Detectors Incorporated D381 User manual

MAN‐D381‐0001

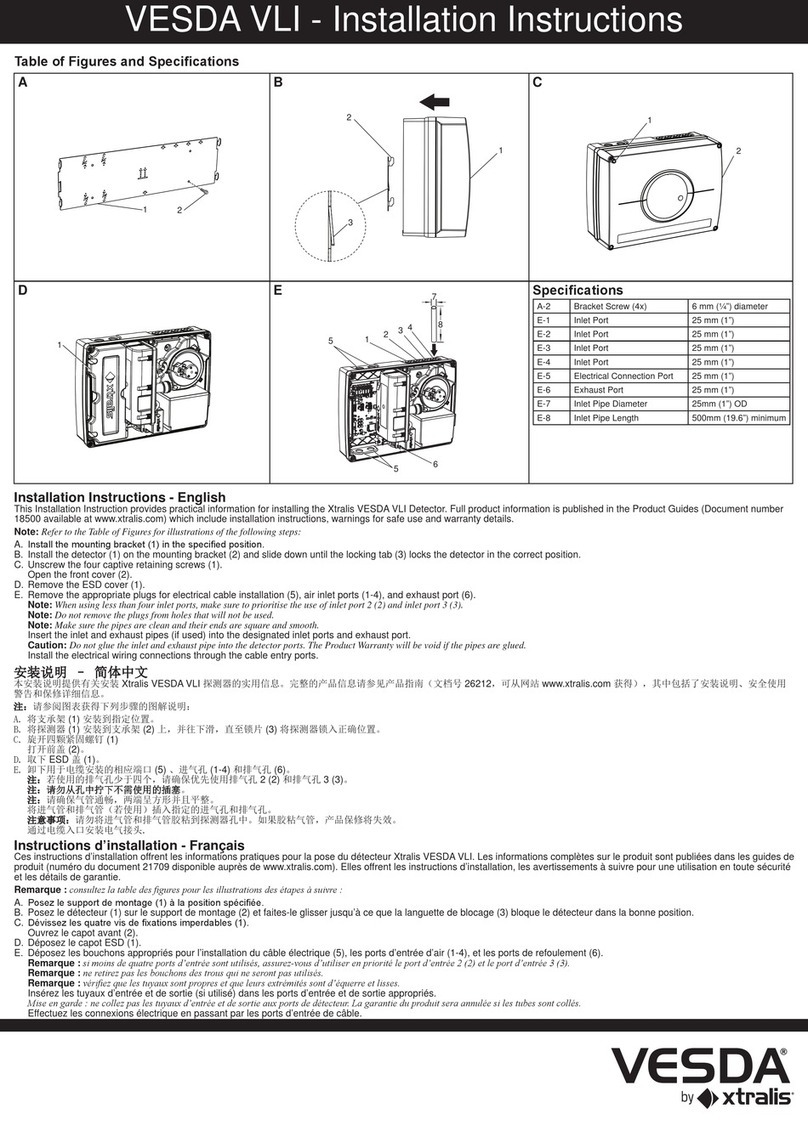

1

INSTRUCTION MANUAL

Detectors Incorporated

Model D381 General Application

Flame Detector

MAN‐D381‐0001

2

TableofContents

INTRODUCTION.………………………………………………………….. 3TROUBLESHOOTING………………………………………………………14

ProductDescription………………………………………………3

Specifications………………………………………………………..4EVENTLOGSANDFireGraphs………………………………..14

General…………………………………………………………………4

Electrical……………………………………………………………….4ACCESSORIES………………………………………………………..14

Environmental……………………………………………………… 4

Mechanical…………………………………………………………… 4PRODUCTSUPPORT……………………………………………….14

INSTALLATION………………………………………………………5TechnicalSupportandCustomerSupport……………….14

DetectorDimensions……………………………………………. 5

MountingtheDetector………………………………………… 5WARRANTY………………………………………………………….15

Positioning…………………………………………………………… 5

UsingSwivelMountingBracket……………………………. 5APPENDIX“A”

