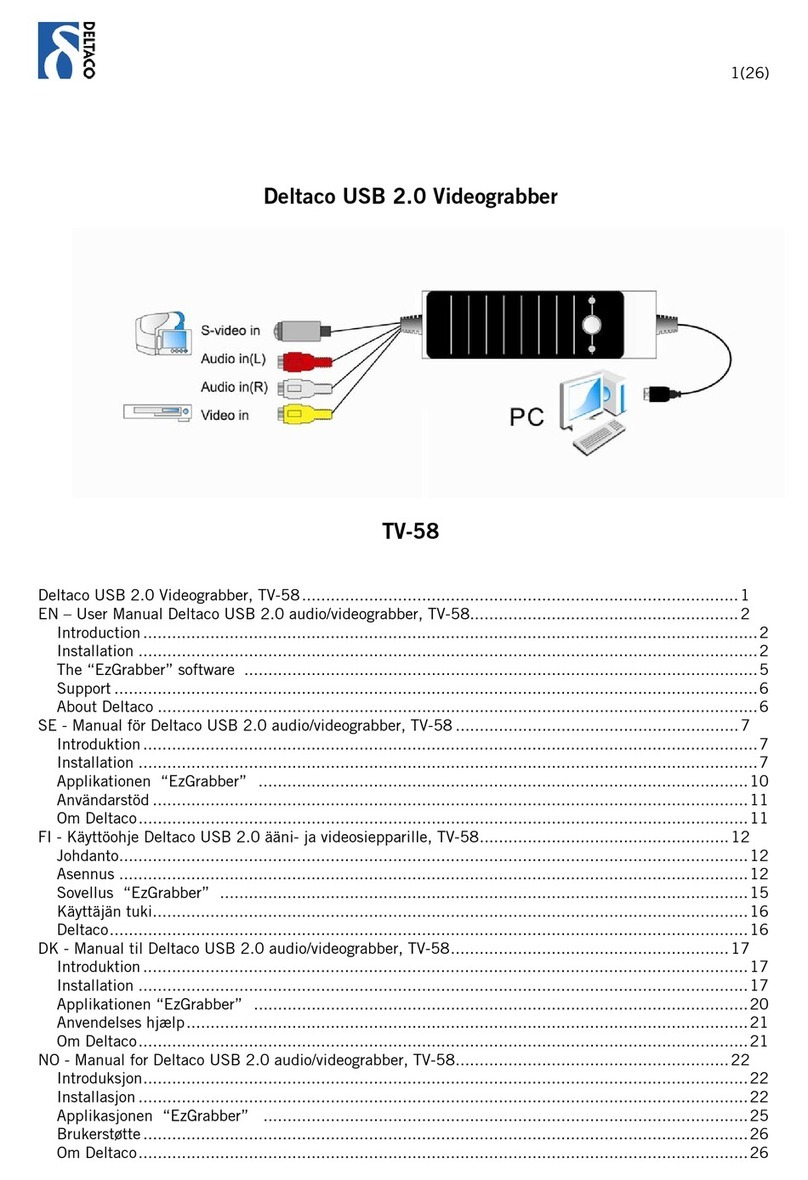

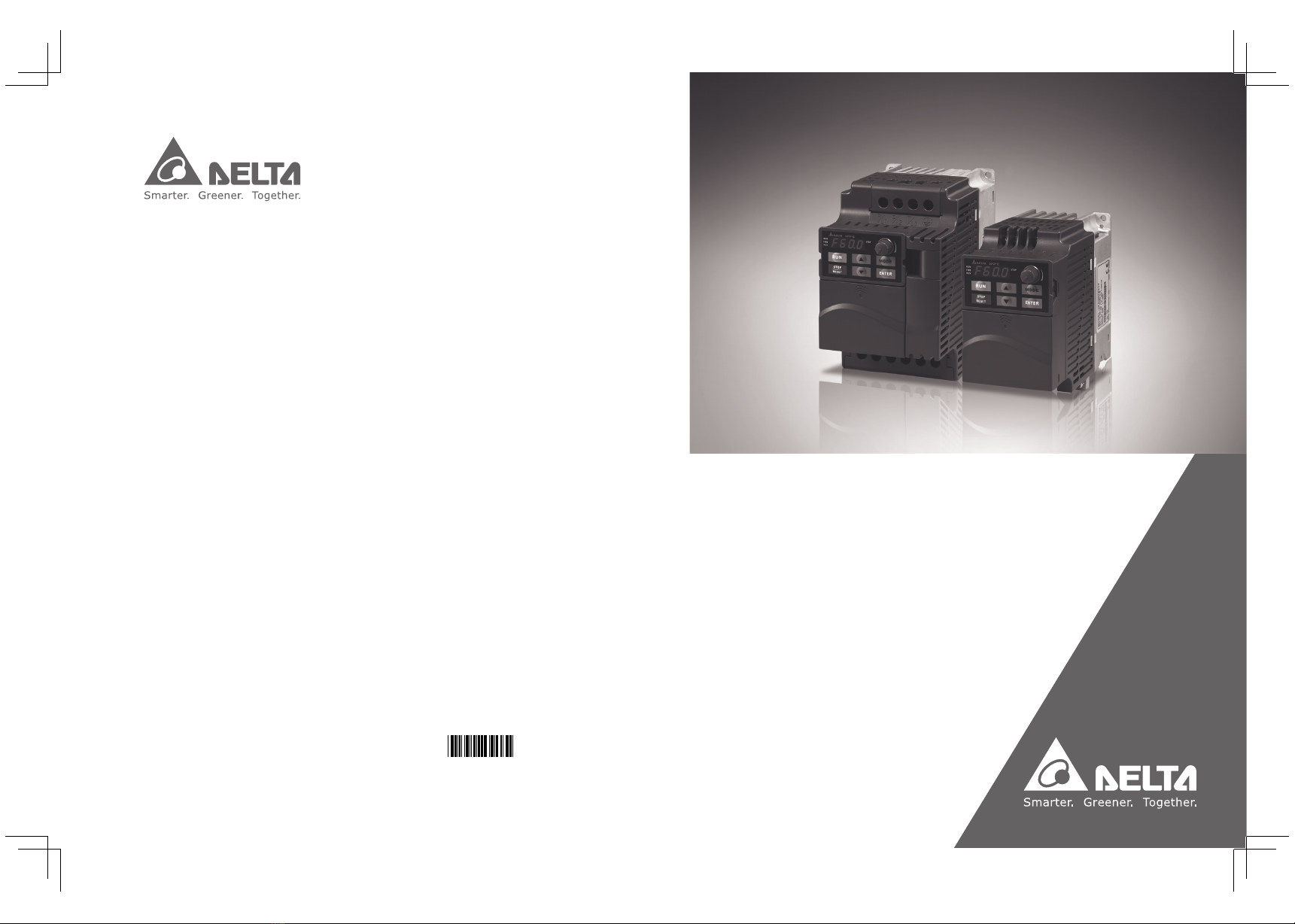

Sensorless Vector

Control Compact Drive

VFD-E Series User Manual

www.deltaww.com

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province,

People's Republic of China (Post code: 215200)

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C.

Post code : 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Office

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Office

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A

Sao Paulo Office

Rua Itapeva, 26 - 3° andar Edificio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: +55 11 3568-3855 / FAX: +55 11 3568-3865

Europe

Deltronics (The Netherlands) B.V.

Eindhoven Office

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL: +31-(0)40-8003800 / FAX: +31-(0)40-8003898

*We reserve the right to change the information in this catalogue without prior notice.

Sensorless Vector Control Compact Drive VFD-E Series User Manual

5011640614

2016-05-16