routes. After the ÒWalk-TestÓ is complete, the LED may be

PROBLEM CAUSE REMEDY

Intermittent

Alarm

Rapid temperature

change. Check for

electric or gas

heaters, open

flames, electric

arcs, etc.

Locate source and

reposition detector.

Drafts causing

drapes, light

fixtures, display

material to move.

Eliminate source of

motion.

PIR does not

appear to be

operating

Polling loop voltage

supplied to detec-

tor is inadequate,

intermittent or

polarity reversed.

Assure that proper

polarity is supplied and

that wiring is intact (no

opens or shorts) and

connection secure.

Check for presence of

8Ð11V PP at terminals

of unit. If too low, polling

loop run to control may

be excessive for the

wire gauge used, or

polling loop current

drain may be excessive.

Increase wire gauge or

add Polling loop exten-

der module to location

in the loop where volt-

age boost is necessary

and connect it to a

power source.

Alternatively, the detec-

tor can be tested using

a 9-volt source (such as

a 9-volt battery or a 9-

volt power supply).

LED

inoperative

LED disable

jumper is on Remove LED disable

jumper

LED malfunc-

tion.Check for

broken shorted

leads.

Return unit for service.

Repositioned fur-

niture or

equipment in the

protected area.

Caution customer about

layout changes.

Reposition detector.

Mounting surface

is unstable. A few

degrees of verti-

cal shift can

change range

substantially.

Mount on

secure surface.

Trouble

Code

Improper ID code.

or PIR not

ÒLearnedÓ.

Set DIP swiitches1Ð7 to

proper code, or ÒLearnÓ

PIR serial No.

Detection

Area

Changes

THE LIMITATIONS OF YOUR PASSIVE

INFRARED MOTION DETECTOR

While the Intrusion Detector is a highly reliable intrusion

detection device, it does not offer guaranteed protection

against burglary. Any Intrusion Detection device is subject

to compromise or failure to warn for a variety of reasons:

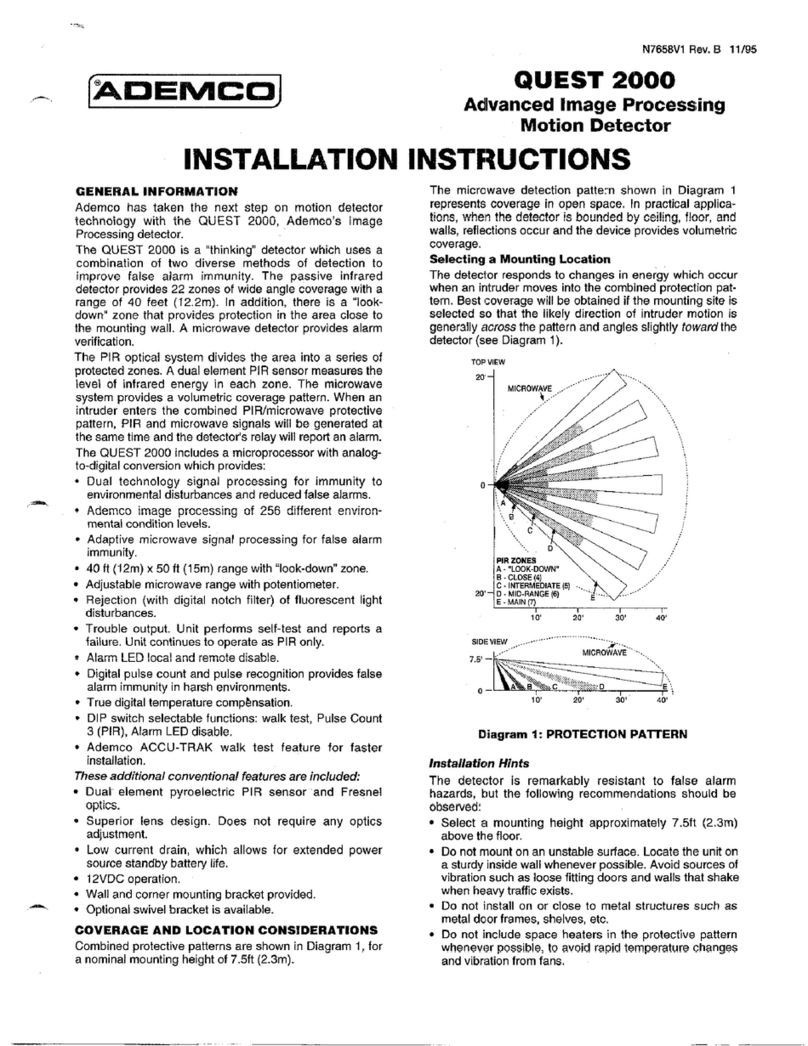

¥ Passive Infrared Motion Detectors can only detect intru-

sion within the designed ranges as diagrammed in this

installation manual.

