Delta Visione DEV7 User manual

DEV7 Rel.4.1 27.12.2017

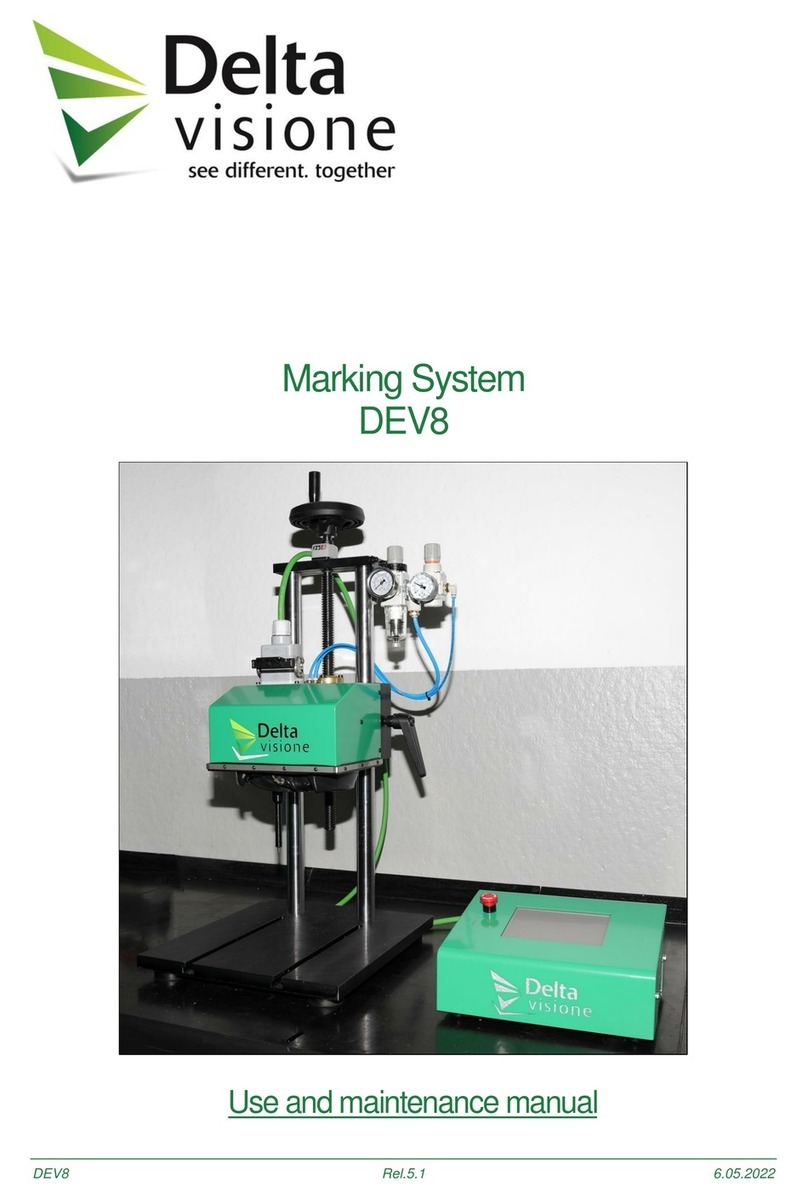

MarkingSystem

DEV7

Useandmaintenancemanual

DEV7 –Use and Maintenance Manual

Pag. 1

Preface

Scope of the document

This manual is a guide for the users and maintenance personnel of the DEV7 Marking System.

This instructions manual relates to a machine designed exclusively for professional use. Simply reading

this manual is not a substitute for experience and, in order for the machine to be correctly operated, it

should be operated by appropriately trained personnel. Although extreme care has been taken in the

collection and verification of these documents, DELTA VISIONE does not accept responsibility for

any imprecision or omissions, nor for the manner in which the operator uses the information

contained in this manual.

The operating manual should be referred to in order to start up the machine, to operate the machine and

to maintain the safety measures. The manual aims to:

1. Reduce the time that the machine is off-line and limit the need to request the manufacturer for

assistance

2. Guarantee that the system runs smoothly by providing complete and detailed instructions

3. Eliminate any risks connected to the use of the machine.

The operator should carefully read all the instructions in this manual and keep it for later reference. The

manual should be retained for future reference.

