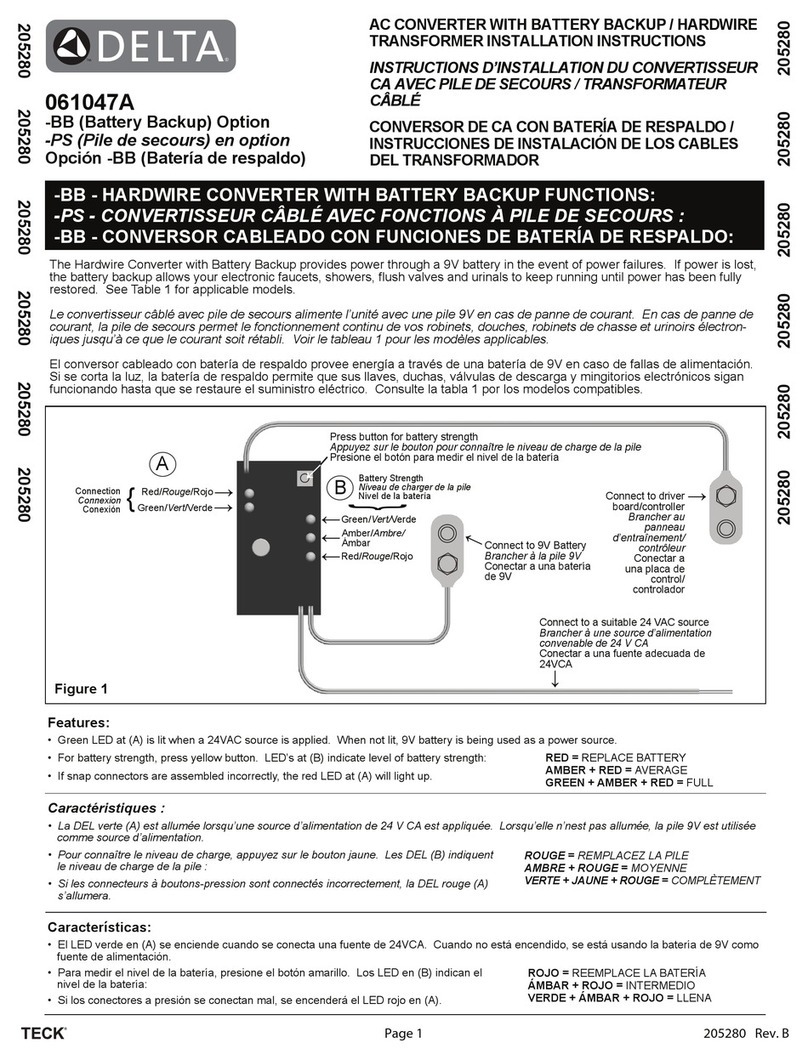

Pr. Functions Settings Factory

Setting

2-04 Reverse operation

inhibit

d0: Enable reverse

d1: Disable reverse

d2: Disable forward

d0

2-05 ACI (4 ~ 20mA)

input loss detection

d0: Decel to 0Hz

d1: Stop immediately, display EF

d2: Run with the last freq.

d0

2-06 Line Start Lockout d0: Enable d1: Disable d0

Group 3: Output Function Parameters

Pr. Functions Settings Factory

Setting

3-00 Desired freq. attained d1.0 ~ d400 Hz d1.0

3-01 Terminal count value d0 ~ d999 d0

3-02 Preliminary count

value

d0 ~ d999 d0

3-03 Multi-function (relay

output)

d0: not used

d1: AC drive operational

d2: Max. Output Freq. Attained

d3: Zero Speed

d4: Over Torque

d5: Base-Block (B.B.)

d6: Low Voltage Detection

d7: AC Drive Operation Mode

d8: Fault Indication

d9: Desired Freq. Attained

d10: PLC Program Running

d11: PLC Program Step Complete

d12: PLC Program Complete

d13: PLC Program Operation Pause

d14: Terminal Count Value Attained

d15: Preliminary Count Value Attained

d16: Ready State Indicator

d8

Group 4: Input Function Parameters

Pr. Functions Settings Factory

setting

a4-00 Potentiometer bias

freq. d0.0~d350Hz d0.0

a4-01 Potentiometer bias

polarity

d0: positive bias

d1: negative bias d0

a4-02 Potentiometer freq.

