Deta SILENT 100 230V User manual

Je

ff

Way Electr cal Serv ces Ltd ta Je

ff

Way Group.

Reg stered n England. No. 01333856

Reg stered O

ffi

ce: The Old Depot, The Square, Knowle, Br stol BS4 2SS

01179090517 enquirie@je

ff

way.co.uk www.je

ff

way.co.uk

Welcome to your

New Home!

As the contractors responsible for the electrical works within this property we would like to

assure you that as an approved NICEIC contractor, the electrical works in your new home

have been carried out to the highest standards.

Sometimes however, problems may occur as a result of a fault to an electrical fitting rather

than the electrical installation itself. You will be reassured to know therefore, that all fittings

come with a minimum of a one-year guarantee from ourselves and will be corrected or

replaced promptly.

WELCOME

If you require any further works to be carried out, please do not hesitate to contact our

Head Oce on 0117 9090517 and we will be more than happy to deal with your enquiry.

Should you experience an electrical defect to your property, then please contact your

developers After Sales as they need to be the first point of contact to be made aware of

the problem. Our After Sales Co-Ordinator will then contact yourself to arrange a suitable

date and time for an electrician to visit your property and rectify the fault.

1

This leaflet is designed to give you a brief overview of the electrical system in your home,

tell you about some of its safety features and give you a few tips on dealing with some of

the more common problems.

UNDERSTANDING YOUR ELECTRICAL SYSTEM

Sometimes the RCD/RCBO will ‘trip out’ when the light bulb ‘blows’. This is caused by a surge of current as the

bulb blows and it is nothing to worry about. Simply replace the light bulb and reset the RCD/RCBO. Low bulb

life cannot be caused by faulty wiring and we recommend that you only purchase good quality bulbs from a

known manufacturer.

LIGHT BULBS

You may have noticed that some green and yellow wires connected to your gas and water mains. This is

known as bonding. These connections are there for your safety and should not be tampered with or removed.

EARTH BONDING

To comply with current building regulations, we have fitted mains operated smoke alarms & heat detectors.

Usually fitted to the hallways, landings, kitchens, if these detect smoke, they will both emit a high-pitched

beeping. If this turns out to be a false alarm, pressing and holding the hush button will silence them.

2

SMOKE ALARMS

The heart of the electrical system is the consumer unit or fuse board as it’s commonly known. It’s usually in the

hallway or under stairs cupboard.

The consumer unit is connected to the electricity meter by the meter tails and all the wiring in your home starts

at this point. You will see that the sockets, cooker, lights etc are all on dierent circuits. This is so each circuit can

be wired in the appropriate size cable, larger cable for the cooker, smaller cable for the lights, and protected by

the appropriate size circuit breaker.

CONSUMER UNIT

The Residual Current Device (RCD/RCBO) for which you have covering dierent circuits within your property,

ensures you are always safe from any potential hazards. The RCD/RCBO is the only device that is designed to

prevent loss of life.

RCD’s and RCBO’s need to be sensitive to oer the correct level of protection, which sometimes lead to

‘nuisance tripping’, where the RCD trips out for no apparent reason. If there is no obvious problem, you can

simply reset the RCD by switching it back on. If it won’t stay in the ‘on’ position, with a socket outlet circuit you

need to unplug all the appliances on that circuit. If the RCD will now reset, try plugging the appliances back

in one by one until you find the appliance which is faulty and causing the tripping. We suggest you get the

appliance checked for safety. In our experience steam irons, cookers, kettles and washing machines are the

most likely culprits.

FAULT FINDING

3

What to do if my

Consumer Unit Trips?

Main Switch to switch o all electrics. Your consumer

unit will then be fitted with either an RCD which covers

a group of circuits or individual RCBO devices which

cover individual circuits, both work and protect the

installation in the same way.

Testing of RCBO’s should be carried out quarterly by

pressing the test button.

It may trip if a light bulb goes.

ABOUT YOUR CONSUMER UNIT

Check the consumer unit to identify which circuit has

tripped out.

Try to reset the RCD/RCBO. If the RCD/RCBO fails

to reset unplug all plugs in the ring main. (TV, Kettle,

toaster, heater etc) Try to reset the RCD/RCBO.

If power is restored, then plug in the appliances one

by one until loss of power. Leave faulty appliance

unplugged and restore power.

Repair or replace faulty appliance. If all trip switches

are o and all appliances are unplugged and the RCD/

RCBO still won’t reset please contact customer care.

WHAT TO DO IF THE POWER GOES OFF

This is usually because a light bulb has blown.

Try to reset the RCD/RCBO.

If the RCD/RCBO resets, turn on the lights to find which

lamp has blown. If the lights do not come on, leave trip

switch o and contact customer care

IF THE LIGHTS GO OFF

RCD CONFIGURATION

RCBO CONFIGURATION

RCD DEVICE

RCBO DEVICE

Deta Smoke Detector

- Datasheet

4

Safety Alarms

DS 0242 V1.1 –NPD 0648/PI 0146 02/2021

Deta Electrical Company Ltd.

UK: Panattoni Park Luton Road Chalton Bedfordshire LU4 9TT UK

EU: Unit 16 Ashbourne Industrial Estate Ashbourne Co. Meath A84 W972 Ireland

Tel. +44 1582 544 548 technical@deta.co.uk

Smoke, Heat and Carbon Monoxide Alarms

Description

Range of mains powered optical smoke and

heat alarms with back-up power options of

either 9V replaceable or 10-year sealed in

non-replaceable battery, satisfying both

Grade D2 and D1 domestic requirements

respectively as laid down by BS 5839: Part 6

and the Building Regulations of England and

Wales, Scotland and Northern Ireland.

A Carbon Monoxide alarm compliments the

range. All alarms supplied with base making

installation easier.

Features

•

Optical alarms are suitable for all

circulation areas and habitable rooms,

making it ideal for hallways and

landings, as well as living rooms and

bedrooms

•

Heat alarms are designed for areas

where fumes or dust may cause

nuisance alarms, making it ideal for

kitchens, attics and garages

•

CO alarm detect dangerous levels of

Carbon Monoxide, making it ideal for

installation in all rooms with fuel

burning appliances.

•

High visibility dust covers supplied

to prevent dust ingress during

building works

•

Linkable up to 12 optical, heat and

Carbon Monoxide alarms in total

for larger properties

•

Alarms have missing battery

indicator and mechanism that

prevents installation of the alarm if

the battery is missing

•

Supplied with common mounting

base that allows alarm to be pushed

simply into place

•

Mounting base has foam gasket

built into mounting surface to

prevent dust ingress

•

Mounting base has large wiring

space and fly lead electrical

connection into alarm

●

5-year guarantee

Range

Optical Smoke Alarm

–9V battery

11

63

Optical Smoke Alarm

–10-yr battery

1164

Heat Alarm

1165

Heat Alarm –10-yr battery

1166

Carbon Monoxide (CO) Alarm

1169

Technical Specification

Voltage

240Vac

Back up (1163, 1165 &

1169)

DC 9V PP3 Alkaline

Back up (1164 & 1166)

Sealed in 10-year long

life battery

Sound Level - Optical &

Heat

85dB at 3m

Sound level - Carbon

Monoxide

85dB at 1m

Operating Temp.

