User Manual XTOXLnie/ XTOXLnce

Contents

Information................................................................................................................................2

NOTES ON THE CORRECT USE OF THE PRINTER ..............................................................................2

GENERAL NOTES...............................................................................................................................2

SAFETY NOTICES...............................................................................................................................3

GENERAL PRECAUTIONS ..................................................................................................................3

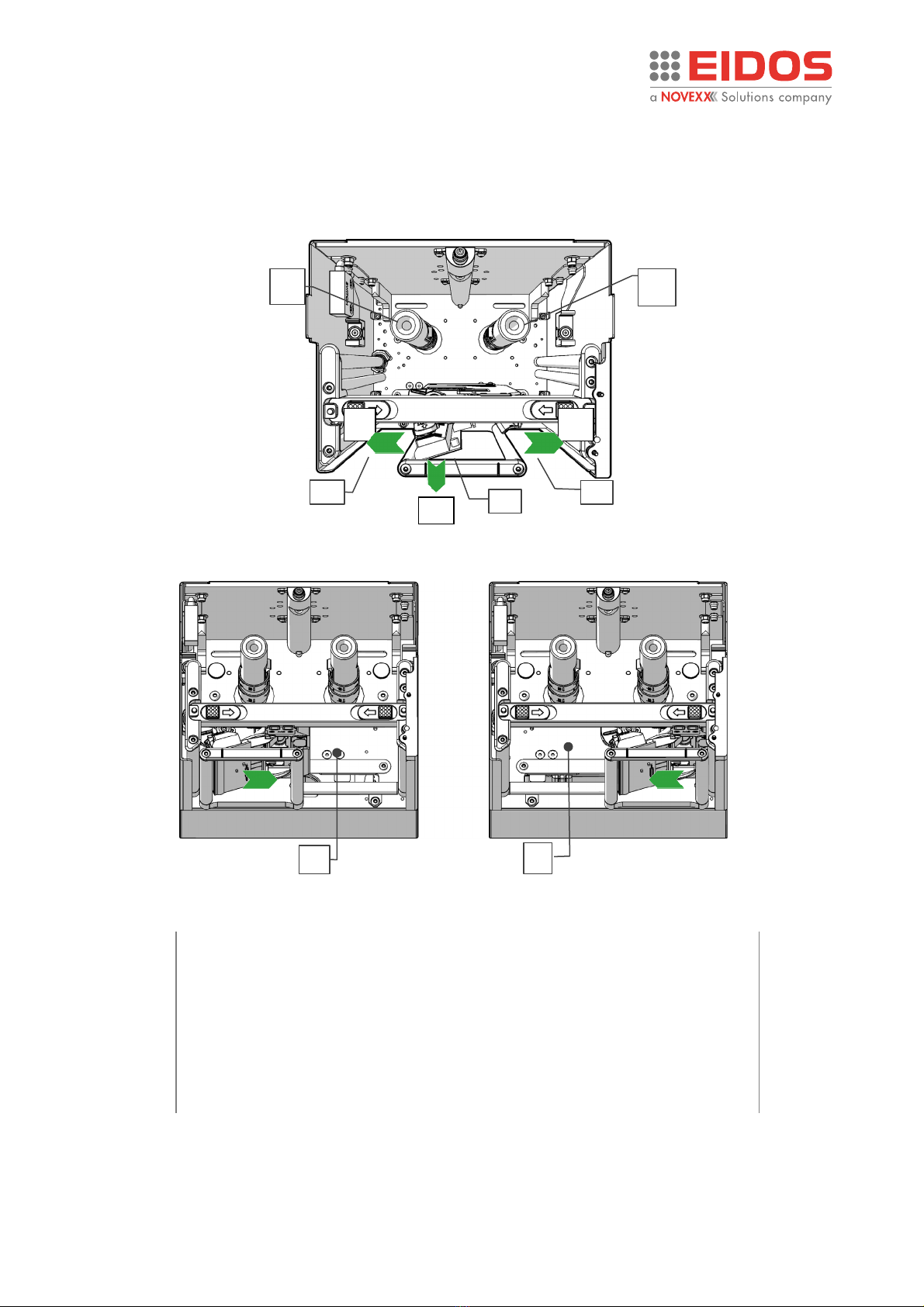

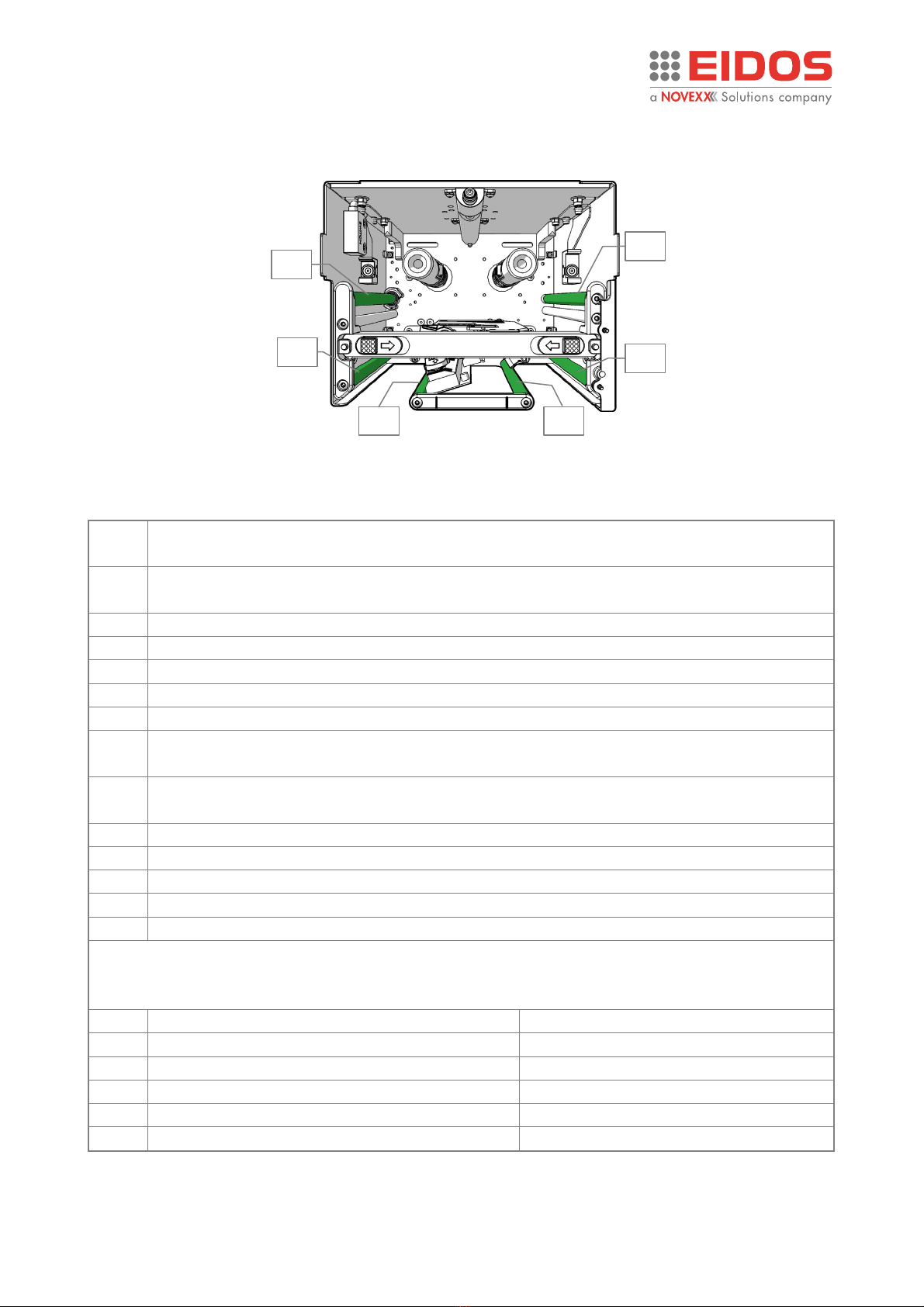

DANGEROUS AREAS ON THE PRINTING UNIT..................................................................................4

PROTECTION ELEMENTS PROVIDED ................................................................................................7

Product Description .................................................................................................................11

FUNCTIONALITY .............................................................................................................................11

PECULIARITY ...................................................................................................................................11

