6

11) Screw the nuts after all equipment has been tested to work well.

Notice:

1. The depth of the PVC tubes buried shall be more than 60mm. The height above the

ground shall be more than 50mm. And the exit of the PVC tube shall be bent return so

as to avoid the water falls in.

2. All the above steps shall be operated under the condition of power off and make sure

that the system protection ground cable is connected.

3. If the equipment is used outdoors, please build a cement platform for the equipment

with the height of 100mm---200mm to resist humidity. Meanwhile, an awning or other

facility is needed to resist rain. It’s forbidden to use the equipment directly in the open

air.

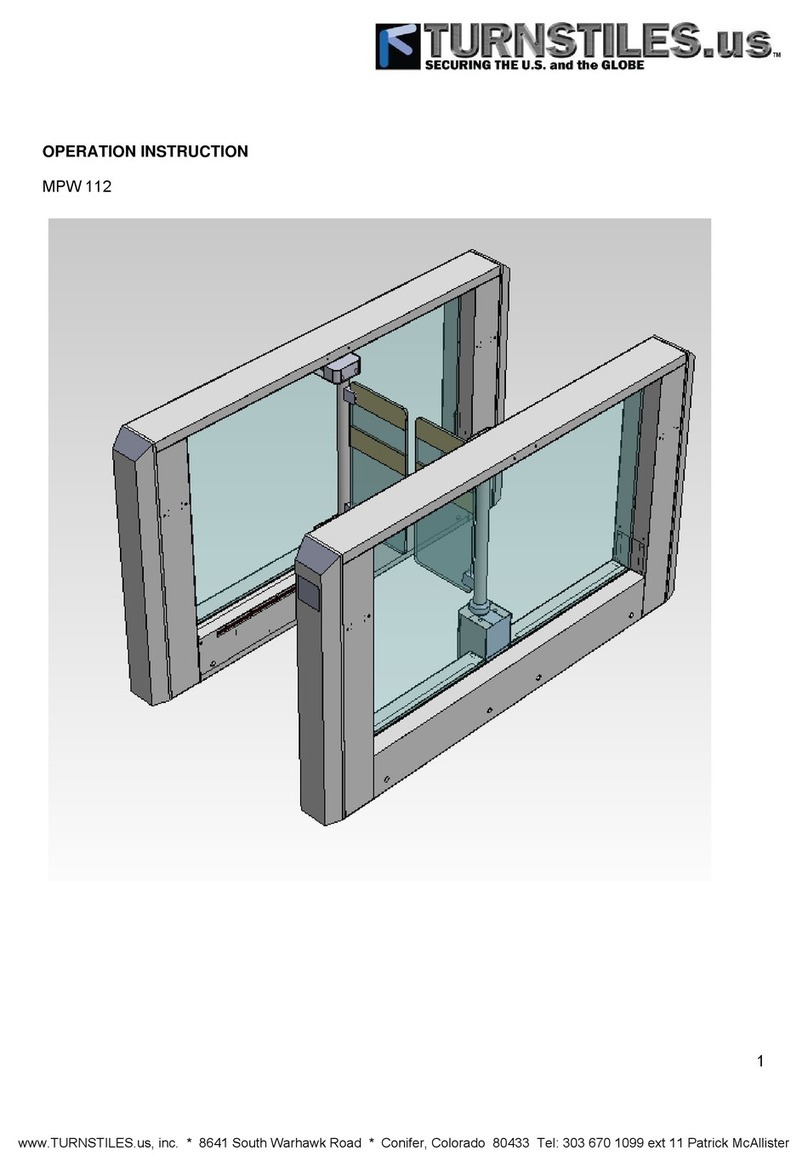

5.2 Equipment Functional Test

The operating procedure is shown below and given the sequence of passage through the

turnstile in either direction. The barrier swing will normally be locked, unless a free

entry/exit option has been specified operate the Access Control Device if fitted. On the

acceptance of a signal from the Access Control Device the barrier swing rotate to 90° for

unlocking, After the pre-set time, the main controller controls the motor drives the barrier

rotate to the limit position and lock automatically, the counter will automatically increase 1

at the passing direction. Go signal will be cancelled if passage through is not completed

within pre-set time. The standard default is 5 seconds. The user may carry out one or

several functional tests as given below in accordance with the requirements on the passage

function of the turnstile.

5.2.1 Single time card reading passage:

When the passenger read an effective card, the main controller electrifies the barrier swing

rotate to 90° for unlocking, After the pre-set time, the main controller controls the motor

drives the barrier rotate to the limit position and lock automatically, the counter will

automatically increase 1 at the passing direction. Go signal will be cancelled if passage

through is not completed within pre-set time (the default pre-set time being 5s).

5.3.2 Function of barrier swing open at power off

The barrier swing should be open automatically when the power of the system is cut off

5.3.3 Far end control

The following setting and test should be carried out when the management computer is

used for far end control of the barrier swing.