MODELS: SLM50-110-C, SLM80-110D-C, SLM50-110LED-C, SLM80-110DLED-C, SLM80-110H-C

Page 1.

Installation and Operating Instructions

CEILING/WALL VENTILATION FAN

READ AND SAVE THESE INSTRUCTIONS

GENERAL SAFETY INFORMATION

1. Make sure that the electric service supply voltage is

AC 120V, 60Hz.

2. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSH Act).

3. Always disconnect the power source before working

on or near the ventilating fan, motor or junction box.

4. Protect the power cord from sharp edges, oil, grease,

hot surfaces, chemicals or other objects.

5. Do not kink the power cord.

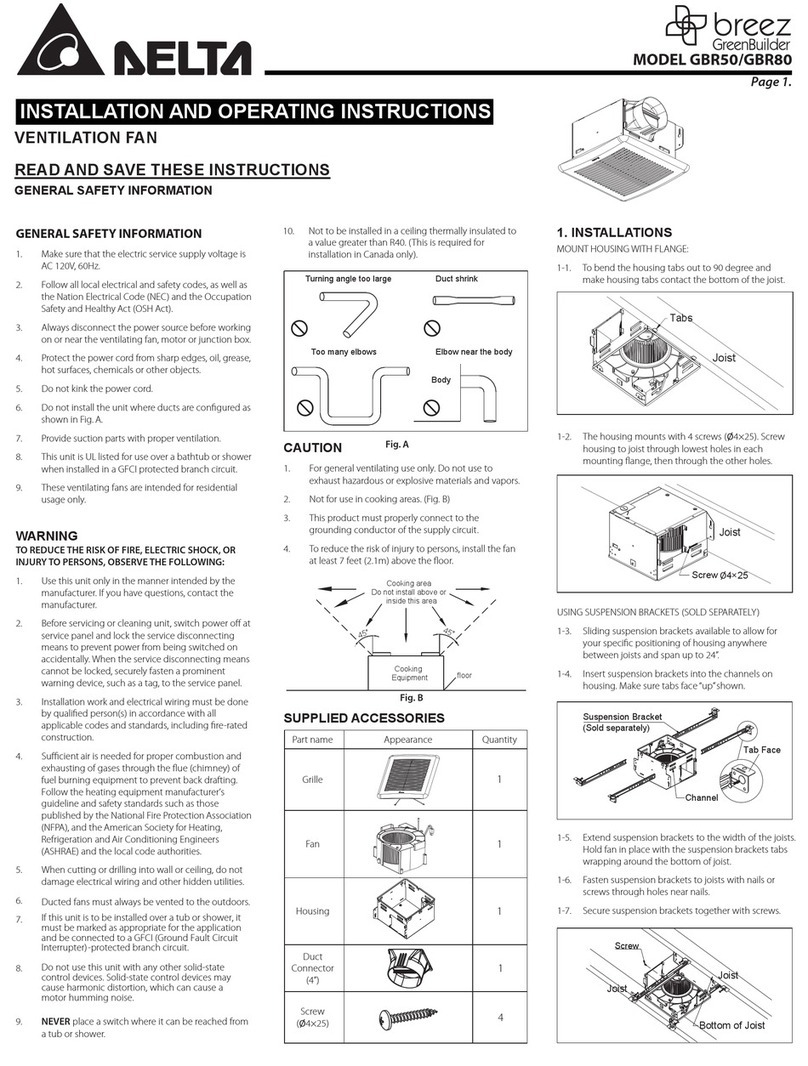

6. Do not install the unit where ducts are configured as

shown in Fig. A.

7. Provide suction parts with proper ventilation.

8. This unit is UL Listed for use over a bathtub or shower

when installed in a GFCI protected branch circuit.

3. This product must properly connect to the grounding

conductor of the supply circuit.

4. To reduce the risk of injury to persons, install the fan

at least 8.2 feet (2.5m) above the floor.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

2. Before servicing or cleaning unit, switch power off at

the service panel and lock the service disconnecting

means to prevent the power from being switched

on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

3. nstallation work and electrical wiring must be

done by a qualified person(s) in accordance with all

applicable codes and standards, including fire-rated

construction.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow

the heating equipment manufacturer’s guideline

and safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) and local code

authorities.

