dIXEL

Operating Instructions 1592009367

1592009367 XW60LS GB rel.1.0 27.10.06.doc XW60LS 2/4

0. Enter the “Pr1” level.

1. Select “Pr2” parameter and press the “SET” key.

2. The “PAS” flashing message is displayed, shortly followed by “0 - -” with a flashing zero.

3. Use oor nto input the security code in the flashing digit; confirm the figure by pressing

“SET”. The security code is “321“.

4. If the security code is correct the access to “Pr2” is enabled by pressing “SET” on the last

digit.

Another possibility is the following: after switching ON the instrument the user can push Set and

DOWN keys within 30 seconds.

NOTE: each parameter in “Pr2” can be removed or put into “Pr1” (user level) by pressing “SET”

+ n. When a parameter is present in “Pr1” LED is on.

4.9 HOW TO CHANGE THE PARAMETER VALUE

1. Enter the Programming mode.

2. Select the required parameter with oor n.

3. Press the “SET” key to display its value ( and LED starts blinking).

4. Use oor nto change its value.

5. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 15s without pressing a key.

NOTE: the new programming is stored even when the procedure is exited by waiting the time-

out.

4.10 HOW TO LOCK THE KEYBOARD

Keep the oand nkeys pressed together for more than 3 s the oand nkeys.

2. The “POF” message will be displayed and the keyboard is locked. At this

point it is only possible the viewing of the set point or the MAX o Min

temperature stored and to switch ON and OFF the light, the auxiliary output

and the instrument.

TO UNLOCK THE KEYBOARD

Keep the oand nkeys pressed together for more than 3s.

4.11 ON/OFF FUNCTION

By pushing the ON/OFF key, the instrument shows “OFF” for 5 sec. and the

ON/OFF LED is switched ON.

During the OFF status, all the relays are switched OFF and the regulations are

stopped;

N.B. During the OFF status the Light button is active.

4.12 TO SEE THE PROBE VALUES

1. Enter in “Pr2” level.

2. Select “Prd” parameter with oor n.

3. Press the “SET” key to display “Pb1” label alternate with Pb1 value.

4. Use o and nkeys to display the other probe values.

5. Press “SET” to move to the following parameter.

5. PARAMETER LIST

REGULATION

Hy Differential: (0,1÷25,5°C; 1÷45°F): Intervention differential for set point, always positive.

Compressor Cut IN is Set Point Plus Differential (Hy). Compressor Cut OUT is when the

temperature reaches the set point.

LS Minimum set point limit: (-50,0°C÷SET; -58°F÷SET) Sets the minimum acceptable value

for the set point.

US Maximum set point limit: (SET÷110°C; SET÷230°F) Set the maximum acceptable value

for set point.

OdS Outputs activation delay at start up: (0÷255 min) This function is enabled at the initial

start up of the instrument and inhibits any output activation for the period of time set in the

parameter. (Light can work)

AC Anti-short cycle delay: (0÷30 min) interval between the compressor stop and the

following restart.

CCt Thermostat override: (0min ÷23h 50min) allows to set the length of the continuous cycle.

Can be used, for instance, when the room is filled with new products.

Con Compressor ON time with faulty probe: (0÷255 min) time during which the compressor

is active in case of faulty thermostat probe. With COn=0 compressor is always OFF.

COF Compressor OFF time with faulty probe: (0÷255 min) time during which the compressor

is off in case of faulty thermostat probe. With COF=0 compressor is always active.

CH Type of action: CL = cooling; Ht = heating.

DISPLAY

CF Temperature measurement unit: °C = Celsius; °F = Fahrenheit. When the measurement

unit is changed the SET point and the values of some parameters have to be modified.

rES Resolution (for °C): (in = 1°C; de = 0,1°C) allows decimal point display.

dE = 0,1°C; in = 1 °C

Lod Local display : select which probe is displayed by the instrument:

P1 = Thermostat probe

P2 = Evaporator probe

DEFROST

tdF Defrost type:

rE = electrical heater (Compressor OFF)

in = hot gas (Compressor and defrost relays ON)

EdF Defrost mode:

in = interval mode. The defrost starts when the time “Idf” is expired.

Sd = Smartfrost mode. The time IdF (interval between defrosts) is increased only when

the compressor is running (even non consecutively).

SdF Set point for SMARTFROST: (-30÷30 °C/ -22÷86 °F) evaporator temperature which

allows the IdF counting (interval between defrosts) in SMARTFROST mode.

dtE Defrost termination temperature: (-50,0÷110,0°C; -58÷230°F) (Enabled only when the

evaporator probe is present) sets the temperature measured by the evaporator probe which

causes the end of defrost.

IdF Interval between defrosts: (1÷120h) Determines the time interval between the beginning

of two defrost cycles.

