3. Wiring The Lights

3.1 - Wiring Harness Overview

Our premium wiring harness features high-quality waterproof components

and a clever HotSwap™ design that enables an effortless swap from the

standard Single-Intensity relay to our Dual-Intensity DataDim™ Controller

(Sold Separately). If adding the DataDim™ Controller upgrade now, jump

ahead and read Section 6 before returning to Section 3.2. If not, continue

to Section 3.2 with peace of mind that you can always upgrade later,

without having to rewire the lights.

Note: The DENALI harness with pods connected is 60 inches in length.

DENALI Harness Extensions are available for purchase if extra length is

required.

DENALIELECTRONICS.COM

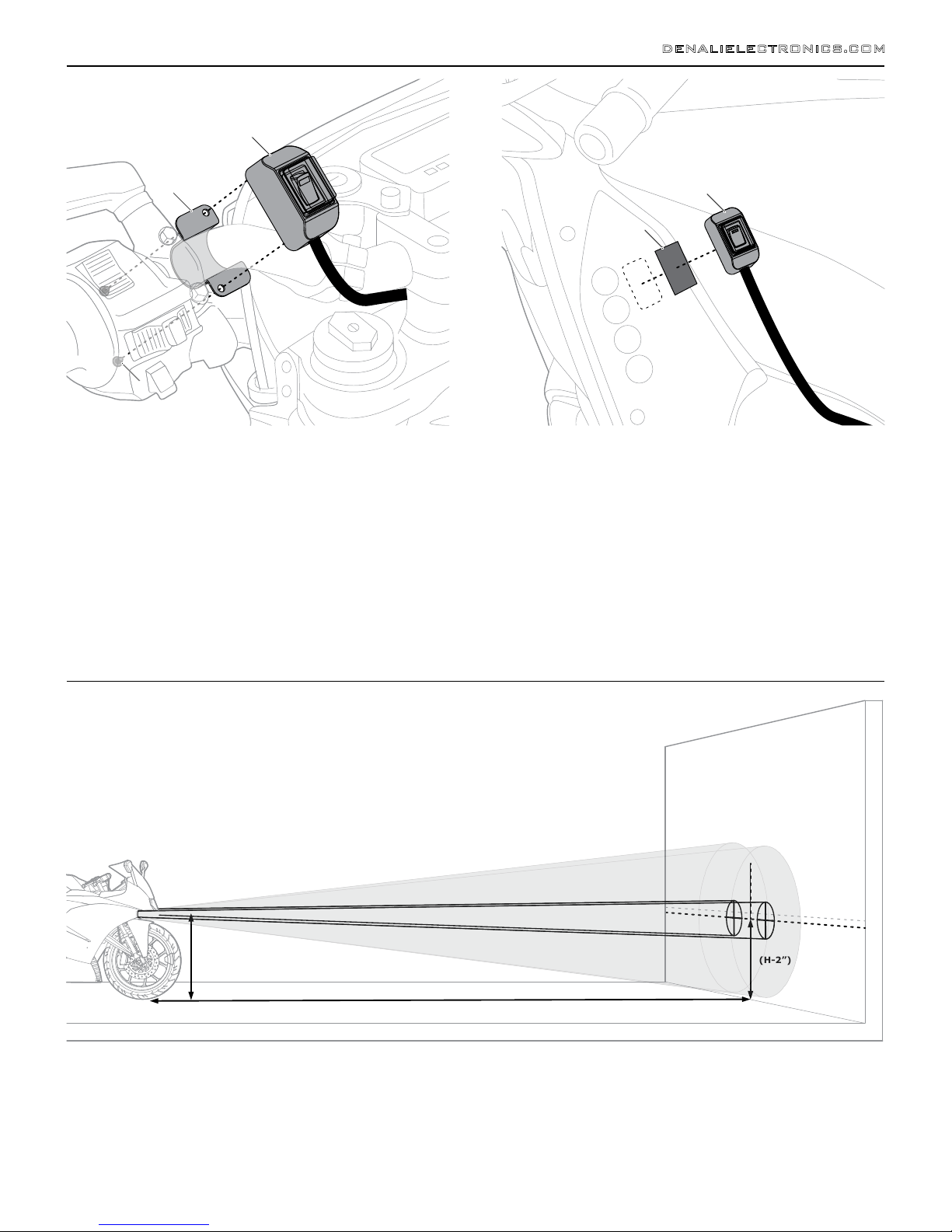

Step One: Find a suitable location near the battery to store the

Single-Intensity Relay.

Step Two: Begin routing the harness towards the mounted light pods.

Secure the harness to the vehicle’s frame along the way with the

included zip ties. Be sure to avoid any moving components such as fan

blades or suspension. Plug the light pods into the base harness.

Step Three: Route the switch wire to the location where the switch will

be mounted and secure it to the vehicle using zip ties. See Section 4 for

switch mounting options.

