Delta-T WET150 User manual

Doc No.: WET150-UM-01-2

User Manual for the

WET150 sensor

Version 2.0

2⚫Notices Copyright © 2022 Delta-T Devices Ltd

Notices

UKCA conformity

The WET150 Sensor conforms to UK regulations regarding electromagnetic

emissions and susceptibility when used according to the instructions

contained within this user manual, and is UKCA marked by Delta-T Devices Ltd

CE conformity

The WET150 Sensor conforms to EC regulations regarding electromagnetic

emissions and susceptibility when used according to the instructions

contained within this user manual, and is CE marked by Delta-T Devices Ltd

FCC Emissions

CFR47 Pt 15 B [Unintentional Radiator emission limits as per

Pt 15.109]

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at their own expense.

Design changes

Delta-T Devices Ltd reserves the right to change the design and

specification of its products at any time without prior notice.

Patents

The WET150 is protected under international law by the following:-

USA: Patent US7944220

Europe: Patent EP1836483

Australia: Patent AU2005315407

China: Patent CN101080631

3⚫Contents

Contents

Notices 2

Contents 3

Getting Started 5

Care and Safety 5

Introduction 6

Description 7

Parts and Accessories 8

Use with a WET150 Meter 9

Take a Reading 9

Options 9

WET150 Meter Buttons 9

Using the WET150 Meter to Change Address 10

Connecting to Loggers & Controllers 11

Wiring 11

Non-Delta-T loggers and systems wiring: 11

GP2 wiring (1): Using internal power 12

GP2 wiring (2): Using external power 13

Assigning Addresses using a GP2 14

Install DeltaLINK 14

1: Open DeltaLink Transparent Mode 15

2: Find out WET150’s current address 15

3: Change the address 16

Create GP2 Program 17

1: Add a WET150 SDI-12 Measurement 17

2: Sensor type Settings 19

3: Set Recording Intervals 21

4: Next Steps 21

Networking 22

Maximum cable length and network size 23

Power supply and communication 23

Warm-up time 24

Multiple WET150s in a network 24

Installation in the Ground 26

Surface installation and spot measurements 26

Installing at depth 27

SDI-12 commands 28

4⚫Contents Copyright © 2022 Delta-T Devices Ltd

Address Query 29

Address Assign 30

Identify 31

Take a measurement 32

Table of pre-configured measurements 33

Customising measurement sets 34

Specifications 36

Pore Water EC (ECp) accuracy 37

Edge Effects 27

Error Codes 37

Configuration 38

How it works 39

Sensing soils and substrates 39

Permittivity and soil composition 39

Converting permittivity to water content 40

Generic soil calibrations 42

Soil-specific calibrations 43

Technical Reference 44

Dielectric properties 44

Measuring Soil Moisture 45

Pore water conductivity 46

References 51

Definitions 52

Technical Support 57

Soil-specific Calibration 59

Laboratory calibration for non-clay soils 59

Laboratory calibration for clay soils 62

Soil-specific Parameter Derivation 65

Appendix 2 66

Soil-specific Parameters 66

Index 67

5⚫Getting Started

Getting Started

Thank you for purchasing the WET150, Delta-T’s robust and accurate sensor for

water content, electrical conductivity and temperature. To ensure you get the most

out of your sensor, we recommend the following steps:

1. Check you have all the equipment you need.

For a list of accessories and additional equipment see section “Parts and

Accessories”.

2. Check your sensor is properly configured for your intended use.

The WET150 is highly customisable to ensure maximum effectiveness in a

wide variety of applications. See section “Configuration”.

3. If using with the WET150 Meter:

See section “Use with a WET150 Meter”

4. If using in a permanent installation:

a. Check how to connect your sensor - See section “Connecting to Loggers

& Controllers”.

b. Check how to install your sensor See section “Installation in the Ground”.

5. Review the care and maintenance requirements of your sensor.

See section “Care and Maintenance”.

Care and Safety

•The pins of the WET150 are sharp.

Care must be taken and handling

precautions followed.

•Avoid touching the pins or exposing

them to other sources of static

charge, particularly when powered

up.

Keep the WET150 in its protective

package when not in use.

•Take care when attaching cables to ensure that the connectors are clean,

undamaged, and properly aligned before pushing the parts together.

•Do not pull the WET150 out of the soil by its cable.

•If you feel strong resistance when inserting the WET150 into soil, it is

likely you have encountered a stone. Stop pushing and re-insert at a new

location.

•WET150 is unsuitable for use in hard soils unless holes are pre-formed.