MdF (Maximum) duration of defrost: (0÷255 min) When P2P = n, no evaporator probe, it

sets the defrost duration, when P2P = y, defrost end based on temperature, it sets the

maximum length for defrost.

dFd Display during defrost:

rt = real temperature; it = temperature reading at the defrost start;

Set = set point; dEF = “dEF” label; dEG = “dEG” label;

dAd Defrost display time out: (0÷255 min) Sets the maximum time between the end of defrost

and the restarting of the real room temperature display.

dSd Start defrost delay: ( 0÷99min) This is useful when different defrost start times are

necessary to avoid overloading the plant.

Fdt Drain down time: (0÷60 min.) time interval between reaching defrost termination

temperature and the restoring of the control’s normal operation. This time allows the

evaporator to eliminate water drops that might have formed due to defrost.

dPO First defrost after start-up:

y = Immediately; n= after the IdF time

dAF Defrost delay after fast freezing: (0min÷23h 50min) after a Fast Freezing cycle, the first

defrost will be delayed for this time.

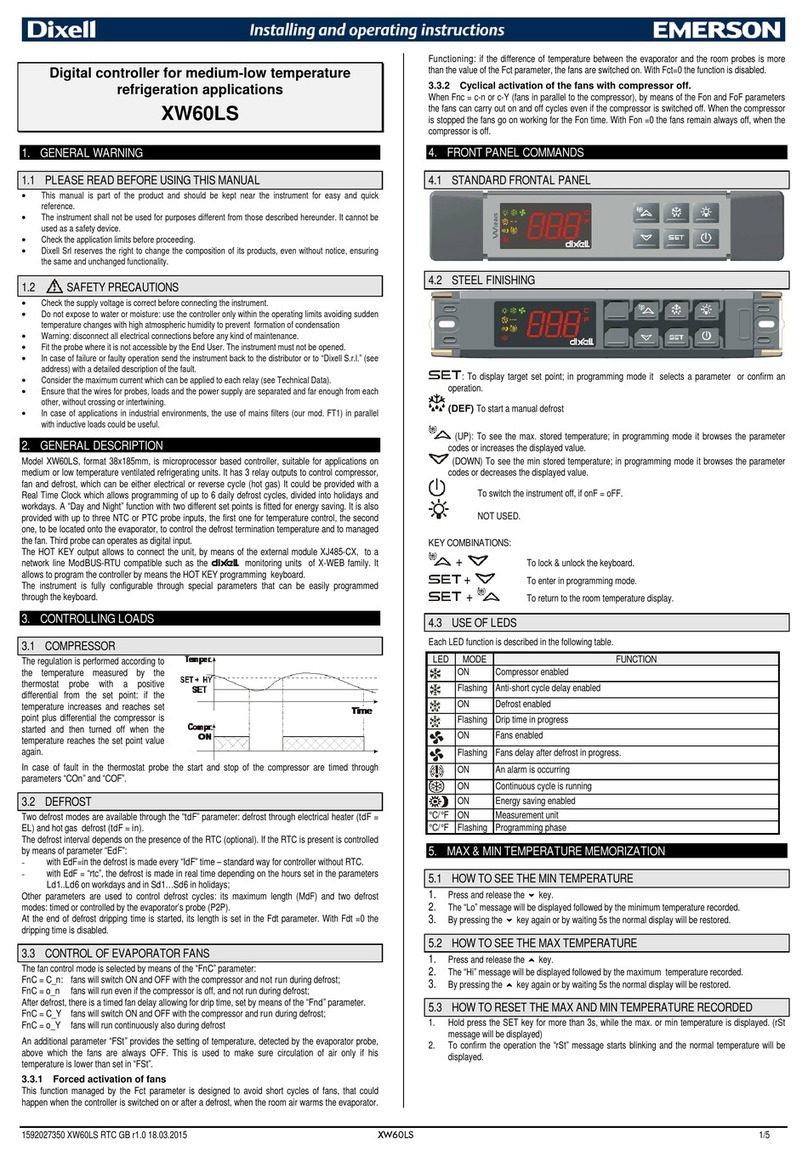

FANS

FnC Fan operating mode:

C-n = running with the compressor, OFF during the defrost;

C-y = running with the compressor, ON during the defrost;

O-n = continuous mode, OFF during the defrost;

O-y = continuous mode, ON during the defrost;

Fnd Fan delay after defrost: (0÷255 min) The time interval between the defrost end and

evaporator fans start.

FSt Fan stop temperature: (-50÷110°C; -58÷230°F) setting of temperature, detected by

evaporator probe, above which the fan is always OFF.

ALARMS

ALC Temperature alarm configuration

rE = High and Low alarms related to Set Point

Ab = High and low alarms related to the absolute temperature.

ALU High temperature alarm setting:

ALC= rE, 0 ÷50°C or 90°F

ALC= Ab, ALL ÷110°C or 230°F

when this temperature is reached and after the ALd delay time the HA alarm is enabled.

ALL Low temperature alarm setting:

ALC = rE , 0 ÷50 °C or 90°F

ALC = Ab , - 50°C or -58°F ÷ALU

when this temperature is reached and after the ALd delay time, the LA alarm is enabled,.

