1C7833 – July 1995 –3

Description Page

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Checking the Packing List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Before Starting the Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Removing the TOP COVER and the HINGE PLATES

from the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Installing the New HINGE PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Installing the SORTER on the PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Installing the ENCODER WHEEL/SPROCKET and Adjusting the Height of the

DRIVE SHAFT on the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installing the New COVER on the ELECTRICAL BOX. . . . . . . . . . . . . . . . . . . . . . 1-15

Installing the New ELECTRICAL BOX HARNESS . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Placing the New ELECTRICAL BOX HARNESS in Position . . . . . . . . . . . . . 1-17

Connecting the New ELECTRICAL BOX HARNESS to J10 and TB5 . . . . . . 1-18

Connecting the New ELECTRICAL BOX HARNESS to the 500 BOARD . . . 1-20

Modifications to the 500 BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Installing the SORTER HARNESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Installing the COVER EXTENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Installing the New SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Installing the FILM TRAY and the TOP COVER of the SORTER . . . . . . . . . . . . . . 1-32

Adjusting the Temperature of the DRYER in the PROCESSOR . . . . . . . . . . . . . . . . 1-32

Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Checking the SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Checking the BIN SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Checking the DIVERTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Installing the PANELS and Checking for Correct Operation of the SORTER . 1-36

Adjustments and Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Service Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

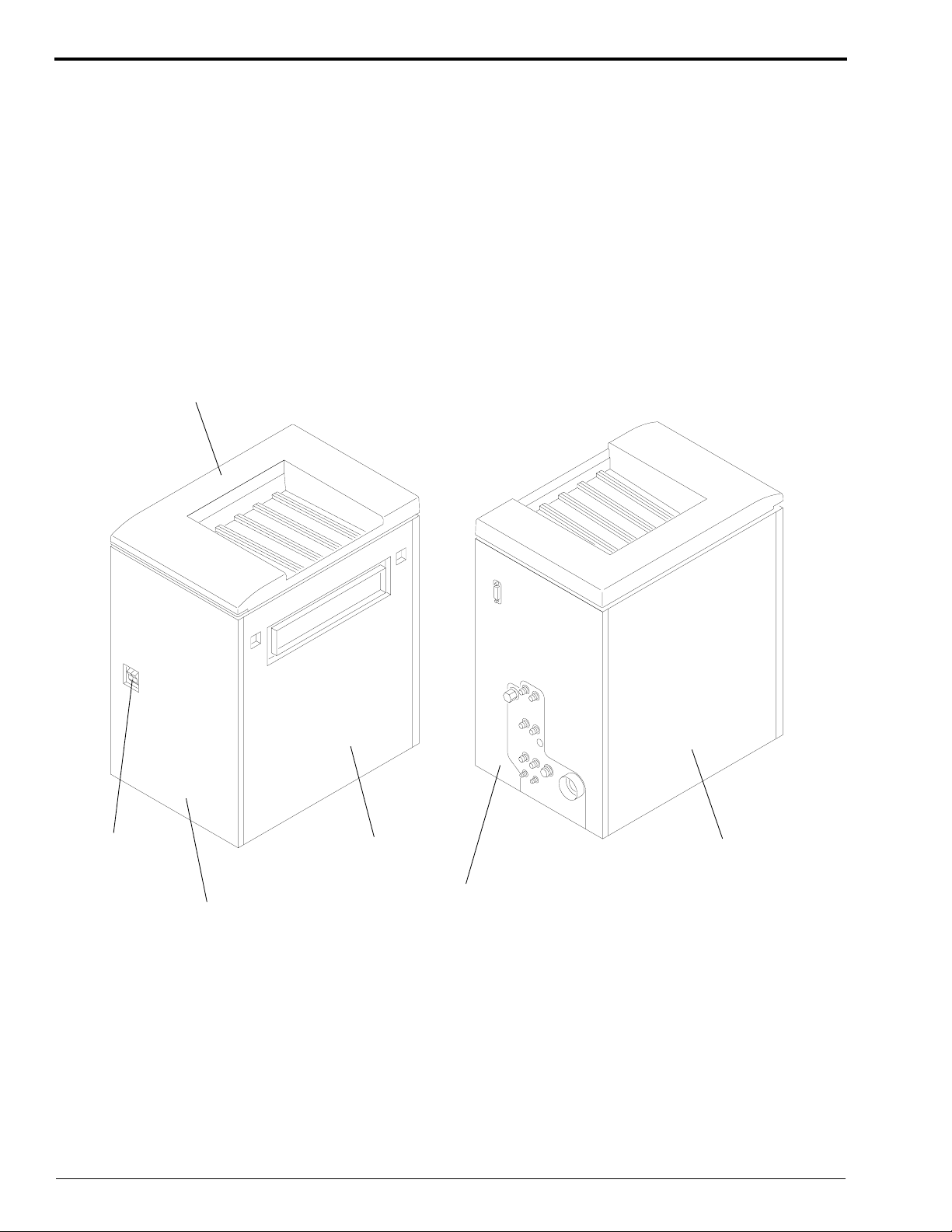

Position and Identification of Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

De-energizing and Energizing the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . 2-5

General Access to the SORTER or to the PROCESSOR . . . . . . . . . . . . . . . . . 2-6

Installing the TOP COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Replacement of the DIVERTERS or the BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Replacement of a SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Replacement of the INTERLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Replacement of a MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Replacement of the SENSOR on a MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Replacement of the ROLLERS

on a LEAD or MAIN MODULE or on the ACCESS DOOR. . . . . . . . . . . . . . . . . 2-14

Replacement of the IDLER ROLLERS and SPRINGS on a MODULE . . . . . . . . . . 2-16

Replacement of the BIN ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Replacement of the Front BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Replacement of the GEAR or the Back BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Replacement and Adjustment of the DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Replacement of the DRIVE MOTOR or the GEARBOX. . . . . . . . . . . . . . . . . . . . . . 2-20

Replacement of the MAIN DRIVE SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Replacement of the WORM GEARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Replacement of the GAS SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Replacement of the 4000 BOARD or MOTOR CONTROLLER BOARD . . . . . . . . 2-24

Replacement of the 100 BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Replacement of the IDLER GEARS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28