DEMA ATLAS 844P Series User manual

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 1 of 17

Rev. C-33371

DEMA Engineering Company

10020 Big Bend Blvd.

St. Louis, MO 63122

(800) 325-3362 or (314) 966-3533

www.demaeng.com

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 2 of 17

Rev. C-33371

Introduction

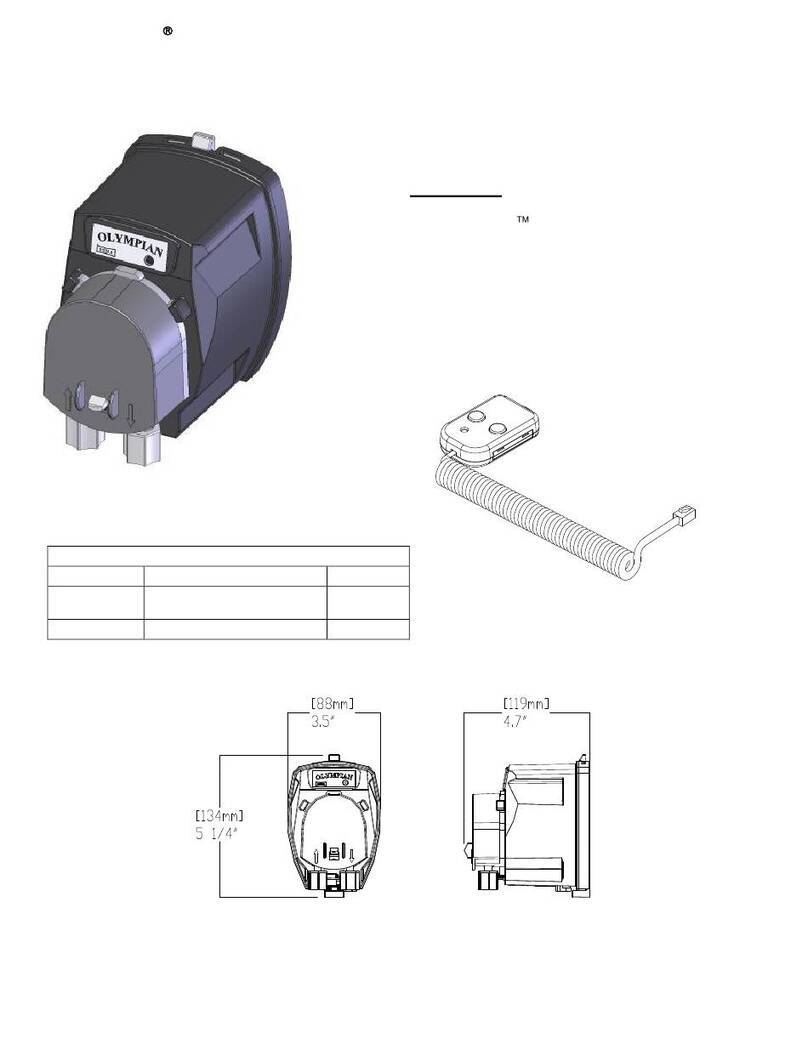

The DEMA 844P Laundry Master dispensing system has been designed to accurately deliver chemical

product to commercial laundry machines. The 844P uses the proven DEMA Quick Change peristaltic

pumps to deliver the chemical product to the laundry machine pocket. The Quick Change pumps and

main control are mounted in a durable and attractive ABS enclosure designed to provide easy access to

the various components inside.

