KT-502H

G-2

• HART protocol

• 330° rotatable display for environment conditions

• DC4-20mA analog output (2-wire)

• Various input (order 1 input type among 22 types)

RTD: 8 types, Thermocouple: 8 types,

mV: 4 types, Ω: 2 types

• Backlight helps to read easily in the darkness

• Explosion class: Ex d IIC T6

• Protection structure: IP67 (IEC standard)

502H 0KT

Model KT-502H

Power supply 10.5-45VDC (with backlight LCD)

Display method

PV display part: 7-segment 5-digit (character size: W4×H8mm),

Parameter display part: 14-segment 8-digit (character size: W2.6×H4.8mm),

52-bar meter

Display range -19999 to 99999

Setting method HART-protocol (no setting key)

Response time 1 sec

Input type

RTD DPt100Ω, DPt500Ω, DPt1000Ω, Ni100Ω, Ni500Ω, Ni1000Ω, Cu50Ω, Cu100Ω

Thermocouple K, J, T, E, N, S, B, R

Resistance transmission (Ω) 0 - 400Ω, 0 - 2000Ω

Voltage transmission (mV)

10 - 75mV,

100 - 100mV,

100 - 500mV,

100 - 2000mV

Output DC4-20mA (2-wire)

Accuracy ±0.3%

Alarm Below 3.8mA, Over 20.5mA/Sensor break 3.6mA

Load Max.(V power supply - 7.5V)/0.22A

Galvanic insulation 2kVAC(input/output)

Environ-

ment

Ambient temperature -20 to 70℃, storage: 20 to 80℃

Ambient humidity 0 to 85%RH, storage: 0 to 85%RH

Explosion class Ex d IIC T6

Protection structure IP67 (IEC standard)

Material Body: Aluminum (AlDc.8S), Cover O-Ring: Buna N

Weight※1 Approx. 1.4kg (approx. 1.2kg)