Rough handling may cause irreparable damage to the pins

6⚫Introduction

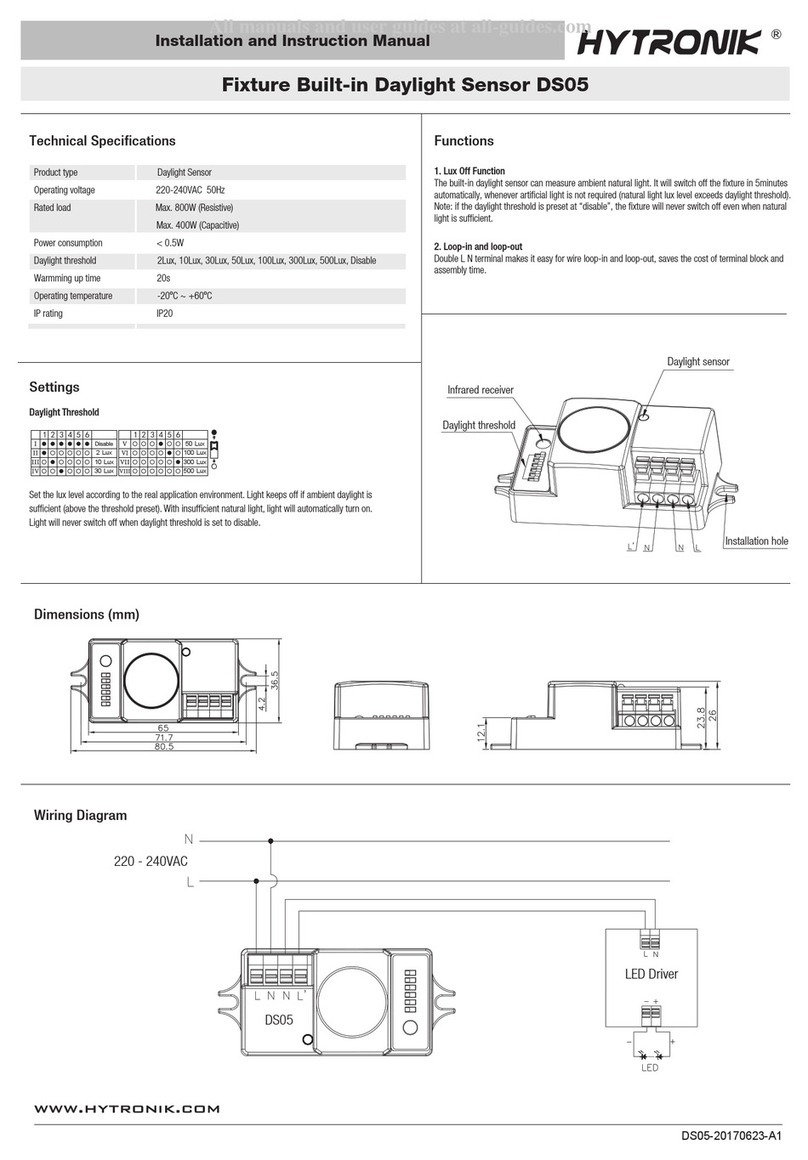

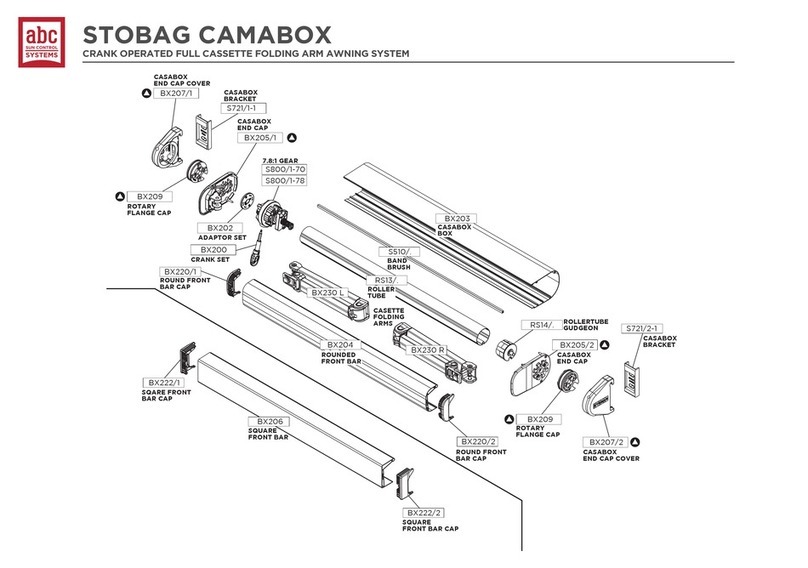

Introduction

Cables

To Meter

Extension cables

To GP2 and other

loggers

Connector

Fully waterproof

M12 connector

Installation

Threads enable

extension rods to be

screwed on for easy

insertion in augured

holes –minimising soil

disturbance Detectors

Soil moisture content

and EC are detected by

sensitive circuits

operating at 100MHz

Sensing field

Extends ~100mm into

the soil, but field is

strongest close to the

rods - install carefully

to avoid air gaps

SDI-12

Industry-standard digital

interface, compliant to

version 1.3

Outputs

Sophisticated correction

algorithms ensure

accurate readings across

the full range of water

content, EC and

temperatures

Temperature

Thermistor is located

within the base –

equilibrates to the soil

temperature when

installed, less well for

portable

measurements

Introduction ⚫7

Description

The WET150 Sensor is a multi-parameter sensor for use in soils, substrates and

other growing media. It measures the dielectric properties of the soil and

calculates:

▪Water Content

▪Electrical Conductivity

▪Temperature

The sensor converts the measured dielectric properties into Water Content over

the full range, 0 to 100%, being most accurate over 5 to 100% water content and

over 0 to 500 mS/m soil bulk conductivity

1

. Generalised calibrations are provided

for most common soil types.

The WET150 Sensor also measures the bulk electrical conductivity of soil (ECb) over

0 to 2000 mS/m, being most accurate, ±(10 mS/m + 6%), from 0 to 1200 mS/m.

It also calculates Pore Water Conductivity, the electrical conductivity of the water

within the pores of the soil (ECp).

Temperature is measured by a miniature sensor built into the body of the sensor.

The WET150 Sensor works with the WET150 Meter and the GP2 logger controller.

It can also be used with other SDI-12 loggers, and with SDI-12 fertigation and

irrigation control systems.

Advantages of the WET150 Sensor

•Fast, accurate, adaptable and easy to use

•Rapid measurements (<0.5 seconds) of all 3 parameters

•In-situ Pore Water Conductivity measurements

•Easy insertion into growing media and soil

•Works with many different soils and growing media

•Stable, accurate readings from

•5 to 100% water content

•0 to 1200 mS.m-1

•-20 to +60°C

•Lightweight ergonomic design

•Versatile SDI-12 digital output

•Systems integrator friendly

•Wide choice and customisable settings, outputs and units

•Low power for long battery life

•2-year warranty extends to 5 years if registered on delivery

1

Best accuracy is achieved with a calibration matching the soil / substrate

8⚫Parts and Accessories

Parts and Accessories

WET150 sensor

WET150 Kit

WET150 + WET150 Meter

SMSC/lw-05

5m cable with 200 mm flying

leads.

Connects WET150 to GP2

directly, or via SDI-12 network

of EXT/5W-xx cables

EXT/5W-01

EXT/5W-05

EXT/5W-10

EXT/5W-25

1 m, 5 m,10 m and 25 m

extension cables with 5-way

M12 connectors. Connects

WET150 to an SDI-12 sensor

network

GP2-STP1

4-pin network T- Piece for

networking of SDI12 sensors

and EXT/5W-xx cables. Not to

be used for logger

communication networks.

GP2-NTP

5-pin network T- Piece with

continuous screen, for

connection of loggers and

EXT/5W-xx cables.

ML/EX50

ML/EX100

Extension tubes,

50 and 100 cm

SM-AUG-100

Spiral Auger 1.2 m

Use with a WET150 Meter ⚫9

Use with a WET150 Meter

The WET150 Meter Kit enables portable monitoring of water

content, electrical conductivity and temperature. It can also

be used to change the address of an SDI12 sensor.

Settings for soil type, conductivity units and temperature

units can be customised.

For more details see the WET150 Kit Quick Start Guide.

Take a Reading

1. Gently insert WET150 pins into soil or substrate.

2. Press READ to take and display water content,

temperature and pore water conductivity.

Options

Water content can be displayed as volumetric water content

(%) using the Mineral, Organic, Peat mix, Coir, Mineral wool

or Custom

2

calibrations; or the meter can display the RAW (unconverted)

permittivity reading (ε’) which has no units.

Temperature can be displayed in °C or °F.

