7503641000000006

09

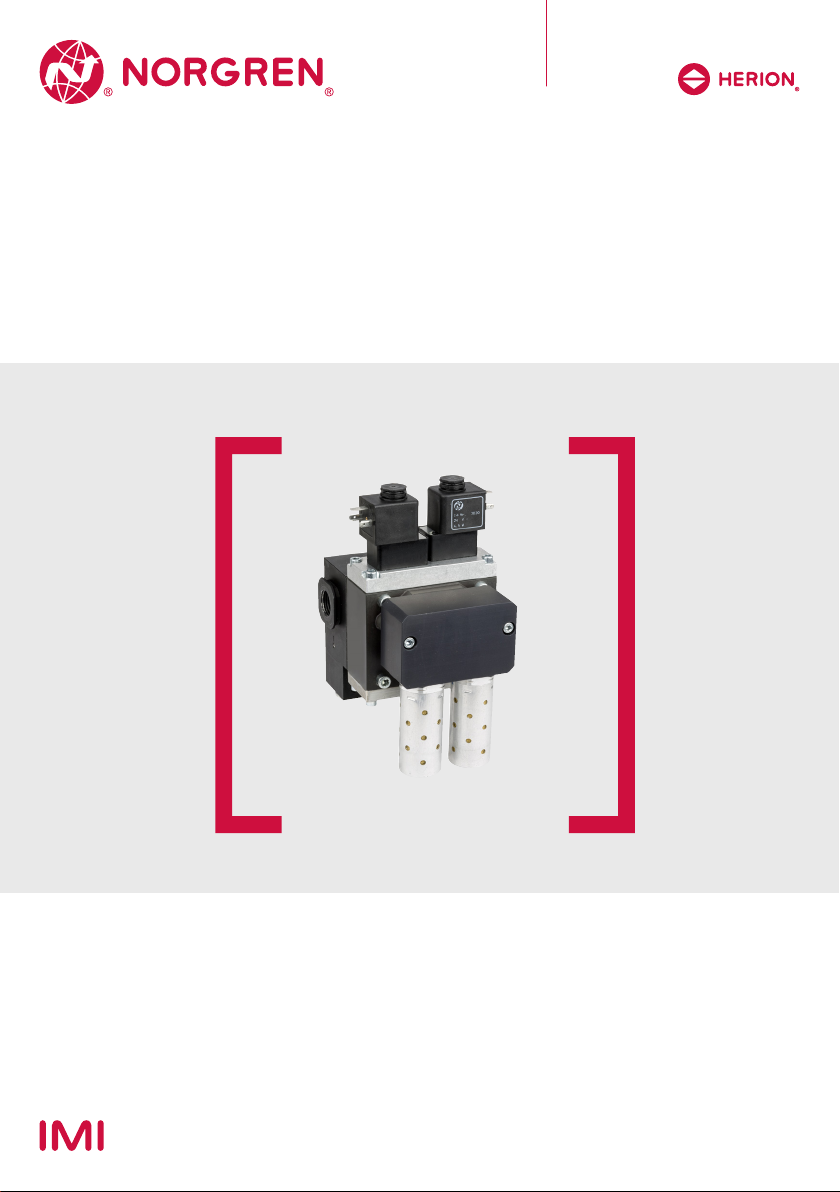

Incorporating

SCSQ10

02/22

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specii cations given in this document. © 2014 Norgren Ltd

WARNING!

Danger of injury caused by lack of training!

People who lack proper training cannot assess

the risks when handling the safety valves and

they place others at risk of serious injury or death.

• Have all work on the pneumatic system car-

ried out by pneumatics specialists.

• Have all electrical installation work carried out

by qualiied electricians.

Pneumatics specialists are trained for the specialist area

they work in, and they know the relevant standards and

regulations.

Because of their special training and experience, pneumat-

ics specialists can carry out work on pneumatic, electro-

pneumatic and mechatronic systems and identify and

avoid risks by themselves.

Because of their specialist training, knowledge and ex-

perience, and their knowledge of the relevant standards

and regulations, qualiied electricians are able to carry

out work on electrical installations and identify and avoid

possible risks by themselves.

Qualiied electricians are specially trained for the area

they work in, and they know the relevant standards and

regulations.

2.3 Personnel

requirements

Pneumatics specialist

Qualiied electrician