SB-2-319-C

IMPORTANT: Before using this equip-

ment, read all safety precautions and

instructions. Retain for future use.

DESCRIPTION

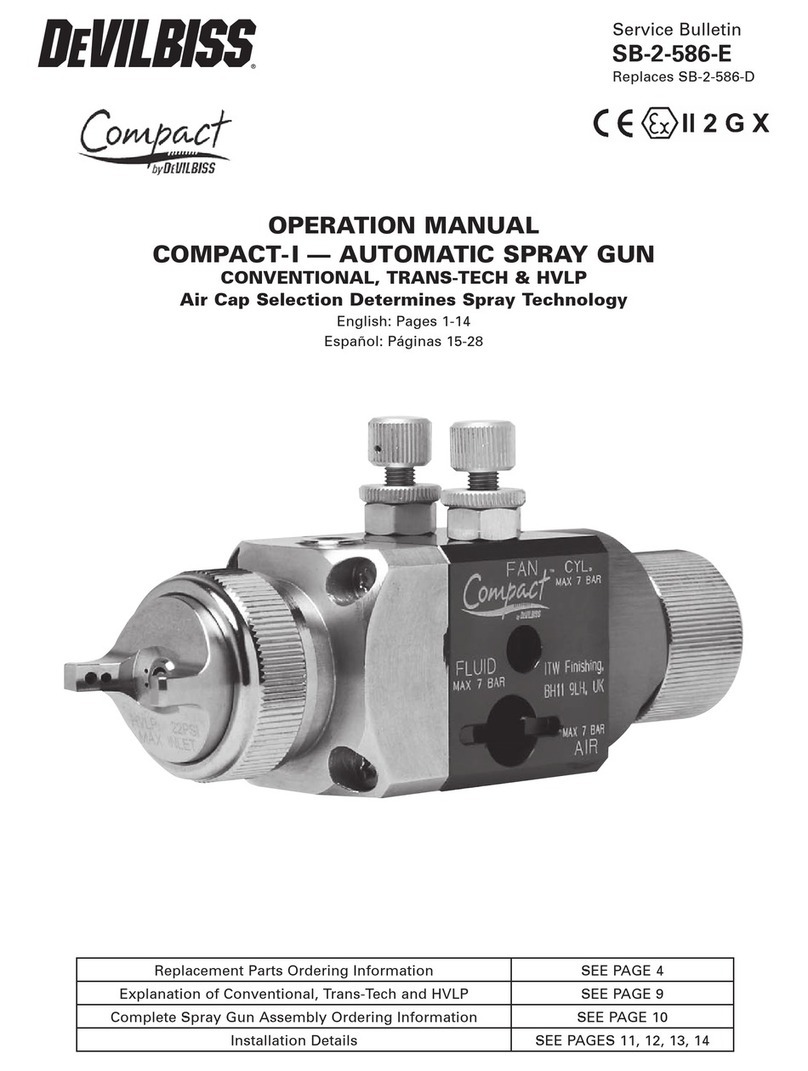

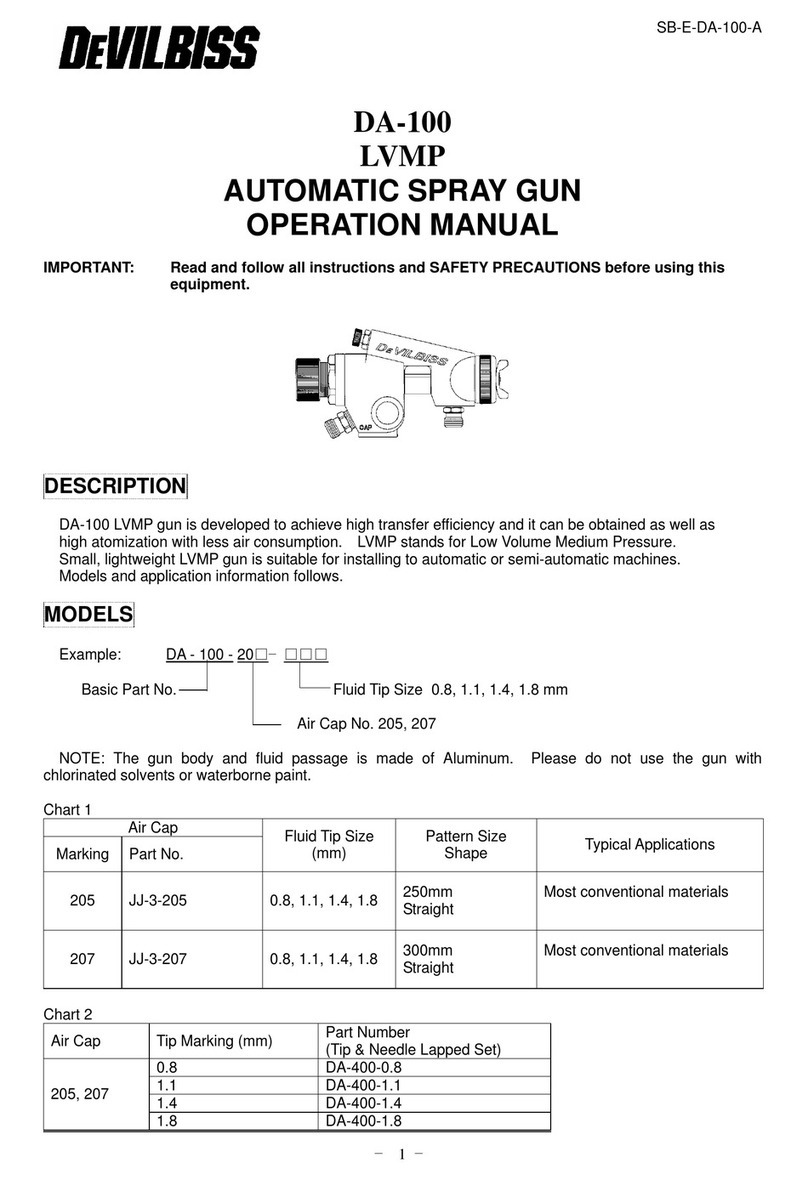

The MSA-510-DEC is a smaller, lighter

weight gun that can apply decorative

spatter effects to wood furniture, metal

panels, etc. Finish may be changed

from a fine mist to larger droplet size

particles. Simply adjust fluid pressure

and/or air pressure

The MSA-510-DEC comes with the

flat-end AV-447 spatter cap assembly.

Small spatter dots are the result of

coarse atomization when using the

standard spatter cap assembly (2).

OPERATION

Note

This gun may be used with

chlorinated solvents. Alumi-

num is not used in the fluid

passage areas.

Mixmaterialaccordingtomanufacturer's

instructions. Itmay be necessary to strain

material.

A greater than normal gun distance

provides a more uniform particle size.

Particlespacingisdeterminedbyspeed

of movement and degree of overlap.

Particle size is dependent on the mate-

rial consistency. Specially formulated

spattermaterialsareavailable,although

standard paints may be used. Apply

standard paints using very little or no

reduction.

Pressure on cup or tank controls mate-

rial flow. Begin with the adjusting

screw (31) wide open. Use adjusting

screw (31) to regulate material flow

under abnormally low material pres-

sure or material viscosity conditions.

SERVICE BULLETIN

MSA-510-DEC DECORATOR SPRAY GUN

Replaces SB-2-319-B

Repair Kit KK-4987-2

Adjust atomization air to get desired

particle size. It should be high enough

to carry particles to surface. Spatter

dot size increases with pressure reduc-

tion, and decreases with pressure in-

crease. Pressure used depends on

material viscosity being sprayed and

desired operation speed.

PREVENTIVE MAINTENANCE

To clean gun passages, blow back

paint to material supply source and

flush fluid passage with clean solvent.

Model HD-503 Gun/Hose Cleaner is a

very fast and effective way of cleaning

(See Accessories). Wipe gun clean

with solvent soaked cloth.

If slots of ring (4) become clogged,

clean by soaking cap in solvent and

scrubbing with a gun cleaning brush.