gain d1~d200%d100

4-03

Potentiometer

reverse motion

enable

d0: not used

d1: reverse motion enable

d2: forward motion only

d0

4-04

Multi-function input

terminal1 (M1)

(d 0~d 20)

d1

4-05 Multi-function input

terminal 2(M2) d6

4-06

Multi-function input

terminal 3(M3)

(d 0, d 4~d 20)

d0: not used

d1: M0: FWD/STOP, M1: REV/STOP

d2: M0: RUN/STOP, M1: FWD/REV

d3: M0, M1, M2: 3-wire operation control

mode

d4: External fault, normally open (N.O.)

d5: External fault, normally closed (N.C.)

d6: RESET

d7: multi-step speed command 1

d8: multi-step speed command 2

d9: jog operation

d10: accel/decel speed inhibit

d11: first or second accel/decel time

selection

d12: base-block (B.B.),normally open (N.O.)

d13: base-block (B.B.),normally closed (N.C)

d14: increase master freq.

d15: decrease master freq.

d16: run PLC program

d17: pause PLC

d18: counter trigger signal

d19: counter reset

d20: select ACI/deselect AVI

d7

Group 5: Multi-step Speed and PLC Parameters

Pr. Functions Settings Factory

Setting

5-00 1st step speed freq. d0.0 ~ d400Hz d0.0

5-01 2nd step speed freq. d0.0 ~ d400Hz d0.0

5-02 3rd step speed freq. d0.0 ~ d400Hz d0.0

5-03 PLC mode d0: Disable PLC operation

d1: Execute one program cycle

d2: Continuously execute program cycles

d3: Execute one program cycle step by step

(separate by STOP)

d4: Continuously execute one program cycle

step by step (separate by STOP)