EC is displayed as the pore water conductivity, ECp, in mS.m-1, for the chosen soil

type; or the soil bulk conductivity, ECb, when the RAW display option is selected.

Address can be a to z, A to Z or 0 to 9 ( 0 is not advised on a network)

WET150 Meter Buttons

READ –takes and displays a reading.

SET shows the settings menu. You can scroll up or down through these

options: Soil type, Units and Address and Contrast... Press SET to select

the highlighted menu and show the current setting in that menu.

Again, scroll up or down and press SET to confirm the choice and

return to the start-up screen. Alternatively, press READ to save the

setting, exit the menu and take a reading.

and scroll through the current options.

Auto-off - after 1 minute saves the current selection and switches off.

2

Please note customisation in the Meter does not change settings stored in the

sensor; see section “Configuration”, page 39

10 ⚫Use with a WET150 Meter

Using the WET150 Meter to Change

Address

The WET150 Meter can only take and display readings from WET150 sensors.

However, it can display and modify the address of most SDI-12 sensors with a

compatible power requirement.

3

In order to connect to a WET150 Meter, the

sensor would need to be fitted with an M12 connector –see section “Non-Delta-T

loggers and systems wiring” on page 11.

You can use this key stroke sequence on a WET150 Meter to change the SDI-12

address of any attached SDI-12 sensor, including WET150 or PR2s. Only attach one

sensor at a time to a WET150 Meter.

1. Press [SET] to wakes the Meter and displays the settings menu

2. Press [] twice to scroll down to the Address setting menu

3. Press [SET] to select that menu, and display the current SDI-12 address

4. Press [] or [] to scroll to the desired target address

5. Press [SET].

The Meter attempts to set that address:

▪Success is indicated by the brief appearance of the ✓symbol,

after which it reverts to the Settings menu.

▪Failure is indicated by , after 3 seconds it reverts to the Address setting

menu.

See also WET150 Kit Quick Start Guide

3

The Meter can supply approx. 100mA at 6 volts to an attached sensor

Each sensor must have a different address on an SDI-12

network or the network will not function properly. The

address must be set BEFORE attaching to the network.

Connecting to Loggers & Controllers ⚫11

Connecting to Loggers & Controllers

The WET150 is fully compliant with the SDI-12 communication protocol standard

(version 1.3). Because of this the WET150 can be used with any third-party logging

or metering device which is also SDI-12 compliant as well as with Delta-T Devices

GP2 logger controllers.

Wiring

GP2 Logger Wiring: See pages 12 and 13

Non-Delta-T loggers and systems wiring

** Optional. The green wire is connected to the cable screen. The SDI-12

specification does not require the green wire / cable screen connected. If there is a

lot of electrical noise in the environment, connecting the green screen wire to

ground in the logger or controller may help reduce the risk of data corruption. Note

that for a continuous screen connection it is necessary to use the NTP T-piece.

For other connection details to third-party loggers and controllers please consult

the SDI-12 sections of those products’ manuals.

For SDI-12 screw terminal cable

connector information see the SDI-12

for GP2 User Manual. See also

“Power supply and communication”

on page 23

If ECp and water content values are being returned from the WET150 sensor,

remember to review the soil parameters and adjust them if required –see section

“SDI-12 commands” (page 28), and the WET150 SDI-12 Programmer’s Guide.

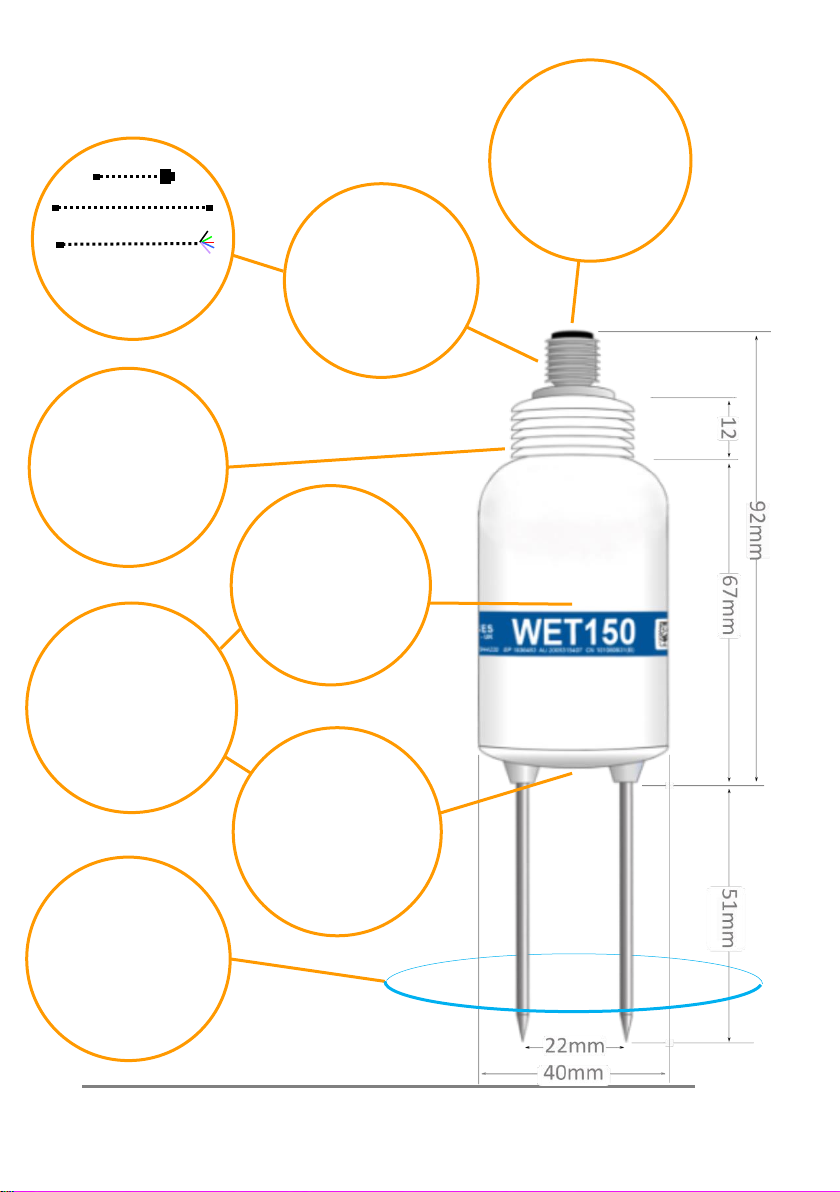

Wire colour

Logger or

controller

SDI-12 function

M12 connector

pin

Brown

Not connected

1

White

+12V 0.5A

Network power

2

Blue

GND

Ground (for power and data)

3

Black

DATA

Data (send and receive)

4

Grey

Not connected

5

Green

Not connected **

(Cable screen) **

Shell / nut

4

4

51

3

2

GROUND

SDI-12 DATA

SDI-12 POWER

SCREEN (if present)

4

4

51

3

2

GROUND

SDI-12 DATA

SDI-12 POWER

12 ⚫Connecting to Loggers & Controllers

GP2 wiring (1): Using internal power

The GP2 logger controller incorporates a program-controlled power rail specifically

for SDI-12 applications. This 12V supply is generated from the internal logger

battery pack via a voltage step-up circuit and is current limited in case of faults on

the SDI-12 network.

