Contents

3 of 84

AmaDrainer Box

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.3 Personnel qualification and training...............................................................................................................9

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety instructions for the operator/user........................................................................................................9

2.7 Safety information for maintenance, inspection and installation ..............................................................10

2.8 Unauthorised modes of operation................................................................................................................10

3 Transport/Storage/Disposal ................................................................................................................ 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................11

3.4 Return to supplier...........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................12

4 Description............................................................................................................................................ 13

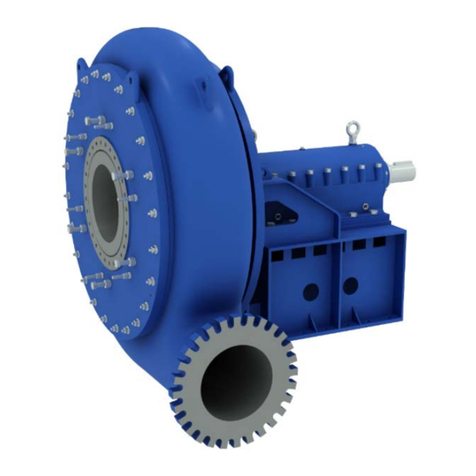

4.1 General description ........................................................................................................................................13

4.2 Product information as per Regulation No. 1907/2006(REACH).................................................................13

4.3 Designation.....................................................................................................................................................14

4.4 Name plate......................................................................................................................................................14

4.5 Design details..................................................................................................................................................15

4.6 Configuration and function...........................................................................................................................16

4.7 Noise characteristics .......................................................................................................................................17

4.8 Scope of supply...............................................................................................................................................17

4.9 Dimensions and weights ................................................................................................................................18

4.10 Accessories ......................................................................................................................................................18

5 Installation at Site................................................................................................................................ 19

5.1 Safety regulations...........................................................................................................................................19

5.2 Checks to be carried out prior to installation...............................................................................................20

5.3 Mounting/installing the underfloor box.......................................................................................................21

5.3.1 Installing the underfloor box ........................................................................................................... 21

5.3.2 Underfloor box: Connecting the piping .......................................................................................... 23

5.3.3 Underfloor box: Fitting the level-adjusting piece/ puddle flange with level-adjusting piece (not

included in the scope of supply) ...................................................................................................... 28

5.3.4 Underfloor box: Backfilling around the collecting tank and pouring concrete around the top. 30

5.3.5 Underfloor box: Fitting the sealing collar ....................................................................................... 32

5.4 Installing the above-floor box .......................................................................................................................35

5.4.1 Installing the above-floor box.......................................................................................................... 35

5.4.2 Above-floor box: Connecting the piping......................................................................................... 36

5.5 Installing the pump set ..................................................................................................................................39

5.5.1 Single-pump lifting units: Installing the pump set ......................................................................... 39

5.5.2 Dual-pump lifting units: Installing the pump set............................................................................ 43

5.6 Electrical connection ......................................................................................................................................49

5.6.1 Underfloor box: Electrical connection ............................................................................................. 49