5oC to 38oC

Humidity

10% to 85% RH

Linkable*

Up to 12 units

Test Button

Yes

Silencer

Yes (Heat and Smoke)

Supply Indication

Green LED

Operation

Red LED

Heat Alarm Class

Class A2: 54-70oC

No user serviceable parts

* Not inter-linkable with legacy models 1111, 1113,

1115, 1151, 1153 or 1155

Standards

Optical

BS EN 14604:2008

Heat

BS 5446-2:2003

Carbon Monoxide (CO)

BS EN 50291-1:2018

Safety Alarms

DS

0242 V1.1 –NPD 0648/PI 0146 02/2021

Deta Electrical Company

Ltd.

UK: Panattoni Park Luton Road Chalton Bedfordshire LU4 9TT UK

EU: Unit 16 Ashbourne Industrial Estate Ashbourne Co. Meath A84 W972 Ireland

Tel. +44 1582 544 548

technical@deta.co.uk

Smoke, Heat and Carbon Monoxide Alarms

Description

Range of mains powered optical smoke and

heat alarms with back-up power options of

either 9V replaceable or 10-year sealed in

non-replaceable battery, satisfying both

Grade D2 and D1 domestic requirements

respectively as laid down by BS 5839: Part 6

and the Building Regulations of England and

Wales, Scotland and Northern Ireland.

A Carbon Monoxide alarm compliments the

range. All alarms supplied with base making

installation easier.

Features

•

Optical alarms are suitable for all

circulation areas and habitable rooms,

making it ideal for hallways and

landings, as well as living rooms and

bedrooms

•

Heat alarms are designed for areas

where fumes or dust may cause

nuisance alarms, making it ideal for

kitchens, attics and garages

•

CO alarm detect dangerous levels of

Carbon Monoxide, making it ideal for

installation in all rooms with fuel

burning appliances.

•

High visibility dust covers supplied

to prevent dust ingress during

building works

•

Linkable up to 12 optical, heat and

Carbon Monoxide alarms in total

for larger properties

•

Alarms have missing battery

indicator and mechanism that

prevents installation of the alarm if

the battery is missing

•

Supplied with common mounting

base that allows alarm to be pushed

simply into place

•

Mounting base has foam gasket

built into mounting surface to

prevent dust ingress

•

Mounting base has large wiring

space and fly lead electrical

connection into alarm

●

5-year guarantee

Range

Optical Smoke Alarm –9V battery

1163

Optical Smoke Alarm –10-yr battery

1164

Heat Alarm

1165

Heat Alarm –10-yr battery

1166

Carbon Monoxide (CO) Alarm

1169

Technical Specification

Voltage

240Vac

Back up (1163, 1165 &

1169)

DC 9V PP3 Alkaline

Back up (1164 & 1166)

Sealed in 10-year long

life battery

Sound Level - Optical &

Heat

85dB at 3m

Sound level - Carbon

Monoxide

85dB at 1m

Operating Temp.

5oC to 38oC

Humidity

10% to 85% RH

Linkable*

Up to 12 units

Test Button

Yes

Silencer

Yes (Heat and Smoke)

Supply Indication

Green LED

Operation

Red LED

Heat Alarm Class

Class A2: 54-70oC

No user serviceable parts

* Not inter-linkable with legacy models 1111, 1113,

1115, 1151, 1153 or 1155

Standards

Optical

BS EN 14604:2008

Heat

BS 5446-2:2003

Carbon Monoxide (CO)

BS EN 50291-1:2018

Deta Optical Detector

- User Instructions

6

240V Optical Alarm with 9V Battery Back-Up

1163

240V Optical Alarm with Sealed 10 Year Battery Back-Up

1164

1 Page

Description

Optical Smoke Alarms with a replaceable 9V battery back-up or a 10-year

sealed for life battery back-up version. The alarms mount onto a wiring

base.

Multiple optical alarms can be interlinked together to provide detection

and audible warning over larger areas or floors.

Alarms suitable for BS 5839-6 requirements for Grade D1 and D2 systems.

All products must be installed by a competent person in accordance BS

7671, the current edition of the IET Wiring Regulations.

Where to Locate

Smoke alarms needs to be installed in circulation areas of a dwelling, for

example, hall ways and landing, as a minimum, and ideally heat alarms

need to be installed in kitchens, as required by BS 5839-6, Code of Practice

for the design, installation, commissioning and maintenance of fire

detection and fire alarm systems in domestic premises.

Ideally, alarms should be located:

•In living and sleeping areas.

•On each floor of the dwelling.

•In every room where electrical appliances are operated, e.g. portable

heaters, tumble dryers.

•In each room where there are fossil fuel burning appliances, e.g. gas

boilers, cookers, fireplaces.

It may be necessary to install more than one smoke alarm in an area, e.g.

in halls/corridors that are more than 9m long. See diagram 1.

Diagram 1

Positioning of Alarms

•Smoke and heat from and burning materials rise to the ceiling and

spread horizontally. Mounting the smoke alarm on the ceiling in the

centre of the room places it closest to all points in the room. Ceiling

mounting is preferred in ordinary residential dwellings.

•If smoke alarms are not positioned centrally on a ceiling within a

room, it is recommended to locate it a minimum of 300mm (12”)

from the side wall (see Diagram 2). If space restrictions prevent this,

e.g. narrow corridors/landings, it must not be located closer than

300mm (12”) from the side wall.

Diagram 2

•Put a smoke alarm at both ends of a hallway/corridor or large room if

it is more than 9000mm (30’) long.

•In rooms with an A-shaped peaked ceiling, a sloped or cathedral

ceiling, install a smoke/heat alarm between 500mm and 1500mm

from the highest point of the ceiling. (See Diagram 3).

Diagram 3

•To limit false alarms as laid within BS 5839-6, it is recommended that

smoke alarms should not be installed within 900mm (3’) of the

following: the door to a kitchen, the door to a bathroom containing a

tub or shower. If space restrictions prevent this, it must not be

located closer than 300mm (12”) from the side wall.

•Also, alarms should be positioned away from forced air supply ducts

used for heating or cooling, ceiling or whole house ventilating fans,

or other high air flow areas to limit false alarming.

•It is recommended that smoke alarms are not installed within

300mm of light fittings.

Do Not Install Smoke Alarms in the Following Places

•Alarms should not be positioned in hard-to-reach areas, such as

above stairwells, that make it difficult to gain access for maintenance

•In unventilated garages as vehicle exhaust fumes may cause false

alarm.

•In an area where the temperature may fall below 0oC or rise above

40oC, such as garages and unfinished attics.

•In dusty areas. Dust particles may cause nuisance alarm or failure to

alarm.

•In very humid areas (greater than 93% R.H.), e.g. bathrooms.

Moisture or steam can cause nuisance alarms.

•In insect-infested areas.

•Near fluorescent lights. Electronic “noise” may cause nuisance

alarms.

Important: These alarms are primarily intended for use in single

family occupancy private dwellings.

300mm Minimum

Recommended

7

2Page

Installation

This alarm should be installed as late as possible within the schedule of

works, particularly in new build properties, e.g. after decorating and

making good works.

•This alarm must not be connected to any other manufacturer alarms.

•These alarms, item numbers, 1163, 1165, 1164 and 1166 are only

compatible with each other and 1169 CO alarm; they are not

compatible with previous generations.

Important

The circuit powering the safety alarms must be unswitched, i.e.

permanently live. The electrical supply for mains powered alarms with

battery back-up, as required by BS 5839-6 Grade D1 and D2 systems, must:

i) Be an independent circuit from the consumer unit where no other

electrical equipment is connected, or

ii) A separately electrically protected, regularly used local lighting circuit

Also, where alarms are interlinked, they must be connected to a single

circuit.