SDI-12 sensors typically require a 3-wire connection: Power, Ground and Data. This

is the case with the WET150 but the cabling system includes additional wires which

are not normally used within an SDI-12 network.

To create an SDI-12 network based upon a GP2 logger controller, use cable type

“SMSC/lw-05” to bring the network connections out of the GP2 case. This is a

shielded 5-way, 5-metre-long cable with bare wires on one end and a 5-way M12

connector on the other. Use this to connect one WET150 directly to a GP2, or with

the addition of other 5-way M12 extension cables and T-pieces, connect multiple

sensors in a network.

** Optional. The green wire is connected to the cable screen. The SDI-12

specification does not require the green wire / cable screen to be connected.

If there is a lot of electrical noise in the environment,

connecting the green screen wire to the GND terminal

(with the blue ground wire) in the GP2 may help

reduce any risk of data corruption. The figure on the

right illustrates the wire and terminal connections with

the optional green screen wire.

The brown and grey wires in cable type “SMSC/lw-05” are not normally required for

SDI-12 so should be insulated from shorting to any terminals inside the GP2, or they

may be trimmed off. The same applies to the green screen wire if it is not used.

4

0.5A assumes good quality alkaline AA cells are used in the GP2. Other battery

types may deliver lower maximum current drain.

Wire colour

GP2 terminal

(SDI-12 block)

SDI-12 function

M12 connector

pin

Brown

Not connected

1

White

+12V 0.5A4

Network power

2

Blue

GND

Ground

(for power and data)

3

Black

DATA

Data (send and receive)

4

Grey

Not connected

5

Green

Not connected**

(Cable screen) **

Shell / nut

Connecting to Loggers & Controllers ⚫13

Power is automatically supplied when the WET150 sensor is selected in the

DeltaLINK program.

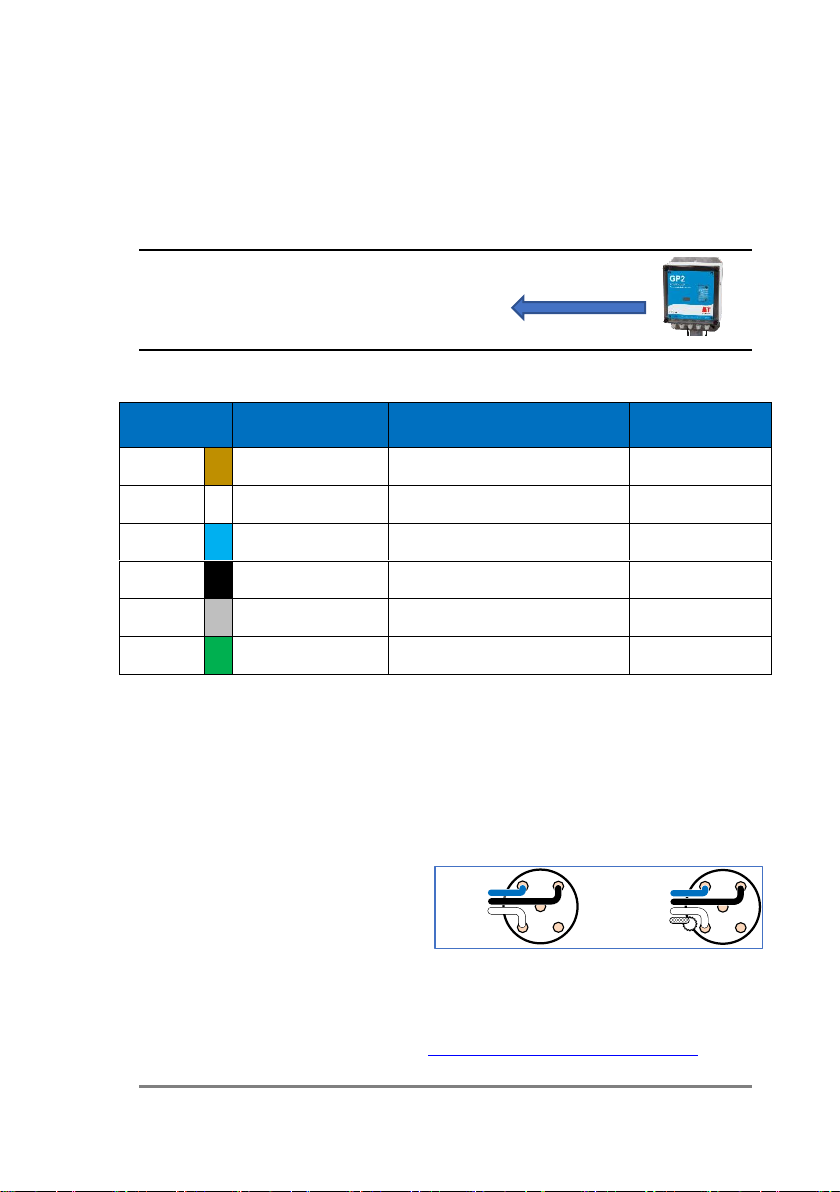

GP2 wiring (2): Using external power

The WET150 is a highly energy efficient sensor. Depending upon the measurement

frequency and the number of WET150 sensors in the network, the internal GP2

logger/controller batteries are capable of providing power for many tens of

thousands of sensor readings over periods longer than a year.

If the WET150 is used in conjunction with other more power-hungry SDI-12

sensors, it may be desirable to use a larger external power supply for the SDI-12

network. The functioning of the GP2 logger/controller itself can remain running on

its own internal batteries independently of an external power source for the SDI-12

network.

To use an external power supply for the SDI-12 network, do not connect anything

to the GP2’s “+12 0.5A” power terminal. Instead wire the SDI-12 network power

(white wire on cable type “SMSC/lw-05”) to the external power source +12Vdc

terminal.

Wiring connection

diagram showing

external SDI-12 power

connections for the SDI-

12 network, along with

the optional green

screen wire.

Ensure there is a fuse or other protection in-line with this external power source in

case short-circuit faults develop on the SDI-12 network.