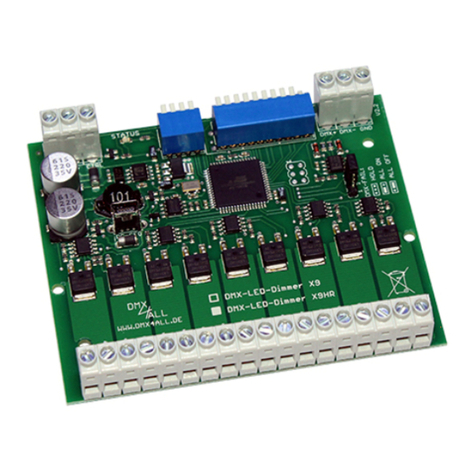

The various electronic components of the DEMA 844P Laundry Master use a “plug and play” concept to

provide easy setup. The heart of the 844P is the IQ-85 electronic control board that provides 30 wash

formula capability. The IQ-85 is mounted in the ABS enclosure with the display and buttons available on

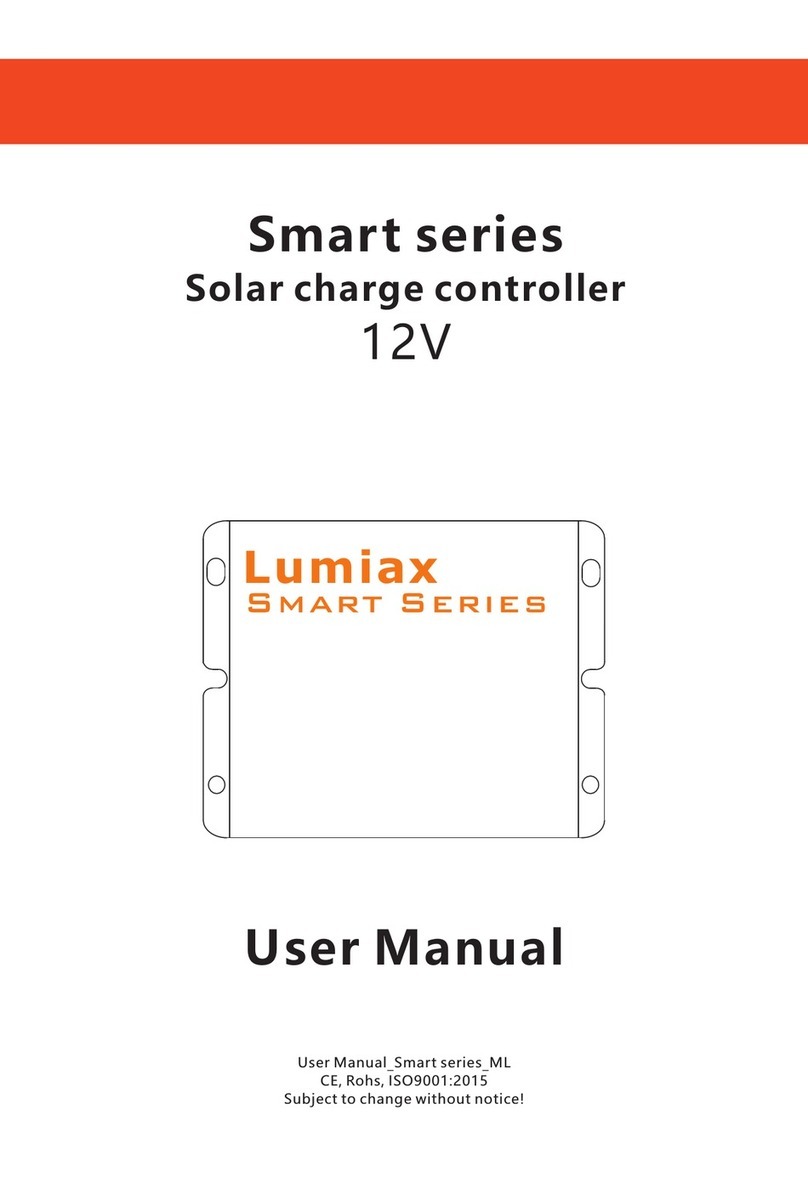

the front panel. Along with the IQ-85 is the self contained Signal Transfer Unit (STU), which can be

mounted at the laundry machine to receive trigger signals. Additionally, a handheld Enhanced Digital

Select Module (EDSM) is available to allow the user to interface with the system remotely. Both the STU

and the EDSM are connected to the IQ-85 via a low voltage communication cable.