d0

5-04 PLC forward/reverse

motion

d0 ~ d15 (d0: Forward, d1: Reverse) d0

5-05 Time duration step 0 d0 ~ d65500 Sec d0

5-06 Time duration step 1 d0 ~ d65500 Sec d0

5-07 Time duration step 2 d0 ~ d65500 Sec d0

5-08 Time duration step 3 d0 ~ d65500 Sec d0

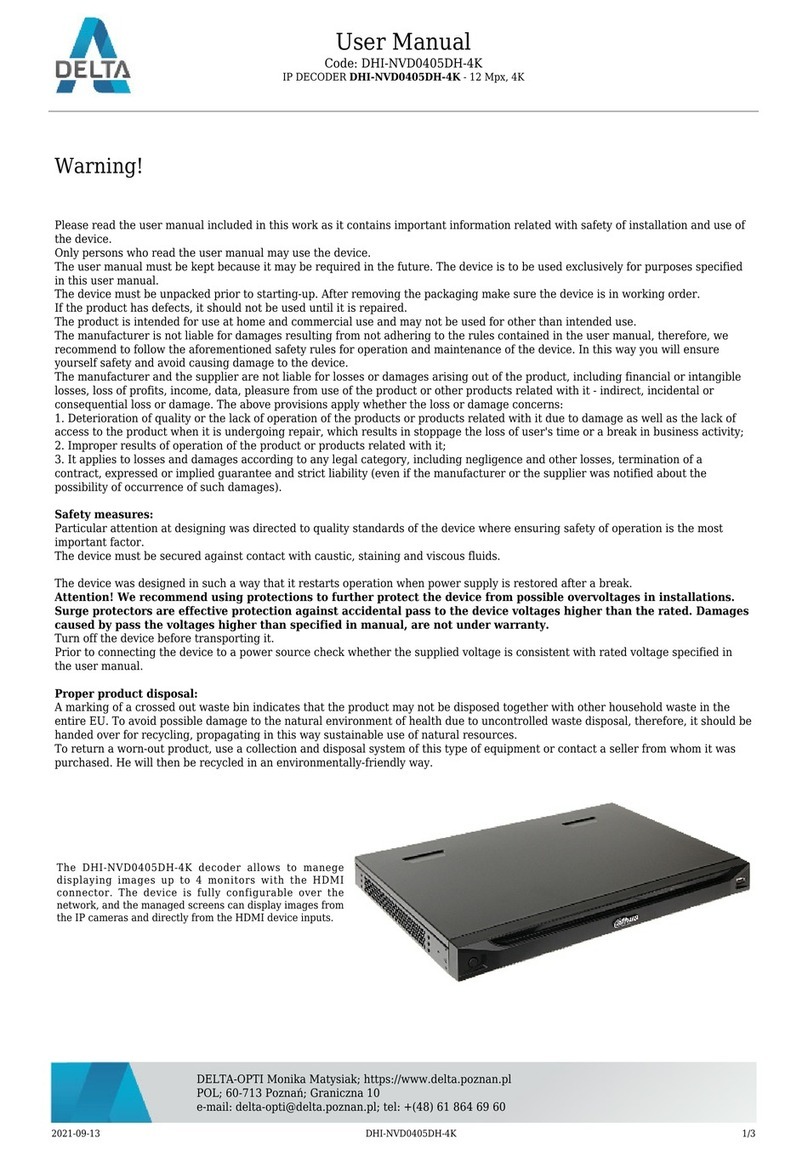

Group 6: Protection Parameters

Pr. Functions Settings Factory

Setting

6-00 Over-Voltage

Prevention Level

d0:disable

d350~d410V d390

Pr. Functions Settings Factory

Setting

6-01 Over-current

Prevention Level

d0: disable

d20~d200%

d170

6-02 Over-torque detection d0:disable

d1:enabled during constant speed operation

and continues until the continuous limit is

reached.

d2:enabled during constant speed operation

and halted after detection.

d3:enabled during accel and continues

before continuous output time limit is

reached.

d4:enabled during accel and halted after

over-torque detection.

d0

6-03 Over-torque detection

level d30 ~ d200% d150

6-04 Over-torque detection

time d0.1 ~ d10.0 Sec d0.1

6-05 Electronic thermal

overload relay

d0: Not used

d1: Act with standard motor

d2: Act with special motor

d0

6-06 Electronic thermal

characteristic d30~d600 Sec d60

6-07 Present fault record

6-08 Second most recent

fault record

6-09 Third most recent fault

record

6-10 Forth most recent fault

record

6-11 Fifth most recent fault

record

6-12 Sixth most recent fault

record

d0: No fault occurred

d1: oc (over current)

d2: ov (over voltage)

d3: oH (over heat)

d4: oL (over load)

d5: oL1 (electronic thermal)

d6: EF (external fault)

d7: Reserved

d8: Reserved

d9: ocA (current exceed during acceleration)

d10: ocd (current exceed during

deceleration)

d11: ocn (current exceed during steady state)

d0

Group 7: Motor Parameters

Pr. Functions Settings Factory

Setting

a7-00 Motor rated current d30~d120 % d85

a7-01 Motor no-load current d0 ~ d90 % d50

a7-02 Torque compensation d0 ~ d10 d1

a7-03 Slip compensation d0.0 ~ d10.0 d0.0

Group 8: Special Parameters

Pr. Functions Settings Factory

Setting

8-00 DC braking voltage level d0 ~ d30% d0

8-01 DC braking time during

start-up d0.0 ~ d60.0 Sec d0.0

8-02 DC braking time during

stopping d0.0 ~ d60.0 Sec d0.0

8-03 Start-point for DC braking d0.0 ~ d400.0 Sec d0.0

8-04 Momentary power loss d0: Stop operation after momentary

power loss.

d1: Continues after momentary power

loss, speed search starts with

master freq.

d2: Continues after momentary power

loss, speed search starts with min.

output freq.

