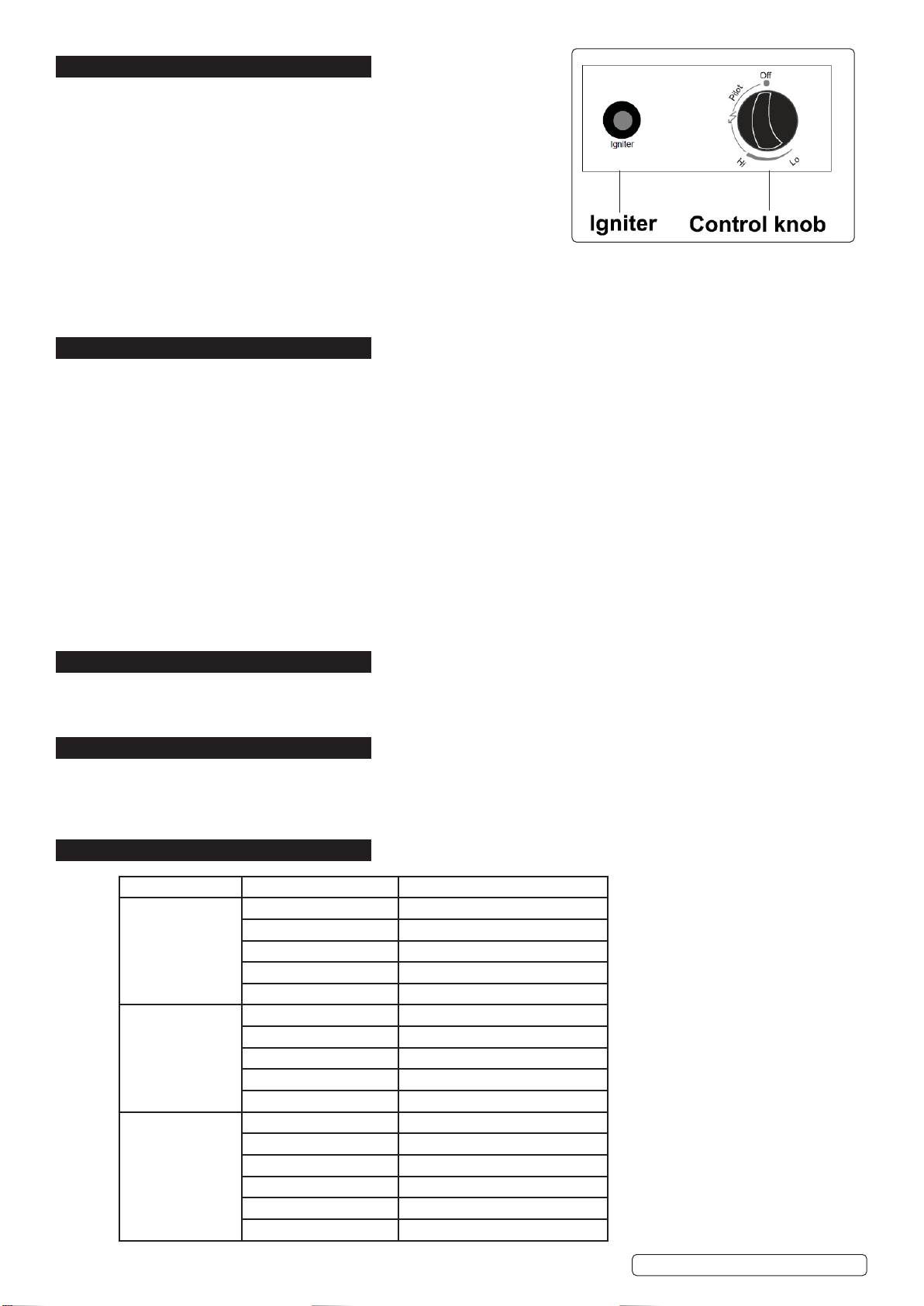

5.7. CONTROL UNIT (CHECK)

5.8. Oncethegashosehasbeensafelyattachedtothecontrolunit(K)andgasbottleregulatorthecontrolunitassemblycannowbe

installedontothemiddleplate(J).Beforemovingontounitassemblycheckforthecorrectorientationofallcomponents(Fig.5).

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

Back of unit

Igniter

Ignition

switch

Control

knob

Burner Mesh

Mixing

chamber

NOTE:

Ensure the control unit assembly (K)

is installed with the controls facing

the front of the unit.