The Ground or 0V terminal of the external power source should be wired into the

GND terminal on the GP2, along with the Ground wire of the SDI-12 network (blue

wire on cable type “SMSC/lw-05”).

In the external power supply configuration shown above, power is permanently

applied to the SDI-12 network. This may not be the most desirable or efficient way

to run the network. An alternative would be to wire one of the GP2 internal relays

in series with the external power supply and the SDI-12 network power wire.

The GP2 logger/controller program can then be configured to switch in the power

only when taking measurements for greater external power efficiency.

e.g In DeltaLINK program’s Measurement, Power channel select RLY1.

14 ⚫Assigning Addresses using a GP2

Assigning Addresses using a GP2

If two sensors have the same address, then neither sensor will be able to

communicate and the SDI-12 network may not function. Each WET150 MUST have

a unique address before connecting it into a network of SDI-12 sensors.

The address of a new sensor is usually 0 (number zero). It can be changed to any

single digit address in the range 0 to 9, a to z or A to Z.

Use either a WET150 Meter connected directly to a WET150 sensor - see page 5, or

use a GP2 and PC running DeltaLINK as described below.

Install DeltaLINK

To operate the functions of the GP2 logger/controller, its companion computer

software “DeltaLINK” needs to be downloaded and installed. This PC software is

available from the Delta-T website at:

www.delta-t.co.uk/software/deltalink

DeltaLINK version 3.9 or later is required for use with the WET150. If your existing

install of DeltaLINK is older than this version, please install the latest version to gain

access to WET150 libraries.

DeltaLINK is available for Microsoft Windows only.

Once DeltaLINK is installed, connect the GP2 to your PC computer using the USB to

GP2 cable supplied with the GP2.

See also:

•GP2 User Manual

•SDI-12 for GP2 User Manual

•WET150 SDI-12 Programmer’s Guide

Assigning Addresses using a GP2 ⚫15

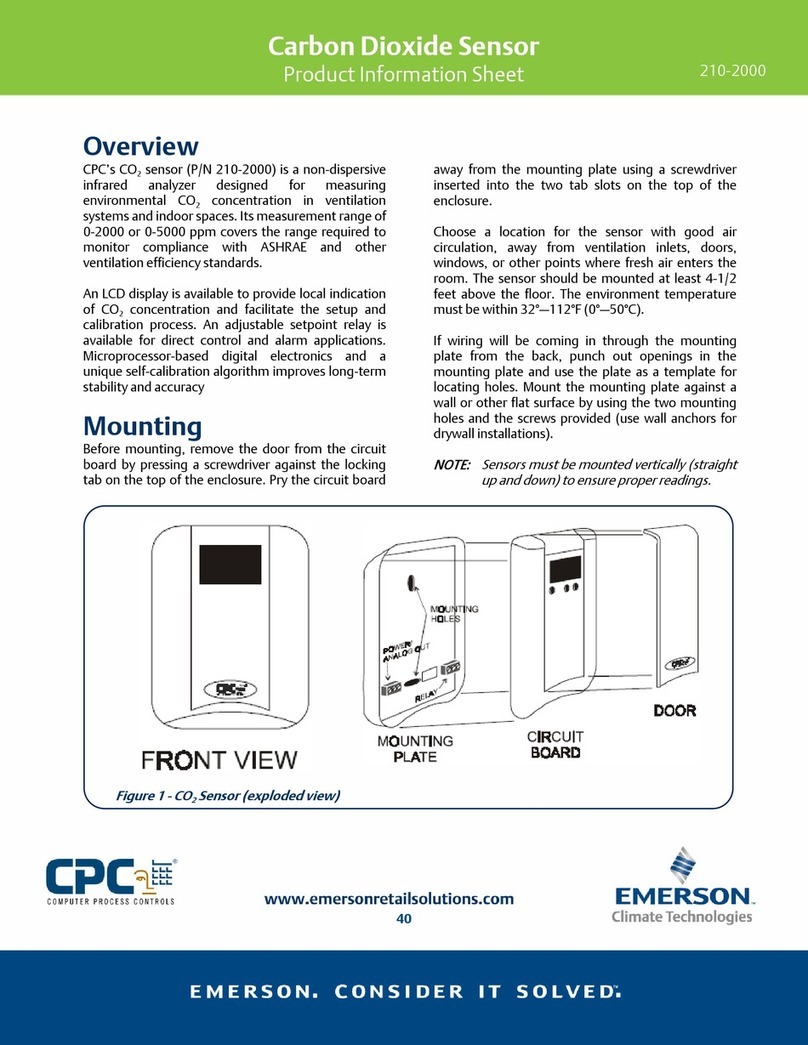

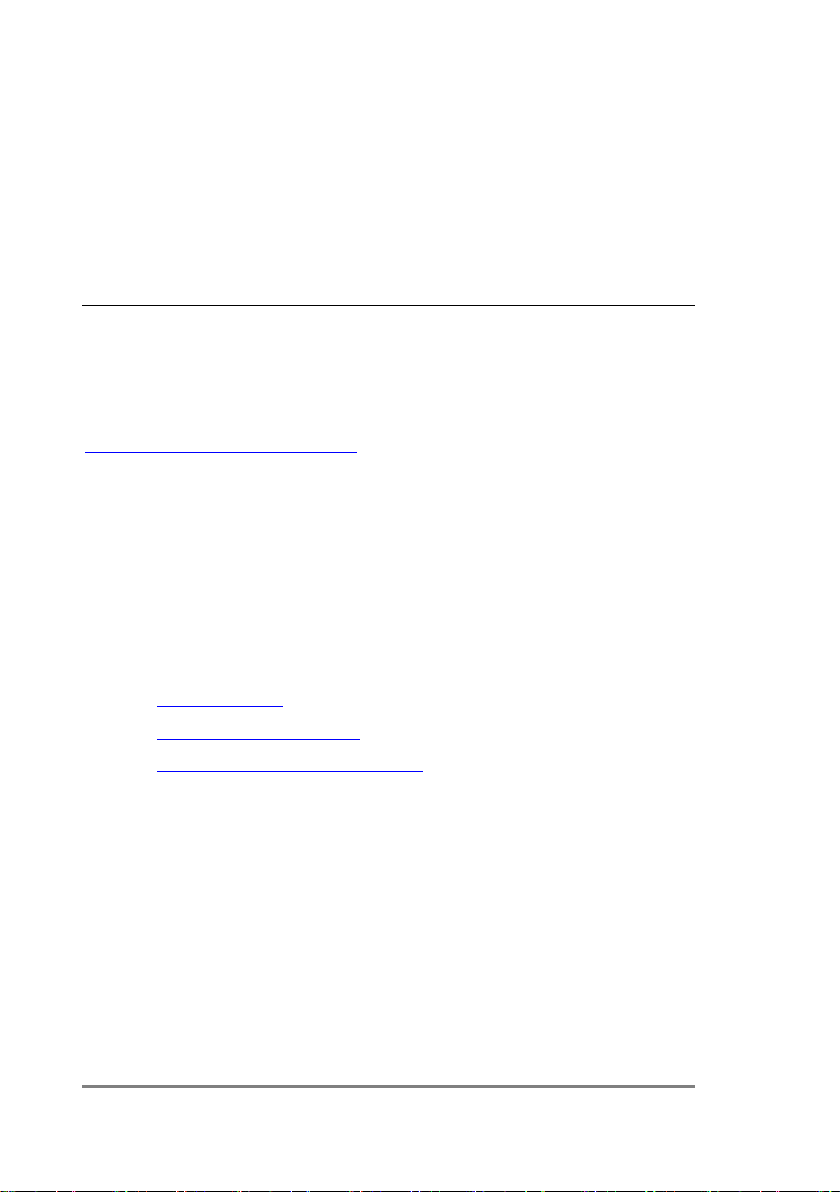

1: Open DeltaLink Transparent Mode

You need a GP2 connected to a PC running DeltaLINK v 3.9 or later.

With no other sensors on the network connect the sensor to the GP2 SDI-12

terminal.

In DeltaLINK select Tools, SDI-12, Transparent mode to open theSDI-12 Transparent

Mode Terminal as shown below.

Once the SDI-12 Transparent Mode Terminal is open, the GP2 behaves like a

transparent serial link between SDI-12 sensors and the PC.

2: Find out WET150’s current address

Send a command to tell the sensor to reply with its address.

You type

?!

Reply

a

We usually expect the address of a new sensor is to be zero, but it might not be. If

you already have another sensor with the same address on the same network the

command will not work.

?!

1

2 3 4

Any logger on COM1

Example:

16 ⚫Assigning Addresses using a GP2

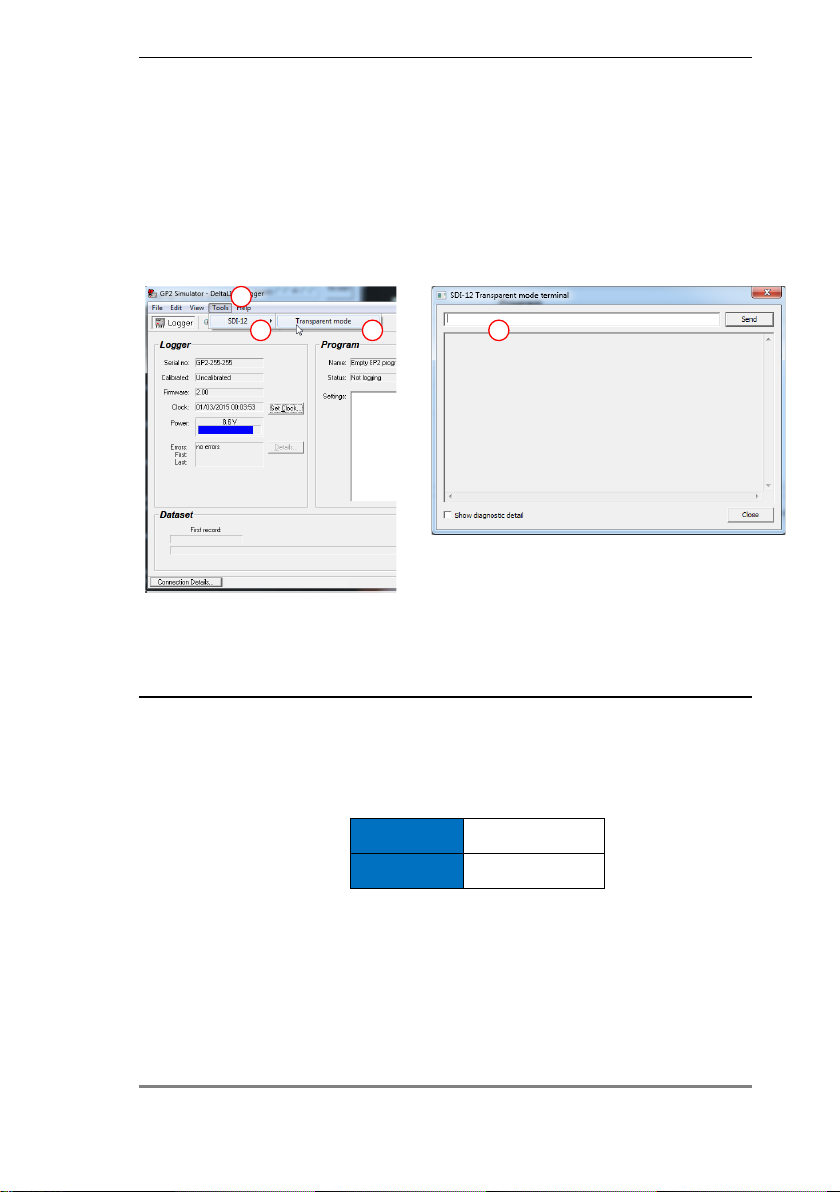

3: Change the address

Send a command to change its address

You type

aAb!

Reply

b

The WET150 is now at address b. It could be anything from ato z, Ato Z, or 0to 9.

Avoid address 0 as it tends to be the default used in new sensors. Any sensors

which share the same address on the network will be unable to communicate.

Make a note of the address and the serial number. Clearly labelling the sensor (or

attached cable) will make setting up and troubleshooting much easier later on.

Later when you have finished giving each sensor a unique address, close the

Transparency Mode window and change the default GP2 program to create a

WET150 sensor type measurement with the correct address, and repeat this for

each sensor to go on the network. See also Create GP2 Program on page 17.

Tip for advanced users:

You can change the default Measurement Name to add useful metadata - for

example, by adding the address as a suffix so that Theta becomes Theta Z. But the

ECp calculation also uses the Permittivity and SoilTemp readings. So, in the

Calculation section of the ECp Measurement parameters change the Permittivity

name e.g. from Theta to Theta Z and likewise for the Temperature name if you

have also changed that, e.g. from SoilTemp to SoilTemp Z.

If you change Measurement name you must also change the Recording Rate entry

to match.