5. When cutting or drilling into the wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. If this unit is to be installed over a tub or shower, it

must be marked as appropriate for the application

and be connected to a GFCI (Ground Fault Circuit

Interrupter) –protected branch circuit.

8. Do not use this unit with any other solid-state control

device. Solid-state control device may cause harmonic

distortion, which can cause a motor humming noise.

(Avertissement: ne convient pas à des régulateurs de

vitesse à semi-conducteurs).

9. NEVER place a switch where it can be reached from a

tub or shower.

10. Not to be installed in a ceiling thermally insulated

to a value greater than R50. (This is required for

installation in Canada only).

11. Do not open/disassemble LED light engine.

ASSEMBLY INSTRUCTION

WARNING: Turn o electricity at breaker box before

beginning installation.

1. Carefully remove unit from carton.

2. Check area above installation location to be sure that

wiring can run to the planned location and that duct

work can be run. Make sure the area is sufficient for

proper ventilation.

3. Inspect duct work and wiring before proceeding with

installation.

4. Before installation, provide inspection and future

maintenance access at a location that will not

interfere with installation work.

5. You may need the help of a second person to install

this fan: one person on the attic side and one on the

room side.

Note: Installations may vary depending on how the

previous bath fan was installed. Supplies necessary for the

installation of your bath fan are not all included. However,

most are available at your local home improvement or

hardware store.

Proper insulation around the fan to minimize building heat

loss and gain. The ducting from this fan to the outside of

the building has a strong effect on the air flow, noise and

energy use of the fan. Use the shortest, straightest duct

routing possible for best performance, and avoid installing

the fan with smaller ducts than recommended. Insulation

around the ducts can reduce energy loss and inhibit mold

growth. Fans installed with existing ducts may not achieve

their rated air flow.

1. The fan will operate most efficiently when located

where the shortest possible duct run and minimum

number of elbows will be needed.

2. Use a roof cap or wall cap that has a built-in damper

to reduce backdrafts.

3. External timer can be used in conjunction with

single-speed mode only, please contact Delta

Breez customer service and consult with a licensed

electrician for compatibility.

4. External dimmer can be used in conjunction with

LED light model, please contact Delta Breez customer

service and consult with a licensed electrician for

compatibility.