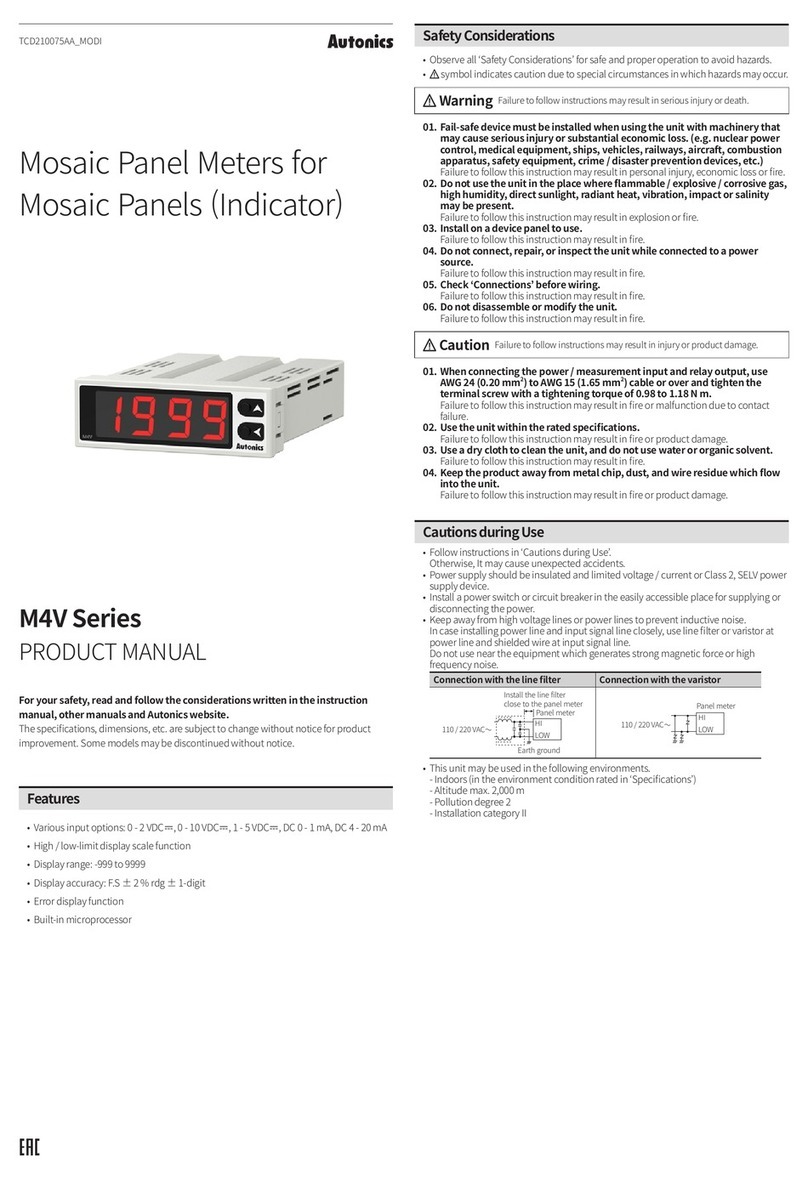

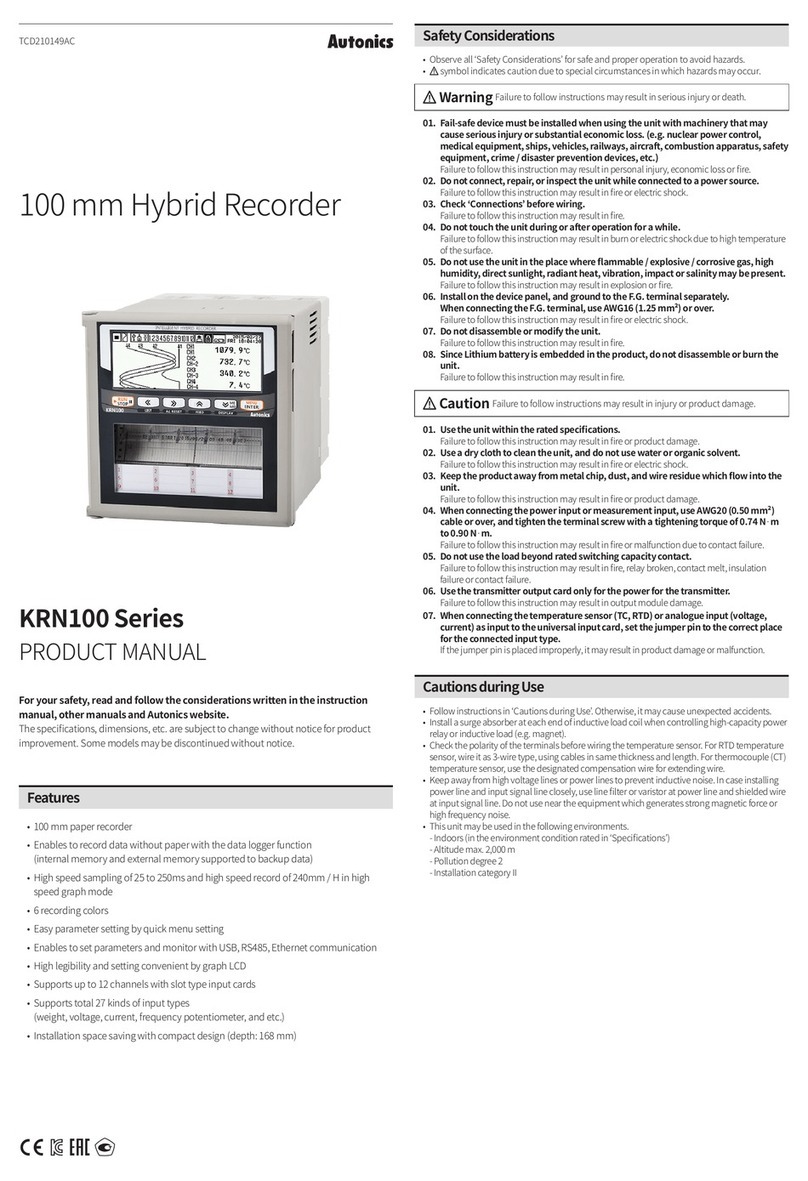

Features

Please read “Caution for your safety” in operation manual

before using this unit.