DirectMounting…………………………………………………… 5OrderingInformation…………………………………………….16

InstallationTips…………………………………………………….5,6

DetectorConfiguration………………………………………… 6APPENDIX“B”…………………………………………………….17

DetectorWiring…………………………………………………….6‐8

DETECTORSENSOR,LEDINDICATIONS

ANDCONDUITENTRYLOCATION………………………… 9

OPERATIONANDSTARTUP………………………………….10

DetectorPerformanceandResponse……………………10

DetectorOperation………………………………………………10

DetectorVisualIndicators…………………………………….10

NormalOperation………………………………………………..10

AlarmCondition…………………………………………………..11

FaultCondition…………………………………………………….11,12

DetectorSelf‐Test………………………………………………..12

DetectorOpticalPathTest…………………………………..12

MAINTAINANCE…………………………………………………..12

InspectionandCleaning……………………………………….12

DetectorTestingProcedures………………………………..12

PeriodicTesting…………………………………………………….12

ManualTest………………………………………………………….13

D383DETECTORRESPONSE

CHARACTERISTICS…………………………………………………13

PerformanceTesting………………………………………………13

ImmunitytoFalseAlarms……………………………………13,14

MAN‐D381‐0001

3

1.0 Introduction

1.1 ProductDescription

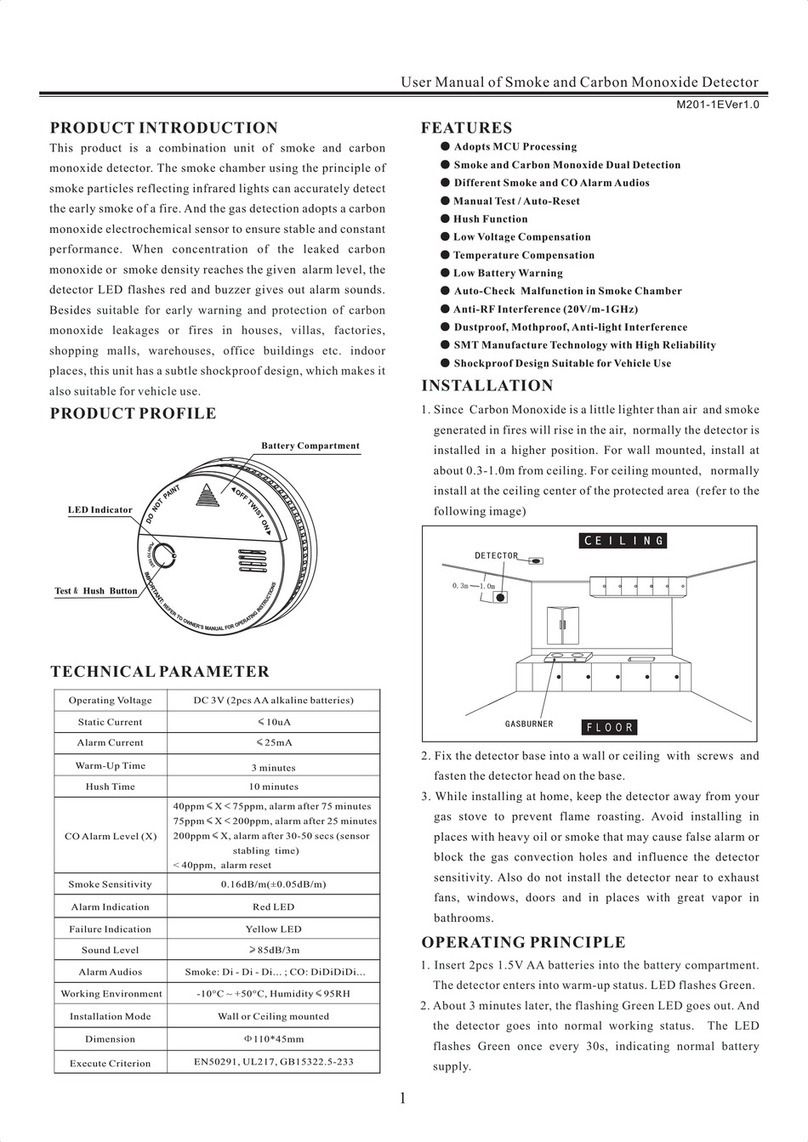

TheDetectorsInc.modelD381isanewgenerationof

general‐purposeandmediumrangeMulti‐Spectrum

3IR + UV flame detector designed for detection of

firesinmultitudeofindoorandoutdoorapplications.

The Model D381 senses the Ultraviolet radiation in

UV spectrum and Infrared radiation in 3 discrete

bandsofIRintherangeof2‐5microns.Thedetector

will respond to Hydrocarbon and non‐Hydrocarbon

basedfireswithin3seconds.

The Model D381 is a stand‐alone flame detector in

watertight NEMA 4 (IP67) and explosion‐proof

aluminum enclosure designed for Class I, Division 2

(Zone 2) installations. The detector offers multiple

outputs including two fire alarm relays, 4‐20 mA

analogandRS485ModBusRTU.

Thedetectorcanbeusedasastand‐alonedeviceor

canbeinterfacedwithanyapprovedfirealarmpanel,

