IMPORTANT

Insulate the shields to prevent shorting to the

device housing or to any other conductor.

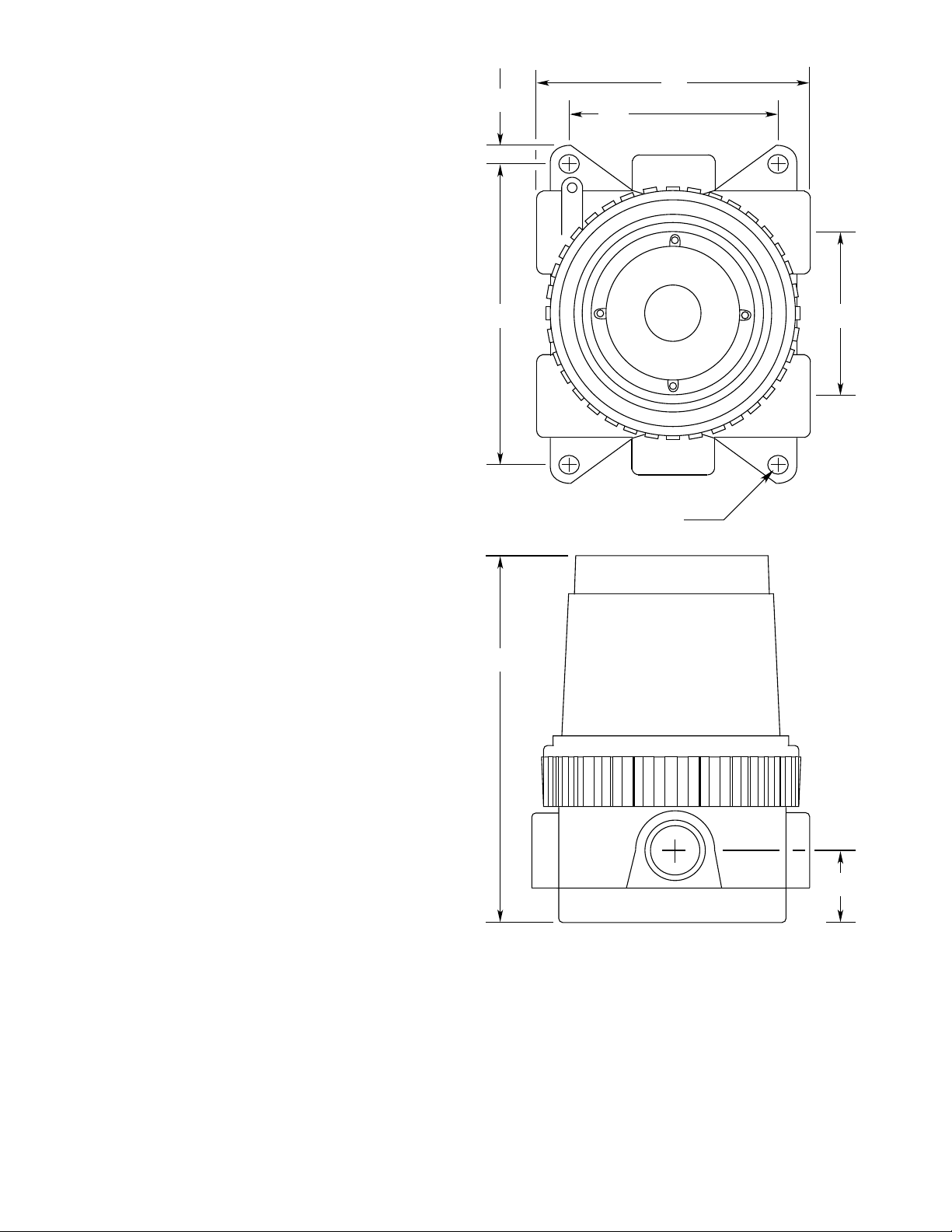

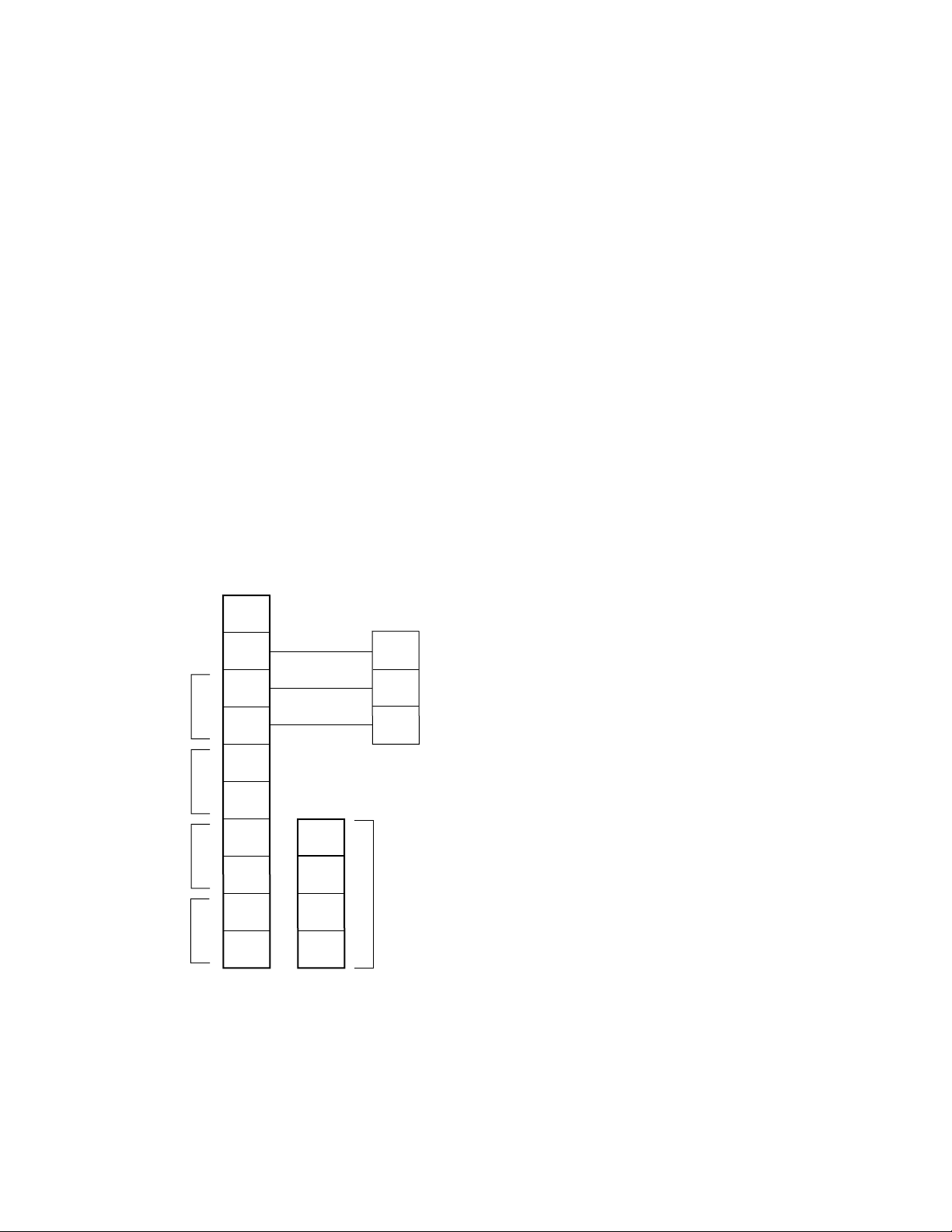

Attach the communication module to the standoffs as

shown in Figure 4. Connect the ribbon cable from the

terminal wiring board to the communication module.

Set the address for the device (see “Addressability”on

page 3).

Check the wiring to ensure proper connections, then

pour the conduit seals and allow them to dry (if conduit

is being used).

NOTE

Before placing the cover back on the enclosure fol-

lowing completion of assembly and wiring, inspect

the enclosure O-ring to be sure that it is in good

condition and properly installed. Lubricate the O-

ring and the threads of the cover with a thin coat of

an appropriate grease to ease installation. If the

installation uses catalytic type combustible gas

sensors, it is imperative that lubricants containing

silicone NOT be used, since they will cause irre-

versible damage to the sensor. Place the cover on

the enclosure. Tighten only until snug. Do not

over tighten.

SENSOR SEPARATION FOR DCU WITH H2S AND

O2 SENSORS

Since the transmitter for the electrochemical sensor is

already mounted within the sensor housing, simply

mount the entire sensor assembly to the sensor separa-

tion kit junction box and wire it to terminals 2 and 4

inside the DCU, the same as a regular (without sensor

separation) installation. Connect the shield to the

ground terminal in the DCU junction box.

Refer to Table 1 for separation distance limitations for

H

2

S/toxic/O

2

sensors.

EQ2200DCU DIGITAL COMMUNICATION UNIT

USED WITH POINTWATCH

Determine the best mounting locations for the detectors.

Whenever practical, detectors should be placed where

they are easily accessible for calibration.