¥ Passive Infrared Motion Detectors do not provide volu-

metric area protection. They do create multiple beams

of protection, and intrusion can only be detected in

unobstructed areas covered by those beams.

¥ Passive Infrared Detectors cannot detect motion or

intrusion that takes place behind walls, ceilings, floors,

closed doors, glass partitions, glass doors, or windows.

¥ Mechanical tampering, masking, painting or spraying of

any material on the lenses, windows or any part of the

optical system can reduce the detection ability of the

Passive Infrared Motion Detector.

¥ Passive Infrared Detectors sense changes in tempera-

ture; however, as the ambient temperature of the pro-

tected area approaches the temperature range of 90¡ to

105¡F (32¡ to 40¡C), the detection performance can

decrease.

¥ This Passive Infrared Detector will not operate without

appropriate DC power connected to it, or if the DC

power is improperly connected (i.e., reversed polarity

connections).

¥ Passive Infrared Detectors, like other electrical devices,

are subject to component failure. Even though this

equipment is designed to last as long as 10 years, the

electronic components in it could fail at any time.

We have cited some of the most common reasons that a

Passive Infrared Motion Detector can fail to catch intrusion.

However, this does not imply that these are the only rea-

sons, and therefore it is recommended that weekly testing

of this type of unit, in conjunction with weekly testing of the

entire alarm system, be performed to ensure that the

detectors are working properly.

Installing an alarm system may make the owner eligible for

a lower insurance rate, but an alarm system is not a sub-

stitute for insurance. Homeowners, property owners and

renters should continue to act prudently in protecting them-

selves and continue to insure their lives and property. We

continue to develop new and improved protection devices.

Users of alarm systems owe it to themselves and their

loved ones to learn about these developments.

ADEMCO SIX YEAR Limited Warranty

Alarm Device Manufacturing Company, a Division of Pittway

Corporation, and its divisions, subsidiaries and affiliates

("Seller"), 165 Eileen Way, Syosset, New York 11791, war-

rants this PIR/Microwave Detector to be in conformance with

its own plans and specifications and to be free from defects

in materials and workmanship under normal use and service

for 72 months from the date stamp control on the product.

Seller's obligation shall be limited to replacing, free of charge

for materials or labor, a detector which is proved not in com-

pliance with Seller's specifications or proves defective in

materials or workmanship under normal use and service.

Seller shall have no obligation under this Limited Warranty or

otherwise if the detector is altered or improperly repaired or

serviced by anyone other than Ademco factory service. In

case of defect, return the detector to ADI, or an authorized

Ademco distributor for an immediate replacement.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED,

OF MERCHANTABILITY, OR FITNESS FOR A PARTICU-

LAR PURPOSE OR OTHERWISE, WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN

NO CASE SHALL SELLER BE LIABLE TO ANYONE FOR

ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR

BREACH OF THIS OR ANY OTHER WARRANTY,

EXPRESS OR IMPLIED, OR UPON ANY OTHER BASIS OF

LIABILITY WHATSOEVER, EVEN IF THE LOSS OR DAM-

AGE IS CAUSED BY THE SELLER'S OWN NEGLIGENCE

OR FAULT.

Seller does not represent that its detector may not be com-

promised or circumvented; that the detector will prevent any

personal injury or property loss by burglary, robbery, fire or

otherwise; or that the detector will in all cases provide ade-

quate warning or protection. Buyer understands that a prop-

erly installed and maintained alarm may only reduce the risk

of a burglary, robbery, fire or other events occurring without

providing an alarm, but it is not insurance or a guarantee that

such will not occur or that there will be no personal injury or

property loss as a result. CONSEQUENTLY, SELLER

SHALL HAVE NO LIABILITY FOR ANY PERSONAL

INJURY, PROPERTY DAMAGE OR OTHER LOSS BASED

ON A CLAIM THE DETECTOR FAILED TO GIVE WARN-

ING. However, if Seller is held liable, whether directly or indi-

rectly, for any loss or damage

arising under this Limited

Warranty or otherwise, regardless of cause or origin,

Seller's maximum liability shall not in any case exceed

the purchase price of the detector, which shall be the

complete and exclusive remedy against Seller. This

warranty replaces any previous warranties and is the

only warranty made by Seller on this detector. No

increase or alteration, written or verbal, of the obliga-

tions of this Limited Warranty is authorized.

disabled (plug in place).