Ensure all components appear as

in (Fig. 5) within the control unit,

if any components are missing or

dislodged. *STOP* Contact the

supplier for assistance.

Fig.5

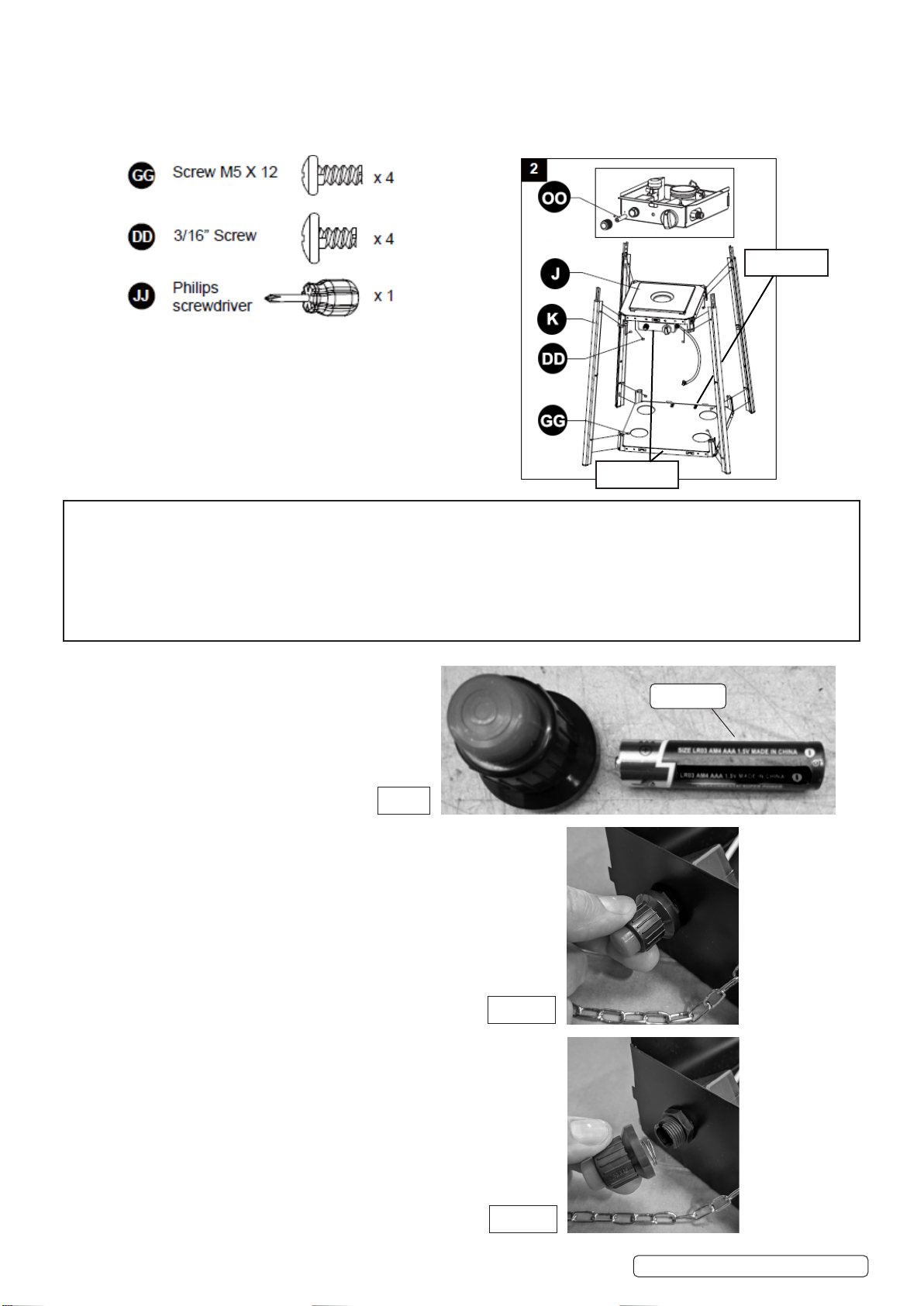

5.9. DIAGRAM 2Unscrewtheswitchbutton,tbattery,rettheswitchbutton.

5.10. Insertthepinsofthebasetotheholesoflowersupport,presstosecurethepins.Use4xM5X12screwstosecurethelowersupport

andbase.