Note

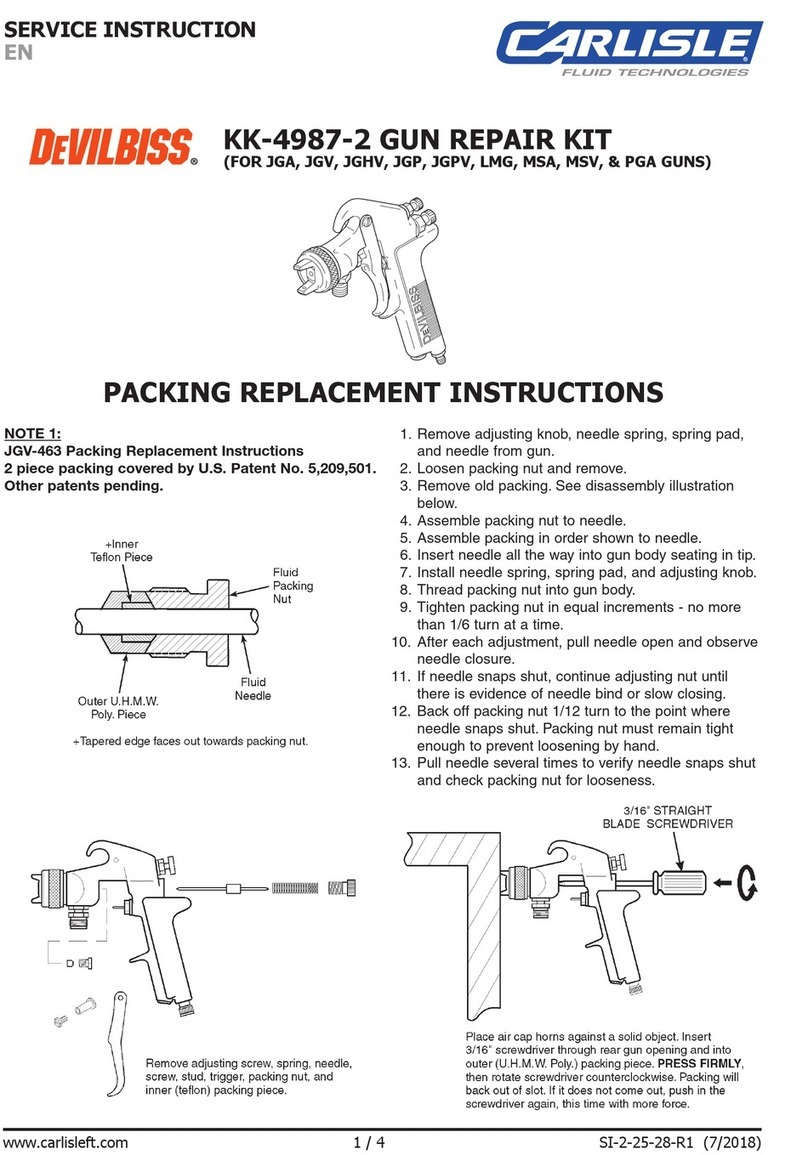

When replacing the fluid tip or

fluid needle, replace both at

the same time. Using worn

parts can cause fluid leakge.

Also, replace the needle pack-

ing at this time.

Using SSL-10 gun lube, lightly lubri-

cate the threads of the fluid tip before

reassembling. Torque to 20-25 ft. lbs.

To prevent damage to the fluid

tip (7) or fluid needle (28), be

sure to either 1) pull the trigger

and hold while tightening the

fluid tip or 2) remove fluid

needle adjusting screw to re-

lieve spring pressure.