Safety Instructions

•Ensure the power supply is switched off before installation and

during maintenance.

•These alarms should be installed by a competent person, e.g. a

qualified electrician.

•These alarms must be installed in accordance with the current

edition of the IET Wiring Regulations BS7671 and the Code of

Practice for the design, installation, commissioning and maintenance

of fire detection and fire alarm systems in domestic premises

BS 5839-6.

•Important: Remove the alarm from the circuit for insulation

resistance testing.

If in doubt, contact a qualified electrician.

Installation

1. Remove the dust cover.

2. Release the alarm from the base by using a screw insert into the slots

and flexing outwards, see diagram. 4

Diagram 4

3. Remove the electrical connector from the alarm by squeezing the

locking arms.

4. Select the cable entry on the base and remove the cut out. Cable

entry can either be through the back of the base or via surface

mounted mini-trunking. Leave the gasket in place to prevent dust

ingress into the alarm.

5. Mount the base in the desired location using the wall plugs and

screws, as required. See Diagram 5.

Diagram 5

6. Terminate the live, neutral and earth supply cables and interlink cable

if alarms are interlinked. See Diagram 6.

Diagram 6.

L (Live): Brown conductor

N (Neutral): Blue conductor

E (Earth): Green / Yellow

I (Interlink): Grey (if using 6243Y cable)

7. A maximum of 12 alarms can be interlinked. If more than 12 alarms

are interlinked it may result in permanent damage.

8. For multiple alarm installations use three core and earth cable

between all the alarms to be interlinked and connect the third core of

that cable to terminal marked I. DO NOT use the earth wire for the

interlink wire. This must be treated as live, i.e. insulated and sleeved.

9. Connect the battery:

•On 1163 by opening the battery cover and inserting it.

•On 1164 by pulling tab on the sealed battery cover.

Test the alarm by pressing the TEST button. See Diagram 7.

10. Refit the electrical connector.

Diagram 7

11. Attached the alarm to the base

12. Replace the dust cap

13. Turning on the electrical power. The green LED should be lit when the

alarm is operating from the power supply.

14. Test the alarm, including the interlink feature if more than one alarm is

installed.

Important: Remove the alarm from the circuit for insulation

resistance testing.

8

3Page

User Information

Alarm Operation

What to do when the alarm sounds

LED indicators

Green LED: Connected to mains voltage power supply.

Red LED: Flashing approximately every 32 seconds indicates

that the smoke alarm is operating properly.

RED LED-Flashing: When the Test button is pressed, the smoke alarm

senses smoke particles, the alarm goes into alarm

mode (constant pulsating sound) and the red LED

will flash once per second. The flashing LED and

pulsating sound will continue until the test button is

released, the air is cleared from alarms sensors or

the ambient temperature is normal.

RED LED-Alarm silencer (Hush mode) indication:

The red LED will flash every 8 seconds, indicating the

alarm is in the silenced (hush) mode.

Alarm silence (hush mode)

•Optical: Push TEST button to silence the alarm.

•This silence feature is only to be used when a known alarm condition,

such as smoke from cooking, activates the alarm. This feature is

useful in areas such as kitchens to prevent nuisance alarms.

•The alarm will automatically reset itself after approx. 8 minutes.

Should smoke particles still be present, the alarm will sound again.

Locating the initiating alarm (Nuisance alarms)

In the event of a nuisance alarm, although all interlinked alarms in the

system sound, RED LED will flash only on the initiating alarm making it easy

to identify.

CAUTION: Before using the alarm silence (hush), identify the source of the

smoke and be certain that a safe condition exists.

1. Alert small children in the home to quickly follow the family escape

plan.

2. Leave immediately by your escape plan. Every second counts, so

don’t waste time getting dressed or picking up valuables.

3. In leaving, don’t open any inside door without first feeling its surface.

If hot, or if you see smoke seeping through cracks, don’t open that

door! Instead, use your alternate exit. If the inside of the door is

cool, place your shoulder against it, open it slightly and be ready to

slam it shut if heat and smoke rush in.

4. Stay close to the floor if the air is smoky. Breathe shallowly through

a cloth, wet if possible.

5. Once outside, go to your selected meeting place and make sure

everyone is there.

6. Call the fire department from your neighbour’s home –not from

yours!

7. Don’t return to your home until the fire officials say that it is all right

to do so.

8. If there is any question as to the cause of an alarm, it should be

assumed that the alarm is due to an actual fire and the dwelling

should be evacuated immediately.

Note: These guidelines will assist you in the event of a fire,

however, to reduce the chance that fires will start,

practice fire safety rules to prevent hazardous situations.

Plan of Escape

•It is recommended that a plan of escape is developed and practiced.

A floor plan indicating doors and windows should be made and, if

possible, that two routes of escape are established.

•It is also recommended that fire extinguishers are installed and

maintained.

DANGER: If the alarm sounds, and it is not being tested, it means the unit

is sensing smoke, THE SOUND OF THE ALARM REQUIRES YOUR

IMMEDIATE ATTENTION AND ACTION.

User Maintenance

Replacing the Battery (1163 models only)

Warning: Only use the specified batteries (see Product Spec). Use of

different batteries may have detrimental effect on the alarm. It is

recommended that the battery is replaced when its voltage is low.

1. Turn off the electrical supply to the alarms at the consumer unit/fuse

box. The green power LED light will go off.

2. To remove the alarm from the base, using a small flat blade screwdriver

gently flex the locking clips on the side of the base away from the

alarm. The alarm will then come away from the base. See Diagram 8.

Diagram 8

3. To remove the electrical connector, squeeze the locking arms on the

sides while pulling it away from the bottom of the alarm. See Diagram

9.

4. After alarm has been removed, you can open the battery cover and

replace with new battery. See Diagram 9.

Diagram 9

5. After the battery is replaced, close the battery cover and test the

alarm by pressing the TEST button.

6. Reconnect the electrical connector, ensuring the orientation is correct

and the locking arms snap back into place. See Diagram 10.

7. Fit the alarm body on to the base, ensuring it clips securely into place.

Diagram 10

8. Turn on the electrical supply and the green LED light will come on.

Test alarm by pressing the test button for at least 5 secs. The alarm

will sound 3 short beeps –1.5 seconds pause, and then repeat until

the button is released.

The smoke alarm will go into hush mode for approx. 8 minutes.

During this period, the RED LED will flash once every 8 seconds. It will

then go to normal status and flash once every 32 seconds. If there is

no sound output when the test button is pushed, the alarm is may be

defective faulty. See the section: “Trouble Shooting”.

Caution: Test the alarm for correct operation using the test facility

whenever the battery is replaced.

Warning: Electricity is dangerous. When replacing the battery, you must

make sure the electrical AC power is turned off.

Battery (1163 models only)

•It is recommended that the battery is replaced annually.

•This alarm uses a 9-volt battery. A new battery should last for at

least one year under normal operate conditions.

•This alarm has a low battery monitor which will cause the alarm to

“chirp”and at the same time as the red LED flash approx. every 32

seconds for a minimum of thirty days when the battery gets low.

Replace the battery when this condition occurs. Please refer to

“Replacing the Battery”.

Important: Do not attempt to remove the cover to clean inside.

This will affect the warranty.

9

4Page

Product Specification

Voltage

220 –240V @ 50Hz with 9V battery

backup

Optical Alarm Button –dual

function

•Push to Test

•Activate Silence (hush) mode

Current

< 100mA

Silence (Hush) Time (approx.)

