ABOUT THIS MANUAL.............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS..........................................................6

NOTE FOR SCHEMATIC DIAGRAM.........................................7

NOTE FOR PARTS LIST...........................................................7

TECHNICAL SPECIFICATIONS................................................9

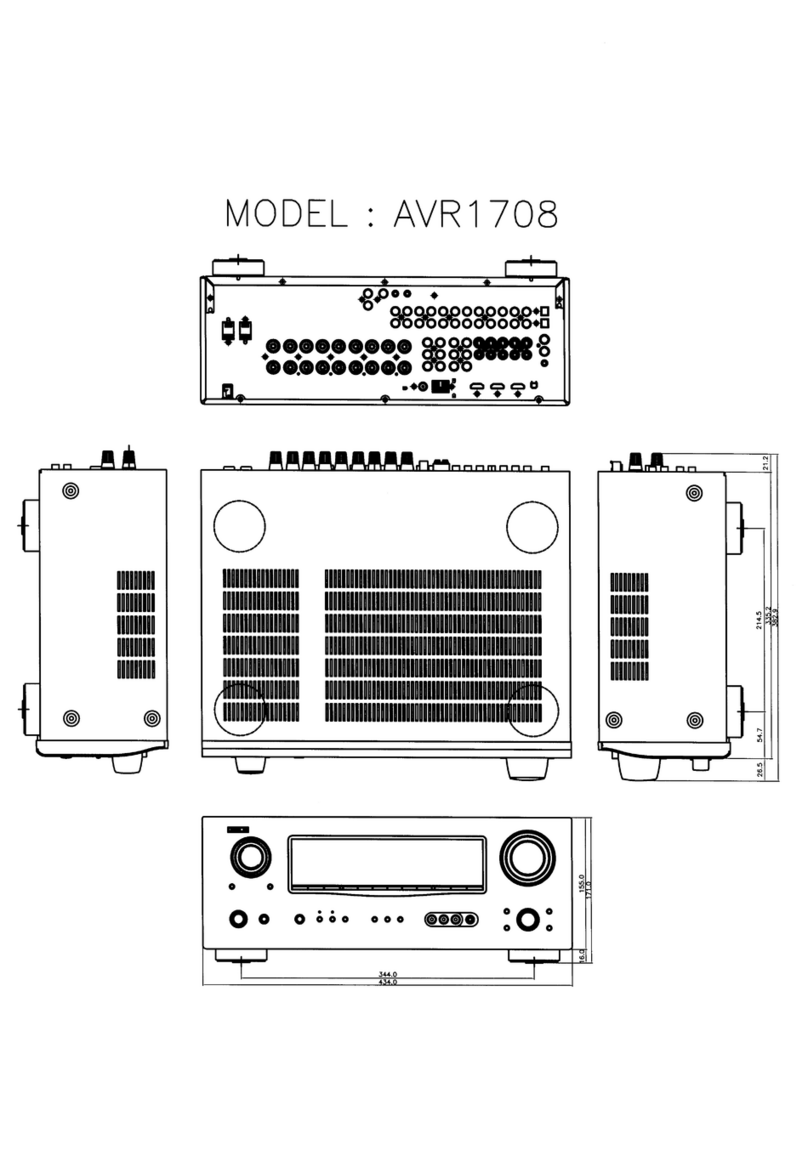

DIMENSION...............................................................................9

CAUTION IN SERVICING........................................................10

Initializing INTEGRATED NETWORK AV RECEIVER ............10

Service Jig ..............................................................................10

DISASSEMBLY........................................................................11

1. FRONT PANEL ASSY ........................................................13

2. HEAT SINK ASSY ..............................................................14

3. DIGITAL UNIT ASSY..........................................................15

4. TRANS MAIN .....................................................................17

SPECIAL MODE......................................................................18

1. µcom/DSP Version display mode.......................................19

2. PANEL/REMOTE LOCK Selection mode...........................23

3. Service Related Selection mode ........................................24

4. Protection Pass mode........................................................56

5. DM860A Reboot mode.......................................................56

6. Remote ID Setup mode......................................................57

JIG FOR SERVICING ..............................................................58

WHEN THE MICROPROCESSOR IS

REPLACED WITH A NEW ONE..............................................61

PROCEDURE FOR UPGRADING

THE VERSION OF THE FIRMWARE ......................................61

1. How to update by DFW ......................................................61

2. How to update by DPMS....................................................65

3. How to update by USB Memory.........................................72

ADJUSTMENT.........................................................................81

Sound modes and channel output........................................82

TROUBLE SHOOTING............................................................85

1. POWER..............................................................................85

2. Analog video ......................................................................86

3. HDMI/DVI...........................................................................89

4. AUDIO................................................................................91

5. Network/USB......................................................................94

6. SMPS.................................................................................97

Audio Check PASS ................................................................99

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK...........100

LEVEL DIAGRAM..................................................................101

POWER DIAGRAM................................................................107

WIRING DIAGRAM................................................................108

PRINTED WIRING BOARDS.................................................109

SCHEMATIC DIAGRAMS (1/30) ...........................................118

SCH01_DIG_CONNECT.......................................................118

SCH02_DIG_POWER...........................................................119

SCH03_DIG_MAIN_CPU......................................................120

SCH04_DIG_SUB_CPU .......................................................121

SCH05_DIG_CPU_LEVEL_CHG .........................................122

SCH06_DIG_DIR ..................................................................123

SCH07_DIG_AUDIO_PLD....................................................124

SCH08_DIG_DSP1...............................................................125

SCH9_DIG_MAIN_DAC1......................................................126

SCH10_DIG_DM860.............................................................127

SCH11_DIG_ETHERNET_PHY............................................128

SCH12_DIG_HDMI_RX ........................................................129

SCH13_DIG_SII9575............................................................130

SCH14_DIG_FRONT_HDMI.................................................131

SCH15_DIG_HDMI TX..........................................................132

SCH16_FRONT ....................................................................133

SCH17_INPUT......................................................................134

SCH18_INPUT......................................................................135

SCH19_INPUT_PREOUT.....................................................136

SCH20_INPUT_F-HDMI .......................................................137

SCH21_VIDEO .....................................................................138

SCH22_VIDEO_RC5_MXPORT...........................................139

SCH23_VIDEO_RS232C_TRIGGER ...................................140

SCH24_AMP_AMP1 .............................................................141

SCH25_AMP_AMP2 .............................................................142

SCH26_SPK .........................................................................143

SCH27_SPK_REGULATOR_TUNER ...................................144

SCH28_CNT_CONNECT_A .................................................145

SCH29_CNT_CONNECT_B .................................................146

SCH30_SMPS ......................................................................147

EXPLODED VIEW .................................................................148

PACKING VIEW.....................................................................149

SEMICONDUCTORS.............................................................151

1. IC's ...................................................................................151

2. FL DISPLAY .....................................................................179

CONTENTS

2