5.11. Insertthepinsofthecontrolboxassemblytotheholesofuppersupport,presstosecurethepins.Use4x3/16”screwstosecurethe

uppersupportandcontrolboxassembly.

NOTE:

It is vital at this stage to ensure that the bottom plate (N) and the middle plate (J) are assembled correctly.

The wheels on the bottom plate (N) are the back of the unit and the magnetic catches on the middle plate

(J) for the door are on the front of the unit, these parts must be on OPPOSITE sides of the unit. This must be

correct at this stage to ensure the unit operates correctly.

AAA Battery

TheignitionswitchmusthaveaAAAbattery

insertedintoit,Unscrewthecollaroftheswitchand

insertabatterythenrescrewtheswitchheadinto

place(Fig.6).

Unscrewthebuttoncollaruntilitcomesawayfromtheunit.(Fig.6.1).

Fig.6.1

SlideinaAAAbatteryandre-screwthebuttonintoposition.(Fig.6.2).

Fig.6.2

Front of unit.

Back of unit.

Fig.6

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

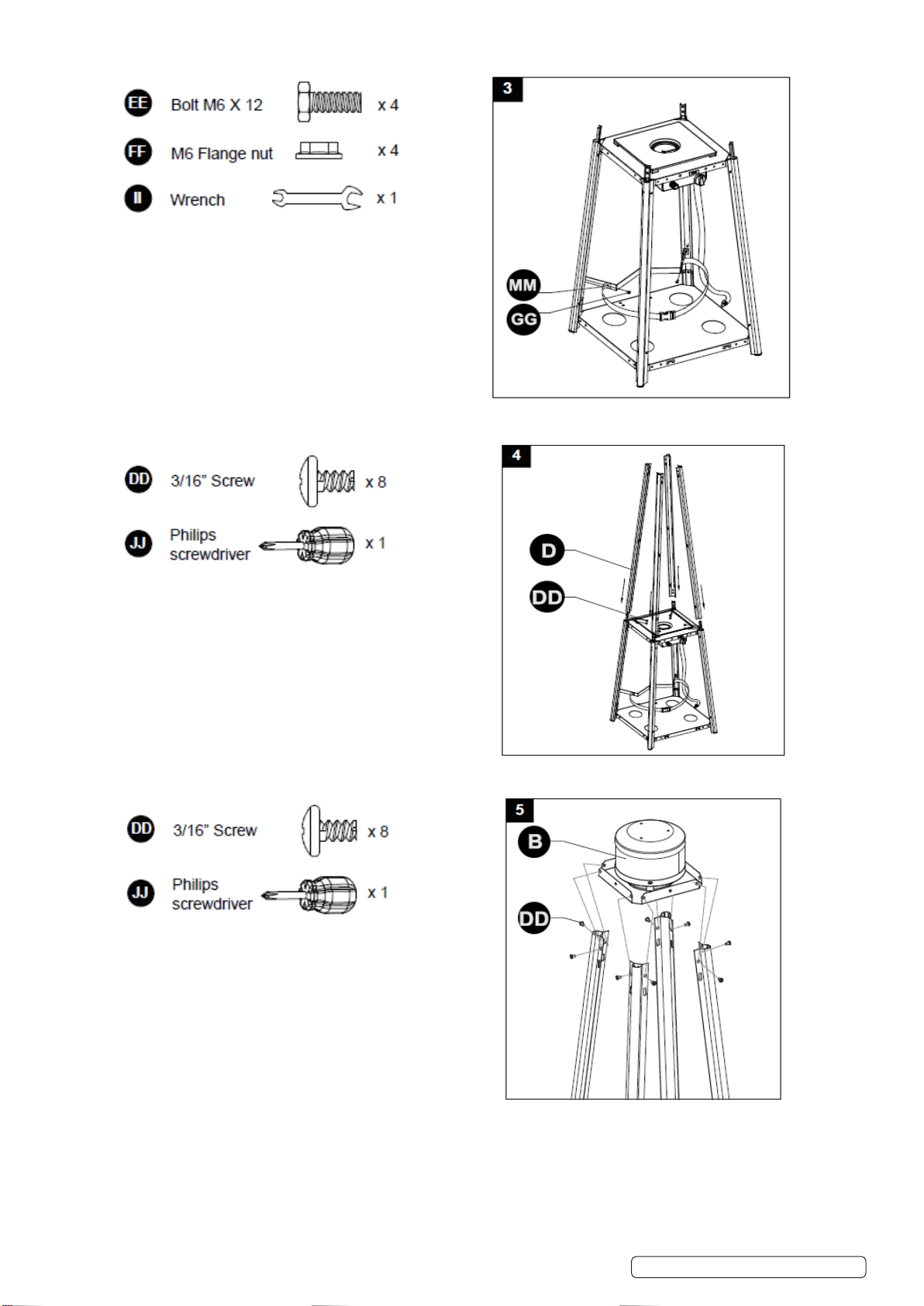

5.12. DIAGRAM 3Assemblethegascylinderbelt.Fixthebelttothetwolowersupportsbehindthefrontdoor,use2xM5x12screws.

5.13. DIAGRAM 4 Assemblethemiddlesupport.Insertthe4pcsuppersupport.Securewith8x3/16”screws.

5.14. DIAGRAM 5Fixtheamescreentotheuppersupports.Use8x3/16”screws.

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

5.15. DIAGRAM 6Fixthereectorontotheamescreen.Screwthe3studsontothetopoftheamescreen.

Place3xØ6mmwashersontopofthestud.Placethereectorontothestudandsecurewith3xØ6mmwashersand3xwingnuts.

5.16. DIAGRAM 7 Carefullyinstalltheglasstubebyliftingitupandinsertingthroughthecentreholeintheupperplate.Ensuretheblack

siliconeringisattachedtotheloweredgeoftheglasstubeasillustrated.Slidetheglasstubethroughtheholeofthelowerplatecover

andontothemiddleplate.Checkandensurethattheglasstubeispositionedproperlyandiscompletelycoveringthecentreholeof

themiddleplate.

5.17. DIAGRAM 8 Assembletheprotectiveguard.Fittheprotectiveguards,pushthehooksintotheslotsintheuppersupportsandletthem

slidedowntosecure.Fixthe4bracketstoretaintheminplace.