8 minute

Battery Specification

9V battery DC. Brands:

Gold Peak: GP1604S, GP1604A, or

Raymax: 6LR61

Long life - CR9V, EVE

Sound Pattern

ISO8201 (BI 0.5s - pause 0.5s - BI

0.5s - pause 0.5s - BI 0.5s - pause

1.5s, with the RED LED flash, then

repeat)

Battery Life

Over one year –1163

10 year –1164

Alarm Volume

> 85dB(A) at 3 meters

Inter-linkable

up to 12 detectors

Alarm Sensitivity

Optical: 0.114 - 0.160dB/m:

Compliance

Optical: EN14604:2005/AC:2008

Product Disposal

These alarms come under the Waste Electrical & Electronic Equipment Regulations and must be disposed of in

accordance to these Regulations.

Testing the Alarm

Important Safety Information:

Test the alarm to ensure proper operation.

1. Test alarm by pressing and holding the test button until it sounds.

The alarm will sound 3 short beeps –1.5 seconds pause, and then

repeat until the button is released.

2. If multiple alarms are installed within the dwelling, test each alarm.

Each alarm should trigger other alarms connected within 10 seconds.

Do not attempt to test the alarm with smoke or heat from a flame. Do not

ignite combustible materials and start a fire.

If no alarm sounds, the unit has a defective battery or other failure. Refer

to “Trouble Shooting” section for a solution.

Caution: Due to the loudness (85 decibels) of the alarm, always stand an

arms-length always from the unit when testing. Test the alarm

weekly to ensure proper operation. Erratic or low sound

coming from your alarm may indicate a defective alarm.

NOTE: WEEKLY TESTING IS REQUIRED

1. This alarm must not be connected to any other manufacturer alarms.

2. These alarms, item numbers, 1163,1165, 1164 and 1166 are only

compatible with each other and CO alarm 1169; they are not

compatible with previous generations.

3. Test alarm weekly to ensure proper operation. The test button

accurately tests smoke alarm functions. Do not use any other test

method.

4. The alarm must not be exposed to dripping or splashing water.

5. These alarms are primarily intended for use in single family

occupancy private dwellings. In multifamily buildings, each individual

living unit should have its own alarms. Do not install in non-

residential buildings. This smoke alarm is not a substitute for a

complete alarm system.

6. The alarm may not alert every household member every time. The

alarm horn is loud in order to alert individuals to a potential danger.

However, there may be some circumstances where a household

member may not hear the alarm (e.g. excessive outdoor or indoor

noise, sound sleepers, drug or alcohol usage, the hard of hearing). If

you suspect that this alarm may not alert a household member,

install and maintain specialty alarms. Household member must hear

the alarms warning sound and quickly respond to it to reduce the risk

of damage, injury, or death that may result from fire. If a household

member is hard of hearing, install special alarms with lights or

vibrating devices to alert occupants.

7. The alarms are designed to give audible warning of a developing fire

and can only sound their alarms when they detect smoke,

combustion particles in the air or abnormal ambient temperature.

Many fires, however, are fast burning and in these circumstances the

alarm may not be triggered quick enough to ensure a safe escape.

8. The alarms have limitations. This alarm is not fool proof and is not

warranted to protect lives or property from fire. The alarms are not

a substitute for insurance. Occupants should insure their lives and

property. In addition, it is possible for the alarm to fail at any time.

For this reason, you must test the alarm weekly and replace unit

after 10 years.

9. Do not paint the alarms.

10. Check the alarms on reoccupation of the premises after a vacation.

Maintenance

Cleaning

The alarm should be cleaned on a monthly basis as a minimum. To do this:

•Turn off the electrical supply to the alarm.

•Use a vacuum cleaner with the soft brush to vacuum all sides and

covers of alarm to remove dust, dirt, and debris. Be sure all the

vents are free of debris.

•Use a damp cloth to clean the alarms cover.

•Turn the electrical supply to the alarm on.

Battery

The battery should be replaced annually on 1163, see ‘Replacing the

Battery’.

1164 model has a sealed 10-year battery and must not be replaced.

Trouble Shooting

Problem

Remedy

Problem

Remedy

The green LED does not light up

1. Check electrical power supply

is switched on

2. Check the electrical connector

is properly connected to the

alarm

3. If the problem still exists,

replace the alarm

The alarm chirp occurs every 32

seconds approx. and goes into fault

mode

1. Clean alarm. Refer to

“Maintenance ”

2. If the problem still exists,

replace the alarm

Alarm does not sound when tested.

Note: push test button for at least

five seconds while testing!

1. Ensure that the battery and

electrical connector is

properly connected

2. Clean alarm

3. If the problem still exists,

replace the alarm

The alarm sounds intermittently or

when residents are cooking, taking

showers, etc. (false alarming)

1. Press test button to pause

alarm

2. Open window or fan alarm to

3. Clean alarm

The alarm chirp occurs every 32

second approx. at the same time as

the red LED flashes once

The battery needs replacing, refer

to “Replacing the Battery”

The alarm sounds different from its

usual sound

4. Clean alarm

5. If the problem still exists,

replace the alarm

Warning: Do not disconnect battery to quiet an unwanted alarm. This will remove your protection. Fan the air or open window to remove smoke or dust.

S24

INS0093 V1.5 07/21 NPD 0648/0534/PI 0146

Deta Electrical Company Ltd

UK: Panattoni Park Luton Road Chalton Bedsfordshire LU4 9TT

EU: Unit 16 Ashbourne Ind. Est. Ashbourne Co. Meath A84 W972

deta.co.uk | Technical Helpline: +44(0)1582 544 548

Deta Heat Detector

- User Instruction

11

12

13

14

INS0096 V1.1 02/21 NPD0648/0532

Deta Electrical Company Lt

d

UK: Pana oni Park Luton Road Chalton Beds. LU4 9T

T

EU: Unit 16 Ashbourne Ind. Est. Ashbourne Co. Meath A84 W972 Irelan

d

deta.co.uk | Technical Helpline: +44(0)1582 544 54

8

Deta CO Detector

- User Instructions

16

1 P a g e

Description

Carbon Monoxide alarm with replaceable 9V battery back-up. The alarm

mounts onto a wiring base.

This Carbon Monoxide alarm can be interlinked with the smoke and

heat alarms, 1163 and 1165 respectively.

All products must be installed by a competent person in accordance BS

7671, the latest edition of the IET Wiring Regulations.

The instructions contain important information on operation and

maintenance of the Carbon Monoxide alarm. Keep this document in a

safe place for future reference.

Where to Locate

Ideally, Carbon Monoxide alarms should be installed in every room

containing a fuel burning appliance and as per BS 5839-6, Code of Practice

for the design, installation, commissioning and maintenance of fire

detection and fire alarm systems in domestic premises.

Additionally, alarms may be installed to ensure that adequate warning is

given for occupants in other rooms, by locating alarms:

•In remote room in which occupants spend considerable time whilst

awake.

•Near every sleeping room or area.

•In each room containing a flueless or open-fueled appliance.

•In a garage as vehicles produce carbon monoxide, any time they are

running.

It is recommended that a CO alarm be installed on each level of a

multilevel home.

Diagram 1

Positioning of Alarms

•CO gas from fueled appliances immediately mixes with the air

around it. Mounting the CO on the ceiling in the centre of the room

places it closest to all points in the room. Ceiling mounting is

preferred in ordinary residential dwellings.