All the rights related to the text, images and documentation present in this manual are reserved: any

reproduction of its whole or parts is prohibited without the written permission of DELTA VISIONE.

The company can be contacted with requests for copies or updates of the manual.

DELTA VISIONE reserves the right to carry out variation in production and in the manual without

warning and without being obliged to update previously produced machines and the preceding manuals.

This manual should be considered an integral part of the machine and should therefore be

retained for reference until such a time as the machine is dismantled.

DEV7 –Use and Maintenance Manual

Pag. 2

Summary

1Identification..................................................................................................... 5

Identification of the maker...................................................................................................................5

Identification of the machine...............................................................................................................5

Intended use ........................................................................................................................................6

Compliance to safety regulations.............................................................................................7

Personnel training.....................................................................................................................7

Stand-alone...............................................................................................................................7

Maintenance service............................................................................................................................ 8

CE Labels........................................................................................................................................... 10

2Description and characteristics.................................................................... 11

General description............................................................................................................................ 11

Marking head..................................................................................................................................... 12

Control unit......................................................................................................................................... 14

E-Stop button .......................................................................................................................... 16

Touch-screen .......................................................................................................................... 17

3Installation ...................................................................................................... 19

Transport............................................................................................................................................ 20

Installation.......................................................................................................................................... 20

Connections....................................................................................................................................... 20

Electrical connection............................................................................................................... 20

Pneumatic connection............................................................................................................ 20

Integration.......................................................................................................................................... 21

Lighting............................................................................................................................................... 21

Protective devices.............................................................................................................................. 21

Noise................................................................................................................................................... 21

Stand-alone operation............................................................................................................ 22

Putting the machine into operation................................................................................................... 23

Operational faults............................................................................................................................... 24

4Residual risks................................................................................................. 25

5Commands and signals................................................................................. 27

6Ordinary maintenance.................................................................................... 29

Prerequisites and cautions................................................................................................................ 29

General............................................................................................................................................... 30

General rules........................................................................................................................... 30

Utensils, tools and materials.................................................................................................. 30

Maintenance interventions general plan.......................................................................................... 31

Safety –General rules............................................................................................................ 31

Maintenance plan.................................................................................................................... 32

Attachment 1 I/O Signals ..................................................................................... 35

Connector CN2 –Output................................................................................................................... 35

Connector CN2 –Input...................................................................................................................... 36

Connector CN2 –Emergency management.................................................................................... 36

Attachment 2 Pneumatic diagram....................................................................... 37

DEV7 –Use and Maintenance Manual

Pag. 3

Attachment 3 Technical specifications .............................................................. 39

Mechanical specifications ................................................................................................................. 39

Electrical specifications..................................................................................................................... 39

Pneumatic specifications................................................................................................................... 39

Attachment 4 Exploded-view drawings of the transmission............................ 41

Attachment 5 Exploded-view drawings of punches.......................................... 45

DEV7 –Use and Maintenance Manual

Pag. 5

1 Identification

Identification of the maker

For any problem related to the operation of the machine arising during and after the warranty period,

please refer to the maintenance and service department of:

DELTA VISIONE s.r.l.

a socio unico

Via Carlo Spegazzini, n° 4

10010 Bairo (TO)

Tel. +39 0124 50 18 58

Fax. +39 0124 50 18 57

E-mail: support@deltavisione.com

Web: www.deltavisione.com

C.F. e P.IVA: 09403750012 - R.E.A.: TO 1049465 - Cap. Soc.: € 75.000,00 i.v.

Identification of the machine

Product type: Scribe Marking Machine

Machine code: DEV7

The DEV7 scribing unit is a registered “CE” machine, built in accordance with the norms of the

European Community, as described in the 2006/42/CE Machine Directive, 2014/30/UE Electromagnetic

Compatibility Directive, 2014/35/UE Low Voltage Directive and successive amendments.

The certificate of conformity and the manufacturer’s declaration that are supplied with the machine

should always be retained.