CARRIAGE STROKE LENGTHS AND MACHINE TYPE........................................................................12

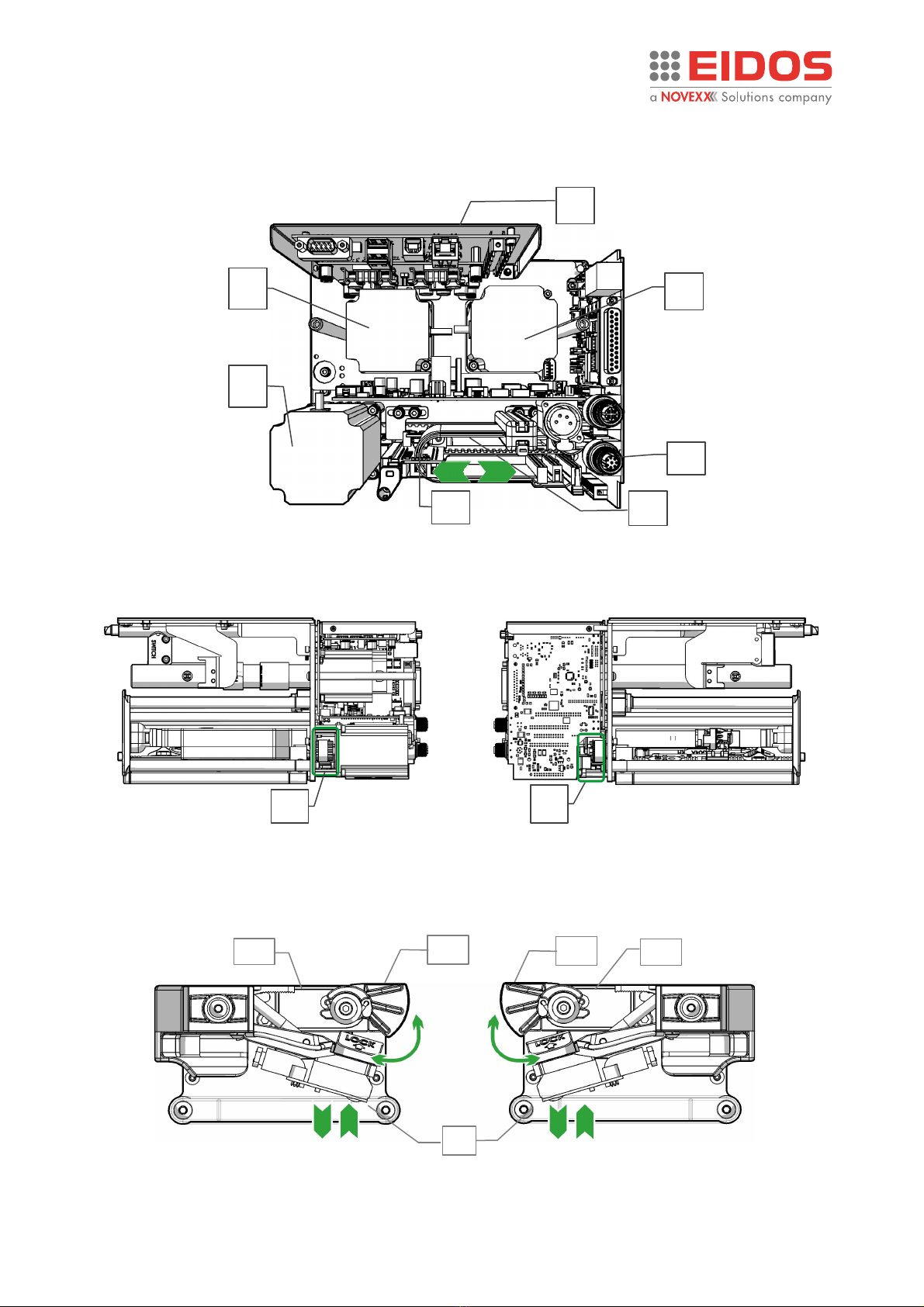

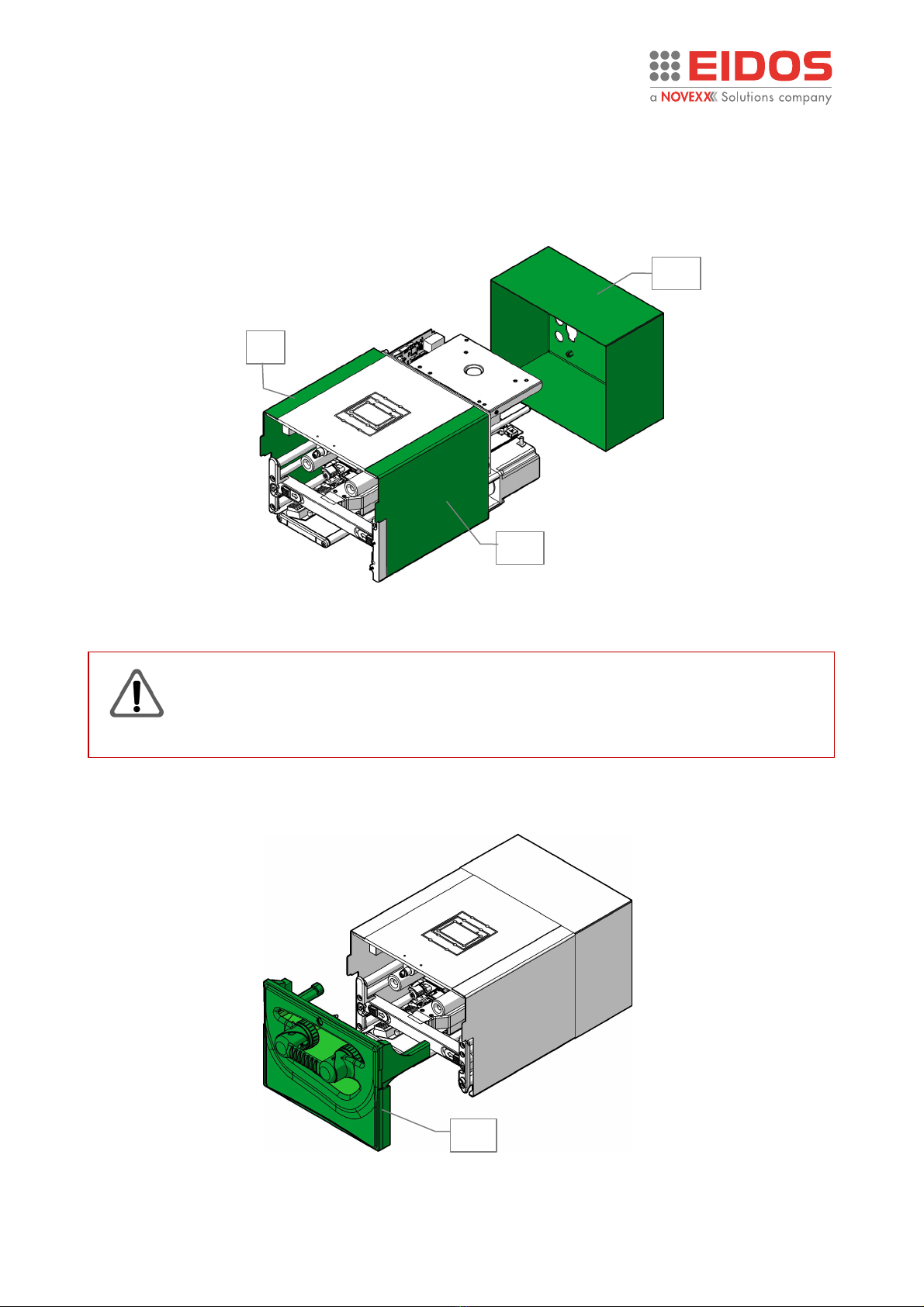

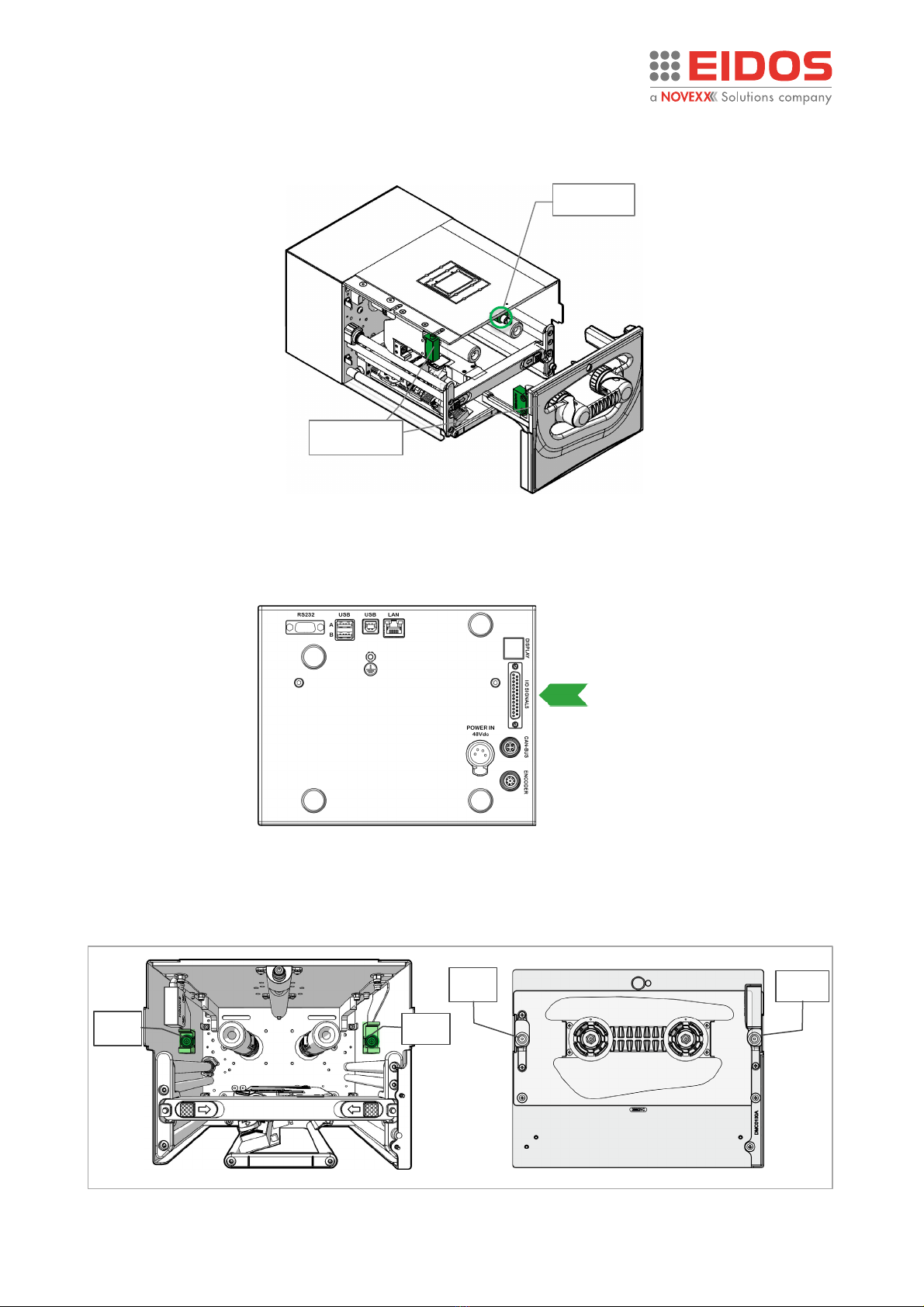

SYSTEM CONFIGURATIONS ............................................................................................................13

REAR CONNECTION PANEL ............................................................................................................16

OPERATING PANEL.........................................................................................................................17

BASIC SETTINGS..............................................................................................................................20

Operation ................................................................................................................................26

INSERTING CONSUMABLES ............................................................................................................26

THE THERMAL RIBBONS.................................................................................................................27

PRINTING........................................................................................................................................28

CREATION AND SENDING OF THE LABEL WITH EASYCODE ...........................................................29

HOW TO STORE LABEL FILES (.LM1)...............................................................................................31

HOW TO BACK UP ..........................................................................................................................31

SETTING AND MONITORING ..........................................................................................................32

STATUS MESSAGES.........................................................................................................................57

Preventive Maintenance ..........................................................................................................59

CLEANING INSTRUCTIONS..............................................................................................................59

CLEANING THE PRINT HEAD...........................................................................................................60

CLEANING THE CARRIAGE SLIDING GUIDE.....................................................................................60

CLEANING THE PRINTING PLATE (XTOXL Intermittent) .................................................................61

CLEANING THE PRINTING ROLLER (XTOXL Continuous) ................................................................61

CLEANING ROLLS AND RIBBON PASSAGES ....................................................................................62

Appendix 1...............................................................................................................................63

EC DECLARATION OF CONFORMITY...............................................................................................63

Appendix 2...............................................................................................................................64

CE LABEL.........................................................................................................................................64

Appendix 3...............................................................................................................................65

ZEBRA and EIDOS NICELABEL EMULATION FILE MANAGEMENT (.prn, .zpl) .................................65