•When mounting an alarm on the ceiling, locate it at a minimum of

500mm (20”) from the side wall (See Diagram 2).

500mm

Minimum

Diagram 2

•In rooms with an A shaped peaked ceiling, a sloped or cathedral

ceiling, install a CO alarm between 500mm and 1500mm from

the highest point of the ceiling. (See Diagram 3).

Diagram 3

•CO alarms should not be installed within 900mm (3’) of the

following: the door to a kitchen, the door to a bathroom containing a

tub or shower, forced air supply ducts used for heating or cooling,

ceiling or whole house ventilating fans, or other high air flow areas.

•CO alarms should be mounted at least 1.8m from the fuel burning

appliance.

Do Not Install CO Alarms in the Following Places

•In the immediate vicinity of a fuel burning appliance.

•In an enclosed space, such as cupboard or behind a curtain.

•In an area where the temperature may fall below -10oC or rise

above 40oC, such as garages and unfinished attics.

•In excessively humid areas such as bathroom.

•Next to a door, a window or an extractor fan.

•In dusty areas. Dust particles may cause nuisance alarm or failure to

alarm.

•Near fluorescent lights. Electronic “noise” may cause nuisance

alarms.

Important: These alarms are primarily intended for use in single

family occupancy private dwellings. In multifamily

buildings, each individual living unit should have its

own alarms. Do not install in non-residential

buildings.

240V Carbon Monoxide Alarm with 9V Battery Back-Up

1169

17

2 P a g e

Installation

This alarm should be installed as late as possible within the schedule of

works, particularly in new build properties, e.g. after decorating and

making good works.

•This alarm must not be connected to any other manufacturer’salarms.

•The CO (1169) alarm is compatible with itself, Smoke (1163) and

Heat (1165) alarms; and is not compatible with previous

generations.

Important

The circuit powering the safety alarms must be unswitched, i.e.

permanently live. The electrical supply for mains powered alarms with

battery back-up, as required by BS 5839-6 Grade D systems, must:

i) Be an independent circuit from the consumer unit where no other

electrical equipment is connected, or

ii) A separately electrically protected, regularly used local lighting circuit

Also, where alarms are interlinked, they must be connected to a single

circuit.

Safety Instructions

•Ensure the power supply is switched off before installation and

during maintenance.

•These alarms should be installed by a competent person, e.g. a

qualified electrician.

•If the alarm is incorrectly installed or tempered with, this may

result in damage to the alarm, a failure in operation or an

electric shock hazard.

•These alarms must be installed in accordance with the current

edition of the IET Wiring Regulations BS7671 and the Code of

Practice for the design, installation, commissioning and maintenance

of fire detection and fire alarm systems in domestic premises

BS 5839-6.

•Important: remove the alarm from the circuit for insulation

resistance testing.

If in doubt, contact a qualified electrician.

Installation

1. Remove the dust cover.

2. Release the alarm from the base by using a screw insert into the slots

and flexing outwards, see diagram. 4

Diagram 4

3. Remove the electrical connector from the alarm by squeezingthe

locking arms.

4. Select the cable entry on the base and remove the cut out. Cable

entry can either be through the back of the base or via surface

mounted mini-trunking. Leave the gasket in place to prevent dust

ingress into the alarm.

5. Mount the base in the desired location using the wall plugsand

screws, as required, see diagram 5.

Diagram 5

6. Terminate the live, neutral and earth supply cables and interlink cable

if alarms are interlinked, see diagram 6.

Diagram 6

L (Live): Brown conductor

N (Neutral): Blue conductor

E (Earth): Green / Yellow

I (Interlink): Grey (if using 6243Y cable)

7. A maximum of 12 alarms can be interlinked. If more than 12 alarms

are interlinked it may result in permanent damage.

8. For multiple alarm installations use three core and earth cable

between all the alarms to be interlinked and connect the third coreof

that cable to terminal marked I. DO NOT use the earth wire for the

interlink wire. This must be treated as live, i.e. insulated andsleeved.

9. Connect the battery by opening the battery cover and inserting it.

Test the alarm by pressing the TEST button, see diagram 7.

10. Refit the electrical connector.

Diagram 7

11. Attached the alarm to the base

12. Replace the dust cap

13. Turning on the electrical power. The green LED should be lit when the

alarm is operating from the power supply.

14. Test the alarm, including the interlink feature if more than one alarm is

installed.

Important: Remove the alarm from the circuit for insulation

resistance testing.

Warning: The installation of this CO alarm should not be used as a

substitute for proper installation, use and maintenance of fuel

burning appliances including appropriate ventilation and

exhaust systems.

18

3 P a g e

User Information

Alarm Operation

What to do if the CO alarm sounds

LED indicators

Green LED: When connected to the mains supply, the alarm goes

through a 40 second initialization routine. After

initialization, the GREEN LED remain permanently on

indicating normal operation.

If GREEN LED flashes every 33 seconds, it indicates the

alarm is being powered by the back-up battery.

Red LED Flashing: When the alarm senses CO gas, it goes into alarm

mode and the RED LED flashes 4 times at 5 second

intervals.

Yellow LED Flashing: Flashing once every 33 seconds approx.

accompanied with a chirping sound indicates low

battery warning.

If flashing approximately twice every 38 seconds with

two chirps, indicates a fault condition.

Alarm Mode

In alarm mode, the CO alarm will sound four beeps in quick succession,

followed by a 5 second pause. This pattern is then repeated.

Test/Silence Button

•Use the Test/Silence button to test the alarm weekly. Please refer to

“Testing the Alarm”.

•The Test/Silence button will silence the alarm only if it is in low

battery condition. The yellow LED will flash during this condition.

The alarm will be silenced for up to 9 hours. To change the

battery, please refer to “Replacing the Battery”.

End of life indication

•The device will give visual and audible warning when it reaches end of

life (10 years). The device chirps 3 times every 33 second approx. with

yellow LED flashing once. The end of life signal cannot be silenced and

the device must be replaced as soon as possible.

If the CO gas is detected, the alarm will emit a series of four beeps

followed

by a short pause.

1. Alert small children in the home and quickly follow the family

escape plan.

2. Keep calm and open all doors and windows to increase the rate of

ventilation.

3. Turn off any fuel burning appliances where possible and stop using

them.

4. Evacuate the property leaving doors and windows open.

5. Leave immediately and don’t waste time getting dressed or

picking up valuables.

6. Once outside, go to your selected meeting place and make

sure everyone is there.

7. Get medical help for anyone suffering the effects of CO

poisoning.

8. Call the appropriate appliance servicing and/or maintenance

agency or, where necessary, the relevant fuel supplier on their

emergency number.

Note: When an alarm sounds, it may be difficult to determine what

triggered the alarm, particularly if CO alarms are interlinked

with smoke/heat alarms. Therefore, evacuate the property

first, then determine the cause and take appropriate action.

Note: The CO alarm will return to normal operating mode once the

CO gas condition is cleared.

Warning: This device alarms only on the detection of carbon Monoxide

gas. If ignored, the presence of Carbon Monoxide can be fatal.

DANGER: If the alarm sounds, and it is not being tested, it means the unit

is sensing Carbon Monoxide gas, THE SOUND OF THE ALARM

REQUIRES YOUR IMMEDIATE ATTENTION AND ACTION.

Plan of Escape

•It is recommended that a plan of escape is developed and practiced.

A floor plan indicating doors and windows should be made and, if

possible, that two routes of escape are established.