844P Laundry Master Contents

The DEMA 844P Laundry Master includes the following:

•844P Dispensing System, which contains the pumps, the power supply, and the IQ-85 electronic

control board

•Hookup Kit, which contains communication cable, Velcro fasteners, various strain reliefs and wire

ties.

•Signal Transfer Unit (STU), for receiving trigger signals and sending commands back to the IQ-85

•Optionally, the 844P Dispensing System will come with an Enhanced Digital Select Module

(EDSM), for all programming functions, selecting 30 formulas, defeating bleach, and emergency

stop remotely.

•Optional Kits:

Tubing and pickup probe kit can also be provided which comes with 20ft of LDPE tubing per

pump, one pickup probe per pump, and wire ties to secure the tubing.

Before installing the 844P Laundry Master it will be helpful to read through the instructions to

become familiar with the system and its options concerning the installation and setup.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 3 of 17

Rev. C-33371

****** IMPORTANT ******

PLEASE READ THE NOTE BELOW AND CLEAR ALL PROGRAMS ON INITIAL USAGE OF

THIS PRODUCT.

ON THE VERY FIRST USAGE OF THE EDSM (NEW OUT OF THE BOX) CONNECT THE

EDSM TO THE LAUNDRY SYSTEM AS DESCRIBED ABOVE. POWER IT UP, ENTER

PROGRAMMING AND PROCEED TO THE UTILITY MENU. “CLEAR ALL PROGRAMS”

BEFORE USING THE EDSM FOR THE FIRST TIME. THIS WILL ONLY NEED TO BE DONE

AT INITIAL USAGE. IT IS NOT NECESSARY TO CLEAR ALL PROGRAMS AFTER THE

INITIAL CLEARING. SEE PROGRAMMING SECTION BELOW TO NAVIGATE TO

UTILITY MENU. PAGES 9 AND 10 OF THIS INSTRUCTION MANUAL SHOW THE

OPTIONS AND HOW TO “CLEAR ALL PROGRAMS.”

ALWAYS SEND A PROGRAM FILE FROM AN EDSM TO EVERY ATLAS THAT IS BEING

SETUP. THE EDSM USED TO SEND THE FILE MUST HAVE BEEN CLEARED AT INITIAL

USAGE AS DESCRIBED IN PREVIOUS PARAGRAPH. THE PROGRAM FILE CAN BE A

FILE THAT CONSIST OF NO SETUP OR A PROGRAM FILE THAT WAS USED ON A

PREVIOUS SETUP.

Laundry Room Survey

A complete survey of the laundry room or site installation should be completed in advance of starting the

Laundry Master installation.

1. Locate the power connection points on the laundry machine. The main power to the Laundry

Master must either be 120V or 230V 50/60Hz (+10%/-15% for voltage is acceptable).

2. Select a location to mount the Laundry Master enclosure on a wall that will allow access to the

chemical product containers and the chemical product feeds points on the laundry machine. The

Laundry Master should be kept away from moisture releasing machinery and from water being

splashed on the unit.

3. Mount the Laundry Master on a wall by use of appropriate screws and wall anchors.

4. Select a location to mount the Signal Transfer Unit (STU). The STU should be mounted close to,

or on, or possibly inside the laundry machine. The STU will need to be wired to the various

trigger signal sources on the machine. The trigger wires that are coming out of the STU are 36

inches in length and are used to receive the trigger signals. The STU can be mounted by use of the

self-adhesive Velcro that is included in the hook up kit. Keep in mind that the STU is wired to the

IQ-85 via the supplied communication cable.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 4 of 17

Rev. C-33371

5. If using the EDSM, select a location to mount the EDSM where the laundry machine operator can

easily access the buttons on the front of the EDSM module. Again, it can be mounted with the

self-adhesive Velcro that is included in the hook up kit. The EDSM can be connected to the IQ-85

or the STU by use of the supplied communication cable. See the EDSM instruction manual for

more information.