WARNING

Do not apply power to the system with the cover

removed unless the area has been verified to be

free of combustible gases and vapors.

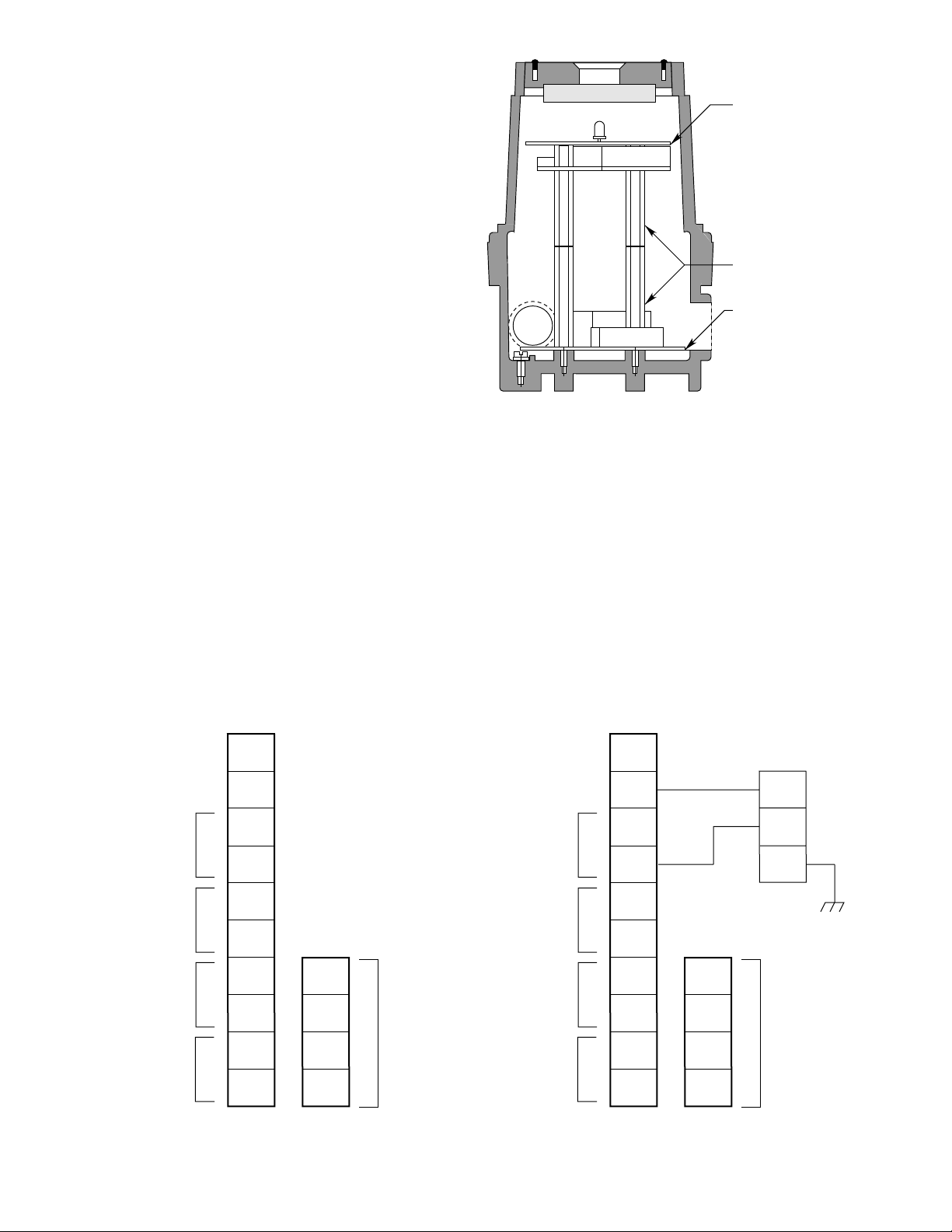

The DCU utilizes the following:

1. A terminal wiring board mounted at the bottom of

the junction box.

2. A communication module mounted above the termi-

nal wiring board using the standoffs provided. See

Figure 4.

Assembly and Wiring Procedure

Attach the PointWatch to the DCU enclosure. Do not

over-tighten. If a sensor separation kit is used, attach

the sensor to the separation kit junction box and wire the

device as described in the “Sensor Separation”section.

Refer to the PointWatch manual (form 95-8440) for com-

plete installation and application information.