User Maintenance

Replacing the Battery

Warning: Only use the specified batteries (see Product Specification).

Use of different batteries may have detrimental effect on the

alarm. It is recommended that the battery is replaced when its

voltage is low.

1. Turn off the electrical supply to the alarms at the consumer unit/fuse

box. The green power LED light will go off.

2. To remove the alarm from the base, using a small flat blade screwdriver

gently flex the locking clips on the side of the base away from the

alarm. The alarm will then come away from the base. See Diagram 8.

Diagram 8

3. To remove the electrical connector, squeeze the locking arms on the

sides while pulling it away from the bottom of the alarm. See Diagram

9.

4. After alarm has been removed, you can open the battery coverand

replace with new battery. See Diagram 9.

Diagram 9

5. After the battery is replaced, close the battery cover and test the

alarm by pressing the TEST button.

6. Reconnect the electrical connector, ensuring the orientation is correct

and the locking arms snap back into place. See Diagram 10.

7. Fit the alarm body on to the base, ensuring it clips securely intoplace.

Diagram 10

8. Turn on the electrical supply and the green LED light will come on

after the 40 second initialization routine, during which the green

light flashes every 3 seconds. Test alarm by pressing the test

button. The alarm will sound 4 short beeps –5 seconds pause, and

then repeat until the button is released.

It will then go to normal status and the Green LED will always be ON.

If there is no sound output when the test button is pushed, the alarm

may be defective. See the section: “Trouble Shooting”.

Caution: Test the alarm for correct operation using the test facility

whenever the battery is replaced.

Warning: Electricity is dangerous. When replacing the battery, you must

make sure the electrical AC power is turned off.

Battery

•It is recommended that the battery is replaced annually.

•This alarm uses a 9 Volt battery. A new battery should last for at

least one year under normal operating conditions.

•This alarm has a low battery monitor which will cause the alarmto

“chirp” once and at the same time the Yellow LED flashes approx.

every 33 seconds for a minimum of 7 days when the battery gets

low. Replace the battery within 30 days of the first occurrence of

"Low battery warning". Please refer to “Replacing the Battery”.

Important: Do not attempt to remove the cover to clean

inside. This will affect the warranty.

19

Testing the Alarm

Important Safety Information

Test the alarm to ensure proper operation.

1. Test alarm by pressing and holding the test button until it sounds.

The alarm will sound 4 short beeps –5 seconds pause, and then

repeat until the button is released.

2. If multiple alarms are installed within the dwelling, test each alarm.

Each alarm should trigger other alarms connected within 10seconds.

The alarm must only be tested by pressing the Test/Silence button. Do not

ignite combustible materials and start a fire. If no alarm sounds, the unit

has a defective battery or other failure. Refer to “Trouble Shooting”

section for a solution.

Caution: Due to the loudness (85 decibels) of the alarm, always stand an

arms-length always from the unit when testing. Erratic or low

sound coming from your alarm may indicate a defective alarm.

NOTE: WEEKLY TESTING IS REQUIRED

•The alarm may not alert every household member every time. The

alarm horn is loud in order to alert individuals to a potential danger.

However, there may be some circumstances where a household

member may not hear the alarm (e.g. excessive outdoor or indoor

noise, sound sleepers, drug or alcohol usage, the hard of hearing). If

you suspect that this alarm may not alert a household member, install

and maintain specialty alarms.

•The alarms have limitations. This alarm is not fool proof and is not

warranted to protect lives from exposure to Carbon Monoxide. The

alarms are not a substitute for insurance. Occupants should insure

their lives and property. In addition, it is possible for the alarm to fail

at any time. For this reason, you must test the alarm weekly and

replace the unit after 10 years.

•Test alarm weekly to ensure proper operation by pressing the

test button. Do not use any other test method.

•Do not paint the alarms.

•Check the alarms on reoccupation of the premises after a vacation.

Maintenance

Carbon Monoxide (CO) Overview

Cleaning

The alarm should be cleaned on a monthly basis as a minimum. To do this:

•Turn off the electrical supply to the alarm.

•Use a vacuum cleaner with the soft brush to vacuum all sides and

covers of alarm to remove dust, dirt, and debris. Be sure all the

vents are free of debris.

•Use a damp cloth to clean the alarms cover.

•Turn the electrical supply to the alarm on.

Battery

The battery should be replaced annually. See ‘Replacing the Battery’

Carbon monoxide (CO) is an extremely poisonous, colorless, odourless and

tasteless gas released by the incomplete combustion of fossil fuels such as

natural gas, bottle gas, petrol, diesel, oil, paraffin, wood, coal coke and

biofuels. When inhaled, it causes chemical asphyxiation, when CO mixes

with the blood and reduces the oxygen carried around the body,

particularly to the brain. The following symptoms are typical to CO

poisoning and should be discussed with all members of the household.

Mild Exposure - Slight headache, nausea, fatigue (flu like symptoms).

Medium Exposure - Severe throbbing headache, drowsiness and vomiting.

Extreme Exposure - Unconsciousness, cardiorespiratory failure, death.

Although feeling unwell, victims of CO poisoning can become so

disorientated that they can no longer decide what to do next, including

being unable to exit the building or call for assistance. Very young

children often show symptoms earlier than adults.

Note: The CO alarm may not prevent the chronic effects of carbon

monoxide exposure, and it will not fully safeguard individuals

with specific medical conditions. If in doubt, consult a medical

practitioner.

Important Safety Information

•This alarm must not be connected to any other manufacturer’s alarms.

•The alarm must not be exposed to dripping or splashing water.

•The alarms are designed to give audible warning of a dangerous levels

of Carbon Monoxide. The alarms do not detect any other gas.

•Commonly occurring materials, vapours or gases, e.g. in cleaning

fluids, polishes, paints, cooking operations may cause nuisance alarms.

Major interferents are acetylene, ethyl alcohol, hydrogen cyanide,

hydrogen sulfide, mercaptan, nitrogen dioxide and sulfur dioxide.

Troubleshooting

Problem

Remedy

Problem

Remedy

The green LED does not light up

1. Check electrical power supply

is switched on

2. Check electrical connector is

properly connected to alarm

3. If the problem still exists,

replace the alarm

The alarm chirps twice every 38

seconds approx. at the same time

as yellow LED flashes twice and

goes into fault mode

1. Clean alarm. Refer to

“Maintenance”

2. If the problem still exists,

replace the alarm

Alarm does not sound when tested.

Note: push test button for at least

five seconds while testing!

1. Ensure that the battery and

electrical connector is

properly connected

2. Clean alarm

3. If the problem still exists,

replace the alarm

The alarm sounds intermittently or

when residents are cooking, taking

showers, etc. (false alarming)

1. Press test button to pause

alarm

2. Open window or fan alarm

3. Clean alarm

The alarm chirps once every 33

second approx. at the same time as

the yellow LED flashes once

The battery needs replacing, refer

to “Replacing the Battery”

The alarm sounds different from it

is used to. It starts and stops.

4. Clean alarm

5. If the problem still exists,

replace the alarm

Warning: Do not disconnect battery to quiet an unwanted alarm. This will remove your protection. Fan the air or open a window to remove smoke/dust.