d0

8-05 Max. allowable power loss

time d0.3 ~ d5.0 Sec d2.0

8-06 B.B. time for speed search d0.3~d5.0 Sec d0.5

8-07 Max. speed search current

level d30~d200% d150

8-08 Skip freq. 1 upper bound d0.0~d400 Hz d0.0

8-09 Skip freq. 1 lower bound d0.0~d400 Hz d0.0

8-10 Skip freq. 2 upper bound d0.0~d400 Hz d0.0

8-11 Skip freq. 2 lower bound d0.0~d400 Hz d0.0

8-12 Skip freq. 3 upper bound d0.0~d400 Hz d0.0

8-13 Skip freq. 3 lower bound d0.0~d400 Hz d0.0

8-14 Auto restart after fault d0~d10 d0

8-15 AVR function d0: AVR function enable

d1: AVR function disable

d2: AVR function disable when decel

d2

8-16 Dynamic braking voltage d350 ~ d450V d380

8-17 DC braking lower bound

limit d0.0 ~ d400 Hz d0.0

Group 9: Communication Parameters

Pr. Functions Settings Factory

Setting

a9-00 Communication address d1 ~ d247 d1

a9-01 Transmission speed d0: Baud rate 4800

d1: Baud rate 9600

d2: Baud rate 19200

d1

a9-02 Transmission fault

treatment

d0: Warn and continue running

d1: Warn and ramp to stop

d2: Warn and coasting stop

d3: No warn and keep running

d0

a9-03 Modbus communication

watchdog timer

d0: Disable

d1~d20: 1 ~ 20 Sec

d0

Pr. Functions Settings Factory

Setting

a9-04 Communication protocol ASCII mode

d0: 7,N,2

d1: 7,E,1

d2: 7,O,1

d3: 8,N,2

d4: 8,E,1

d5: 8,O,1

RTU mode

d6: 8,N,2

d7: 8,E,1

d8: 8,O,1

d0

5 Troubleshooting and Fault Information

The VFD-L AC drive has a comprehensive fault diagnostic system that

includes several different alarms and fault messages. Once a fault is detected,

the corresponding protective functions will be activated. The following faults

are displayed on the AC drive digital keypad. The six most recent faults can be

read on the digital keypad display by viewing Pr.6-07 to Pr.6-12.

NOTE: faults can be cleared by pressing the Reset key on the keypad or Input

Terminal.

Common Problems and Solutions

Fault

Name Fault Descriptions Corrective Actions

The AC drive detects an

abnormal increase in

current.

1. Check whether the motors horsepower

corresponds to the AC drive output power.

2. Check the wiring connections between the AC

drive and motor for possible short circuits.

3. Increase the Acceleration time (Pr.1-09,

Pr.1-11).

4. Check for possible excessive loading

conditions at the motor.

5. If there are any abnormal conditions when

operating the AC drive after the short-circuit is

removed, the drive should be sent back to

manufacturer.

The AC drive detects

that the DC bus voltage

has exceeded its

maximum allowable

value.

1. Check whether the input voltage falls within

the rated AC drive input voltage.

2. Check for possible voltage transients.

3. Bus over-voltage may also be caused by

motor regeneration. Increase the decel time.

The AC drive

temperature sensor

detects excessive heat.

1. Ensure that the ambient temperature falls

within the specified temperature range.

2. Make sure that the ventilation holes are not

obstructed.

3. Remove any foreign objects on the heat sink

and check for possible dirty heat-sink fins.

4. Provide enough spacing for adequate

ventilation.

The AC drive detects

that the DC bus voltage

has fallen below its

minimum value.

Check whether the input voltage falls within the

rated AC drive’s input voltage.

Internal electronic

overload trip

1. Check for possible motor overload.

2. Check electronic thermal overload setting.

3. Increase motor capacity.

4. Reduce the current level so that the drive

output current does not exceed the value set

by the Motor Rated Current Pr.7-00.

The external terminal

EF-GND goes from OFF

to ON.

When external terminal EF-GND is closed, the

output will be turned off. (under N.O.E.F.)

Motor overload. Check

the parameter settings

( Pr.6-03 to Pr.6-05)

1. Reduce the motor load.

2. Adjust the over-torque detection setting to an

appropriate setting.

Over-current during

acceleration:

1. Short-circuit at motor

output.

2. Torque boost too high.

3. Acceleration time too

short.

4. AC drive output

capacity is too small.

1. Check for possible poor insulation at the

output line.

2. Decrease the torque boost setting in Pr.7-02.

3. Increase the acceleration time.

4. Replace with the AC drive with one that has a

higher output capacity (next HP size).

Over-current during

deceleration:

1. Short-circuit at motor

output.

2. Deceleration time too

short.

3. AC drive output

capacity is too small.

1. Check for possible poor insulation at the

output line.

2. Increase the deceleration time.

3. Replace with the AC drive with one that has a

higher output capacity (next HP size).

External Base Block.

AC drive output is

turned off.

1.When the external input terminal (B.B) is

active, the AC drive output will be turned off.

