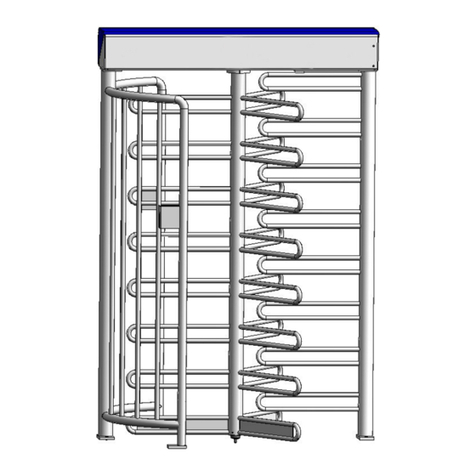

Operating Instructions

581E,5811_07 5

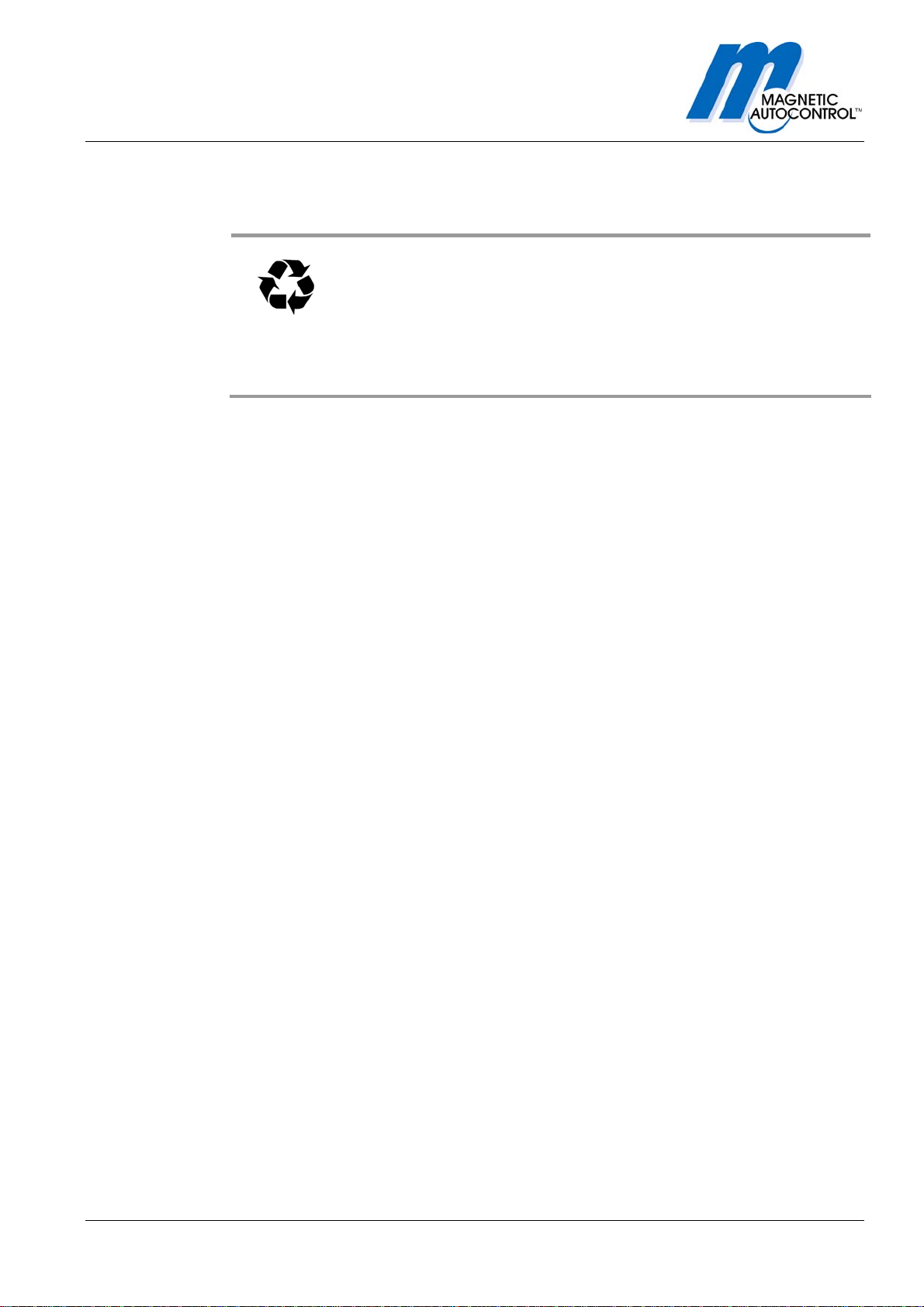

RECYCLING!

When disposing of the unit at the end of utilisation ensure those noxious and

dangerous residues are disposed of in accordance with the regulations.

Based on the different material, disposal must occur in a separate manner.

The used lubrication and auxiliary material such as oils and fats will be

disposed of in accordance with the statutory provisions.

2.4 Safety notes

- Disconnect all external opening or closing devices (remote control, control

desk, etc.) during maintenance work.

- Do not operate the equipment without effective anchoring to the

foundation.

- A main supply power circuit breaker must be installed.

- This operating manual and any other additional information must be kept

in a, for all authorized person, accessible location.

- Before commissioning make sure all electrical and functional features are

tested.

- The electrical wiring must comply with these instructions.

- Only certified and trained electrical technicians shall perform any

electrical work.

- Before any maintenance or troubleshooting work the main power supply

must be disconnected.

- Electrical voltage components like transformers, solenoids, resistors, and

stator housings of motors, lamps etc. may be hot during and after

operation. Do not touch such components; it can cause skin burns.

●Disconnect all external opening or closing devices (remote control, control

desk, etc.) during maintenance work

●It is prohibited to install the barrier without proper mounting to the

foundation

●A main power switch or residual current operated device is compulsory

●Risk of bodily harm while cover is open

●Pedestrian barriers are maintenance free

●Documentation should be easily accessible.

●Before commissioning make sure all electrical and functional features are

tested.

●Permissible environmental conditions