Specications

T-900 Coin Washer

Capacity 55lbs.

Dimensions

Cylinder Depth 22”

Cylinder Diameter 30”

Cylinder Volume (cubic feet) 9.0

Door Opening 15 1/4”

Door Height (oor to bottom of

door)

18 3/8”

Overall Height 54”

Cabinet Width 34 3/8”

Overall Depth 38 3/4”

Drain Diameter (O.D.) 3”

Drain Height (oor to center of

outlet)

7 1/2”

Recommended Clearance Be-

tween Machines (min)

1/2”

Necessary Service Clearance

Behind Machine

24”

Cylinder RPM

Tumble Speed 43

Extract Speed 531

Extract Speed G-Force 120

Cylinder Direction in Extract Counter-clockwise

Motor H.P.

Wash Single Phase 3

Wash Three Phase 3

Extract Single Phase 3

Extract Three Phase 3

Amperage (avg. measured on L1)

Wash Single Phase 3

Wash Three Phase 3

Extract Single Phase 4.2

Extract Three Phase 4.2

Running Amps (Maximum)

Single Phase 8.4

Three Phase 8.4

Circuit Breaker (Amps)

Single Phase 15

Three Phase 15

Built-in Controls Circuit Breaker Yes

Built in Motor Protection Yes

Voltage 60Hz.

Single Phase 220-240

Three Phase 208-240

Service

Single Phase 2 wires + ground

Three Phase 3 wires + ground

Wire Size (Minimum)

Single Phase 12

Three Phase 12

Water

Recommended Hot Water

(degrees)

140

Water Pressure (min/max) 30-120psi

Water Inlet Size (hose

thread)

3/4”

Water Flow Rate (gallons/

minute)

9

Wash Cycle

Wash Temperatures Hot, Warm, &

Cold

Rinse Temperatures Cold-Std;

Warm-Opt

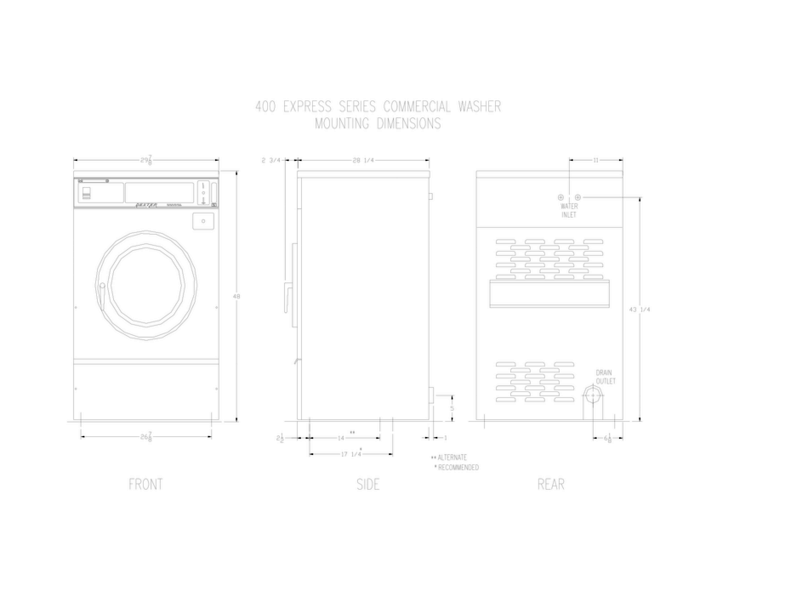

Mounting Hole Dimensions

Left to Right 27 3/4”

Front to Cabinet to First

Hole

2 3/4”

First Hole to Second Hole 23”

Second Hole to Third Hole 11”

Mounting Bolt Diameter 3/4”

Hole Diameter in Base 1”

Concrete Thickness (min) 8”

Recommended Mounting

Height

4” to 10”

Weight

Shipping (lbs.) 1075

Net (lbs.) 1025

Wash Formulas

Application Formula Mechanical

Timer

Rotary Switch

Position

Shirt Laundry

oxygen bleach

Shirts (No Starch)

Shirts (Starch)

X

X

4 (A)

4 (A)

Hotel/Motel

chlorine bleach

White sheets

White pillowcases

White towels, bath mats, & washclothes

Colored sheets & towels

Delicate Wash

Housekeeping rags & mops

Houskeeping Uniforms

Stain Treatment

Reclaim Part 1

Reclaim Part 2

X

X

X

X

X

X

X

No

No

No

2 (B)

1 (B)

3 (B) or 1 (B)

4 (B) or 1 (B)

4 (B)

1 (C)

2 (D)

Healthcare

chlorine bleach

Sheets & Pillowcases

Towels

Diapers & Pads

Personals

Delicates

X

X

X

X

X

2

3 or 1

1 (K)

4

4

Food & Beverage

chlorine bleach

White (Cotton/Blend) Table Linen

Colored (Cotton/Blend) Table Linen

White (100% Polyester) Table Linen

Colored (100% Polyester) Table Linen

White Chef Coats

Kitchen & Maintenance Rags

X

X

X

X

X

X

3 (E)

2 (F)

3 (E)

2 (F)

1 (J)

1 (G)

oxygen bleach White/Colored (Cotton/Blend) Table Linen

White/Colored (100% Polyester) Table Linen

White Chef Coats

Kitchen & Maintenance Rags

X

X

X

X

3 (H)

3 (H)

1 (G)

1 (G)

Other

oxygen bleach

Oxygen Bleach Terry

Oxygen Bleach Terry (No Iron)

Open

X

X

No

1 (G) or 3 (L)

1 (G) or 3 (L)

(A) Switch Position #4 gives 7 minute wash. Flush & Prewash eliminated with jumper (connect

orange/white wire to terminal strip #2).

(B) Flush & Prewash eliminated with jumper (connect orange/white wire to terminal strip #2).

(C) Switch Position #1 gives 2 ushes/3 rinses after bleach

(D) Switch Position #2 gives either 2 ushes or 0 ushes. Flush & Prewash eliminated with

jumper (connect orange/white wire to terminal strip #2).

(E) Switch Position #3 gives 7 minute wash.

(F) Switch Position #2 gives either 2 or 0 ushes with a 7 minute wash. Flush & Prewash

elimiated with jumper (connect orange/white wire to terminal strip #2).

(G) Switch Position #1 gives 3 minutes ush/3 min. prewash/7 min. wash/5 rinses

(H) Switch Position #3 gives 7 minute wash/7 minute 2nd rinse

(J) Switch Position #1 gives 3 minute ush/3 min. prewash/7 min. wash

(K) Switch Position #1 gives 2 ushes

(L) Same as (G) only deletes rst ush

Please refer to OPL Washer CYCLE TIMES charts for all available options.

16 17

Part # 8533-031-001 6/22 Part # 8533-031-001 6/22