Create GP2 Program ⚫17

Create GP2 Program

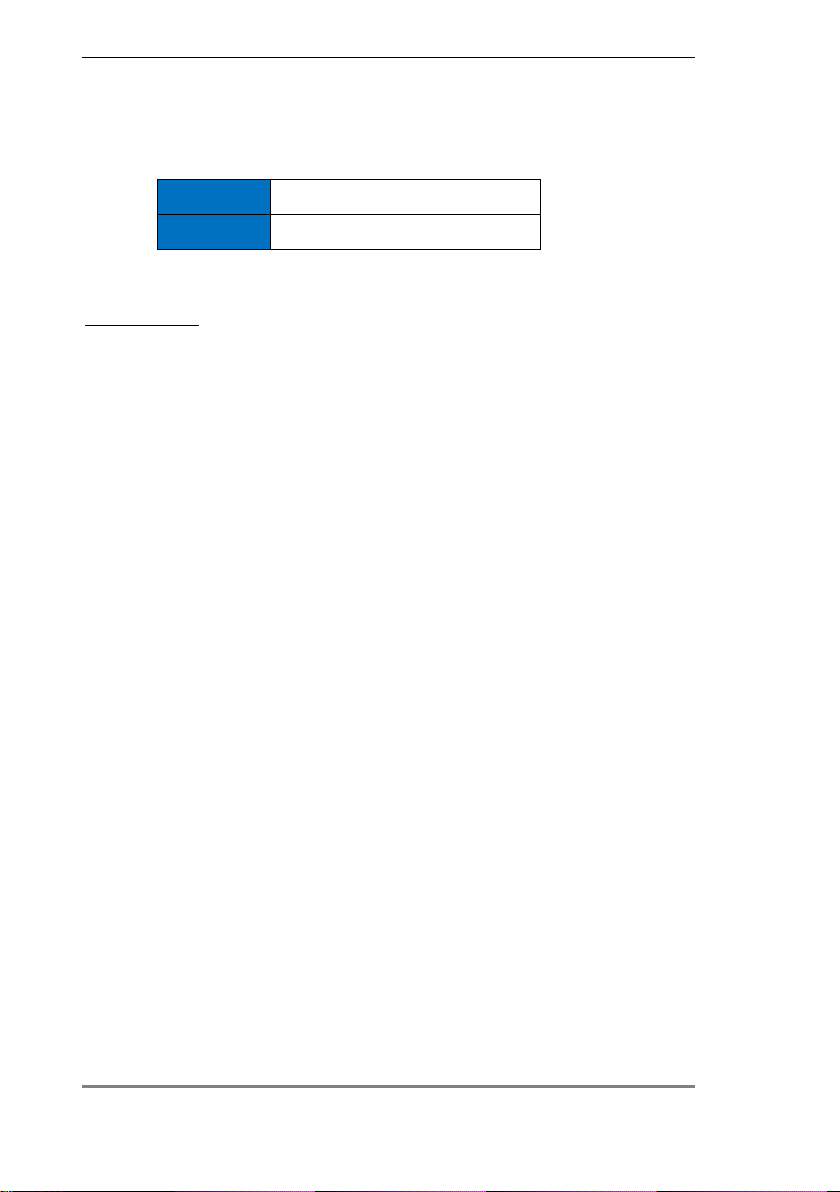

1: Add a WET150 SDI-12 Measurement

Illustration: showing steps in the creation of a WET150 soil moisture sensor

measurement type in a GP2 program.

1. With DeltaLINK 3.9 or later running on your PC and connected to a

GP2 select Program.

2. Select Change.

3. Under Measurements click on “click to add a new item”.

4. Select Soil Moisture.

1

2

3

4

5

Change

18 ⚫Create GP2 Program

5. Select WET150 (complete). This will create three sensor

measurement types for soil moisture, electrical conductivity and

temperature, each with a default 1 hour recording period.

6. Select the Address to that of the WET150 sensor, as described on

page14. You should now see the following:

Illustration showing three sensor measurement types added to take readings from

a single WET150, for soil moisture, pore water conductivity and temperature. These

all have the same SDI-12 address, which in this example has been changed to 7

from the default 0 address. The default measurement period of 1 hour for all

readings can be also seen.

Create GP2 Program ⚫19

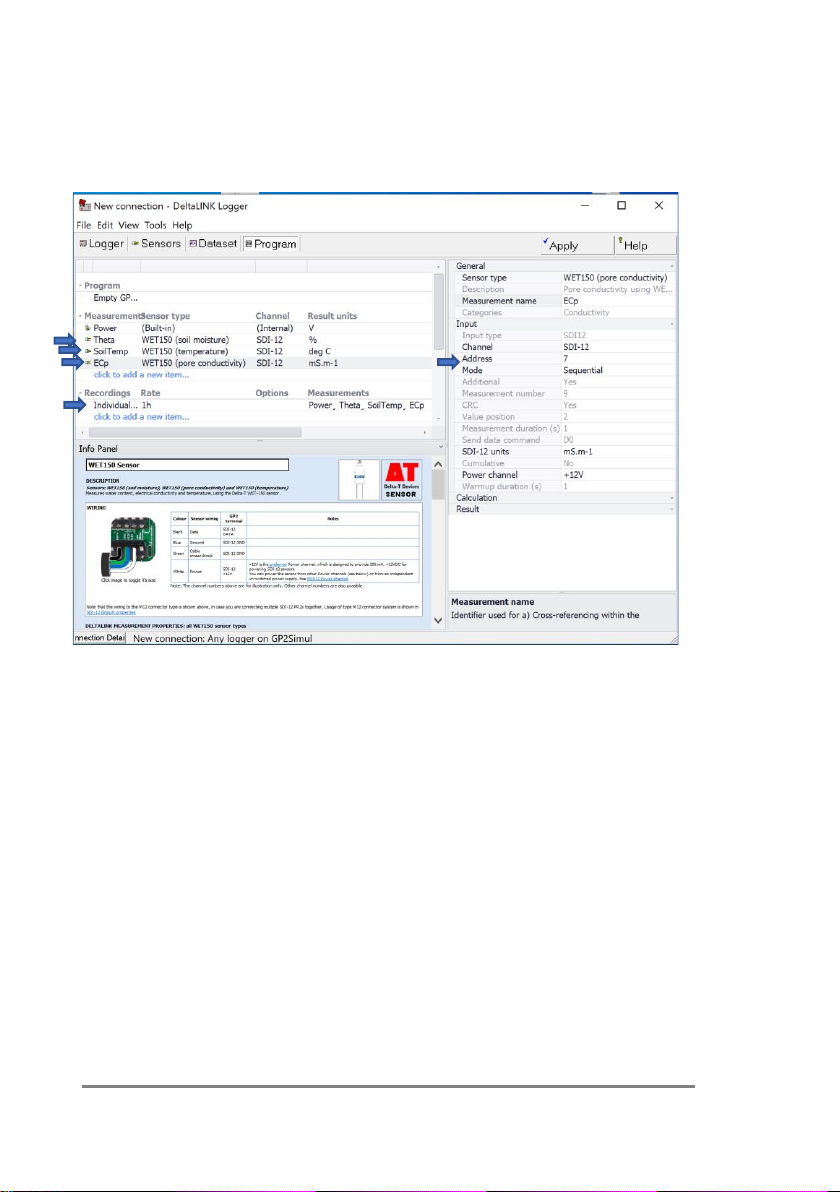

2: Sensor type Settings

This explains the Measurement and Parameter settings supplied in the WET150

sensor types in the DeltaLINK sensor library.