6. If using the DEMA 950 flush manifold or any other flush manifold , select a location that will

allow all the electrical (power for solenoid valve and pressure switch) and tubing connections. It

should be noted that the flush output on the IQ-85 is a 24VDC signal. The solenoid coil for the

flush valve will need to match this output signal.

Cleaning Instructions

Do not expose inside of unit to moisture! Do not expose unit to direct water/chemical spray! Clean

external shell with damp cloth.

844P Pump Configurations

The pumps are numbered 1 through 6 from left to right.

Electrical Installation

All installations must be in accordance with city, county, parish, state or provincial electrical codes and

should be performed by a certified electrician. A ½” nonmetallic conduit system must be used to install

the power cord. For questions, please contact local licensed electrical contractor.

Before the electrical installation, it is important to understand the various modes that the 844P Laundry

Master has to offer. The following describe the 3 main modes, however there are sub-options that can be

set up within these 3 modes. See the setup section for additional information.

Formula Select Mode:

This is where the unit can be programmed with up to 30 different formulas. Each formula is

driven to operate by individual trigger sources that are generated by the laundry machine.

Sequence Mode:

This is where the unit can be programmed to count a single event from the laundry machine. A

good example of this is using the drain valve on the laundry machine as a trigger source. The IQ-

85 will count the drain valve operations and will operate pumps based on these counts. Up to 30

formulas can be programmed in this mode as well.

Relay Mode:

There is only one programming variable to set on the IQ-85. A flush can be set to run with, and

for an additional time after, each pump operation. Otherwise the IQ-85 is not programmed, but

instead the laundry machine is programmed to provide various formulas. The IQ-85 acts like a

relay board and will only operate pumps for the length of time that the STU receives a trigger

signal from the laundry machine.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 5 of 17

Rev. C-33371

Auto Formula Select

One sub-option to become familiar with before wiring the STU is Auto Formula Select. This

feature allows the formula to be selected based on a trigger signal that is received from the laundry

machine. It is necessary to have a separate programmable input from the laundry machine to

correctly use the Auto Formula Select. For more information, see Auto Formula Select section in

this instruction manual.

1. CAUTION: All electrical power must be turned off to the laundry machine and any other

circuit that is to be used for this installation. Lockout and tag procedures must be observed

when installing this device. Never open the DEMA Laundry Master while power is applied.

Signals may be active from laundry machine, even with the DEMA Laundry Master power

turned off. Use appropriately rated insulated wiring, electrical fixtures and other materials

that meet all applicable electrical and building codes.

2. Connect the power to the Laundry Master. The power requirement is from 100VAC to

240VAC 50/60 Hz. Power should be applied to Laundry Master anytime the laundry machine is

on. Some laundry machines have a terminal block setup for power (see schematic or owner’s

manual for the specific machine being used). Locate the power terminal block inside the Laundry

Master enclosure. Connect “hot” or “live” wire to the terminal labeled “L1”. Connect the

“return line” to the terminal block position labeled “L2”. The ground wire MUST be

connected to a suitable earth ground point. The power line should be secured by use of proper

electrical fitting through access hole in Laundry Master enclosure. The access hole is sized to

accept a ½” conduit fitting. The power line must also be secured properly between the laundry

machine or power source and the Laundry Master according to any electrical codes that apply.

3. Connect the flush manifold. See note labeled flush switch below if a flush manifold is not being

used. If using a flush manifold, the solenoid valve that supplies the manifold must be rated for

24V DC. The valve should be connected to the output terminal position labeled “FLUSH” on the

IQ-85 control board. In addition, a manifold flush switch must be wired to the terminals labeled

“Flush SW” on the IQ-85 control board.