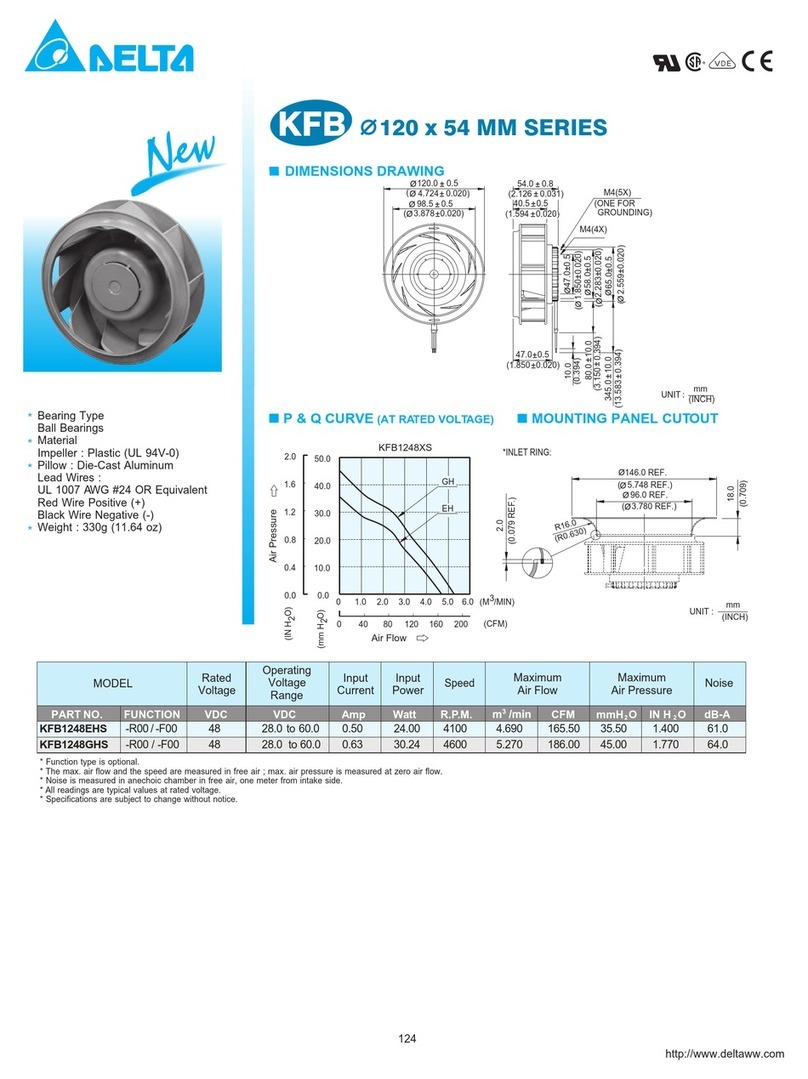

Fig. A

Cooking area

Do not install above or

inside this area

Cooking

Equipment oor

Turning angle too large Duct shrink

Too many elbows Elbow near the body

Body

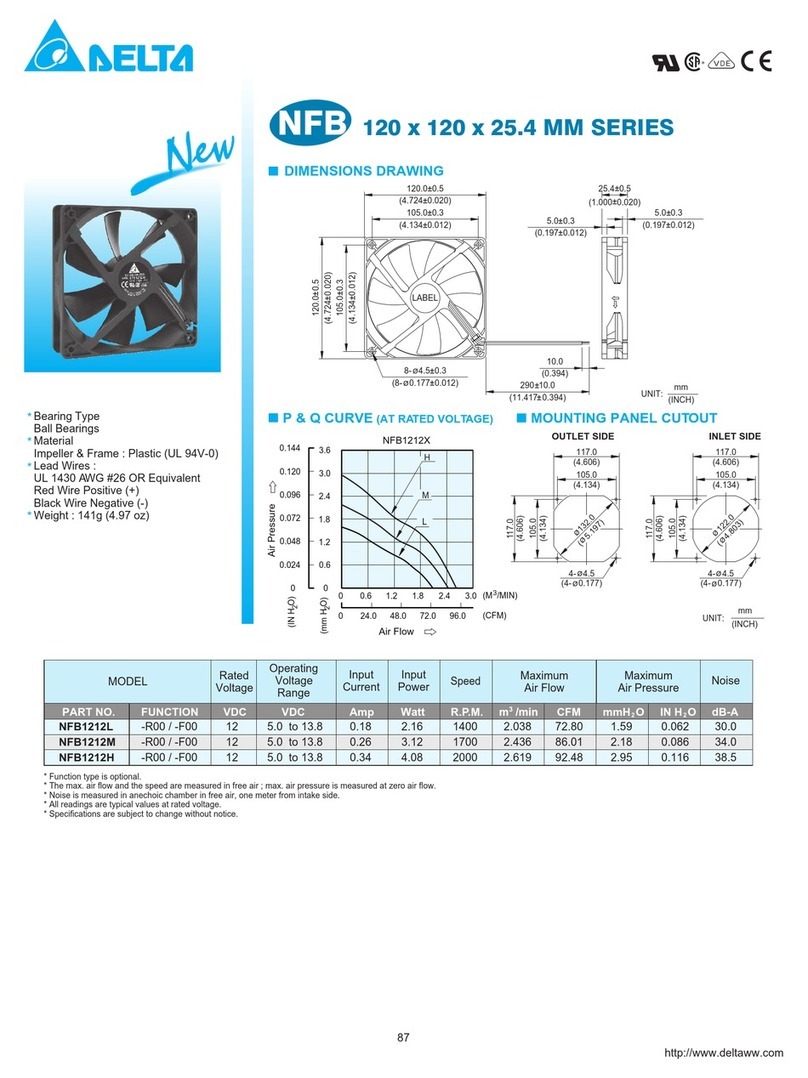

PACKAGE CONTENTS

For all Models:

