Zakład Wytwórczy Aparatów Elektrycznych Sp. z o.o.

5

1. TRANSPORT

1.1. Unpacking and inspection

Immediately after receiving the disconnector, the delivery’s compliance with the packing list should be chec-

ked. Then one should check whether the disconnector has not been mechanically damaged during transport

and the data on the nameplate match the order.

1.2. Storage and transport

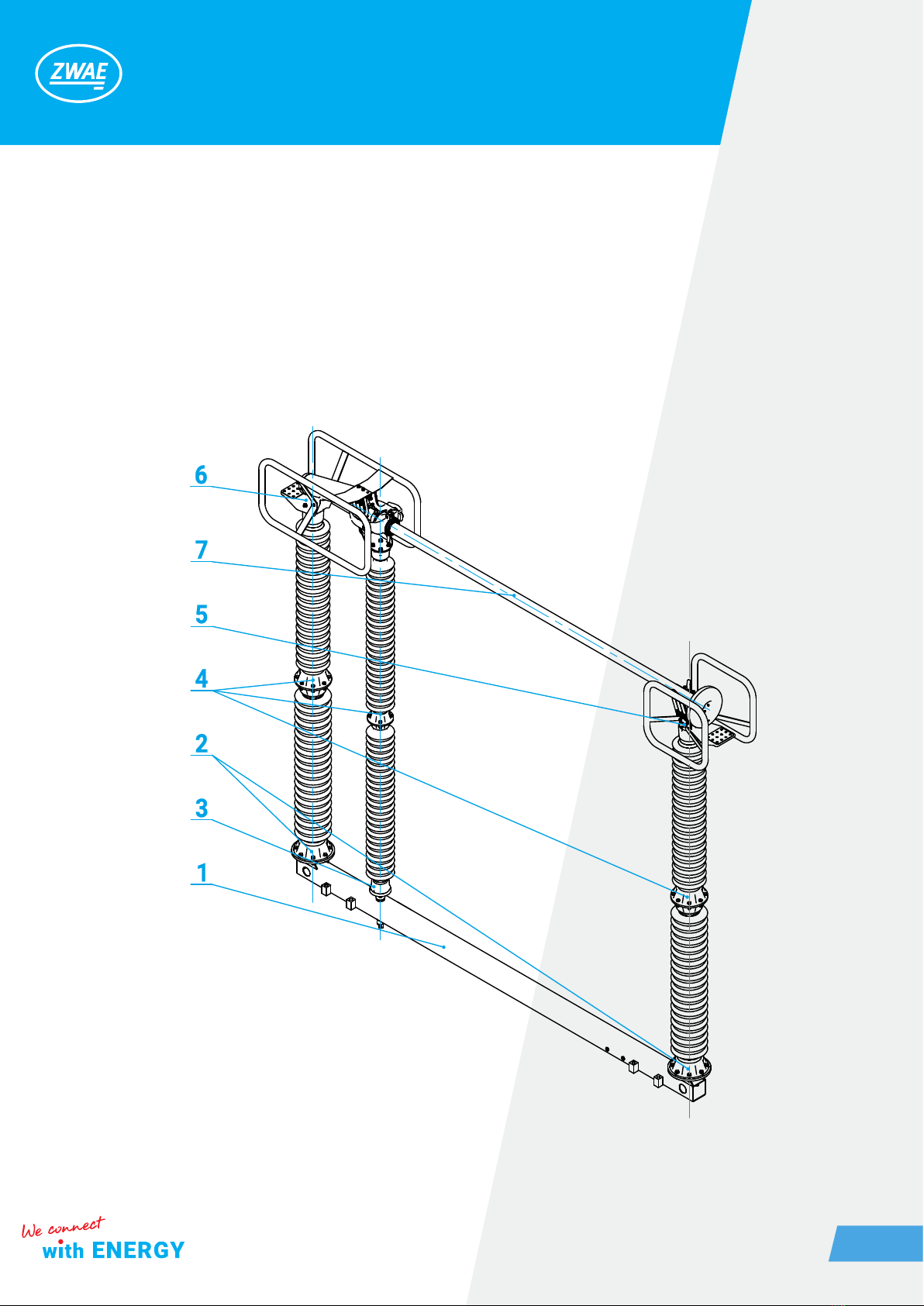

The disconnectors poles are transported in a partially assembled condition, ie the base frame together with

the current path form the basic set, while the other elements (insulators, contact’s corona rings, driving soc-

kets, etc.) are delivered separately for installing during assembly. The basic sets are packed in several pieces

on a wooden structure, as it is shown in the following drawing.

wooden structure

In the case of the purchase of a disconnector’s version with an earthing switch, all parts used for the earthing

switch’s construction ( the knife of earthing switch, counterweight beams, counterweights, pins, spacers, co-

upling tie rods, earthing switch contact, knife’s support and shaft of the earthing switch) are also delivered se-

parately in packs. When preparing the pole for assembly, the wooden beams should be removed by unscrewing

the four screws with the spanner 13.