controlsystem,orPLC.TheD381detectorfeatures

anAutomaticSelf‐Testforcontinuously monitoring its sensors and electronics. Additionally, the detector is

equippedwithOptiRadarfeaturethatcontinuouslychecksthedetector’sopticalpathintegrityandthewindow

blockagebyexternalobjects.ThisfeaturewillinitiateaFaultsignalifanyobjectisblockingtheviewingwindow

within1”ofdetector.

MAN‐D381‐0001

4

1.2 Specifications

1.2.1 General

Field‐of‐View: 90°Horizontal&Vertical

SpectralSensitivity: UV: 180‐260nanometers

IR: 2‐5microns(3discretebands)

SensitivityRange: Low&High

ResponseTime: Alarm: 3‐5Seconds

DetectionRange: 1’x1’n‐Heptanefire:80feet

1.2.2 Electrical

OperatingVoltage: 24VDCnominal(18‐31),Regulated

PowerConsumption: Standby:60mA@24VDC

Alarm:90mA@24VDC

RelaysOutputs: Alarm&AuxiliaryRelays:

SPDT—contactsrated2A@24VDC

De‐EnergizedwithN.O.contacts(powerapplied)

Auxiliaryrelaysettings:0.3,3,10,20seconds

FactoryDefaultforAux.relay:3seconds

Faultrelay:

SPST–contactrated2A@24VDC

EnergizedwithN.C.contact(powerapplied)

AnalogOutput: 0‐20mAStepped‐Source

Communication: RS485ModBus

VisualIndications: GreenLED–NormalOperation

RedLED‐Alarm

AmberLED‐Fault

Wiring Integral15‐conductorpre‐wiredcableharness

20AWG,10’long

1.2.3 Environmental

HumidityRange: 5to95%relativehumidity,non‐Cond.

TemperatureRange: ‐40to+185°F(‐40to+85°C)

EnclosureType: NEMA4,IP67

1.2.4 Mechanical

EnclosureMaterial: Aluminum,powdercoated

Weight: 2lbs.(0.9kg)

ConduitEntry (1)M25–M25X3/4"adapteravailable

Mounting: Swivelbracket—Optional

MAN‐D381‐0001

5

2.0 Installation

2.1 DetectorDimensions

TheD381detectorissuppliedwithpowdercoatedAluminumenclosure.Theenclosurehas(4)7mm

holesintherearmountingflange(Figure1)thatcanbeusedtomountthedetectordirectlyonaflat

surfaceorontotheoptionalswivelmountingbracketthatallowsthedetectoradjustmentinverticaland

horizontalaxis.