Troubleshooting

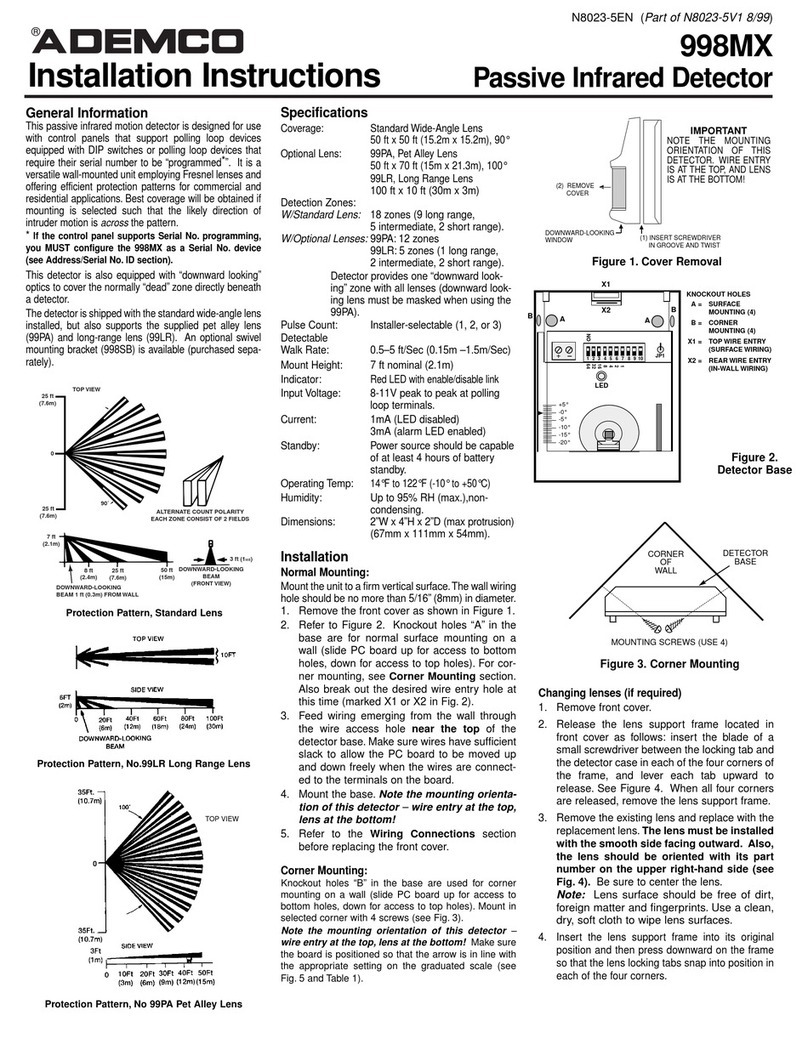

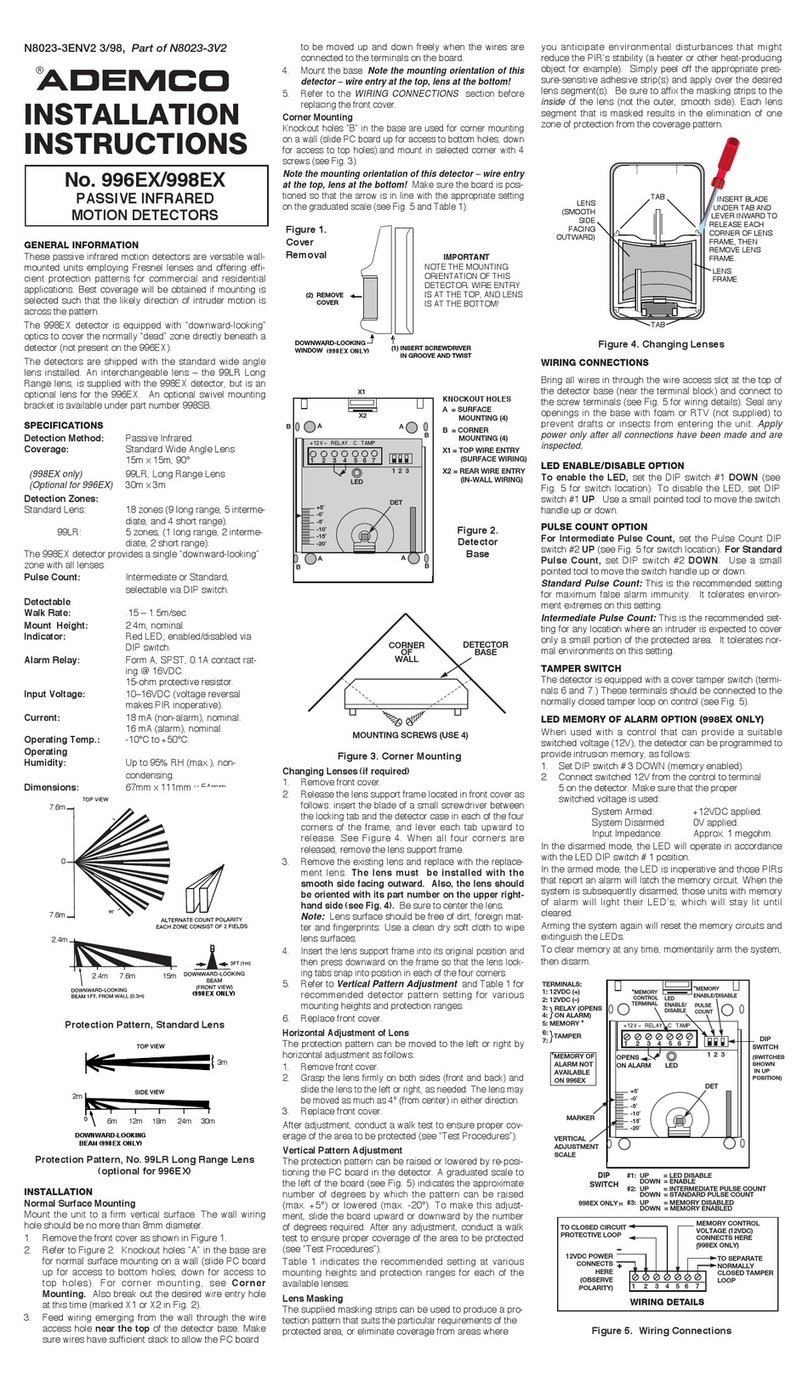

Table 1. Installation Guide for Lenses

STAN-

DARD LENSES

PROTECTION RANGE

you must also mask the look down window.

Wi

ring Connections

Bring wires in through the wire access slot at the top of the

detector base (near the terminal block) and connect to the

screw terminals (see fig. 5 for wiring terminals). Seal all open-

ing in the base with foam or RTV (not supplied) to prevent

drafts or insects from entering the unit.

Apply power only after

the wiring

connections have been made and are inspected.

Address/Serial No. ID

This PIR includes a DIP switch for use in setting the ID num-

ber when the associated control does not support devices

which can be ÒlearnedÓ. See the Point ID Programming Chart

for DIP switch settings.

IMPORTANT: If the PIR is to be used with a control that

supports serial number learning, you MUST configure

this PIR as a Serial No. device during the zone program-

ming procedure (see the control panelÕs Installation

Instructions). For manual entry, the serial number can be

found on the bar code label on the left-hand corner of the PC

board (see Fig. 5) Before ÒlearningÓ this PIR, make sure

jumper JP1 is cut and that the DIP switch is set with all

positions OFF.

Pulse Count Option

This detector includes Pulse count circuitry that provides sta-

bility in adverse environments to minimize false alarms.

Selectable 1, 2 or 3 event pulse count is provided by position-

ing a jumper across the appropriate pulse count terminals

shown in Figure 5. When programmed for 2 or 3 event pulse

count, the detector will signal an alarm within 3 to 4 steps,

since the processing logic requires more complex motion than

just a momentary event. When the detector verifies an intru-

sion, the LED lights for approximately 1 to 3 seconds.

LED Enable/Disable Option

The Alarm LED is disabled when the LED enable/disable plug

is in place). To enable the LED, remove the LED enable/dis-

able plug (see Fig. 5). To prevent loss of the plug we suggest

you install it on one pin when the plug is not in use. Note: The

LED is viewed through the front cover lens.