DEV7 –Use and Maintenance Manual

Pag. 6

Intended use

The DEV7 scribe marking unit –produced and sold to be installed and integrated into a production line

or as an adjunct to pre-existing machinery –conforms to the current laws and is destined solely for

professional use by appropriately authorised and trained personnel.

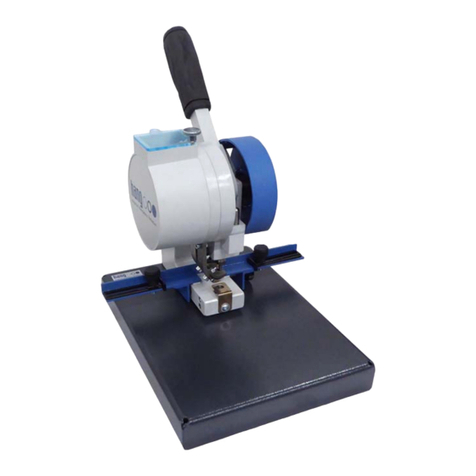

Its intended use is the Scribe Marking, that is, marking made by motorised stylus, of one or more

characters or inscriptions on parts, equipment, machines, in order to allow their identification or

traceability within the production or distribution processes.

The following figure shows an example of marking made with the DEV7 device.

Figure 1 –Marking example

Note: Use of the machine or its single parts in production processes or for purposes different from those

for which it was designed, and its use by methods different from those described in the instructions

given in this document, are prohibited. DELTA VISIONE declines all liability for risks and damages to

persons or things caused by improper use of the machine.

In order to use the machine as intended, full respect must be paid to the technical instructions in this

operating manual.

The machine as a whole (including the computerized control system provided) has been designed to

provide optimal performance in its standard configuration.

DELTA VISIONE declines all liability for system faults, instability and deteriorations in

performance caused by changes made by third parties to the original mechanical, electrical,

electronic, hardware and software configurations.

DEV7 –Use and Maintenance Manual

Pag. 7

Compliance to safety regulations

The machine was designed and built to function and to be checked and maintained without causing the

operator to be exposed to undue risk, as long as these operations are carried out according to the

operating manual. During the design and construction phases, the mechanical and electrical risks were

eliminated as far as possible together with those resulting from the materials adopted, using the methods

described in detail later on in this document. The measures taken minimize the risks of injury throughout

the machine’s life cycle, within the scope of its intended use and any other reasonably predictable uses.

Note: As the marking head can be integrated with existing devices, its supply does not include any

additional protective measures resulting from the particular nature of the elements to be marked, or the

configuration of the integration line or the workbench.

Personnel training

Thanks to the simplicity of its operation and interface software, the DEV7 marking machine, can be

used by personnel who have not undergone specific training, but who have, however, read and

understood the operating manual.

There must only be one operator responsible for operating the machine.

Stand-alone

The DEV7 marking machine can be used as a stand-alone machine not integrated into a production line

or other devices that extend the compatibility with the essential health and safety requirements of the

2006/42/EC Directive by adding safety repairs.

AT T E NT ION

When the machine is not integrated into a production line or other devices

compatible with the essential health and safety requirements of the 2006/42/EC

Directive, the operator must be informed and warned about the pinching / crushing

residual risks posed by the punch during the marking process.

AT T E NT ION

When the machine is not integrated into a production line or other devices

compatible with the essential health and safety requirements of the 2006/42/EC

Directive, the operator should avoid bringing fingers, hands or other objects inside

the marking area during the marking process. In general, it is prescribed to keep

hands away from the machine during the marking process to avoid the risks

mentioned above.

Note: Delta Visione is not responsible for injuries that result from disregard of the above rules of

operation or other general safety rules applicable to the use of this equipment. Furthermore,

disregarding these rules will result in the cancellation of the guarantee.

DEV7 –Use and Maintenance Manual

Pag. 8

Maintenance service

During the warranty period, in accordance with the contract agreements and with reference to Your

orders, DELTA VISIONE s.r.l. is completely available for interventions on the DEV7 Marking System

provided that:

•The causes of malfunction are not due to improper or wrong use of the machine

•The causes of malfunction are not due to the use of parts and consumables not recommended

by this manual

•The causes of malfunction are not due to modifications or interventions not performed and

supported by DELTA VISIONE s.r.l.