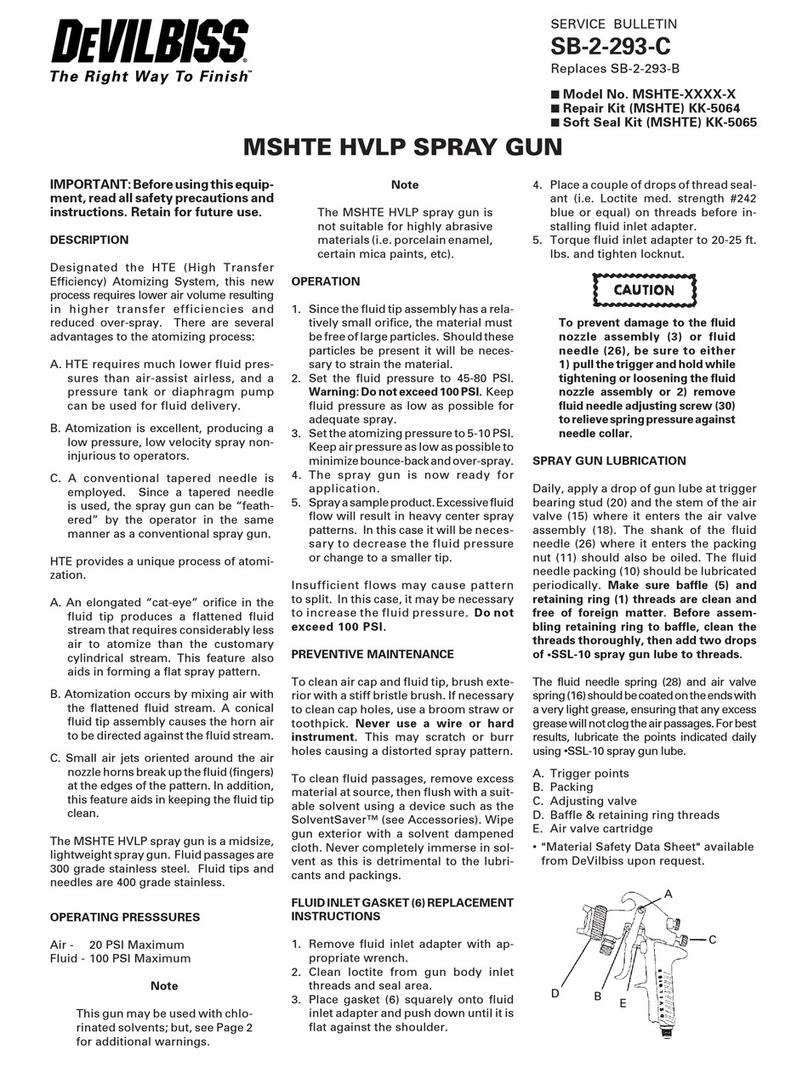

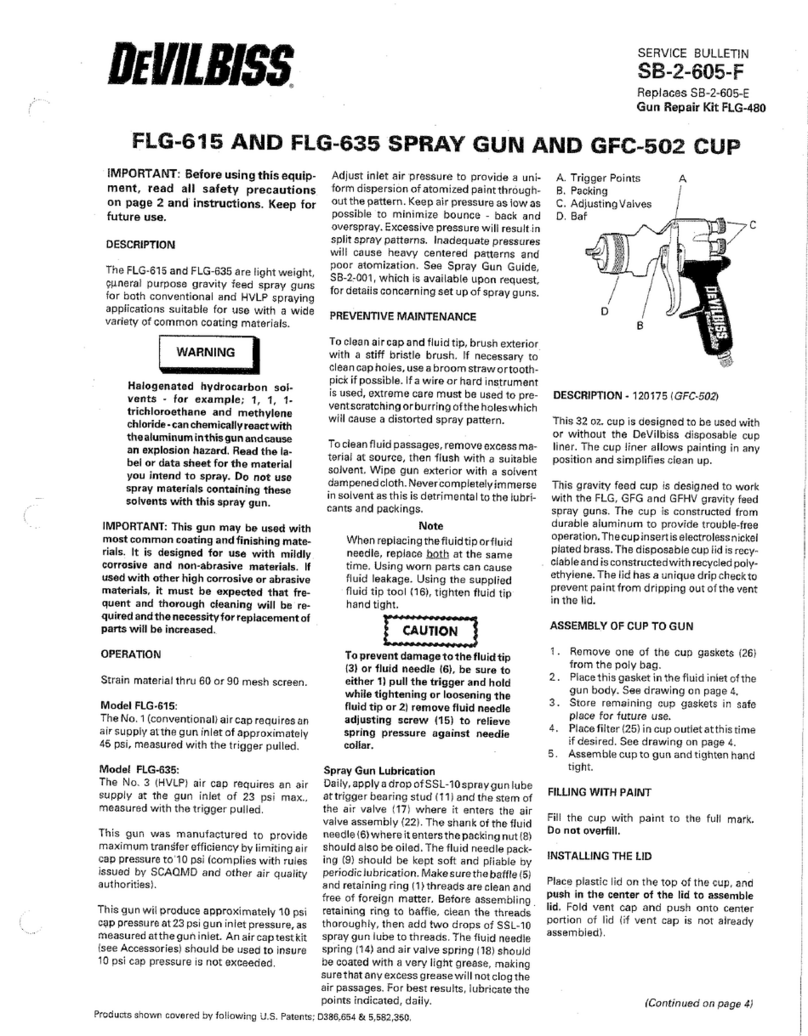

A

C

DBA

B

Spray Gun Lubrication

For best results, lubricate the points

indicated, daily. Use SSL-10 Spray

Gun Lube to lubricate.

A. Trigger Points

B. Packings

C . Adjusting Valves

D. Air Baffle Threads