Delta PMT-24V350W1AK Instruction Manual

Other Delta Power Supply manuals

Delta

Delta CliQ II DRP048V120W1B Series Instruction Manual

Delta

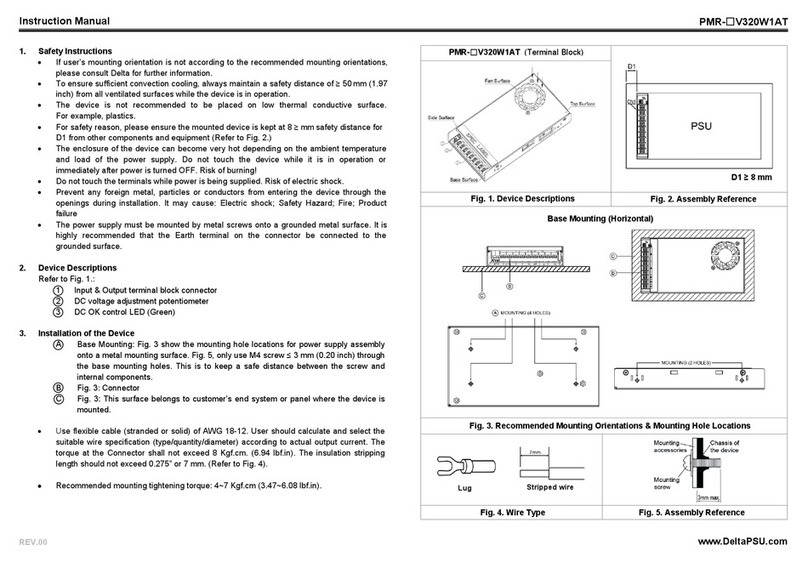

Delta PMR V320W1AT Series User manual

Delta

Delta A9000 User manual

Delta

Delta DRS-24V100W1A Series Instruction Manual

Delta

Delta PMC-24V150W1AA User manual

Delta

Delta HPH-20KA01KAT User manual

Delta

