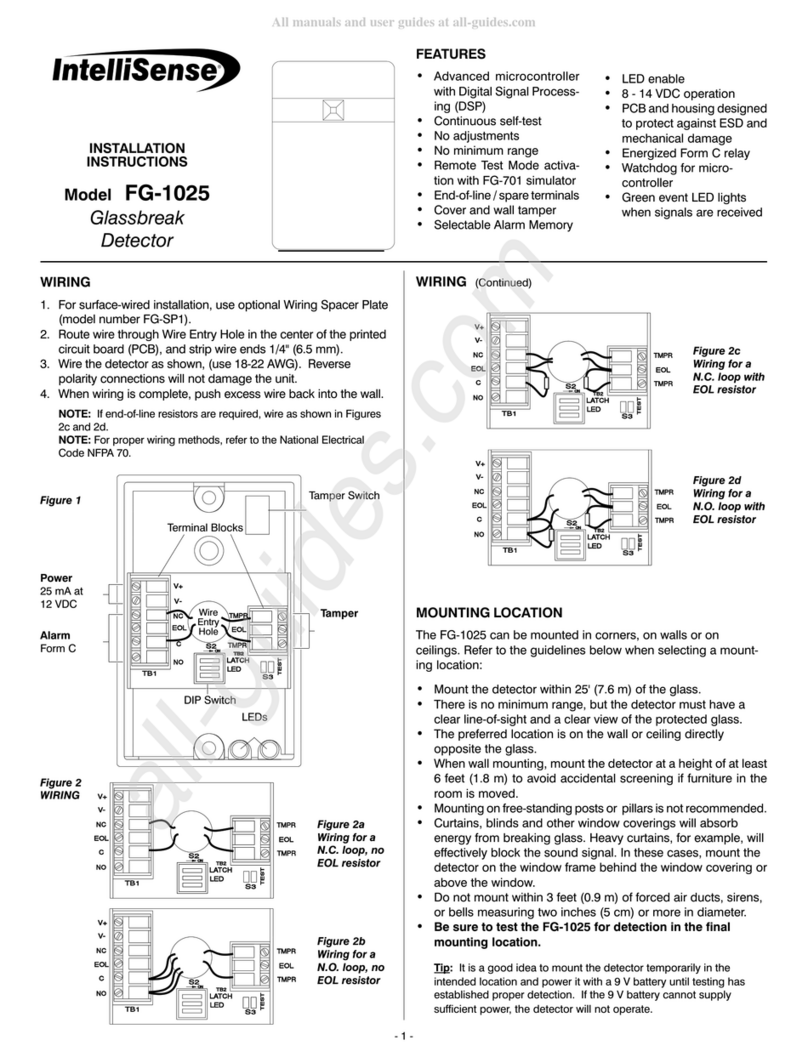

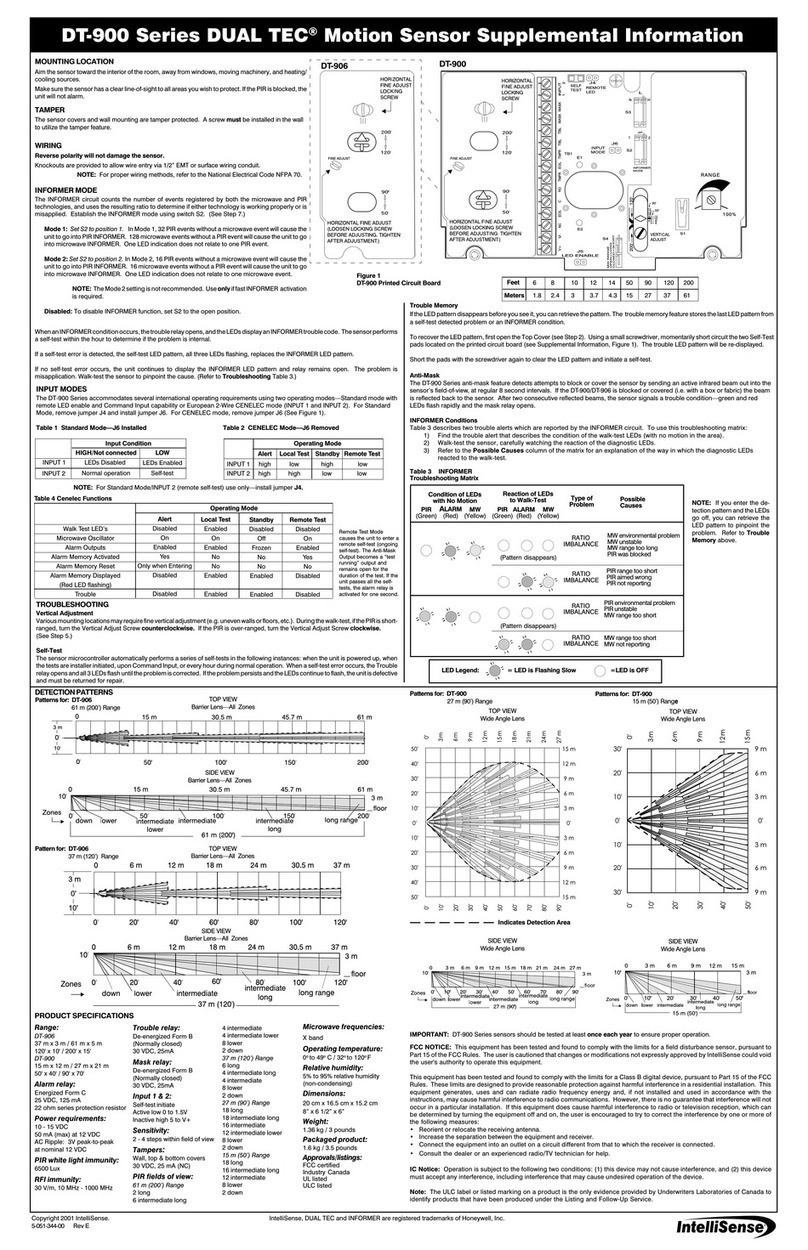

- 3 -

TESTING (Continued)

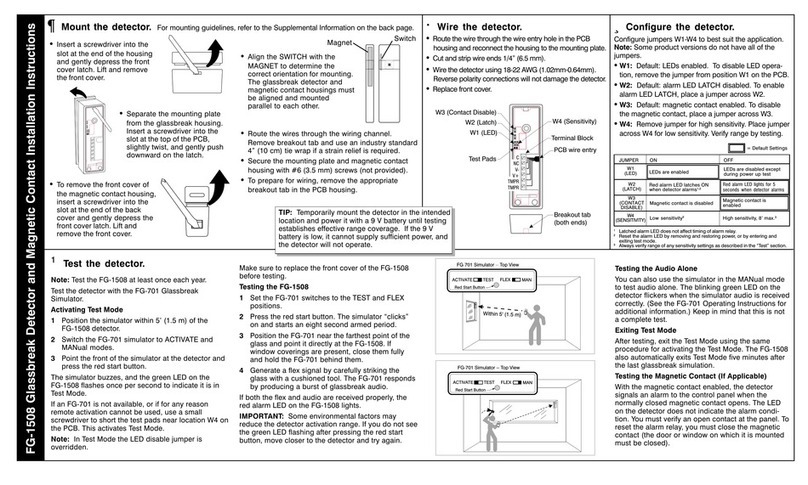

IMPORTANT: Some environmental factors may reduce the detector

activation range. If you do not see the green LED flashing after pressing

the red start button, move closer to the detector and try again.

Figure 7

ed Start

Button

After testing, exit the Test Mode using the same procedure for

activating the Test Mode. The FG-1025 also will automatically

exit Test Mode after ten minutes.