For the Model of SLM50-110-C, SLM80-110D-C,SLM80-110H-C

For the Model of SLM50-110LED-C, SLM80-110DLED-C

Part name Appearance Quantity

Fan Body 1

Tapping Screw

(Ø4×25mm) 6

(Machine Screw

(#8-32x5/16”) 1

Machine Screw

(M4x6 mm) 1

Hanger Bar 1

Wiring Cover 1

Part name Appearance Quantity

Grille 1

Part name Appearance Quantity

Grille 1

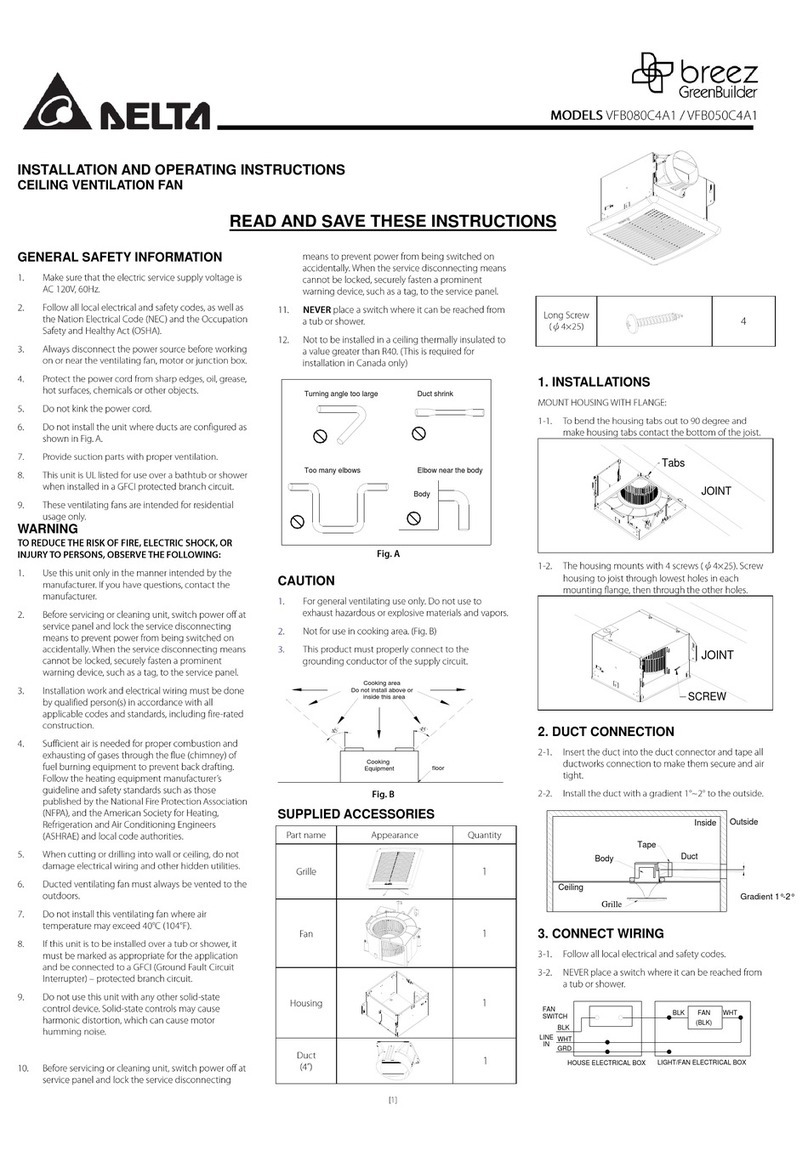

ASSEMBLY INSTRUCTION

Installation I

(Ceiling/Wall mount housing with ange)

1. To bend the housing tabs out to 90 degree and make

housing tabs contact the bottom or front of the joist.

Installation II

(Using suspension bracket):

1. The housing mounts with 4 screws (Ø4×25 mm)

Screw housing to joist through the round holes in

each mounting flange, then through the other holes.