The occurrence of a malfunction during the warranty period due to one of the causes listed above will

immediately void the warranty, freeing DELTA VISIONE s.r.l. from any subsequent responsibility.

At the end of the warranty period, DELTA VISIONE s.r.l. is available for interventions on the machine

after a service call of the customer or periodically if the customer has signed the maintenance program

offered by DELTA VISIONE s.r.l.. A written report will be provided at the end of each service

intervention.

If a maintenance program is subscribed after the warranty period has expired or in case of request of

intervention of remarkable entity, DELTA VISIONE s.r.l. reserves the right to make an inspection in

order to determine the overall functionality of the machine.

In order to obtain an efficient service intervention, follow this recommended procedure:

DEV7 –Use and Maintenance Manual

Pag. 9

•Go to the following address:

http://www.deltavisione.com

•Select CONTATTI (Contacts) in the top-right corner, then in “Scegli un tipo di richiesta” (select

a request type) select Richiesta assistenza (Service request)

Fill the form indicating the type of product involved using the data provided by the identification labels

applied on the Control Unit and/or on the Marking Head, detailing the reason of the request and/or the

error condition or malfunction.

Alternatively, send the service request to the following mail address:

support@deltavisione.com

providing the data detailed above.

Service requests can be issued through this phone number:

Tel. +39 0124 50 18 58

and will be satisfied accordingly to the availability of the service personnel.

For maintenance and service requests relative to electrical, mechanical and software issues, please refer

to the mail address provided above.

DEV7 –Use and Maintenance Manual

Pag. 10

CE Labels

Both on the Control Unit and the Marking Head there is a CE label with the following identification

data:

•Model: DEV7

•Code: UX (Control Unit)

•Code: 7 XXX YY (Marking Head, see the note below)

•S/N: Serial number of the unit

•Year: 20xx

The identification data present on these labels must be provided at each service request or when ordering

spare parts.

The following figure shows an example of a CE label (for the Control Unit of a DEV8 model):

Figure 2 –CE Label of the Control Unit

Figure 3 –CE Label of the Marking Head

Note: The Marking Head code (e.g. 7 77 DV) is made up of an initial figure possibly followed by a

letter (7 for model DEV7, 7N for model DEV7N, 8 for model DEV8), two, three or four figures

indicating the size of the marking area (e.g. 77 indicates 70 x 70 mm marking area, 108 100 x 80 mm)

and two final figures identifying the punch type. Check Attachments 4 and 5 at the end of this document

for the details on the punch and marking unit types).