Product Specification

Voltage

220 - 240V @ 50Hz with 9V battery back-up

CO Alarm Button –dual

function

•Push to Test

•Temporarily silence low battery warning

Power Consumption

<5W

Battery Specification

9V battery DC. Brands:

Gold Peak: GP1604S, GP1604A,

Raymax: 6LR61 or Duracell: MN1604

Sound Pattern

ISO8201 (BI 0.1s -pause 0.1s -BI 0.1s-pause

0.1s-BI 0.1s-pause 0.1s-BI 0.1s-pause 0.1s with

RED LED flash, then repeat)

Battery Life

Over one year

Alarm Volume

> 85dB(A) at 3 meter

Inter-linkable

up to 12 detectors

Alarm Sensitivity (alarm

conditions)

30PPM - Alarms after 120 minutes

50PPM - Between 60 to 90 minutes

100PPM - Between 10 to 40 minutes

300PPM - Less than 3 minutes

Operating Conditions

- 10 to +55℃, 10 to 95%RH

Storage Conditions

-20 to +55℃, 10 to 95% RH

Compliance

BS EN 50291-1:2018

Product Disposal

This alarm come under the Waste Electrical & Electronic Equipment Regulations and must be disposed of in

accordance to these Regulations.

INS 0079 V1.305/21 NPD 0592

4 P a g e

Deta Electrical Company Limited

UK: Panattoni Park Luton Road Chalton Bedsfordshire LU4 9TT UK

EU: Unit 16 Ashbourne Ind. Est. Ashbourne Co. Meath A84 W972 Ireland

deta.co.uk | Technical Helpline: +44(0)1582 544 548

20

Testing the Alarm

Important Safety Information

Test the alarm to ensure proper operation.

1. Test alarm by pressing and holding the test button until it sounds.

The alarm will sound 4 short beeps –5 seconds pause, and then

repeat until the button is released.

2. If multiple alarms are installed within the dwelling, test each alarm.

Each alarm should trigger other alarms connected within 10seconds.

The alarm must only be tested by pressing the Test/Silence button. Do not

ignite combustible materials and start a fire. If no alarm sounds, the unit

has a defective battery or other failure. Refer to “Trouble Shooting”

section for a solution.

Caution: Due to the loudness (85 decibels) of the alarm, always stand an

arms-length always from the unit when testing. Erratic or low

sound coming from your alarm may indicate a defective alarm.

NOTE: WEEKLY TESTING IS REQUIRED

•The alarm may not alert every household member every time. The

alarm horn is loud in order to alert individuals to a potential danger.

However, there may be some circumstances where a household

member may not hear the alarm (e.g. excessive outdoor or indoor

noise, sound sleepers, drug or alcohol usage, the hard of hearing). If

you suspect that this alarm may not alert a household member, install

and maintain specialty alarms.

•The alarms have limitations. This alarm is not fool proof and is not

warranted to protect lives from exposure to Carbon Monoxide. The

alarms are not a substitute for insurance. Occupants should insure

their lives and property. In addition, it is possible for the alarm to fail

at any time. For this reason, you must test the alarm weekly and

replace the unit after 10 years.

•Test alarm weekly to ensure proper operation by pressing the

test button. Do not use any other test method.

•Do not paint the alarms.

•Check the alarms on reoccupation of the premises after a vacation.

Maintenance

Carbon Monoxide (CO) Overview

Cleaning

The alarm should be cleaned on a monthly basis as a minimum. To do this:

•Turn off the electrical supply to the alarm.

•Use a vacuum cleaner with the soft brush to vacuum all sides and

covers of alarm to remove dust, dirt, and debris. Be sure all the

vents are free of debris.

•Use a damp cloth to clean the alarms cover.

•Turn the electrical supply to the alarm on.

Battery

The battery should be replaced annually. See ‘Replacing the Battery’

Carbon monoxide (CO) is an extremely poisonous, colorless, odourless and

tasteless gas released by the incomplete combustion of fossil fuels such as

natural gas, bottle gas, petrol, diesel, oil, paraffin, wood, coal coke and

biofuels. When inhaled, it causes chemical asphyxiation, when CO mixes

with the blood and reduces the oxygen carried around the body,

particularly to the brain. The following symptoms are typical to CO

poisoning and should be discussed with all members of the household.

Mild Exposure - Slight headache, nausea, fatigue (flu like symptoms).

Medium Exposure - Severe throbbing headache, drowsiness and vomiting.

Extreme Exposure - Unconsciousness, cardiorespiratory failure, death.

Although feeling unwell, victims of CO poisoning can become so

disorientated that they can no longer decide what to do next, including

being unable to exit the building or call for assistance. Very young

children often show symptoms earlier than adults.

Note: The CO alarm may not prevent the chronic effects of carbon

monoxide exposure, and it will not fully safeguard individuals

with specific medical conditions. If in doubt, consult a medical

practitioner.

Important Safety Information

•This alarm must not be connected to any other manufacturer’s alarms.

•The alarm must not be exposed to dripping or splashing water.

•The alarms are designed to give audible warning of a dangerous levels

of Carbon Monoxide. The alarms do not detect any other gas.

•Commonly occurring materials, vapours or gases, e.g. in cleaning

fluids, polishes, paints, cooking operations may cause nuisance alarms.

Major interferents are acetylene, ethyl alcohol, hydrogen cyanide,

hydrogen sulfide, mercaptan, nitrogen dioxide and sulfur dioxide.

Troubleshooting

Problem

Remedy

Problem

Remedy

The green LED does not light up

1. Check electrical power supply

is switched on

2. Check electrical connector is

properly connected to alarm

3. If the problem still exists,

replace the alarm

The alarm chirps twice every 38

seconds approx. at the same time

as yellow LED flashes twice and

goes into fault mode

1. Clean alarm. Refer to

“Maintenance”

2. If the problem still exists,

replace the alarm

Alarm does not sound when tested.

Note: push test button for at least

five seconds while testing!

1. Ensure that the battery and

electrical connector is

properly connected

2. Clean alarm

3. If the problem still exists,

replace the alarm

The alarm sounds intermittently or

when residents are cooking, taking

showers, etc. (false alarming)

1. Press test button to pause

alarm

2. Open window or fan alarm

3. Clean alarm

The alarm chirps once every 33

second approx. at the same time as

the yellow LED flashes once

The battery needs replacing, refer

to “Replacing the Battery”

The alarm sounds different from it

is used to. It starts and stops.

4. Clean alarm

5. If the problem still exists,

replace the alarm

Warning: Do not disconnect battery to quiet an unwanted alarm. This will remove your protection. Fan the air or open a window to remove smoke/dust.

Product Specification

Voltage

220 - 240V @ 50Hz with 9V battery back-up

CO Alarm Button –dual

function

•Push to Test

•Temporarily silence low battery warning

Power Consumption

<5W

Battery Specification

9V battery DC. Brands:

Gold Peak: GP1604S, GP1604A,

Raymax: 6LR61 or Duracell: MN1604

Sound Pattern

ISO8201 (BI 0.1s -pause 0.1s -BI 0.1s-pause

0.1s-BI 0.1s-pause 0.1s-BI 0.1s-pause 0.1s with

RED LED flash, then repeat)

Battery Life

Over one year

Alarm Volume

> 85dB(A) at 3 meter

Inter-linkable

up to 12 detectors

Alarm Sensitivity (alarm

conditions)

30PPM - Alarms after 120 minutes

50PPM - Between 60 to 90 minutes

100PPM - Between 10 to 40 minutes

300PPM - Less than 3 minutes

Operating Conditions

- 10 to +55℃, 10 to 95%RH

Storage Conditions

-20 to +55℃, 10 to 95% RH

Compliance

BS EN 50291-1:2018

Product Disposal

This alarm come under the Waste Electrical & Electronic Equipment Regulations and must be disposed of in

accordance to these Regulations.