2.Disable this connection and the AC drive will

begin to work again.

Over-current during

steady state operation:

1. Short-circuit at motor

output.

2. Sudden increase in

motor loading.

3. AC drive output

capacity is too small.

1. Check for possible poor insulation at the

output line.

2. Check for possible motor stall.

3. Replace with the AC drive with one that has a

higher output capacity (next HP size).

Fault

Name Fault Descriptions Corrective Actions

Internal memory IC can

not be programmed.

1. Switch off power supply.

2. Check whether the input voltage falls within

the rated AC drive input voltage.

3. Switch the AC drive back on.

Internal memory IC can

not be read.

1. Check the connections between the main

control board and the power board.

2. Reset drive to factory defaults.

Drive’s internal circuitry

abnormal.

1. Switch off power supply.

2. Check whether the input voltage falls within

the rated AC drive input voltage. Switch on

the AC drive.

Auto accel/decel failure Don’t use the function of auto acceleration/

deceleration.

Hardware protection

failure Return to the factory.

Software protection

failure Return to the factory.

Communication Error

1. Check the connection between the AC drive

and computer for loose wires.

2. Check if the communication protocol is

properly set.

The AC drive detects

excessive drive output

current.

1. Check whether the motor is overloaded.

2. Reduce torque compensation setting as set in

Pr.7-02.

3. Increase the AC drive’s output capacity.

Note: The AC drive can withstand up to 150% of

the rated current for a maximum of 60 seconds.

