vi

I N T R O D U C T I O N

Table of Contents

SECTION ONE—Installing the System

Unpacking and Inspection..........................................................1-1

Packaging Drawing and Parts List.......................................1-1

System Description.....................................................................1-2

Track and Docking Station................................................... 1-3

Scanning Head ....................................................................1-4

Vacuum Pump......................................................................1-4

Reattaching the Scanning Head................................................. 1-5

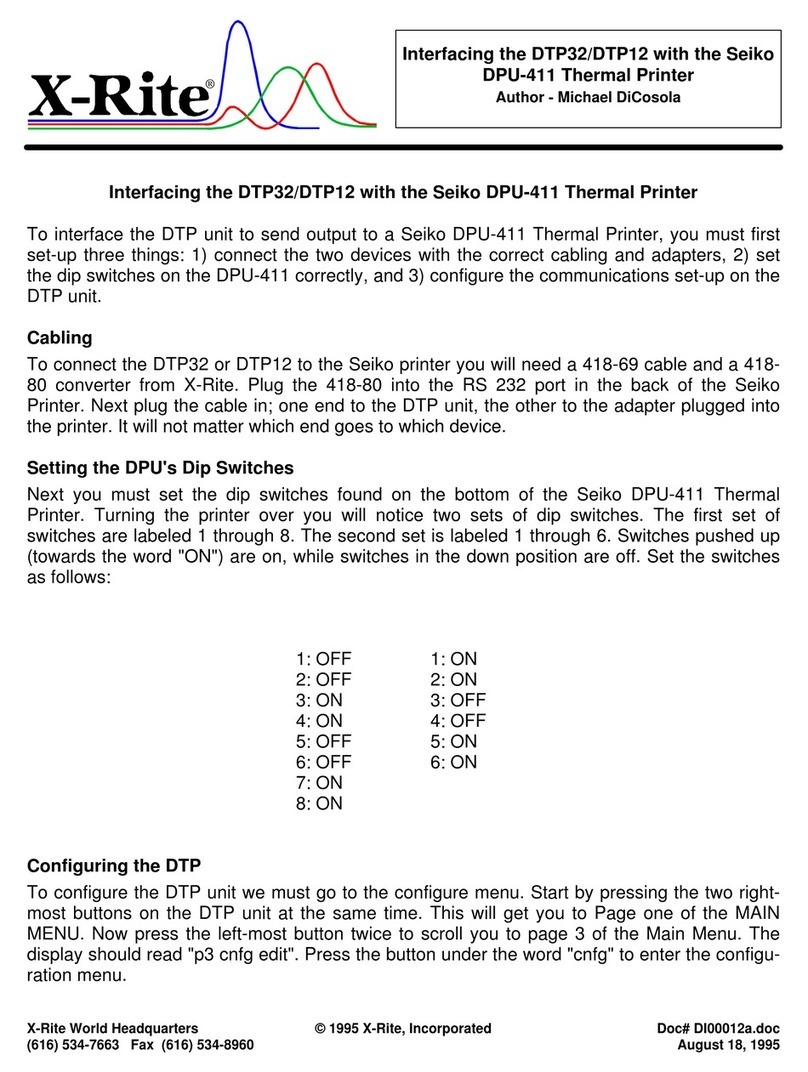

System Connections...................................................................1-6

Vacuum Pump Connections ................................................1-6

RS-232 Interface Connection ..............................................1-8

Connecting Power................................................................1-9

SECTION TWO—Operating the System

Calibrating the Scanning Instrument..........................................2-2

Sheet Loading and Alignment....................................................2-3

Standard Track Positioning.................................................. 2-3

Feed-Through Track Positioning .........................................2-4

Taking a Measurement with the ATD Sheet Instrument ............ 2-5

Taking a Measurement with the ATD News Instrument............. 2-6

SECTION THREE—General Maintenance

Repair Information......................................................................3-1

Overview..................................................................................... 3-1

Scanning Head...........................................................................3-1

Cleaning...............................................................................3-2

Maintenance......................................................................... 3-3

Scanning Track...........................................................................3-3

Cleaning...............................................................................3-3

Maintenance......................................................................... 3-3

Cleaning the Scanning Instrument Calibration Disks.................3-4

SECTION FOUR—Troubleshooting Tips ................. 4-1

APPENDIX A—Technical Specifications................A-1

APPENDIX B—Parts List and

Packaging Drawing ......................................................... B-1