2. Insert suspension bracket into the channel on

housing.

2. The housing mounts with 4 screws (Ø4×25 mm).

Screw housing to joist through the round holes in

each mounting flange, then through the other holes.

Fig. B

CAUTION

1. For General Ventilating Use Only. Do Not Use To

Exhaust Hazardous Or Explosive Materials And Vapors.

2. Not for use in cooking area. (Fig. B)

For humidity sensing models only (SLM80-110H-C)

•

Locate unit above (GFCI-protected circuit required) or

within 5 feet of the shower head.

•

Locate unit away from heating or cooling sources

which can affect humidity levels.

•

Do not locate near window. Unit may respond to the

outdoor humidity level.

•

Unit must be installed in ceiling to properly sense

moisture.

•

Locate unit only on flat ceilings up to 12 feet high for

proper sensing.

45°

45°

Joist

Tabs

Joist

Tabs

Screw Ø4x25 mm

Joist

Screw Ø4x25 mm

Joist

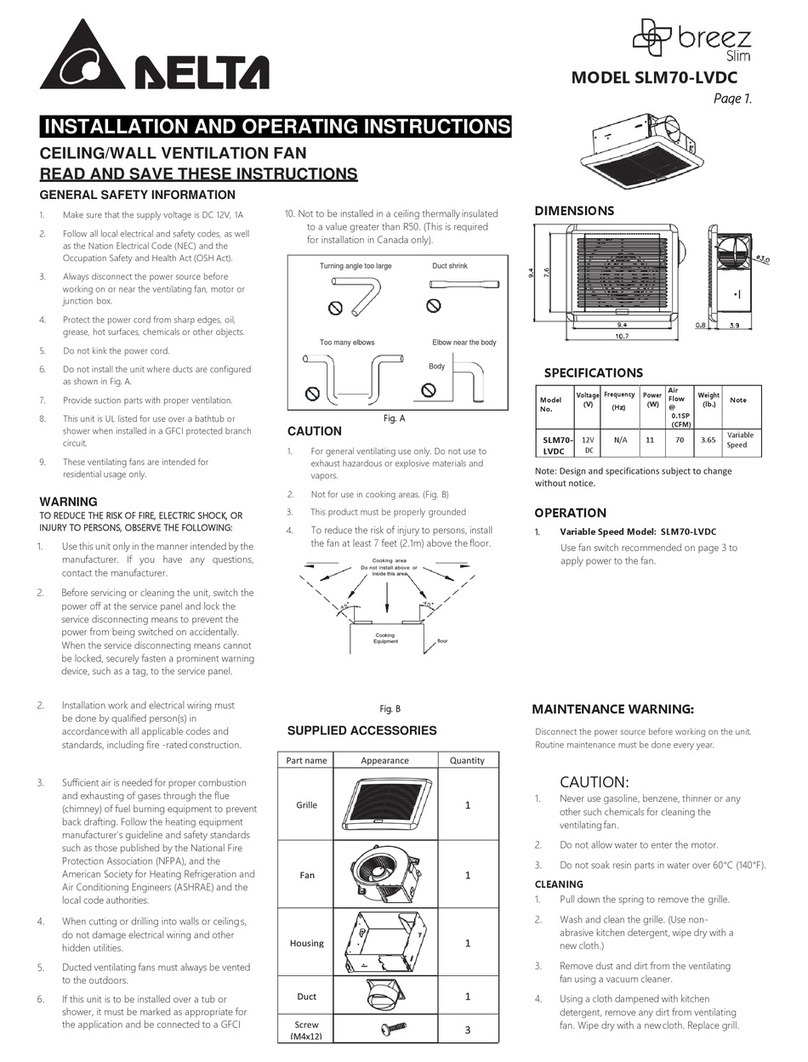

Short piece of exible

duct helps alignment

and absorbs sound

Caulk termination

to duct

2~3 ft

straight run

before elbow

Roof cap

(with built-in

damper)

Wall capWall cap

(with built-in(with built-in

damper)damper)

Seal gap

around

housing

Fan housing

or