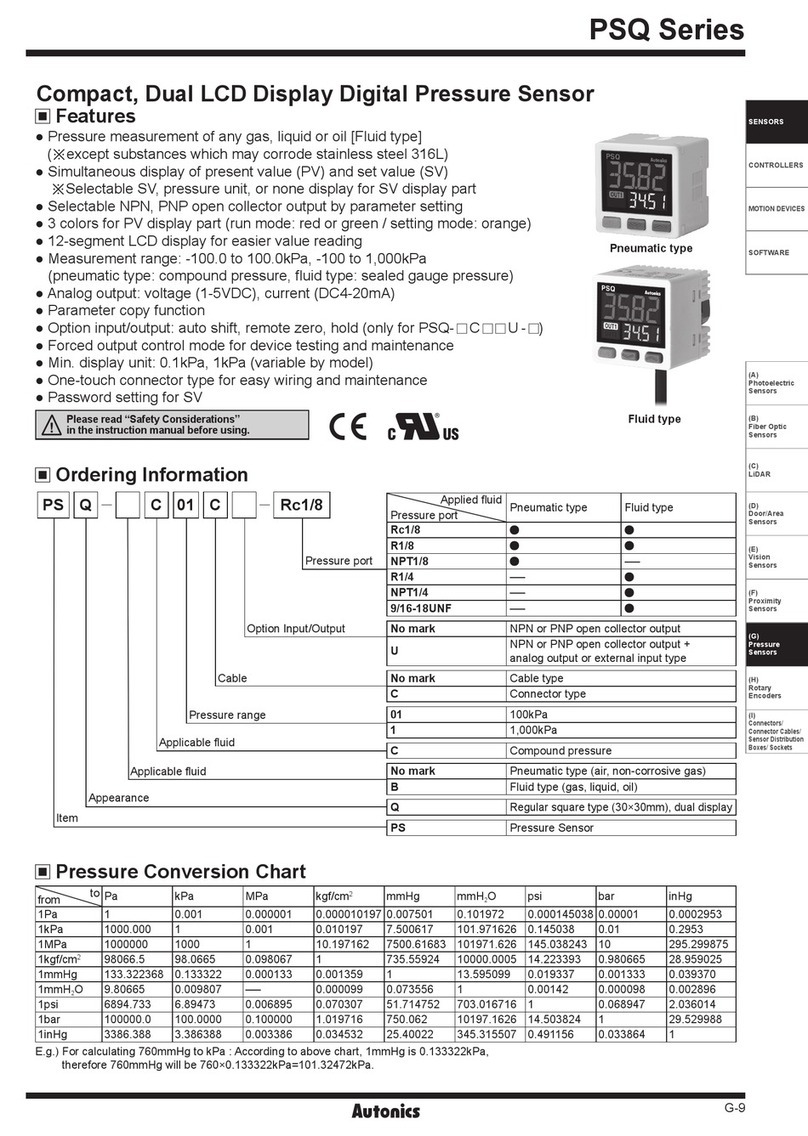

Ordering Information

Specications

※1: The weight includes packaging. The weight in paranthesis is for unit only.

※Environment resistance is rated at no freezing or condensation.

Item Description

①Mounting bracket 0 Without bracket 1 With bracket

②User temperature range 1: To order this unit, write the temperature sensor type and the temperature range.

(-270 to 1372, K)※1

① ②

Hart Field Communications Protocol may depend on several factors,

including calibrators, software, or rmware updates.