Figure1–DetectorDimensions

2.2 MountingtheDetector

2.2.1 Positioning‐Thedetectorshouldbeinstalledsuchthatthecenterofthedetector’sfield‐of‐view

isaimeddirectlyatthecenteroftheareatobeprotected(hazardarea).Detectorsshouldbe

installedwithnoobstructionoftheField‐of‐View.

2.2.2 UsingSwivelMountingBracket–Thismethodwillallowthedetectortobeadjustedinvertical

andhorizontalaxisforoptimumorientation.First,securetheSwivelMounttothesurfacetobe

mounted.Nextattachthedetectorontotheswivelmountingbracketusingboltssupplied.

2.2.3 DirectMounting.‐Thedetectormayalsobemounteddirectlytoaflatsurfaceusingthe(4)7

mmmountingholesontherearmountingflangeandsecureitfirmlywith(4)steelscrews.

2.2.4 InstallationTips:‐Wheninstallingthedetectors,beawareofthefollowingconditions:

a) Field‐of‐Viewofdetectorsshouldnotbeblockedbyanyobjectsforoptimumperformance.

b) Thedetectorshouldbeinstalledsuchthatthecenterofthedetectorisaimedatthecenter

oftheareatobeprotected(hazardarea).Detectorsshouldbeinstalledabovethehazard

MAN‐D381‐0001

6

areapointingdownwardatananglebetween35‐55degreesfromhorizontalwithno

obstructionoftheField‐of‐View.Detectorheightgenerallyshouldbeapproximately1½to

2½timestheheightoftallestobjectinthehazardarea.Theheightmayvarydependingon

theapplication,indoor/outdoorinstallationandsizeofthehazardarea.Detectorshouldbe

easilyaccessibleformaintenance.

c) Forindoorapplications,thedetectorsshouldbeinstalledsothattherearenohighintensity

lightsintheviewofdetectors.Highintensitylightsmaydiminishdetectorsensitivity.

d) Detectorsshouldbeinstalledsothattheyareeasilyaccessibleformaintenance.

2.3 DetectorConfiguration

2.3.1 Unlessspecifiedotherwise,theD381detectorsareshippedfactoryconfiguredasdescribedbelow:

FireAlarmRelay: SPST,NormallyDe‐Energized,N.O.,Non‐Latching

WarningRelay SPST,NormallyDe‐Energized,N.O.,Non‐Latching

FaultRelay: SPST,NormallyEnergized,N.C.,Non‐Latching

4‐20mA SteppedAnalog,Sourcing

Communication ModBusRTUProtocol

2.3.2 Allrelayswithstandardfactoryconfigurationare“Non‐Latching”.If“Latching”modeisrequired,

itmustbespecifiedwhenordering.PleaserefertoAppendix“A”forotherconfigurationoptions.

2.3.3 Maximumloopresistancefortheanalogoutputis800Ohms

2.3.4 TheD381DetectorisalsoequippedwithastandardRS485ModBuscommunicationprotocolfor

interfacingwithdevicesorcontrollersusingtheModbusstandard.TheRS485communication

protocolisalsousefulincommunicatingwithdetectorforviewingordownloadingEventLogsand

FireGraphsusingalaptopandtheLabVIEWprogrammingsoftware.

2.4 DetectorWiring

2.4.1 The D381 Detector issupplied with an integral multi‐conductor shielded cable with Individual

conductorscolor‐codedforeasyidentification(Table1).

2.4.1 DetectorshouldbewiredinaccordancewiththeNationalElectricalCode(NFPA70)Division2

hazardous (Classified) locationwiring procedure inthe United Statesoraccordingtothelocal

codesinothercountries,observingtherequirementsforElectricalSafety.