Flush Switch: When a flush manifold is not used, step number 3 can be skipped. However, it is

essential that a jumper be connected between the “Flush SW” terminals on the IQ-85 control

board. The jumper is installed at the factory. Examine the unit to be installed to assure that it has

the jumper installed. Without the jumper, the Laundry Master pumps will not run. If a jumper

needs to be installed, use a short piece (2-4 inches) of insulated 18GA electrical wire stripped

approximately 3/16” at each end.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 6 of 17

Rev. C-33371

NO. QTY. PART NO. DESCRIPTION

1 6 81-13-4 Modular Connector

2 1 81-13-2 Modular Connector

3 1 81-13-4 Modular Connector

GREEN/YELLOW

SWITCH

MOUNTED ON

ACCESS PANEL

MOTORMOTOR

3

6

5

BROWN

BLACK

LOW VOLTAGE

POWER CABLE W/

BARRER PLUG

JUMPER CABLE MUST

CONNECT ACROSS THE

PAIR OF "FLUSH SW"

TERMINALS

21

4

3

NO. QTY. PART NO. DESCRIPTION

1 1 84-153-1 Control Board & Display Assy.

2 1 82-7-2 Jumper Line

3 2 81-196-4 Cable Assy.

4 1 84-125-4 Power Supply Cable

5 1 80-106-4 Power Cable

6 1 81-186-7 Access Panel Assy.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 7 of 17

Rev. C-33371

4. Wire the STU to the laundry machine. The hookup configuration will depend on

which of the operational modes the DEMA 844P Laundry System will be used. The

following two tables show the wiring configurations for the input signals to the

STU. The first is for normal and relay modes and the second is for sequence mode.

Verify the mode that will be used and wire the STU according to the appropriate

table below using the leads that are coming out of the left side of the STU. Keep in

mind that trigger sources should be at least 24VAC but no higher than 240VAC

50/60Hz.

STU Wiring Configuration (For Formula Select Mode or Relay Mode)

Trigger Input Line (signal) Common Function of Trigger Input

1 Black White/Black Stripe Signal Pump 1

2 Brown White/Brown Stripe Signal Pump 2

3 Red White/Red Stripe Signal Pump 3

4 Orange White/Orange Stripe Signal Pump 4

5 Yellow White/Yellow Stripe Signal Pump 5

6 Green White/Green Stripe Signal Pump 6

7 Blue White/Blue Stripe Signal Flush (optional)

8 Purple White/Purple Stripe Auto Formula Select

STU Wiring Configuration (For Sequence Mode)

Trigger Input Line (signal) Common Function of Trigger Input

1 Black White/Black Stripe Event Trigger

2 Brown White/Brown Stripe Event Trigger

3 Red White/Red Stripe

Reset (optional) example, door switch

4 Orange White/Orange Stripe

5 Yellow White/Yellow Stripe

6 Green White/Green Stripe

7 Blue White/Blue Stripe

Not Used

8 Purple White/Purple Stripe Auto Formula Select

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 8 of 17

Rev. C-33371

5. Auto Formula Select. This allows the formulas to be selected based on a trigger

signal that is received from the laundry machine. The following list outlines the

setup of this feature: The 8th trigger input on the STU is used for this purpose (see

table in the electrical installation section of Laundry Master Instruction Manual). A

trigger source that can be programmed at the laundry machine will be required. The

timing of this trigger source is what determines which formula is selected by the IQ-

80. To determine the amount of signal time for any formula simply calculate as

follows: i. Multiply the formula number by 2 then subtract 1

1. Example: Formula 7 needs a trigger signal equal to 13 seconds.

(7 X 2 = 14 then 14-1 = 13). A 13 second trigger signal to STU

input number 8 (purple and purple striped wires) will change the

Atlas to formula 7.

6. Connect the EDSM (See EDSM instruction manuals for more details) and STU modules to the IQ-

85 by using the RJ45 patch cords that are supplied with the Laundry Master. The STU is required

in all installations, but the EDSM is optional. It is possible to connect the EDSM to the STU RJ45

jack instead of connecting to the IQ-85, providing that the STU is connected to the IQ-85. See the

following note concerning the EDSM.