1. Sensor type: This is the name of the default WET150 Sensor type as

loaded from in the GP2 sensor library.

2. Change the Measurement name to anything useful e.g Theta (100mm)

or Treatment A.

If you have more than one WET150, give each measurement a unique

name here –e.g. “ECp at 100mm”. This information will be displayed

at the top of the column of measurements in the results table.

If you change a Measurement name then ensure it is updated in the

Recording Rate. (The program will object and fail to “Apply” if you don’t

do this).

Also if changing the WET150 Theta or SoilTemp Measurement names

you will need to use the same names used in the ECp Calculation

section.

Example: change the Measurement name to add useful metadata e.g.

Theta becomes Theta Z to display the address in the results. The ECp

calculation needs to use the Permittivity and SoilTemp readings. So, in

the Calculation section of the ECp Measurement parameters, change

the Permittivity name from Theta to Theta Z and likewise for the

Temperature name, if you have also changed that, e.g. from SoilTemp

to SoilTemp Z.

Showing the

addition of

address Z to

the WET150

Measurement

names

20 ⚫Create GP2 Program

3. Address: Enter the WET150 address so the GP2 will know

which sensor to contact. You must do this.

Use DeltaLINK, SDI-12, Transparent mode (or a WET150 Meter)

to give it a unique address before putting it on the SDI-12

network with other sensors, or else the network will crash.

See also Assigning Address on page 14.

4. Mode: The default WET150 sensor type uses the SDI-12

Sequential data measurement and reporting method.

See also Concurrent Measurements on page 24.

5. Additional: No action required. The default value cannot be

changed. The additional features are of use to less capable

loggers from other manufacturers, which can’t do maths as

well as the GP2).

6. Send data Command: No action required. Your GP2 logger

knows which D command to send, so this is not something you

need to worry about.

(Note for other logger users: The Dn command is sent by the

logger to retrieve the results when the sensor is ready (n can

be 0 to 8). In reply the sensor may send up to 76 characters to

the logger. The number of characters required for each

reading can vary: depending, for instance, on whether

readings are concurrent or sequential. So additional

commands, D1–D8, are available if necessary.

See also WET150 SDI-12 Programmers Guide)

7. SDI-12 units: options:

Soil moisture: % or m3.m-3.

Pore water conductivity: mS.m-1 mS.cm-1 or µS.cm-1

Temperature: °C

8. Soil type:options:

Coir, Mineral Soil, Mineral Wool, Organic soil, Peat Mix, or add

your own soil type coefficients.

Table of contents

Other Delta-T Accessories manuals

Popular Accessories manuals by other brands

Inductosense

Inductosense Wand Echo 45 Installation & user manual

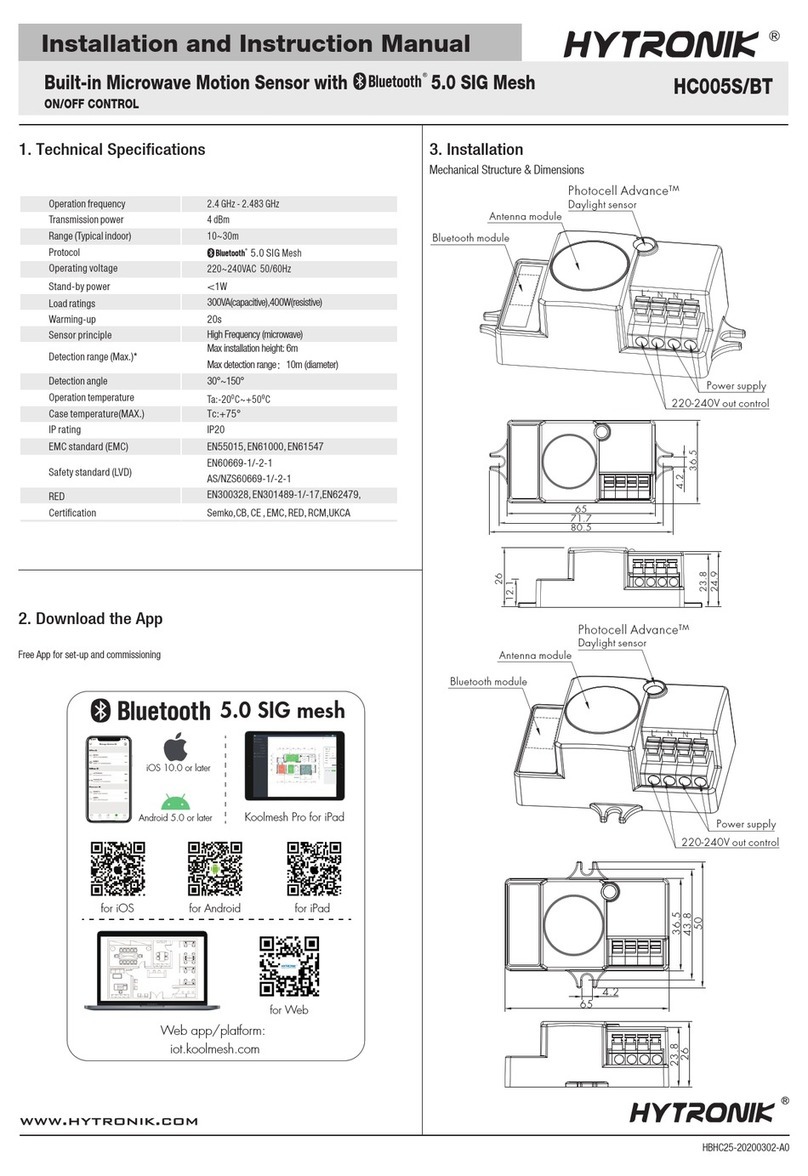

Hytronik

Hytronik HC005S/BT Installation and instruction manual

Adventure Parks

Adventure Parks 38-BITE Installation, operating and maintenance instructions

urmet domus

urmet domus Grothe CALIMA 400 Series Installation and operating instructions

Vega

Vega VEGAFLEX 65 operating instructions

Cooluli

Cooluli CONCORD-20LDX instruction manual