LED Indicators:

The two LEDs on the front cover are used to indicate the

detector's operational status. The following table summarizes

the LED operation when the LEDs are enabled.

APPLICATIONS INFORMATION

The FG-1025 is designed to detect framed glass broken by an

impact sufficient to make a hole.

NOTE: The FG-1025 detects shattering of framed glass by a

direct impact. It may not consistently detect breakage by blows

that only crack the glass, by high velocity projectiles (such as

bullets) or if the glass is broken without an impact.

To minimize the chance of false alarms:

Do not use outside.

Avoid installing in rooms with high-level noise sources, such

as air compressors, bells, power tools, etc., if those sources

can be active when the detector can signal an alarm.

Test false alarm immunity by activating any known noise

sources in the room.

To maximize detection:

Mount the detector on a wall or ceiling directly opposite the

glass if possible. The least desirable mounting location is on

the same wall as the glass.

Minimize range to the glass. Do not install beyond the

maximum specified range even if testing indicates greater

range.

Verify all installations back to the panel to be sure that the

protection loop is intact.

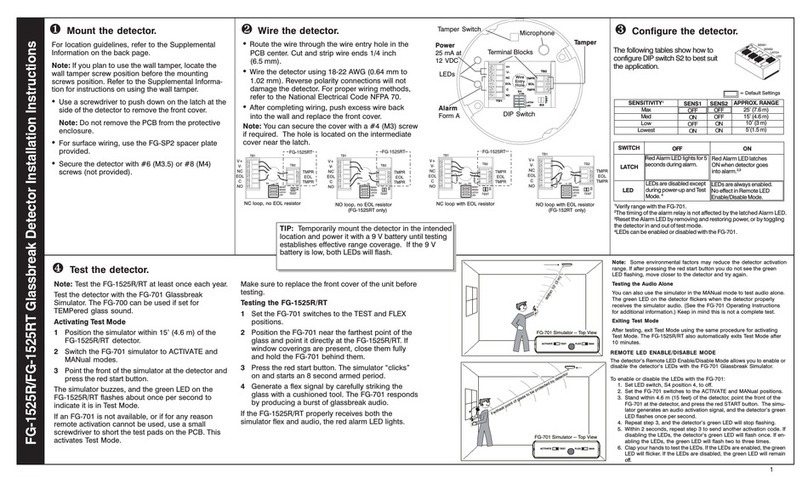

Figure 6

ed Start

Button

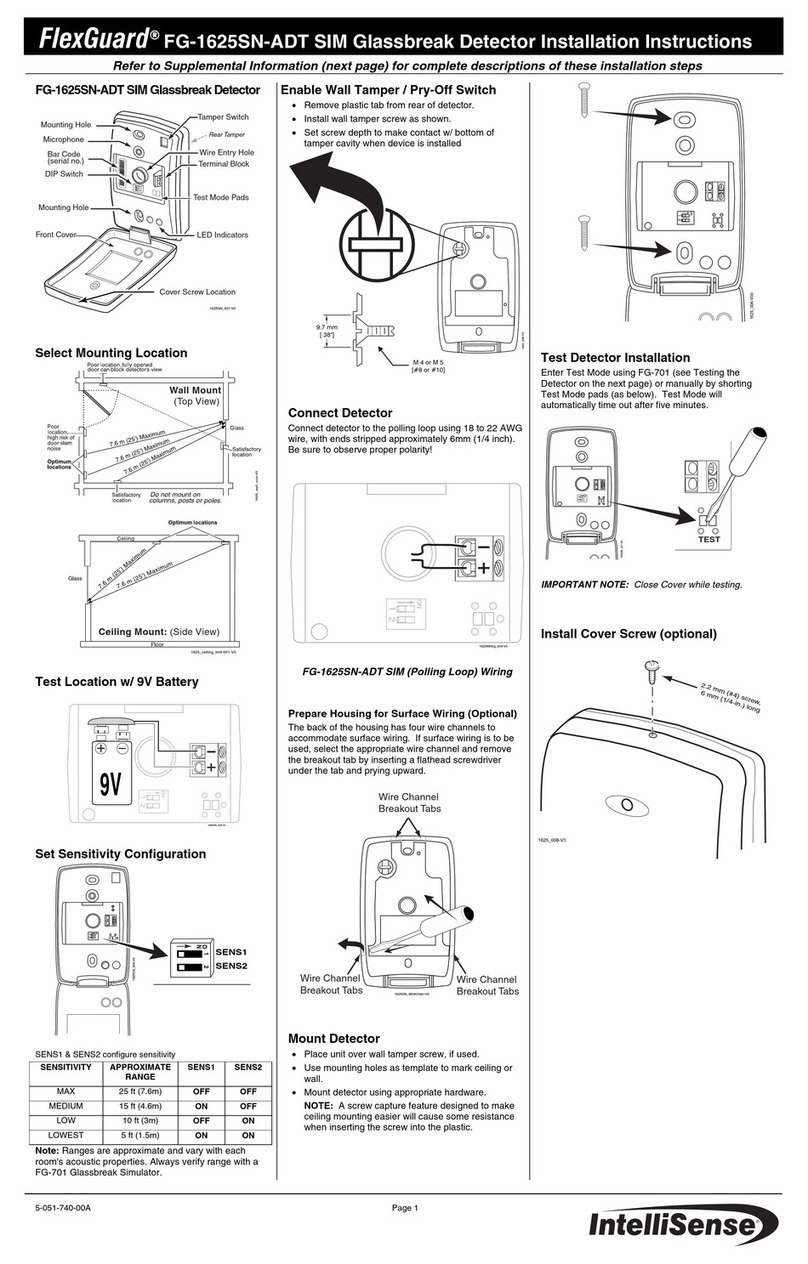

If an FG-701 is not available, or if for any reason remote activa-

tion cannot be used, use a screwdriver to short the test pads at

location S3 on the PCB (see Figure 1). This will activate Test

Mode. Make sure to close the front cover of the FG-1025 before

beginning test.

To test the FG-1025:

1. Place the detector in Test Mode as described above.

2. Set the FG-701 switches to the TEST and FLEX positions.