EDSM Note: The EDSM module is a hand held, remote control that gives the operator the ability

to select formulas, defeat a bleach operation, or do an emergency stop. It is not necessary to use it,

but without the EDSM the only way to manually select a formula would be to select it at the IQ-85

board in the front of the enclosure.

Note: The patch cord is a communication link between the IQ-85 board, the STU and the EDSM

and can be subjected to electrical interference when not installed properly. When securing the

RJ45 patch cord between the On-Premise Laundry Controller and the Laundry Master, avoid sharp

edges, electrical motors and relays; additionally do not run parallel to electrical power lines and

conduit.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 9 of 17

Rev. C-33371

Tubing Connections

ALWAYS WEAR PROTECTIVE CLOTHING AND EYEWEAR WHEN WORKING WITH

CHEMICALS PRODUCTS.

An optional installation kit may be ordered with the 844P Laundry Master. The kits includes a 20ft of

LDPE tubing per pump to connect from the chemical container to the DEMA 844P pump, and from the

DEMA 844P pump to the fittings on the machine and 18” pickup tubes designed to accommodate 5 gallon

buckets.

For identification purposes, the pumps are identified starting with 1 and up to a possible 6 depending on

the model. In all cases pump number 1 is the pump that is furthest left, count up as you see pumps to the

right of this position. Included with the 844P Laundry Master is a sheet of product labels that can be

adhered to the front of the Laundry Master or any other useful locations to identify the product that each

pump is supplying.

Measure the length of tubing needed for the suction side from the chemical container to the inlet of the

pump and then cut the tubing to the proper length. The 18” pickup tubes may be used with 5-gallon

buckets of chemical products. Feed the LDPE tubing through the compression nut and sleeve and into the

pickup tube until the LDPE tubing is about a ¼” from the bottom of the pickup tube (LDPE tubing should

not stick out through the bottom of pickup tube). Tighten the compression nut to secure LDPE tubing.

Route the tubing to the suction side of the pump and insert into squeeze tube approximately ½”. Secure

the tubing together by tightening a cable tie around the squeeze tube. Use the same procedure on the

outlet of the squeeze tube and route the LDPE tubing to the injection feed points of the laundry machine.

Cut off all excess tubing and keep tubing away from hot surfaces and sharp edges to prevent damage or

leakage.

At this point the Laundry Master installation is complete. See IQ-85 OPL Laundry Control Board

instructions for setup and programming.

Laundry Master Operation

Once the system has been programmed and set up to the desired configuration the 844P Laundry Master

is ready for operation.

Priming the Pumps

There are two ways to prime a pump. The first way, is to press the LEFT arrow on the front of the 844P.

“P1” will be displayed indicating pump 1. Use the UP and DOWN arrows to select the desired pump.

Press the ENTER button to start and stop the pump. Pressing the RIGHT arrow will return the 844P to

formula select mode. If no action is taken in the pump priming mode the 844P will return to formula

select mode after 30 seconds. The second way, is to use the EDSM (Enhanced Digital Selection Module).

Refer to the EDSM Instruction Sheet I-901.

Emergency Stop

At anytime, the pumps and flush can be stopped by pressing the “STOP” button on the EDSM. When

pressed, it will also reset the system to a starting point of the formula.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 10 of 17

Rev. C-33371

Changing Formulas

Formulas can be manually changed at the EDSM or on the front of the 844P.

Use the UP and DOWN arrows on the 844P to select the desired formula. If in the pump priming mode

pressing the RIGHT arrow will return the 844P to formula select mode.

The EDSM has 30 formula capability and has a numeric display that will identify the formula. See the

EDSM instruction sheet for more details.

Bleach Defeat

The bleach defeat function is activated with the EDSM. See the EDSM instruction sheet for more details.

Load Counts

Load counts are displayed on the EDSM. See the EDSM instruction sheet for more details.