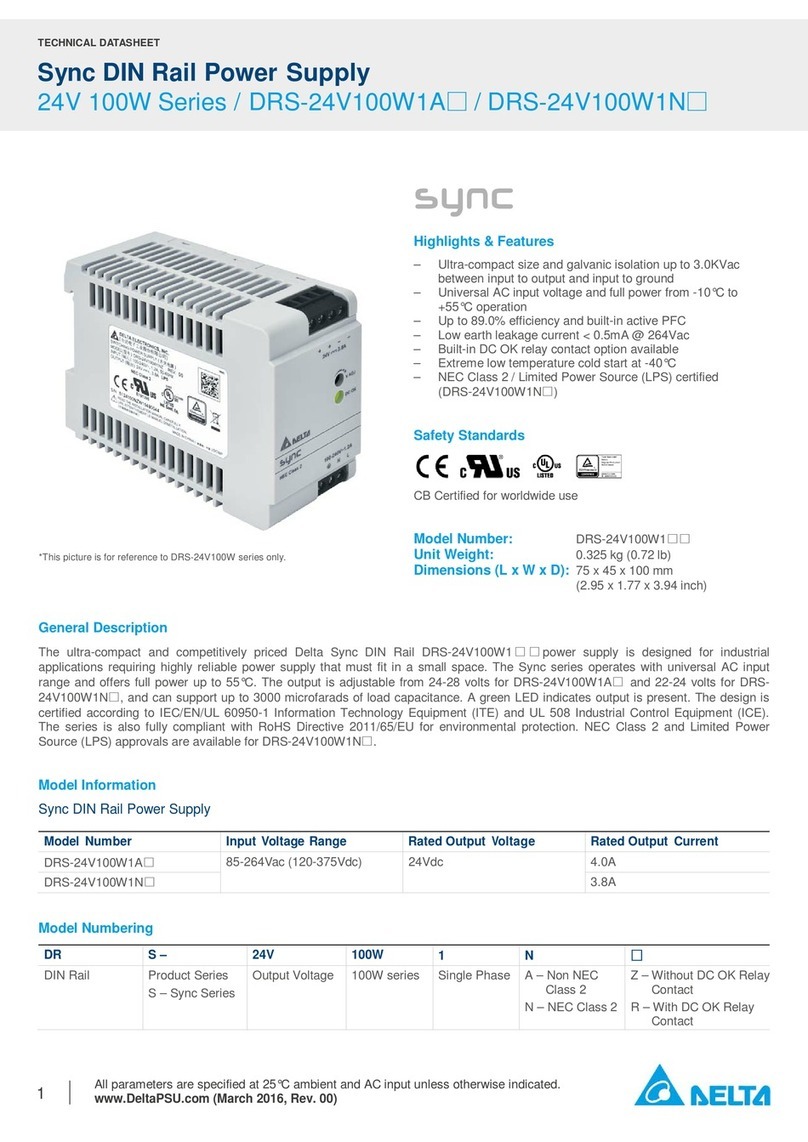

Delta sync 24V 100W Series Instruction Manual

Delta

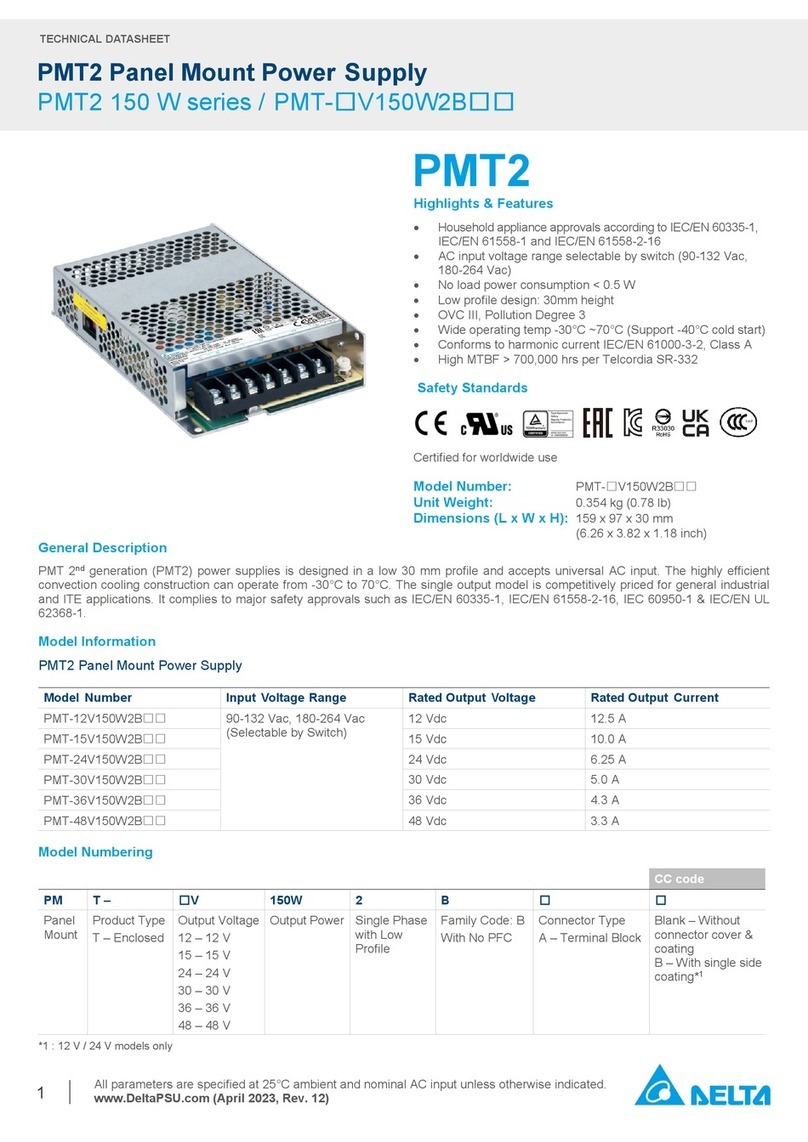

Delta PMT2 150 W Series Instruction Manual

Delta

Delta DRP-24V240W2BN Instruction Manual

Delta

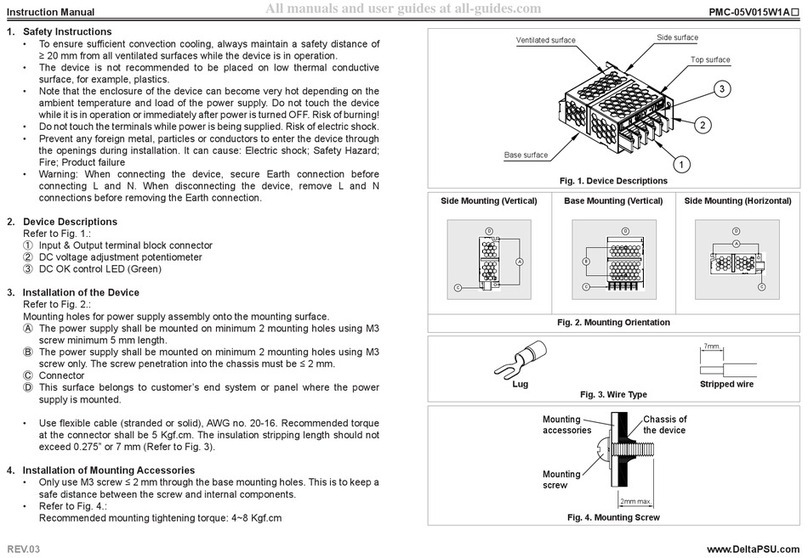

Delta PMC-05V015W1A Series User manual

Delta

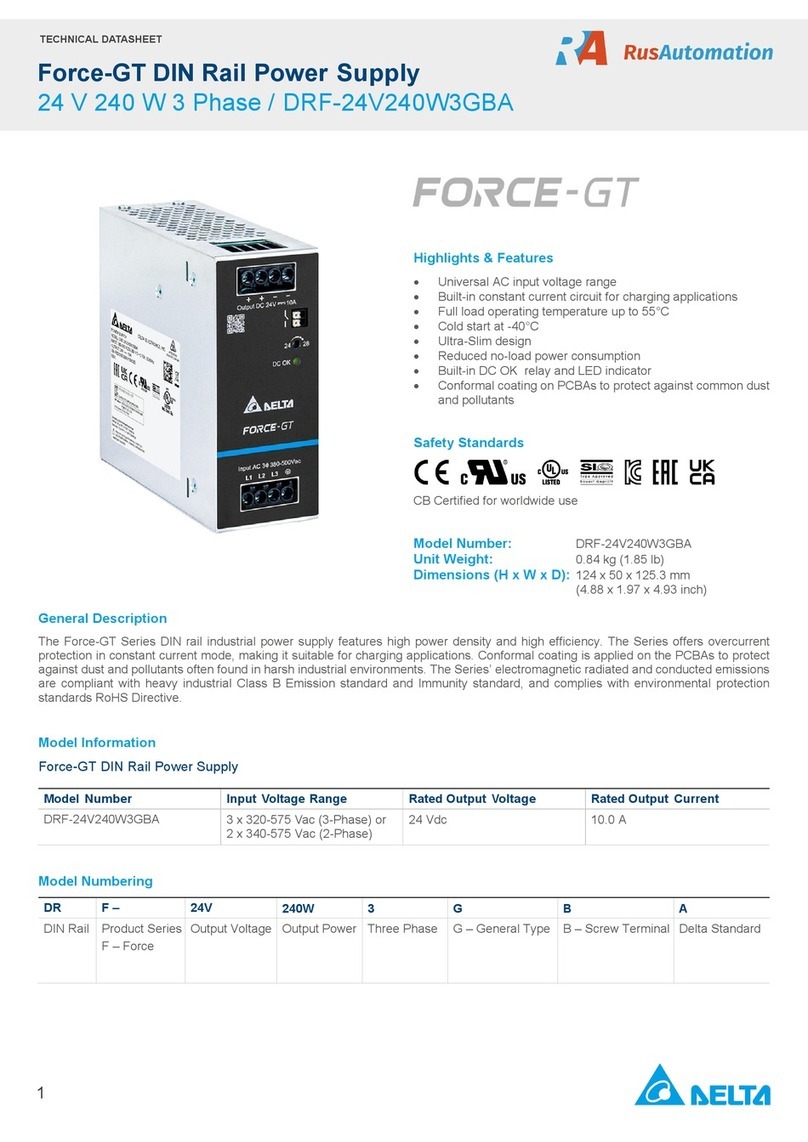

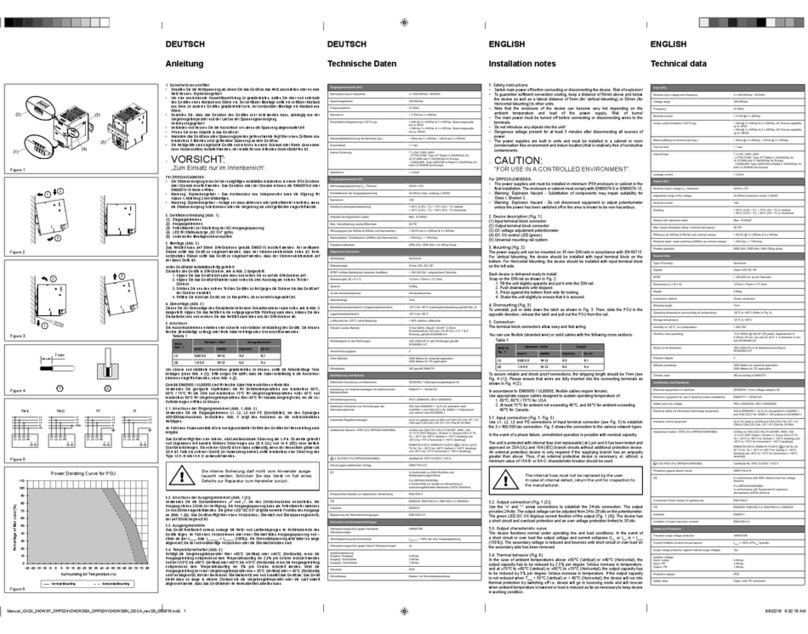

Delta FORCE-GT Series Instruction Manual

Delta

Delta PMC Series User manual

Delta

Delta PMT Series Instruction Manual

Delta

Delta DVP-SE Series User manual

Delta

Delta DRP024V240W3BA Quick start guide

Delta

Delta PMC Series User manual

Delta

Delta HPP-1K5A01KAT User manual

Delta

Delta DRP024V480W1B Series Instruction Manual

Delta

Delta LYTE DRL-24V240W1A Series Instruction Manual

Delta

Delta PMR V320WC Series User manual