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

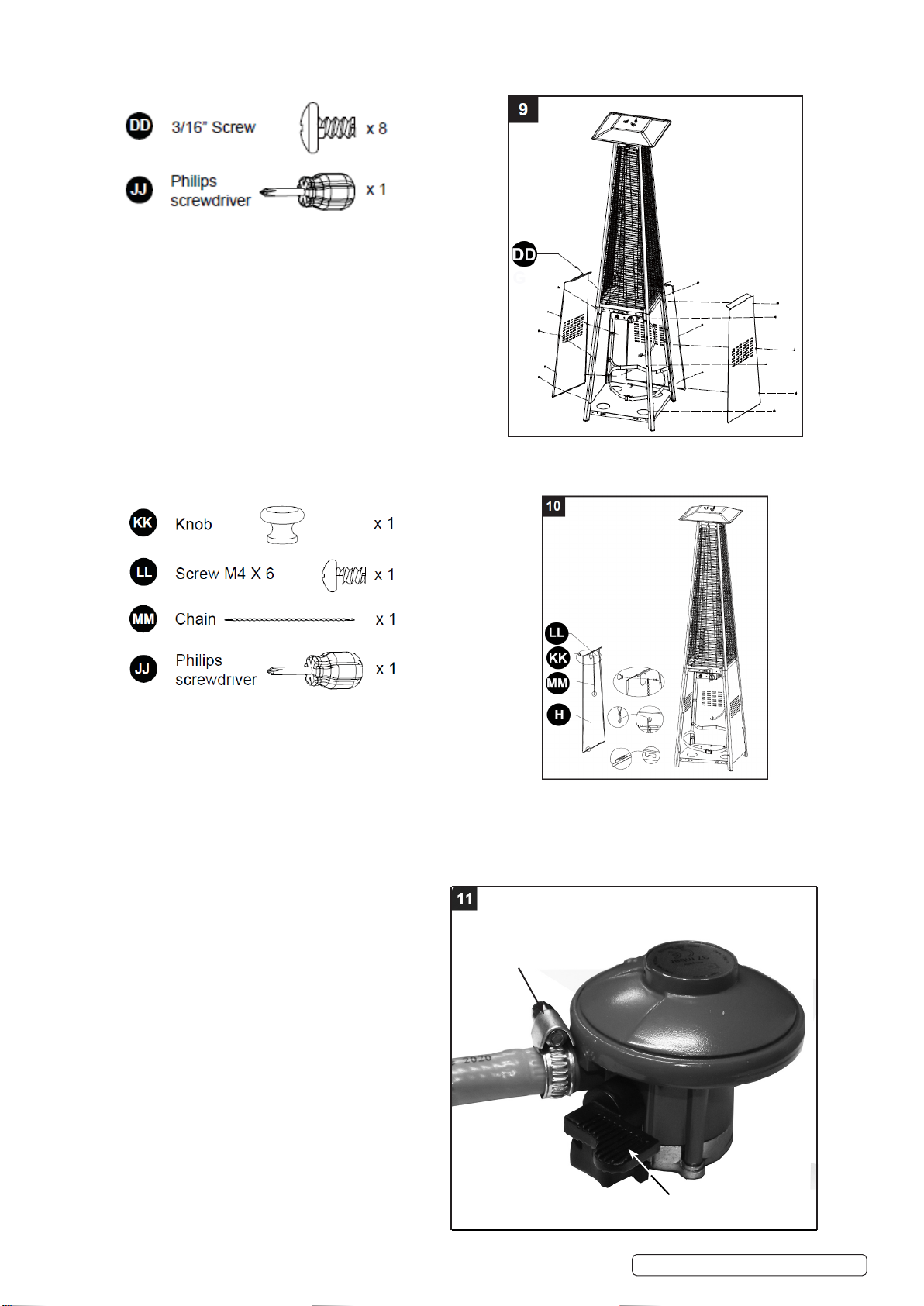

5.18. DIAGRAM 9 Attachthe3sidepanelstotheheaterusing18x3/16”screw.Note: DO NOTtthefrontpanelatthisstage.

5.19. DIAGRAM 10

Fitknobtodoorandchaintotherearofthedoor.UseM4x6screw.Fixtheotherendofchainontotheholeonthecontrolbox

assembly.Locatethehooksonthebottomedgeofthedoorintothecutoutsonthebottomplateandpushthedoorintoposition.

5.20. DIAGRAM 11 (REGULATORARRANGEMENT)

Checkthattheregulatorisclosedandthetapisintheopositioni.e.horizontal.Removethesealcapfromthe

cylinderautomaticvalveandconnectregulatortothegascylinderbypushingregulatordownverticallyandrmlyontothecylinder

valve.Conrmfullandsecureengagementofregulatortothecylindervalve.

NOTE: Ensure you leak test this joint as directed in

Section 6 after assembly is complete and when you

rst connect the gas bottle.

WARNING! Ensure full engagement of hose to regulator

andcontrolunit.

WARNING!Checkthatthewormdriveclipsatbothends

ofthegashosearefullytightened.

WARNING!Arrangethegashoseandregulatortoensure

thehosedoesnotcomeintocontactwithanyhigh