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 11 of 17

Rev. C-33371

Replacement Parts

Replacement Parts

Item No. DEMA Part Number Description

1 IQ-85 Control Board

2

(not shown) EDSM Remote Kit

3 84.65.6 STU Kit

4 80.59.60

80.59.105 60 RPM Gear/Motor 24VDC

105 RPM Gear/Motor 24VDC

6 84.65.9 80VA Power Supply Kit

7 83.11 Power Switch (Toggle Switch)

8 84.65.4 Toggle Switch Boot Mounting Nut

13 84.48.2 Fuse 2A, 250V 5 X 20mm Kit

14

(not shown) 84.27.3 25 Foot, RJ-45 Patch Cable (connection between STU-DSM/FSM-IQ-80)

15

(not shown) 84.27.4 6 Foot, RJ-45 Patch Cable (connection between STU-DSM/FSM-IQ-80)

Accessory Replacement Parts

DEMA Part No Description

25-68-20 20 ft of ¼” O.D. LDPE Tubing

25-68-40 40 ft of ¼” O.D. LDPE Tubing

25-68-60 60 ft of ¼” O.D. LDPE Tubing

25-68-80 80 ft of ¼” O.D. LDPE Tubing

25-68-100 100 ft of ¼” O.D. LDPE Tubing

25-68-120 120 ft of ¼” O.D. LDPE Tubing

25-115 20 ft of 3/8” O.D. LDPE Tubing

25-115-40 40 ft of 3/8” O.D. LDPE Tubing

25-115-60 60 ft of 3/8” O.D. LDPE Tubing

25-115-80 80 ft of 3/8” O.D. LDPE Tubing

25-115-100 100 ft of 3/8” O.D. LDPE Tubing

25-115-120 120 ft of 3/8” O.D. LDPE Tubing

80-66 10” PVC Pick-up Tube Assembly

80-66-2 18” PVC Pick-up Tube Assembly

81-16-1 8” Tie Wrap (for securing wiring or tubing)

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 12 of 17

Rev. C-33371

SIGNAL TRANSFER UNIT

(STU)

84-17-2

INSTALLATION KIT PARTS

QUANTITY PART NUMBER DESCRIPTION

2 83-16-1 Velcro, Black Hook & Loop

1 L709-1 Laundry Product Label Sheet

8 81-16-1 Tie Wrap, 8” Lg.

1 84-9-1 Signal Transfer Unit (STU) Assembly

1 84-152-2 25’ RJ445 Cable

1 84-152-1 6’ RJ45 Cable

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 13 of 17

Rev. C-33371

Technical Specifications

Main Power 100V – 240V 50/60 Hz 1.5A

Motor/Solenoid Rating 24 VDC

Case High Impact

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 14 of 17

Rev. C-33371

13

14

38

1516

18

17

20

19

21

15

6

22

23

6

22

15

24

615 25

20

26

26

39

HOOK POINTS

UP

HOOK POINTS

DOWN

32

33

31

31

28

28

17

HOOK POINTS

UP

39

HOOK POINTS

DOWN

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 15 of 17

Rev. C-33371

NO. QTY. DEMA NO. DESCRIPTION

1 4 81-20-1 #4 HI-LO SCREW

2 1 84-153-1 CONTROL BOARD AND DISPLAY ASSY.

3 1 81-147-1 KEY PAD

5 1 81-139-1 CONTROL COVER

6 11 44-116-2 #8 X 3/8" HI-LO SCREW

7 1 81-137-1 FIREWALL

8 4 41-63-10 #8-32 X 1 3/4 PHIL. SS SCREW

10 1 81-138-1 POWER SUPPLY BRACKET

11 1 84-154-1 POWER SUPPLY (includes 84-xxx-x power supply cable)

12 1 84-125-1 POWER SUPPLY CABLE

13 8 44-116-1 #8 X 1/2 HI-LO SCREW

14 1 81-170-1 ENCLOSURE ASSY. BACK

15 7 81-47-1 1/2" HOLE PLUG

16 1 81-187-1 MOUNTING BRACKET

17 5 41-40-2 #6-32 X 1/2 PHIL SS SCREW

18 1 81-168-1 ENCLOSURE ASSY.