DEV7 –Use and Maintenance Manual

Pag. 11

2 Description and characteristics

General description

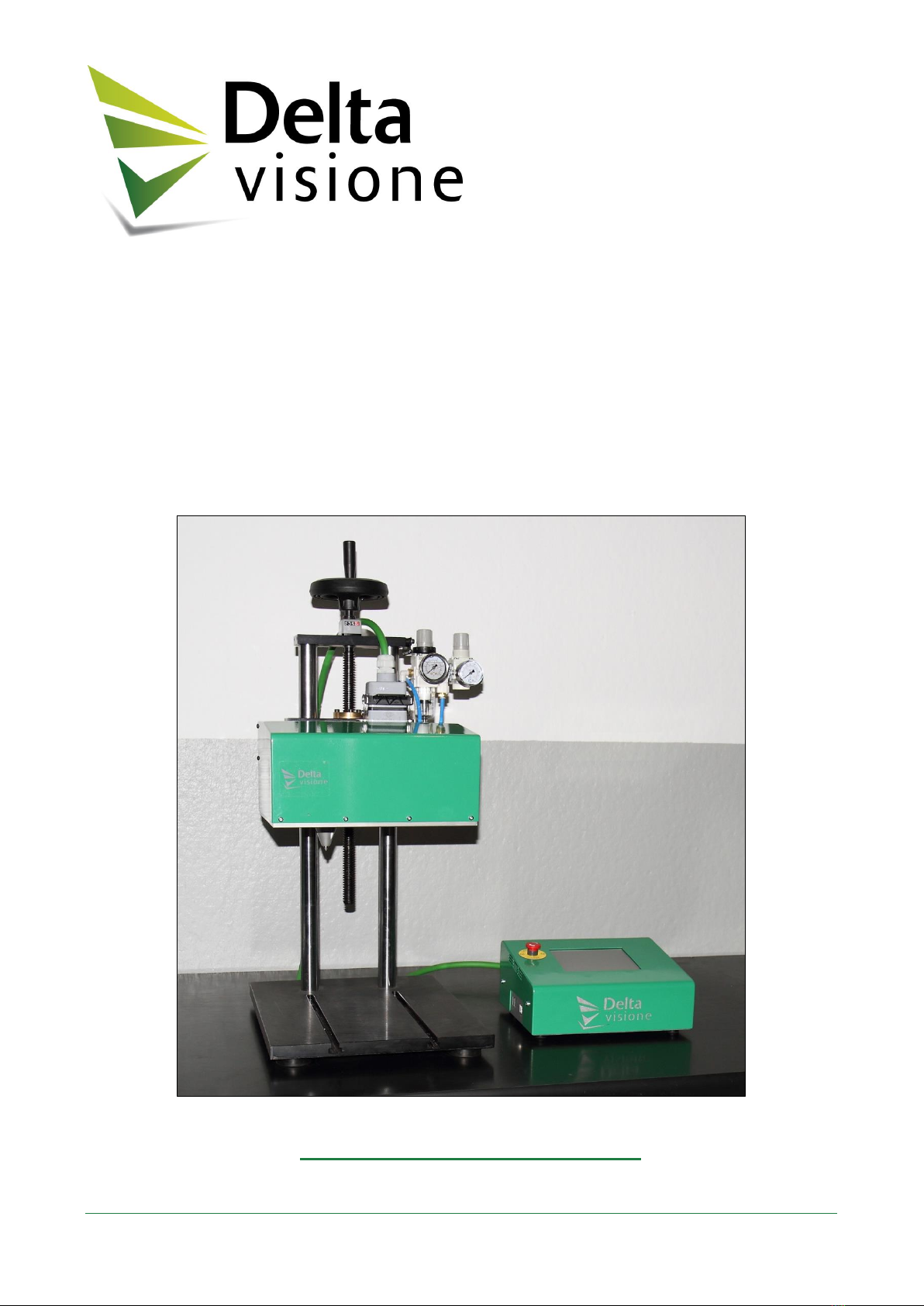

The DEV7 scribe machine is made up of two main parts (see the figure below):

•Marking Head

•Hardware-software Control Unit.

Figure 4 –Overall view

Item

Description

1

Marking head

2

Hardware-software control unit

2

1

DEV7 –Use and Maintenance Manual

Pag. 12

Marking head

The marking head contains the body of the punch that performs the marking operations, and the motors

and transmission elements for moving the punch. All the moving parts of the marking head are isolated

by a protective metal cover, which can be removed exclusively for maintenance purposes by unscrewing

the fastening screws and with the machine at a standstill.

ATTENTION! The protective cover guarantees safe use of the machine both for its intended use and

any other reasonably predictable uses, and for the risk of unintentionally incorrect movements by the

operator. Deliberate, voluntary access to the moving elements cannot however be ruled out and this

could represent a hazard that is not justified by any production needs.

Figure 5 –Marking head

Item

Description

1

Multipolar cable (from/to Hardware-software control unit) connector

2

Stylus unit

Various models are available, differentiated by the size of the marking head and therefore of the marking

area. A list of the currently available models and their dimensions and weights can be found in the

Appendix.

2

1

DEV7 –Use and Maintenance Manual

Pag. 13

Figure 6 –Punch unit

Figure 7 –Multipolar cable and compressed air inlet

Item

Description

1

Multipolar cable (from/to Hardware-software control unit) connector

2

Compressed air inlet

2

1

DEV7 –Use and Maintenance Manual

Pag. 14

Control unit

The control unit of the DEV7 marking machine contains the hardware and software devices and power

electronics for controlling and driving the motors present in the marking head to which it is connected

by a multipolar cable in a protective sheath with a length of 2 m (standard version).

Figure 8 –Hardware-software Control Unit

On the back side of the Control Unit there is the connectors’ compartment, also housing the power

supply socket and the power button.

