Contents

1SIGNAL WORD AND SYMBOL DEFINITION...............................................................4

2SAFETY INSTRUCTIONS .............................................................................................5

2.1. Safety Instructions for Electronic Screwdrivers ..........................................................5

3INTENDED USE ............................................................................................................5

4DELIVERY CAPACITY..................................................................................................6

5GENERAL......................................................................................................................6

6OPERATION..................................................................................................................7

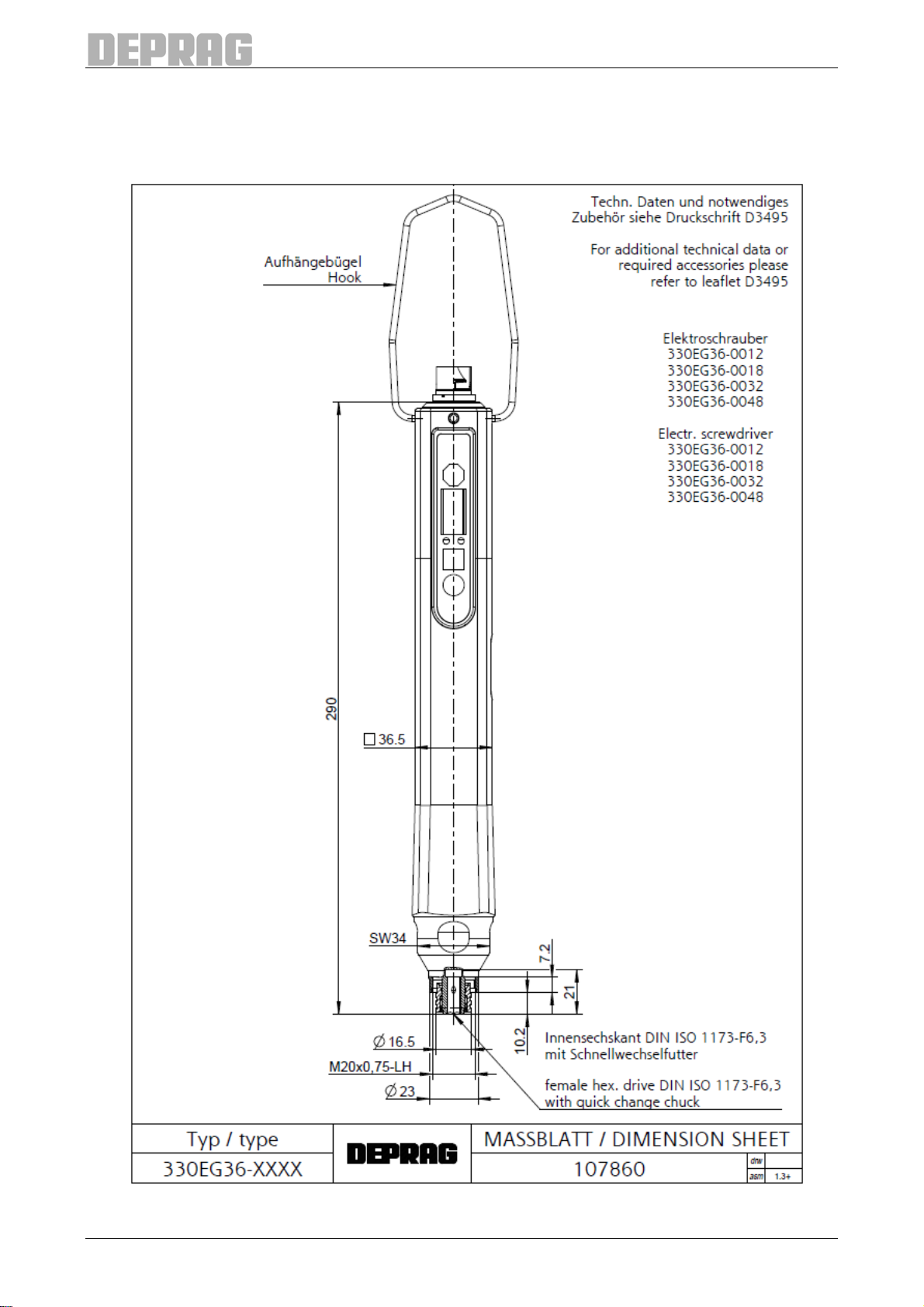

6.1. Dimensional Drawing .................................................................................................7

6.2. Assembly Instructions ................................................................................................8