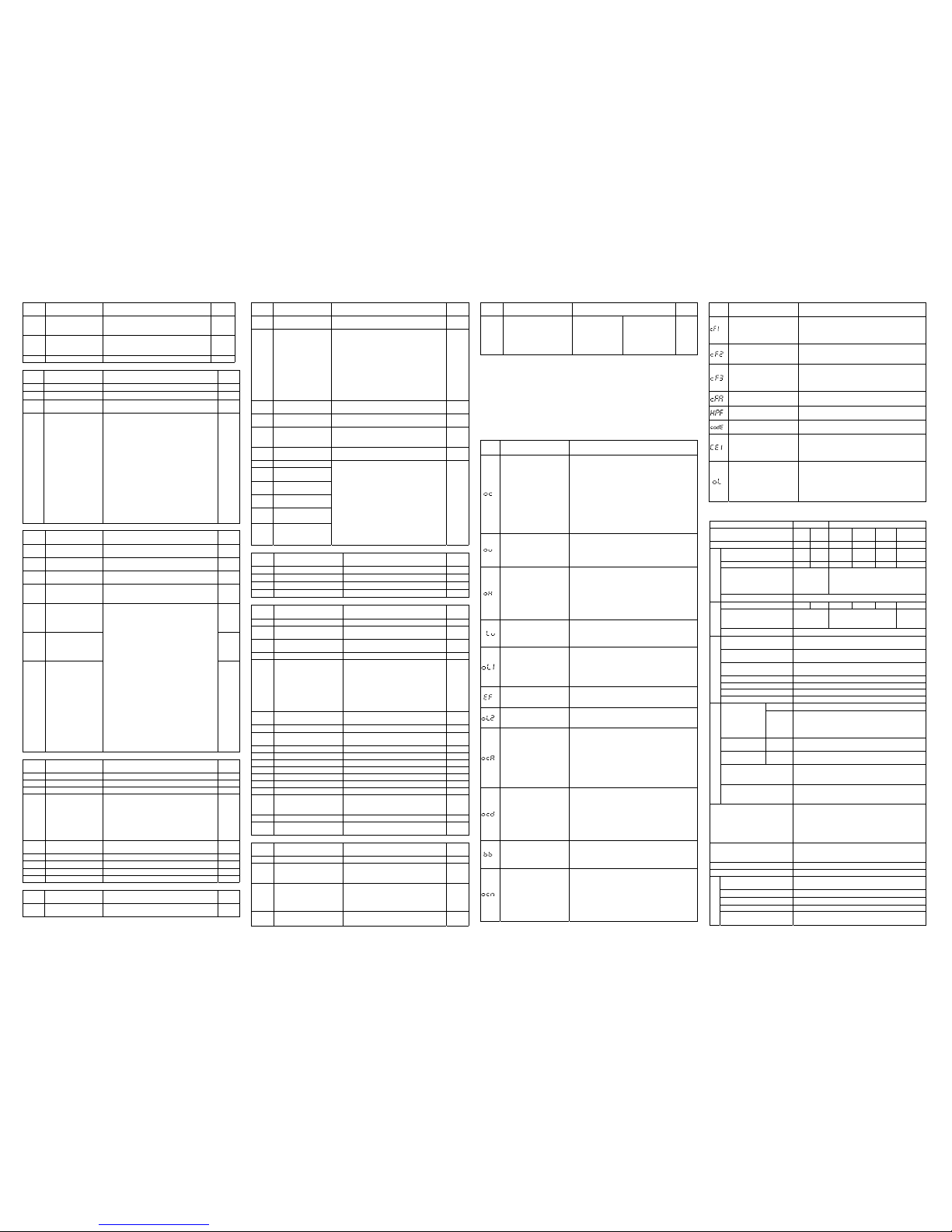

6 Standard Specifications

Voltage Class 115V 230V

Model Number

VFD-XXXLXXA/B 002 004 002 004 007 015

Applicable Motor Output (kW) 0.2 0.4 0.2 0.4 0.7 1.5

Rated Output Capacity

(KVA) 0.6 1.0 0.6 1.0 1.6 2.7

Rated Output Current (A) 1.6 2.5 1.6 2.5 4.2 7.0

Max. Output Voltage (V)

3-phase

corresponds

to double

input voltage

Three-phase corresponds to input

voltage

Output Rating

Rated Frequency (Hz) 1.0~400Hz

Rated Input Current (A) 6 9 4.9/1.9 6.5/2.7 9.7/5.1 Ì/9

Input voltage Tolerance

Single phase

90~132V

50/60Hz

Single / 3-phase

180~264V 50/60Hz

3-phase

180~264V

50/60Hz

Power

Frequency tolerance ±5%

Control system SVPWM (Sinusoidal Pulse Width Modulation, carried

frequency 3kHz~10kHz)

Output Frequency

Resolution 0.1Hz

Torque Characteristics Including the auto-torque, auto-slip compensation,

starting torque can be 150% at 5 Hz

Overload Endurance 150% of rated current for 1 minute

Accel/Decel Time 0.1~600Sec. (can be set individually)

V/F pattern V/F pattern adjustable

Control Characteristics

Stall Prevention Level 20~200%, setting of Rated Current

Keypad Setting by ▲▼ keys or V.R

Frequency

Setting External

Signal

Potentiometer-5KΩ/0.5W, DC 0 ~ +10V (input

impedance 47KΩ), 4~20mA (output impedance

250Ω), multi-function inputs1 to 3 (3steps, JOG,

UP/DOWN command), communication setting

Operation

Setting Keypad Setting by RUN//STOP keys

Signal External

Signal

M0,M1,M2,M3 can be combined to offer various

modes of operation, RS-485 communication port

Multi-function Input Signal

Multi-step selection 0 to 3, Jog, accel/decel inhibit,

first/second accel/decel switch, counter, PLC

Operation, external Base Block (NC,NO) selection

Operating Characteristics

Multi-function Output Signal

AC Drive Operating, Frequency Attained, Non-zero

speed, Base Block, Fault Indication, Local/Remote

indication, PLC Operation indication.

Other Function

AVR, S-curve, Over-Voltage Stall Prevention, DC

Braking, Fault Records, Adjustable Carried

Frequency, Starting Frequency Setting of DC

Braking , Over-Current Stall Prevention, Momentary

Power Loss restart, Reverse Inhibition, Frequency

Limits, Parameter Lock/Reset

Protection

Over Voltage, Over Current, Under Voltage,

Overload, Electronic thermal, Overheating,

Self-testing

Other Including EMI Filter

Cooling Forced air-cooling

Installation Location Altitude 1,000 m or below, keep from corrosive

gasses, liquid and dust

Ambient Temperature -10℃-40℃(Non-Condensing and not frozen)

Storage Temperature -20℃to 60℃

Ambient Humidity Below 90%RH (non-condensing)

Environment

Vibration 9.80665m/s2(1G) less than 20Hz, 5.88m/s2 (0.6G) at

20 to 50Hz