temperaturesurfacesasitmaymeltandcauseare.

Afterthecylinderisplacedinsidetheheater,tightly

securethecylinderwiththebelt.

NOTE:Seesection6forLeakCheckprocedure.

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

Ensuregashoseisfully

engagedtostemandthe

wormdriveisfully

tightened.

TapinOffposition

6. LEAK CHECK

WARNING!Aleaktestmustbeperformed:

-beforerstuse

-annually

-eachtimeacylinderischanged

-orifanypartofthegassystemhasbeenreplaced.

WARNING!Neveruseanopenametocheckforgas

leaks.Makesuretherearenosparksoropenamesin

theareawhilstcheckingforleaks.

6.1. Removeallsourcesofignition.

6.2. Turnallburnercontrolstotheoposition.Turngasregulatoron.Brushahalf

andhalfsolutionofliquidsoapandwaterontoalljointsandconnections(regulator,hose,manifoldsandvalves.)

6.3. Bubbleswillindicateagasleak.Tightenorloosentheloosejointorhavethepartreplacedwitharecommendedgenuinepart.Have

thepatioheaterinspectedbyacertiedgasinstaller.

6.4. IftheleakcannotbestoppedSHUT OFF THE GAS SUPPLY IMMEDIATELY,disconnectitandhavethepatioheaterinspectedbya

certiedgasinstallerordealer.DO NOTusethepatioheateruntiltheleakhasbeencorrected.