2.4.2 Terminate each color‐coded wire to an appropriate terminal in the Fire Alarm Panel, PLC, or

ControlSystem.Figure3showsthebasicwiringconfigurationsforthedetector

MAN‐D381‐0001

7

Table 1 - D381 Detector Wiring Identification

Wire

Number

Wire

Color

Description

3 Red 24 VDC (+)

1 Black 24 VDC (Return)

8 Red/Black Alarm Relay Contact A (COM)

13 Red/White Alarm Relay Contact B (N.O.)

4 Green Fault Relay Contact A (COM)

9 Green/Black Fault Relay Contact B (N.O.)

5 Orange Auxiliary Relay Contact A (COM)

10 Orange/Black Auxiliary Relay Contact B (N.O.)

2 White ModBus RTU (+)

7 White/Black ModBus RTU (-)

6 Blue 4-20 mA (+)

11 Blue/Black Test

12 Black/White Not Used

14 Green/White Not Used

15 Blue/White Not Used

Cable

Shield

To be terminated at chassis ground of PLC or Fire Alarm Panel

MAN‐D381‐0001

8

2.5 BasicWiringSchematics

MAN‐D381‐0001

9

3.0 DetectorSensors,LEDIndicatorsandConduitEntryLocation

MAN‐D381‐0001

10

4.0 Operation&Start‐Up

4.1 DetectorPerformance&Response

TheD381isaMulti‐SpectrumUV/IR/IRmediumrangeflamedetectoroptimizedforuseinvarietyof

indoor/outdoorapplicationsinClassI,Division2areainstallationsthedetectorincludesahighly

sensitiveUVsensorand3separateQuantumIRsensorstunedpreciselyto3separatebandsofIR

radiationintheelectromagneticspectrumforrespondingtovarioustypesoffires.Thedetectorwill

respondtobothHydrocarbonandNon‐Hydrocarbonwithin3‐5seconds,theresponsetimewilldepend

onthesizeoftheflame,typeoffuel,andthedistancefromtheflame.

4.2 DetectorOperation

Oncepoweredup,theD381detectorwillgothroughitsself‐diagnosticsprocessandwillbereadyfor

operationafter10‐12seconds.Duringtheself‐diagnosticprocess,theGreen,Amber,andRedLEDswill

turnonsequentiallyindicatingthisprocess.Duringtheself‐diagnostics,theMicroprocessorwillcheck

thestatusofUVandIRsensors,relays,variousdevices,andtheself‐testfeature.Oncethe

Microprocessordeterminesthatalldevicesandfunctionshavebeentestedandfoundtobewithinthe

specifications,itwillthenterminatetheself‐testdiagnosticsandwillreturnthedetectortonormal

operation.Duringthenormaloperation,theGreenLEDwillbeturn“ON”for1secondand“OFF”for1

secondindicatingthatthedetectorisnowreadytodetectfires.

4.3 DetectorVisualStatusIndications

TheD381detectorhas(3)brightLEDsforindicatingthestatusofthedetector:

GreenLED NormalOperation

REDLED AlarmCondition

AmberLED Faultcondition

4.3.1

NormalOperation:

DuringthenormaloperationandwithnoAlarmorFaultexisting,thedetectorwillturnthe

GreenLED“ON”for1secondand“OFF”for1secondindicatingnormalstatus.Unlessotherwise

specifiedthedetectorwillbeshippedwiththefollowingstandardfactoryoutputconfiguration

withpowerapplied:

Alarmrelay NormallyDe‐Energized,N.O.Contacts

Auxiliaryrelay NormallyDe‐Energized,N.O.Contacts

Faultrelay NormallyEnergized,N.C.Contacts

Analogoutput 4.0+/‐0.2mA–Normaloperation

Relaymodes Non‐Latching

MAN‐D381‐0001

11

4.3.2

AlarmCondition:

WhentheD381detectorisexposedtofiresanddeclaresanAlarm,thefollowingconditionswill

occur(withstandardfactoryconfigurations):

RedAlarmLED Willturn“ON”steady

GreenLED Willcontinueflashing“ON”and“OFF”

Alarmrelay Willbeactivated

Auxiliaryrelay Willbeactivated

Faultrelay Willremainunchanged

Analogoutput 20.0+/‐0.2mA

ModBusoutput Willdeclare“Alarm”command

PleasenotethattheRedAlarmLEDwillremain“ON”andtheAlarmrelaywillremainEnergized

aslongthefireispresent.Oncethefirehasbeenextinguishedthedetectorstatuswillbeas

follows:

a) Non‐LatchingAlarmRelaymode:ThedetectorwillautomaticallyresetitselfbyDe‐

EnergizingtheAlarmandAuxiliaryRelays,turningofftheRedLED,switchingtheanalog

outputto4mAandremovingtheAlarmcommandfromModBusoutput

b) LatchingAlarmRelaymode:ThedetectorstatuswillremainunchangedwithAlarmand

AuxiliaryrelaysstillEnergizedandtheRedAlarmLEDremaining“ON”untilthedetectoris

resetbyrecyclingthe24VDCpowertodetectormomentarily.Thedetectorshouldnow

returntoNormaloperation.

4.3.3

FaultCondition:

AFaultmayoccurifoneormoreofthefollowingconditionsexist(withstandardfactory

configurations):

FaultyUVorIRSensor

FaultyMicroprocessor

FaultyRelay

Lowinputpower(lessthan19VDC)

Highinputpower(higherthan34VDC)

Hightemperature

Dirtyviewingwindow

Blockageofdetector’swindow

DuringdetectorFaultthefollowingconditionswilloccur(withstandardfactoryconfigurations):

AmberLED Willturn“ON”steady

GreenLED Willcontinueflashing“ON”and“OFF”

Faultrelay WillbeDe‐Energized(deactivated)

Analogoutput 2.0+/_0.2mA–DirtyWindow

Analogoutput 0.3–0.9mA–OtherFaults

ModBusoutput Willdeclare“Fault”Command

MAN‐D381‐0001

12

a) Non‐LatchingFaultRelaymode:WhentheFaulthasbeencleared,thedetectorwill

automaticallyresetitselfbyturningofftheAmberLEDandEnergizingtheFaultrelay.

b) LatchingFaultRelaymode:ThedetectorstatuswillremainunchangedwithFaultrelaystill

De‐EnergizedandtheAmberFaultLEDremaining“ON”untilthedetectorisresetby

recyclingthe24VDCpowertodetectormomentarily.

4.3.4

DetectorAutomaticSelf‐Test:

TheD381detectorisprogrammedtoperformanautomaticdiagnosticself‐testperiodically

(factorydefaultisevery5minutes).DuringtheautomaticSelf‐Test,thedetectorwillturnon

bothAmberLEDsflashingforseveralsecondsindicatingtheself‐testprocess.Duringtheself‐

testprocess,thedetectorwillturnonitsinternalUVandIRtestsourcesmomentarilywhichwill

bereflectedfromtheSapphirewindowbackintotheUVandIRsensorsforanalysis.Following

theautomaticSelf‐Test,thedetectorwillreturntoNormalOperationifnoFaultwasdetected.

4.3.5

DetectorOpticalPathTest:

Thedetectoralsomonitorsthecleanlinessofitsviewingwindowandblockageofitsviewing

windoweverysecondusingtheOptiRadarfeature.Ifthecontaminationofthewindowexceeds

thepresetthreshold,thedetectorwilldeclareaFault.Thedetectoralsomonitorstheblockage

ofthewindowbyexternalobjects.Ifanobjectisplacedwithin1”ofdetector’swindow,the

detectorwillturnonitsAmberlightflashingfor60seconds;andiftheblockageisnotremoved

after60seconds,thedetectorwilldeclareaFaultbychangingtheflashingAmberlighttosteady

on.