If desired, the LED may be controlled from a remote location, as

follows: Remove the LED enable/disable plug. Connect a

switched line to the right-hand pin (#1) of the two LED pins (see

Fig. 5) which can be grounded or opened. Grounding pin #1 will

disable the LED, disconnecting it from ground will enable the

LED.

Tamper Switch

Removal of the cover causes a tamper switch to open. The

panel is automatically notified via the polling loop when this

event occurs.

Test Procedures

Important: Two-minute warm-up time is required after apply-

ing power. Testing should be conducted with the protected

area cleared of all people. Disarm the protective systemÕs con-

trol during the test procedure to prevent reporting of unwanted

alarms.

1. Remove front cover and install the jumper across Pulse

Count pins "1" (this will provide instant response). The

LED must be enabled at this time (LED jumper plug

removed).

2. Replace front cover and walk through protective zones,

observing that the detectorÕs LED lights whenever

motion is detected. (The LED serves as a Walk-Test

Indicator during this procedure.

Note: In the Instant mode, the LED stays lit for approxi-

mately 1-3 seconds after detecting motion.

3. Test the downward looking zone by walking along the

wall directly beneath the detector (this does not apply to

the Pet Alley lens or the standard lens masked to act as

a Pet Alley lens, which should have the downward-look-

ing window on the detector masked.

4. If pulse count is to be used, set the pulse count jumper

to desired setting and repeat the walk test procedure.

With pulse count on, the LED serves as an alarm

Indicator.

The absolute range of all PIR units is subject to variation

because of different types of clothing, backgrounds and

ambient temperature. For this reason, ensure that the most

likely intruder routes are well within the PIRÕs protective

zones and that walk-testing is carried out along these

Figure 5. INTERIOR VIEW

@@@@@@@@e?

@@@@@@@@e?

@@h?

@@h?

@@h?

@@h?

@@h?

@@h?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

?@@

?@@

?@@

?@@

?@@

?@@

?@@@@@@@@

?@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

@@g

@@g

@@g

@@g

@@g

@@g

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

PULSE

COUNT

SERIAL

NUMBER

TAMPER

SWITCH

LONG RANGE - 998-LR

PROTECTION RANGE

Important: When using the Long Range lens,

set the PIR for Instant response (Pulse Count 1)

PET ALLEY LENS– 998-PA

PROTECTION RANGE

Mtg 15' 20' 30' 40' 50'

Height (4.6m) (6m) (9m) (12m) (15m)

8.5Ft -20¡ -16¡ -11¡ -8¡ -7¡

(2.6m)

8Ft -20¡ -15¡ -10¡ -8¡ -6¡

(2.4m)

7Ft -16¡ -12¡ -8¡ -6¡ -5¡

(21m)

6Ft -13¡ -10¡ -6¡ -5¡ -4¡

(1.8m)

Mtg 20' 40' 60' 80' 100'

Height (6m) (12m) (18m) (24m) (30.4m)

8.5Ft -15¡ -9¡ -6¡ -5¡ -5¡

(2.6m)

8Ft -14¡ -8¡ -6¡ -5¡ -4¡

(2.4m)

7Ft -11¡ -6¡ -5¡ -4¡ -4¡

(21m)

6Ft -8¡ -5¡ -4¡ -3¡ -3¡

(1.8m)

–––––

Vertical Pattern Setting

–––––

––––––––

Vertical Pattern Setting

––––––––

TO THE INSTALLER

Regular maintenance and inspection (at least annual-

ly) by the installer and frequent testing by the user are

vital to continuous satisfactory operation of any alarm

system.

The installer should assume the responsibility of

developing and offering a regular maintenance pro-

gram to the user, as well as acquainting the user with

the proper operation and limitations of the alarm sys-

tem and its component parts. Recommendations must

be included for a specific program of frequent testing

(at least weekly) to insure the systemÕs operation at all

@@@@@@@@e?

@@@@@@@@e?

@@h?

@@h?

@@h?

@@h?

@@h?

@@h?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

?@@

?@@

?@@

?@@

?@@

?@@

?@@@@@@@@

?@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@

@@g

@@g

@@g

@@g

@@g

@@g

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

Mounting Height: 3 Ft. - 3.5 Ft. (0.9 - 1m)

Vertical Pattern Setting (for all ranges): +2¡

Important: Be sure to affix the provided masking

label over the look-down window.

ALARM DEVICE MFG. CO.

A DIVISION OF PITTWAY CORPORATION

165 Eileen Way, Syosset, N.Y. 11791

Copyright © 1995 PITTWAY CORPORATION