19 1 81-186-11 LARGE ACCESS PANEL ASSY.

20

1

1 81-186-5

81-186-7 SMALL ACCESS PANEL ASSY. W/TWO HOLE PLUGS

SMALL ACCESS PANEL ASSY. W/CONDUIT FITTING

21 1 81-148-3 CONDUIT FITTING

22 2 81-47-6 1" HOLE PLUG

23 1 81-47-5 3/4” HOLE PLUG

24 1 81-16 LIQUID-TIGHT FEED THROUGH

25 1 81-47-4 7/8” HOLE PLUG

26 2 81-159-1 GASKET - PUMP BASE

28 2 – 6

2 – 6 81-173-5

81-173-1 PUMP 2 SPRING 1/4” ID – 105RPM

PUMP 2 SPRING 1/4" ID – 60RPM

29 6 81-19-7 #8 SCREW ( HINGE SCREW)

30 1 81-140-1 HINGE

31 2 81-29-2 CAPTIVE SCREW

32 1 L942 DISPLAY LABEL

33 1 L941 ATLAS LABEL

35 2 81-32-44 RED CABLE ASSEMBLY

36 2 81-32-43 BLACK CABLE ASSEMBLY

38 1 81-198-4 PUMP MODULE ASSY. W / 2 SPRING ¼” ID 105 RPM

PUMP

39 2 81-144-1 SIDE MODULE JOINT

40 1 81-173-1 DETERGENT PUMP - 60 RPM (SEE BREAKOUT

DRAWING)

44 4 81-193-1 SPACER

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 16 of 17

Rev. C-33371

81-173-5

PUMP ASSEMBLY

NO. QTY

. DEMA NO. DESCRIPTION

1 1 81-174-1 PUMP COVER

2 1 81-172-1 (Detergent) ROLLER ASSY.

3

1

2

81-177-1 (Detergent)

--------------------------------------

81-176-1 (Detergent)

SQUEEZE TUBE

(includes plastic connectors)

---------------------------------------

Plastic connectors only

4 4 25-85-2 SCREW

5 1 81-128-2 PUMP BASE

6 1 80-59-105MK-1

(Detergent) GEARMOTOR – 105 rpm

Replacement Kit

1 oz. 81-17-5 SILICONE LUBE PACKET

DEMA ATLAS 844P

™

SERIES

LAUNDRY CONTROL

I-907 Page 17 of 17

Rev. C-33371

Return Policy

No merchandise may be returned for credit without DEMA Engineering Company’s written permission.

Return Merchandise Authorization (RMA) number required in advance of return.

Warranty

DEMA products are warranted against defective material and workmanship under normal use and service

for one year from the date of manufacture. This limited warranty does not apply to products that have a

normal life shorter than one year or failure and damage caused by chemicals, corrosion, improper voltage

supply, physical abuse or misapplication. Rubber and synthetic parts such as “O”-rings, diaphragms,

squeeze-tubes and gaskets are considered expendable and are not covered under warranty. This warranty

is extended only to the original buyer of DEMA products. If products are altered or repaired without prior

approval of DEMA, this warranty will be void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows

them to be defective, they will be repaired or replaced without charge. F.O.B. factory DEMA assumes no

liability for damages. Return merchandise authorization number to return units for repair or replacement

must be granted in advance of return.

NOTE:

This unit shall be used within the following limits:

For Indoor Use Only!

Max Altitude: 2000 Meters

Environmental Temp: 0 – 50 °C

Installation Category: II

Pollution Degree: II

Disclaimer:The integrity and operational characteristics of this unit are not guaranteed outside

of the above mentioned parameters. Use of this unit outside of these parameters nullifies

warranty.

Table of contents

Other DEMA Controllers manuals