3.3 - Tapping Switched Power

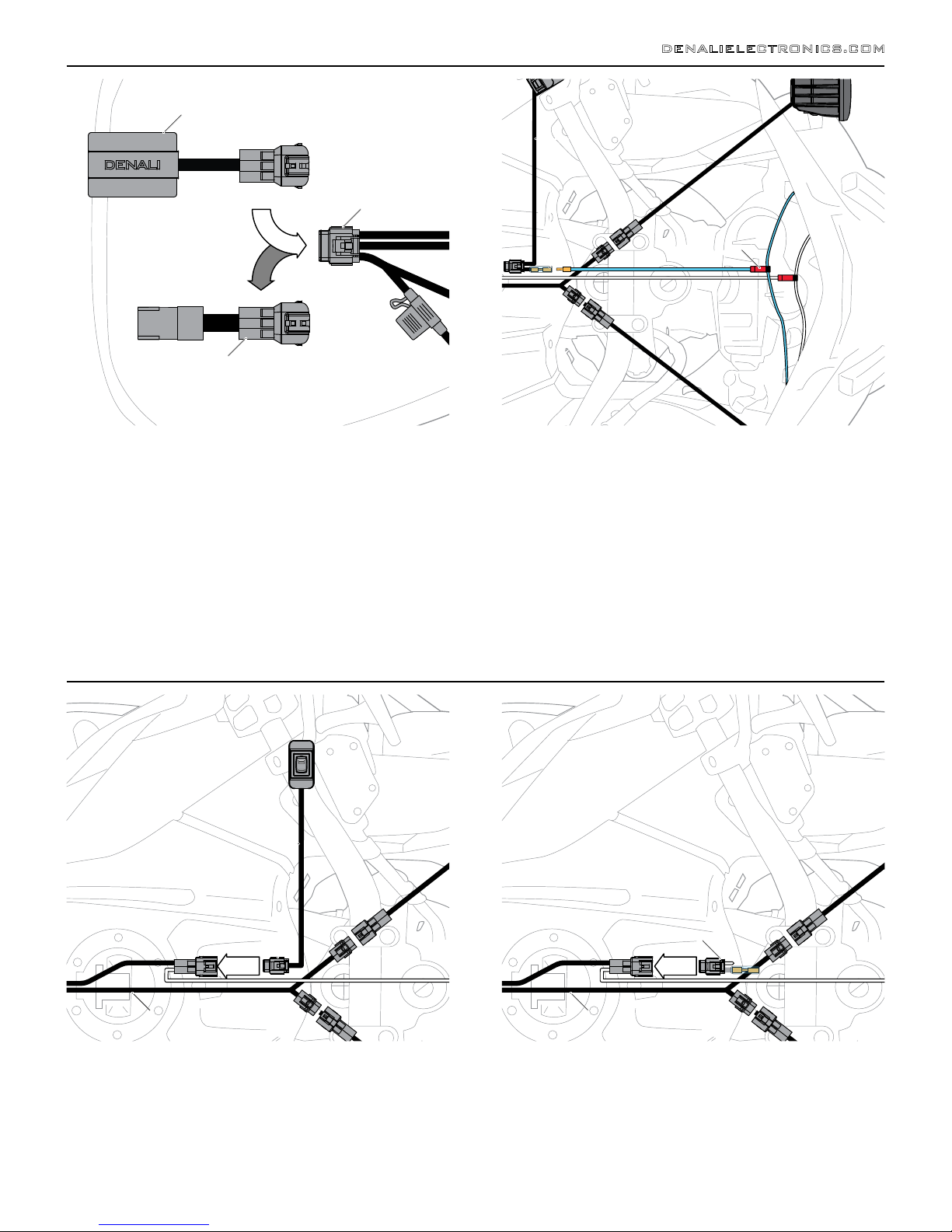

Step One: Two examples of possible switched power sources are the

low beam and tail light, however there are many other possible sources

in most vehicles. The simplest way to identify switched power is to use a

test light to probe connectors/wires while cycling the ignition. A clean

switched power source will only be live when the ignition is cycled “ON”,

it should lose power when the ignition is cycled “OFF”.

Step Two: Once a proper switched power source has been identified

use the included Posi-Tap to tap the white trigger wire into the identified

switched power source.

3.4 - Connecting To The Battery

Step One: Remove the fuse from the fuse holder.

Step Two: Access the vehicle’s battery and disconnect the negative (-)

and positive (+) terminals.

Step Three: Connect the DENALI wiring harness to the battery via the

ring terminals, be sure the red wire lead with the fuse holder in-line

goes to the positive (+) terminal of the battery.

Step Four: Re-install the fuse into the fuse holder.

Note: When possible, place the fuse holder in an easily accessible

location for convenient service in the event of a blown fuse.

+

-

3.2 - Routing The Wiring Harness

Single-Intensity Relay

Base Harness

On-Off Switch

Fuse Holder

Battery

+

-

Battery

Posi-Tap

DR1 Pod

Trigger Wire