INS 0079 V1.305/21 NPD 0592

4 P a g e

Deta Electrical Company Limited

UK: Panattoni Park Luton Road Chalton Bedsfordshire LU4 9TT UK

EU: Unit 16 Ashbourne Ind. Est. Ashbourne Co. Meath A84 W972 Ireland

deta.co.uk | Technical Helpline: +44(0)1582 544 548

20

This manual suits for next models

1

Table of contents

Other Deta Security Sensor manuals

Popular Security Sensor manuals by other brands

M-E

M-E 820833 operating instructions

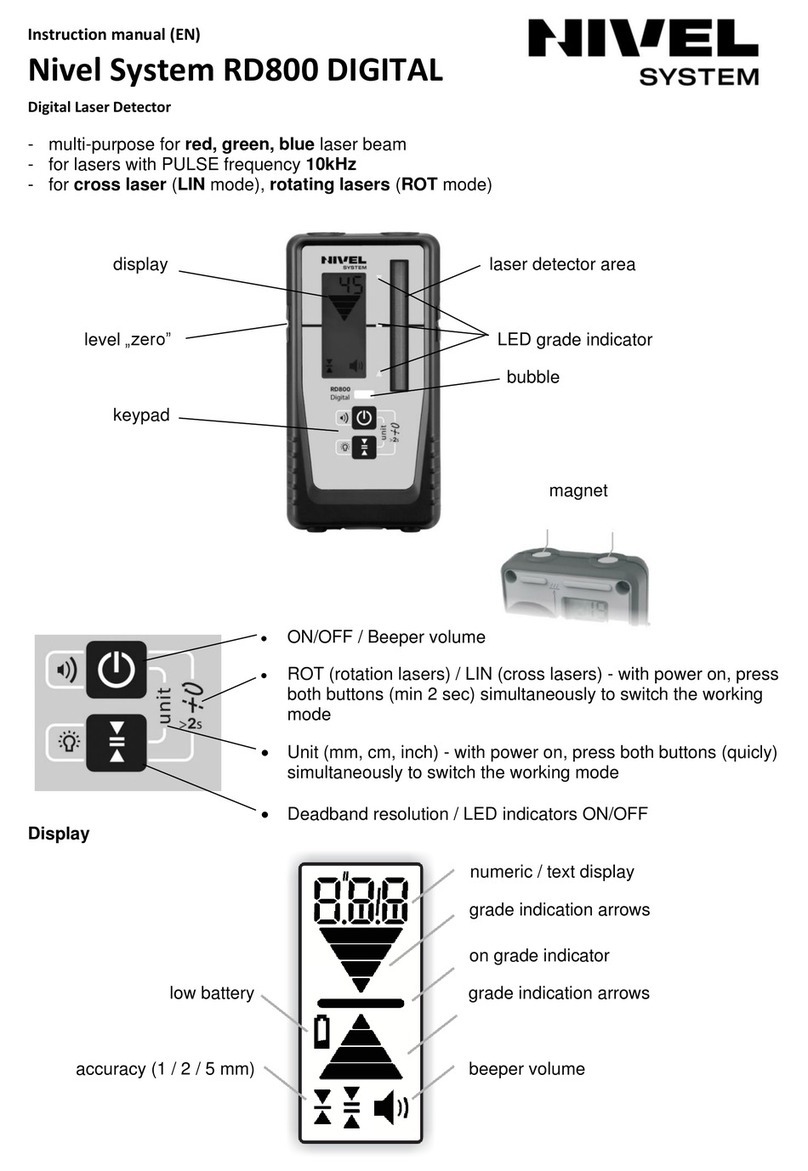

Nivel System

Nivel System RD800 DIGITAL instruction manual

RIDGID

RIDGID micro CD-100 Operator's manual

AVS Electronics

AVS Electronics SPECTRUM PA WALL manual

Transmitter Solutions

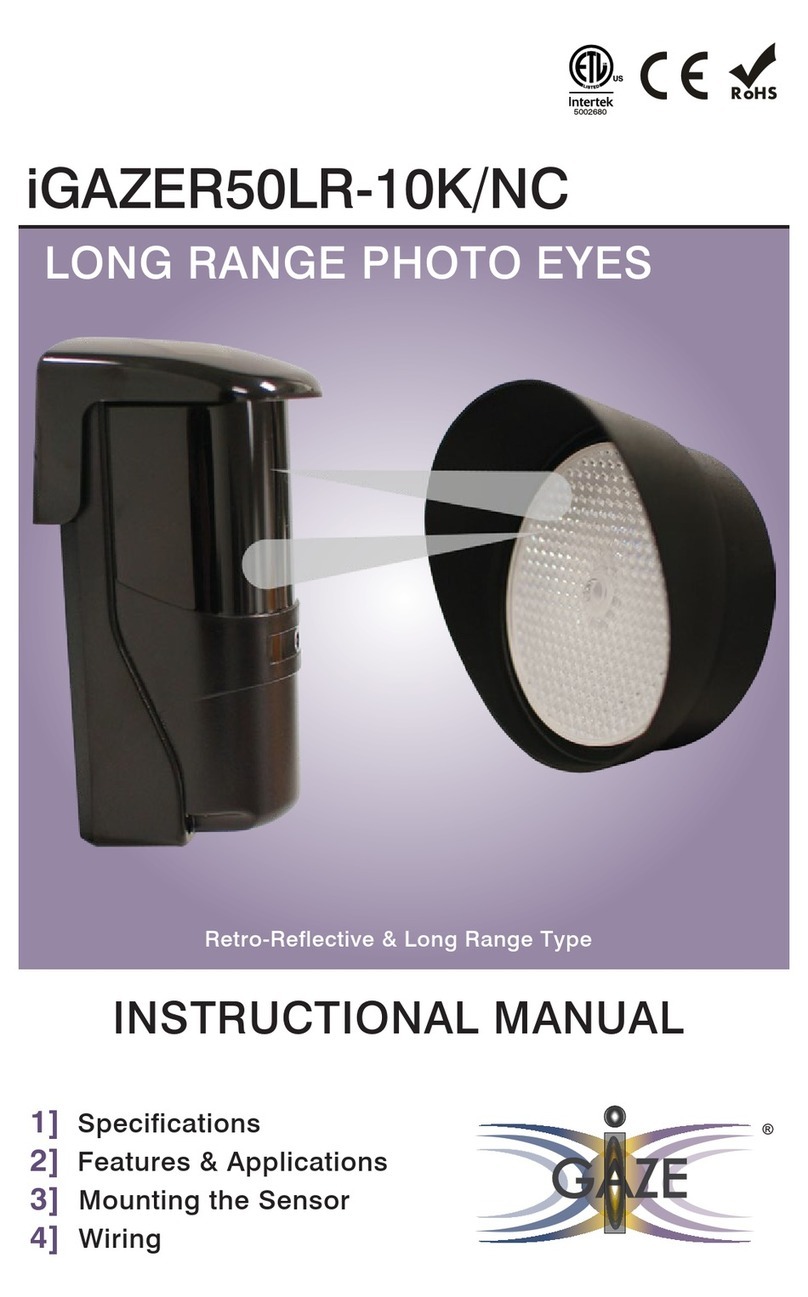

Transmitter Solutions iGAZER50LR instruction manual

Apollo

Apollo 65 Series installation guide