Figure 9 –Back connectors and on/off switch

Item

Description

1

ON/OFF switch

2

Fuse holder 5X20 T5A

3

Mains cable connector

2

1

3

4

5

6

7

8

DEV7 –Use and Maintenance Manual

Pag. 15

Item

Description

4

Optional card connector

5

Optional card connector

6

COM1 RS232 serial port

(PLC or host with serial communication port controlling the marking cycle, for the details

refer to the System management software manual)

7

Marking head cable connector

8

Input/output cable connector

On the left side of the control unit there are other connectors (see the following figure).

Figure 10 –Connectors on the left side of the control unit

Item

Description

1

USB ports (2)

2

COM2 RS232 serial port (used by a Windows PC running the Mark Wizard software that

allows creating a marking file, see the details in the System management software manual)

The DEV7 marking machine uses a software interface that can be run directly from the integrated

keyboard or from an external keyboard connected to one of the USB ports situated on the side panel of

the Control Unit.

2

1

DEV7 –Use and Maintenance Manual

Pag. 16

E-Stop button

Figure 11 –Control Unit (top view)

The standard emergency stop button is situated in the upper left part of the control panel (see the figure

above).

The button can be pushed at any time, causing the immediate interruption of machine operation. If any

further operations are attempted, the following message will be displayed:

In addition to the above error message, the red LED on the left-hand side of the display will light up.

To exit from the emergency status and restore normal operation, simply press RET.

DEV7 –Use and Maintenance Manual

Pag. 17

Touch-screen

The touch-screen situated on the body of the control unit was designed to provide all the functions

necessary to perform the operations involved in controlling the marking machine (see example below).

Figure 12 –Touch-screen view

Note: At the end of the machine testing procedure, the display is covered with a film that is to be peeled

off slowly and carefully to avoid creating electrostatic charges.