3. Press the red start button. The simulator will "click" on and

start an eight second armed period.

4. Position the FG-701 near the farthest point of the protected

glass and point it directly at the FG-1025.

5. Generate a flex signal by carefully striking the glass with a

cushioned tool. The FG-701 will respond by producing a

burst of glass break audio. ( efer to Figure 7.)

If both the flex and audio are received properly, the red alarm

LED on the FG-1025 will light.

IMPORTANT: If window coverings are present, close them fully and

hold the FG-701 behind the window coverings for testing.

NOTE: You can also use the simulator in the MANual mode to test

audio alone. The blinking green LED on the detector will flicker

when the simulator audio is received correctly. (See the FG-701

Operating Instructions for additional information.)

Condition Green LED Red LED

Normal, no event OFF OFF

Normal, event detected Flicker OFF

Normal, break detected OFF ON

Power-up self-test ON, one second ON, one second

Trouble detected Flash ON/OFF Flash OFF/ON

Test mode, no alarm Flash once per second OFF

Test mode, event detected Flicker OFF

Test mode, alarm Flash once per second ON

SELF-TESTS

The FG-1025 automatically performs a series of self-tests during

power-up, and continuously (when the detector is not detecting

a trouble or alarm condition).

If any self-test fails, the detector will signal trouble by flashing the

LEDs alternately about once per second. Protection will continue

if possible. If the trouble condition clears, the LEDs will return to

the normal state. Always return the detector for repair if there is

any indication of trouble, even if the trouble is temporary.

Glassbreak

Detector

Glassbreak

Detector