5.0 Maintenance

5.1 InspectionandCleaning

Oncethedetectorhasbeeninstalledandpoweredup,itshouldprovidemaintenancefreeperformance

foryears.Thefollowingisasimpleguidelineforkeepingthedetectorworkingandtroublefree:

5.1.1 TheD381detectorrequiresnofieldcalibrationoradjustment.

5.1.2 The detector and the viewing window should be kept clean from dirt, dust, oil and other

contaminantsatalltimes.Disconnectpowerbeforecleaningthedetector’swindow.Toremove

dirtanddustusesoftcottonandsoapywaterandrinsethewindowwithcleanwater.Asoftcloth

andIPA(IsopropylAlcohol)canbeusedtoremoveoilandotherresiduesfromthewindow.

5.2 DetectorTestingProcedure

5.2.1

PeriodicTesting:

Thedetectorshouldbefunctionallytestedend‐to‐endannuallyorasrequired

bylocalcodesorauthoritieshavingjurisdiction.Priortotestingthesystem,alldetectoroutputs

toFireAlarmPanelorextinguishingsystemsshouldbedisabledordisconnected.Thefunctional

testshouldbeperformedbyqualifiedpersonnelbeingfamiliarwiththesystem.

MAN‐D381‐0001

13

5.2.2 ManualTest:InadditiontothecontinuousAutomaticSelf‐Test,theD381detectorscanbetested

manuallyonaperiodicbasis.ReferringtoFig.3,DetectorWiringSchematic,themanualtestcan

beinitiatedbymomentarilyconnectingwireBlue/Black(Test)to24VDC(return)ofpowersupply.

Tofacilitatethemanualtest,Amomentarypushbuttonswitchcanbeinstalledandlocatedatthe

FireAlarmpanelorControlCenter.

6.0 D381DetectorResponseCharacteristics

6.1 PerformanceTesting

TheD381detector,likeanyotherflamedetectors,willrespondtovarioustypesoffiresdifferentlyboth

intimeanddistance.Forthisreason,theFactoryMutual(FM)baselineperformancetestingisperformed

forallflamedetectorsusing1ft.x1ft.n‐Heptanepanfireforfuelfiresand30”‐36”highplumefireforgas

flames.Thisprocedurewouldallowtheend‐usersameansofcomparingtheflamedetectorsofvarious

manufacturersforresponsetimeandsensitivity.Belowistheresponse characteristic of the D381

detectorastestedandwitnessedbyFM:

Table2–D381DetectorResponse@HighSensitivity‐Indoor

FuelType FlameSize Distance

(ft/m)

Response

Seconds(Average)

n‐Heptane 2”Dia. 11.75/3.6 3.2

n‐Heptane 12”x12” 80/24.4 5.4

IPA 12”x12” 80/24.4 4.2

JP4 12”x12” 40/12.2 5.7

Hydrogen 36”plume 60/18.3 4.7

6.2 ImmunitytoFalseAlarmSources

DetectorD381ishighlyimmunetomanyfalsealarmsourcestested.Belowtablesaresamples

ofFalseAlarmImmunitytovarioussourcesandthedetectorresponsetimeinthepresenceof

falsealarmsources:

Table3–D381DetectorFalseAlarmImmunity@HighSensitivity

FalseAlarmSource Distance

Unmodulated Modulate

Sunlight ‐ NoResponse NoResponse

IncandescentLamp–60W 3ft/0.91m NoResponse NoResponse

InfraredHeater–1500W 3ft/0.91m NoResponse NoResponse

SodiumVaporLamp–150W 3ft/0.91m NoResponse NoResponse

FlorescentLamp–22W 3ft/0.91m NoResponse NoResponse

HalogenLamp–500W 3ft/0.91m NoResponse NoResponse

MagFlashlight 3ft/0.91m NoResponse NoResponse

Heater–6kW 3ft/0.91m NoResponse NoResponse

ArcWelding 30ft/9.1 NoResponse NoResponse

MAN‐D381‐0001

14

Table4–D381DetectorResponseinthePresenceofFalseAlarmSource

FalseAlarmSource FireSizeand

Fuel

Distance

(ft./m)

Unmodulated

ResponseTime

Seconds(Ave.)