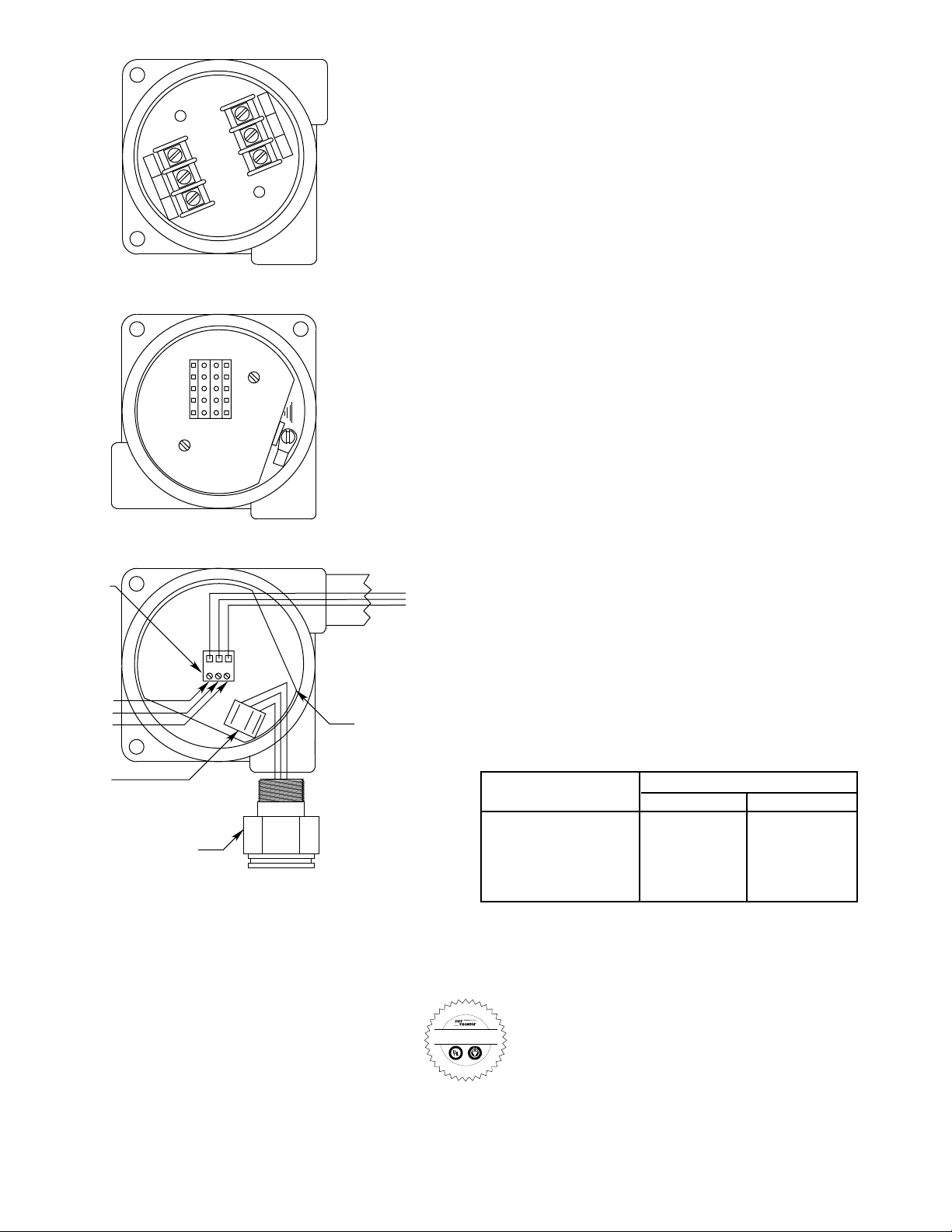

Refer to Figure 7 when wiring a PointWatch IR gas

detector and a DCU. The wiring code for PointWatch is:

Red = + (24 vdc)

Black = –(common)

White = 4 to 20 ma signal

Yellow = Calibration input

Green = Chassis ground

IMPORTANT

Insulate the shields to prevent shorting to the

device housing or to any other conductor.

Set the address for the device (see “Addressability”on

page 3).

Sensor Separation for DCU with PointWatch

Shielded four wire cable is recommended for connect-

ing the detector junction box to the DCU. Cable with a

foil shield is recommended. The shield of the cable

should be open at the detector junction box and con-

nected to earth ground on the DCU junction box.

NOTE

To ensure proper operation, a minimum of 18 vdc

(including ripple) must be maintained at the PointWatch.

5 90-1118

Table 1—Maximum Separation Distances —

Electrochemical Sensor to DCU

Wire Size Maximum Wiring Distance

Feet Meters

18 AWG (1.0 mm2)* 5700 1750

16 AWG (1.5 mm2)* 9000 2800

* Approximate Metric Equivalent.