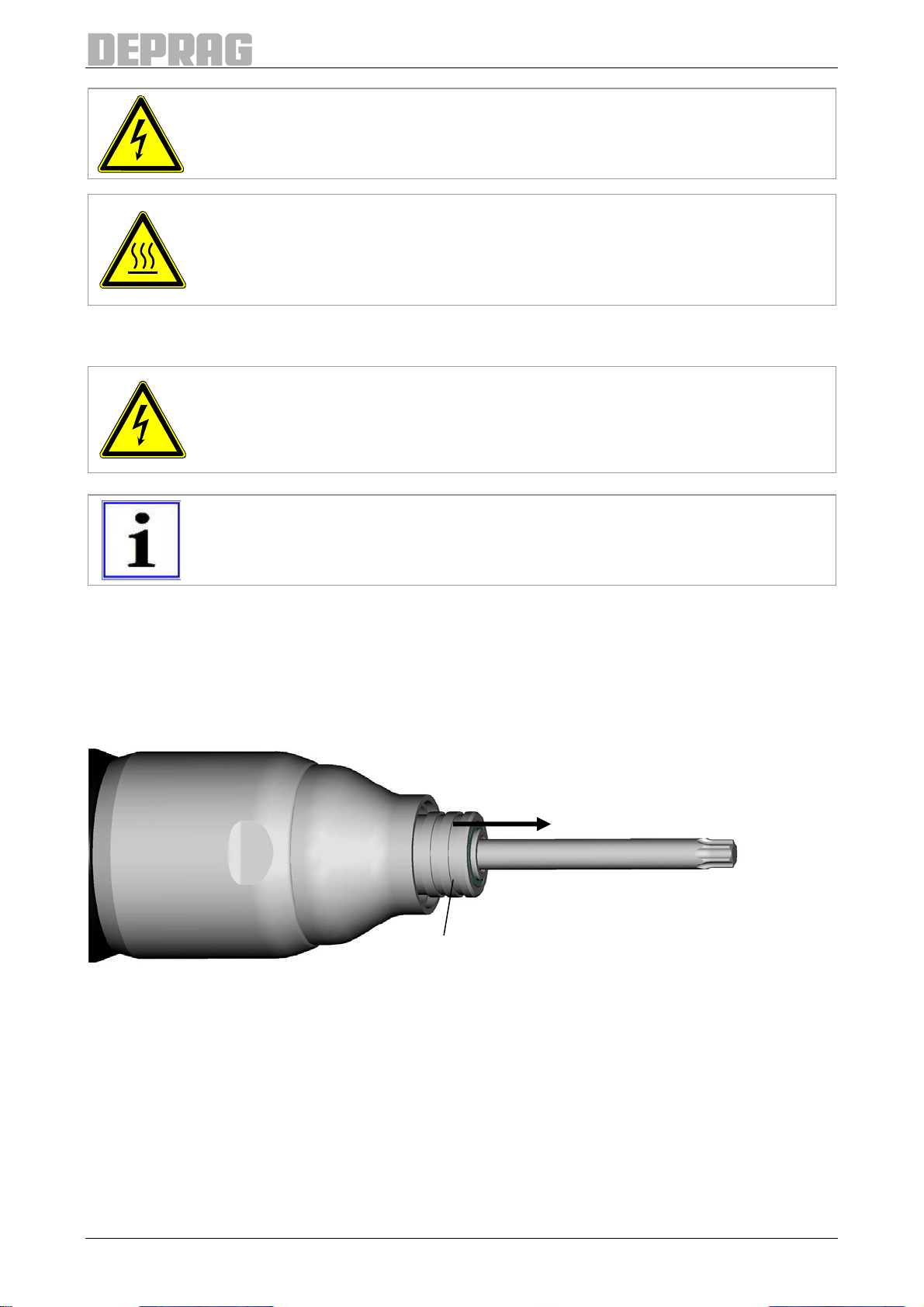

6.3. Change of Bits..........................................................................................................10

7OPERATION................................................................................................................11

7.1. Operating element....................................................................................................11

7.1.1 Status LEDs...........................................................................................................11

7.1.2 Function buttons.....................................................................................................11

7.1.3 Display ...................................................................................................................12

7.2. Screwdriver start ......................................................................................................12

7.3. Program selection / Torque setting...........................................................................12

7.4. Menu operation ........................................................................................................12

7.5. Menu structure .........................................................................................................13

7.6. Pressure test function...............................................................................................14

7.7. Display test...............................................................................................................14

8DESCRIPTION OF THE SETTINGS............................................................................16

9SCREWDRIVING TEMPLATE.....................................................................................17

9.1. Description of the screwdriving sequences ..............................................................17

9.2. Screw assembly program.........................................................................................17

9.3. Loosening program ..................................................................................................18

10 MAINTENANCE AND UPKEEP ................................................................................19

11 ERROR DISPLAY AND TROUBLESHOOTING........................................................20

11.1. System error...........................................................................................................20