7. OPERATION

7.1. TO TURN ON THE HEATER

7.1.1. Openthegasregulatorvalvefully.

7.1.2. PressandturnthevariablecontrolknobtothePILOTposition(anticlockwise90°).

7.1.3. Pressdownthecontrolknobfor60seconds.Whilstholdingdownthecontrolknob

presstheigniterbuttonseveraltimesuntilthepilotamelights.Releasethe

controlknobafterthepilotamelights.

Note:Ifanewcylinderhasbeenttedallowatleastoneminuteforairinthegas

pipelinetopurgeoutthroughthepilothole.

Whenlightingthepilotame makesurethatthecontrolknobispresseddown

continuously,whilstpressingtheigniterbutton.Thecontrolknobcanbereleased

afterthepilotamelights.Ifthepilotamedoesnotlightrepeatstep7.1.3.

7.1.4. Afterthepilotamelightsturnthecontrolknobtoitsmaximumpositionandleaveit

therefor5minutesormorebeforeturningthecontrolknobtothedesiredtemperatureposition.

WARNING!Checkthattheglassis NOTbrokenbeforeoperation.

7.2. TO TURN OFF THE HEATER

7.2.1. TurnthecontrolvalvetothePILOTposition.

7.2.2. PressandturnthecontrolknobtotheOFFposition.Turnothegascylindercompletely.

8. STORAGE

8.1. Alwaysclosethegasvalveatthegascylinderandremovetheregulatorfromthecylinder.

8.2. Checkthegasvalvefordamage.Ifdamageissuspectedhaveitinspectedbyagasdealer.

8.3. Storeinachildproof,dryareawithadequateairventilation.Neverstorealiquidgascylinderinacellarorbelowgroundlevel.

9. MAINTENANCE

9.1. CLEANING

9.1.1. Wipesurfaceswithamoist,softrag.DO NOTcleanwithaggressiveorcombustiblecleaners.

9.1.2. Removedebrisfromtheburnertokeepitsafeforuse.

9.1.3. Covertheheaterwithaprotectivecoverwhentheheaterisnotinuse,(Sealeymodelno:DG7notsupplied).

10. TROUBLESHOOTING

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

Problem Probable cause Solution

Pilot will not light Gasvalvemaybeoff Turngasvalveon

Cylinderempty Renewcylinder

Openingblocked Cleanorreplaceopening

Airinsupplysystem Purge air from lines

Loose connections Checkallfittings

Pilotwillnotstayon Debrisaroundpilot Cleardirtyarea

Loose connections Tighten connections

Thermocouplebad Replacethermocouple

Gasleakinline Checkconnections

Lackoffuelpressure Cylindernearlyempty,refillcylinder

Burner will not light Pressure is low Cylindernearlyempty,refillcylinder

Openingblocked Removeandclean

Control not on Turnvalvetoon

Thermocouplebad Replacethermocouple

Pilotlightassemblybent Placepilotlightproperly

Not in correct location Positionproperlyandretry

WEEE REGULATIONS

DisposeofthisproductattheendofitsworkinglifeincompliancewiththeEUDirectiveonWasteElectricalandElectronicEquipment

(WEEE).Whentheproductisnolongerrequired,itmustbedisposedofinanenvironmentallyprotectiveway.Contactyourlocalsolid

wasteauthorityforrecyclinginformation.

Dellonda Ltd., KempsonWay,SuffolkBusinessPark,BuryStEdmunds,Suffolk.IP327AR

01284757575 [email protected]www.dellonda.co.uk

ENVIRONMENT PROTECTION

Recycleunwantedmaterialsinsteadofdisposingofthemaswaste.Alltools,accessoriesandpackagingshouldbesorted,takento

arecyclingcentreanddisposedofinamannerwhichiscompatiblewiththeenvironment.Whentheproductbecomescompletely

unserviceableandrequiresdisposal,drainanyfluids(ifapplicable)intoapprovedcontainersanddisposeoftheproductandfluids

accordingtolocalregulations.

Note:Itisourpolicytocontinuallyimproveproductsandassuchwereservetherighttoalterdata,specificationsandcomponentpartswithoutprior

notice.

Important:NoLiabilityisacceptedforincorrectuseofthisproduct.

Warranty:Guaranteeis12monthsfrompurchasedate,proofofwhichisrequiredforanyclaim.

Original Language Version DG5,DG6Issue:6(3,4,5)30/06/2021

This manual suits for next models

1

Table of contents

Other dellonda Heater manuals