Modulate

ResponseTime

Seconds(Ave.)

Sunlight 12”x12”n‐Heptane 80/24.4 5.7 2.5

IncandescentLamp–60W 2”Dia.n‐Heptane 9.75/2.97 2.7 3.3

InfraredHeater–1500W 2”Dia.n‐Heptane 9.75/2.97 2.5 2.3

SodiumVaporLamp 2”Dia.n‐Heptane 9.75/2.97 3.9 1.6

FlorescentLamp 2”Dia.n‐Heptane 9.75/2.97 3.8 3.0

HalogenLamp–500W 2”Dia.n‐Heptane 9.75/2.97 3.5 7.3

MagFlashlight 2”Dia.n‐Heptane 9.75/2.97 2.8 2.9

Heater–6kW 2”Dia.n‐Heptane 9.75/2.97 2.9 2.8

ArcWelding 2”Dia.n‐Heptane 30/9.1 10.0 10.4

7.0 Troubleshooting(tobeaddedlater)

8.0 EventLog&FireGraph(tobeaddedlater)

9.0 Accessories(tobeaddedlater)

10.0 ProductSupport

10.1 TechnicalSupportandCustomerSupport

ForTechnicalandCustomerSupportandquestionsconcerningthedetectorsorapplications,

pleasecontact:

MAN‐D381‐0001

15

11.0 Warranty

DetectorsIncorporatedwarrantstheproductsmanufacturedandsuppliedbyDetectorsIncorporated

againstdefectsinmaterialsandworkmanshipundernormaluseandserviceforaperiodoffive(5)

yearsfromthedateofshipment.DetectorsIncorporatedatitssolediscretionwillrepairorreplaceat

nochargeanyproductsfoundtobedefectiveduringthewarrantyperiod.Thedefectiveproductmust

beshippedtransportationpaidtoDetectorsIncorporatedorDistributor/Representativewherethe

productswaspurchased.ThisexpresslimitedwarrantyisextendedbyDetectorsIncorporatedtothe

originalpurchaseronlyandisnotassignableortransferabletoanyotherparty.

Thiswarrantydoesnotcoverthefollowing:

1. Damageincurredintransit.

2. Defectsordamagefrommisuse,accident,“ActofGod”,orneglect.

3. Defectsordamagefromimproperinstallation,lackofmaintenance,impropertestingand

operation.

4. Defectsordamagecausedbyalterations,unauthorizeddis‐assemblies,repairsormodifications.

5. Damagescausedbyapplyinghighvoltage,electricalpowersurgeorfaultypowersupplies.

6. Transportationchargestoandfromrepairfacility.

7. Illegalorunauthorizedalterationsofthefirmware/softwareintheproduct.

ThisisthecompletewarrantyfortheproductsmanufacturedbyDetectorsIncorporated.Exceptfor

thewarrantyexpressedabove,DetectorsIncorporateddisclaimsallotherwarrantiesexpressor

impliedwithregardstoitsproductssold.DetectorsIncorporatedsoleliabilityunderthiswarrantyis

limitedonlytorepairorreplacementoftheproductsandshallnotincludeanyliabilityfor

consequentialorotherdamagesarisingfromtheuseoftheproduct.

MAN‐D381‐0001

16

APPENDIX“A”

MAN‐D381‐0001

17

APPENDIX“B”

Table of contents

Other Detectors Incorporated Security Sensor manuals