11.2. Error in the screwdriving sequence........................................................................21

12 TROUBLESHOOTING...............................................................................................22

13 ACCESSORIES - OPTIONAL EQUIPMENT .............................................................23

13.1. Required accessories.............................................................................................23

13.1.1 Motor cable ..........................................................................................................23

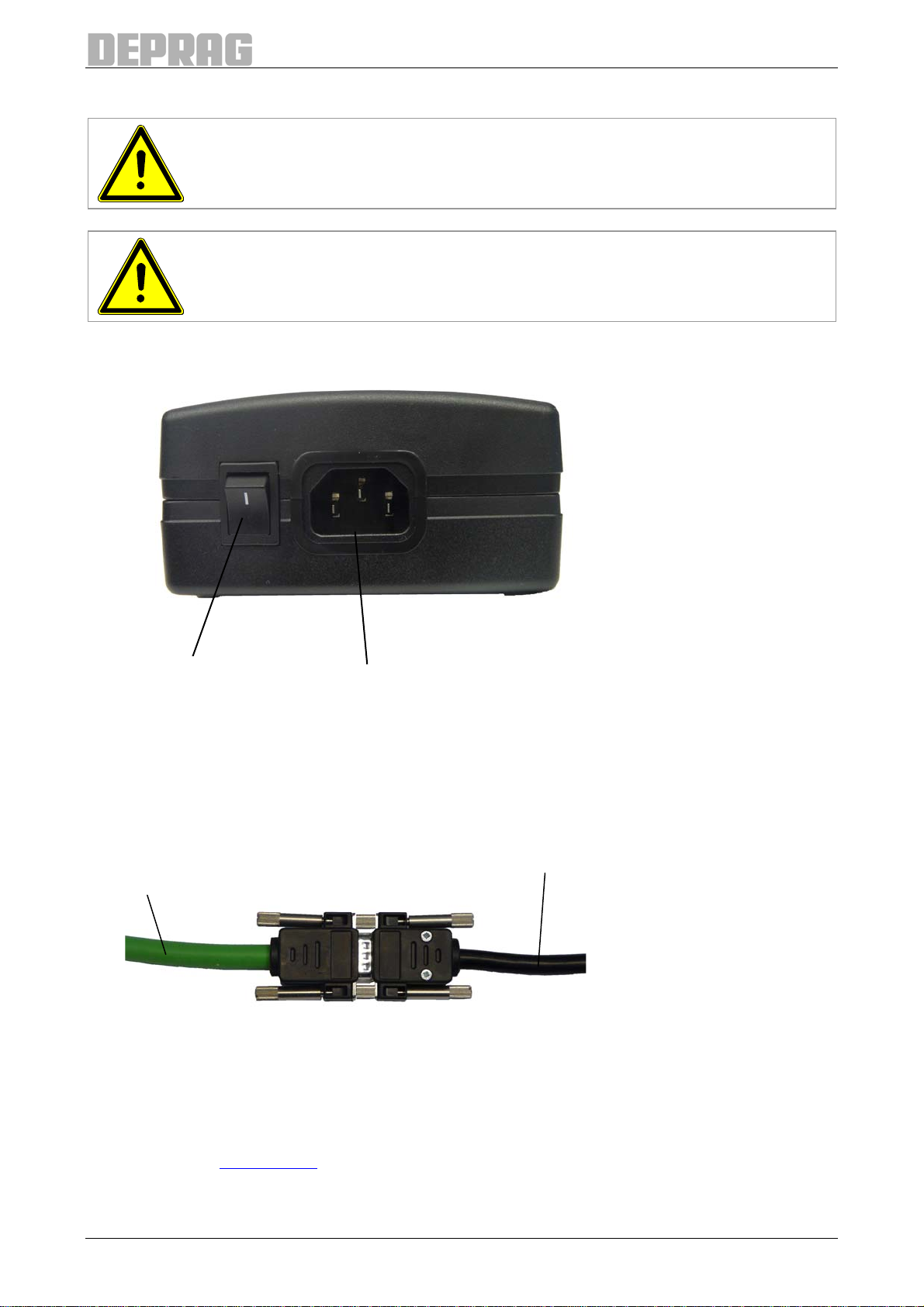

13.1.2 Power unit ............................................................................................................23

13.1.3 Power supply cable..............................................................................................23

13.2. Optional accessories..............................................................................................24

13.2.1 Spring sleeve .......................................................................................................24

13.2.2 EF-Control............................................................................................................25

13.2.3 Screwdriver adapter.............................................................................................25

13.2.4 Balancer...............................................................................................................26

13.2.5 Additional accessories..........................................................................................26

14 SHUT DOWN AND STORAGE..................................................................................27

2