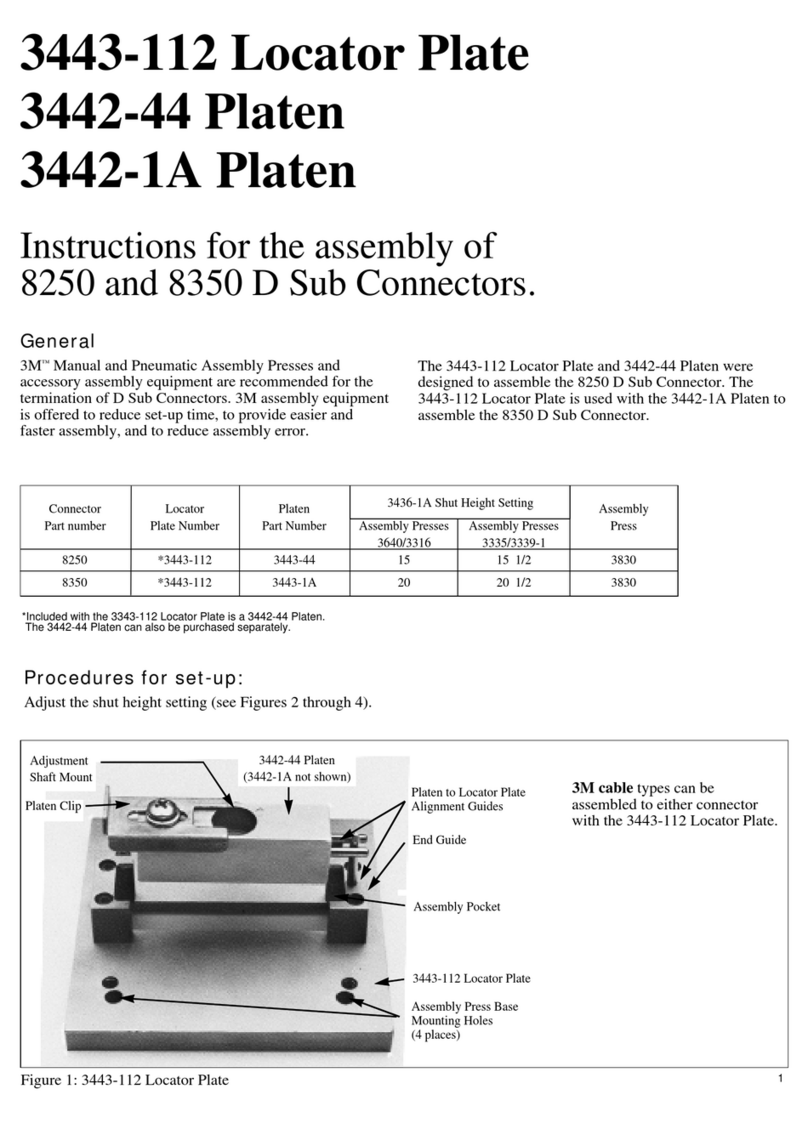

Table of contents

Other Delta Visione Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TopGears

TopGears ITG 125 Operation and maintenance manual

ABB

ABB HT842663 Operation manual

3M

3M 8350 D Instructions for the assembly

Schmalz

Schmalz FXP Operating instructions manual

Cooper Power Systems

Cooper Power Systems NOVA 15 Installation and operation instruction

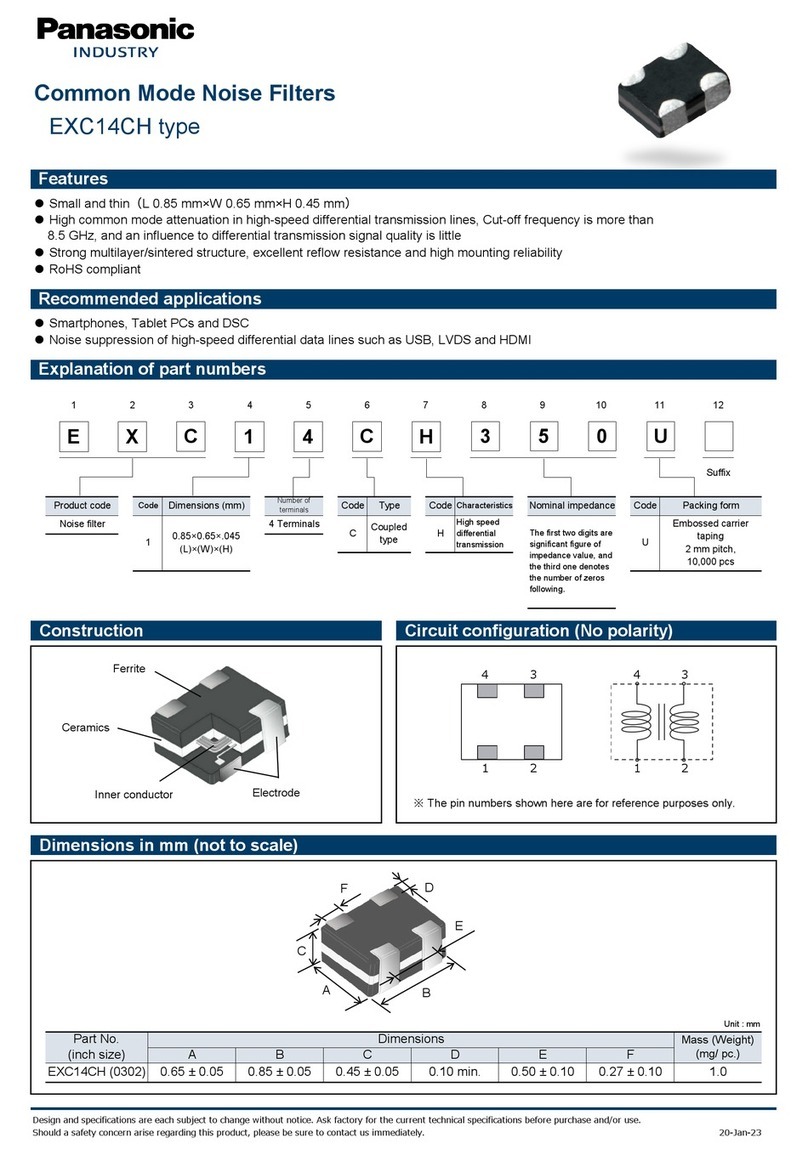

Panasonic

Panasonic EXC14CH quick start guide