AFH Temperature alarm and fan differential: (0,1÷25,5°C; 1÷45°F) Intervention differential

for temperature alarm set point and fan regulation set point, always positive.

ALd Ritardo allarme temperatura: (0÷255 min) intervallo di tempo tra la rilevazione di un

segnale di allarme temperatura e la sua segnalazione.

dAO Delay of temperature alarm at start-up: (0min÷23h 50min) time interval between the

detection of the temperature alarm condition after the instrument power on and the alarm

signalling.

EdA Alarm delay at the end of defrost: (0÷255 min) Time interval between the detection of the

temperature alarm condition at the end of defrost and the alarm signalling.

PROBE INPUTS

Ot Thermostat probe calibration: (-12.0÷12.0°C/ -21÷21°F) allows to adjust possible offset

of the thermostat probe.

OE Evaporator probe calibration: (-12.0÷12.0°C/ -21÷21°F) allows to adjust possible offsets

of the evaporator probe.

P2P Evaporator probe presence: n= not present: the defrost stops only by time; y= present:

the defrost stops by temperature and time.

OTHER

oA1 Third realy configuration: ALr= alarm; Fan= Fan; Lig = Light; AUS = don’t

use it; OnF = on -off

PbC Type of probe: it allows to set the kind of probe used by the instrument:

PbC = PBC probe, ntC = NTC probe.

rEL Release software: (read only) Software version of the microprocessor.

Ptb Parameter table: (read only) it shows the original code of the dIXEL parameter map.

Prd Probes display: (read only) display the temperature values of the evaporator probe Pb2.

Pr2 Access to the protected parameter list (read only).

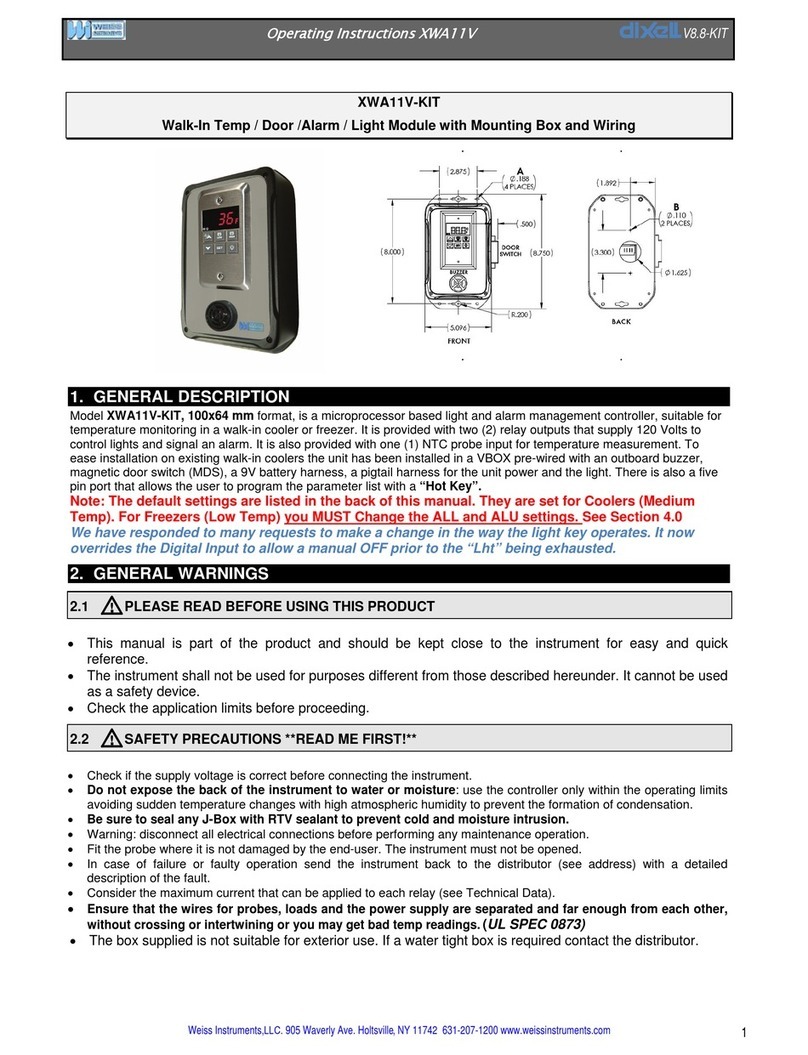

6. INSTALLATION AND MOUNTING

Instruments XW60LS shall be mounted on vertical panel, in a 150x31 mm hole, and fixed using

two screws ∅3 x 2mm. To obtain an IP65 protection grade use the front panel rubber gasket

(mod. RG-L). The temperature range allowed for correct operation is 0 - 60 °C. Avoid places

subject to strong vibrations, corrosive gases, excessive dirt or humidity. The same

recommendations apply to probes. Let the air circulate by the cooling holes.