DEZEGA CARBOFit-400 User manual

User manual

Руководство по эксплуатации

Kullanım Kılavuzu

Instrukcja użytkowania

CARBOFit-400

POSITIVE PRESSURE LEAK TESTING DEVICE

FOR SELF-CONTAINED SELF-RESCUERS

УСТРОЙСТВО ДЛЯ КОНТРОЛЯ ГЕРМЕТИЧНОСТИ САМОСПАСАТЕЛЕЙ

POZİTİF BASINÇ SIZDIRMAZLIK TEST

CİHAZIOKSİJENLİ FERDİ KURTARICI CİHAZLARI İÇİN

PRZENOŚNE URZĄDZENIE DO KONTROLI

SZCZELNOŚCI APARATÓW UCIECZKOWYCH

CARBO

CI-30 KS

ROXY 40

ROXY 30

TR PLRUEN

AS-UPG-1(2)5-ENEU

AS-UPG-1(2)5-RURU

AS-UPG-1(2)5-TRTR

AS-UPG-1(2)5-PLPL

UPG5.00.000 РЭ-U1

Red. 20.11.2020_V1

USER MANUAL........................................................................................ 3

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ................................................. 17

KULLANIM KILAVUZU ........................................................................... 31

INSTRUKCJA UŻYTKOWANIA............................................................... 45

RU

EN

TR

PL

USER

manual

EN

CARBOFit-400

POSITIVE PRESSURE LEAK TESTING DEVICE

FOR SELF-CONTAINED SELF-RESCUERS

CARBO

CI-30 KS

ROXY 40

ROXY 30

CONTENTS

DESIGNATION.......................................................................................... 5

INTRODUCTION....................................................................................... 6

1. PURPOSE.......................................................................................... 6

2. TECHNICAL DATA.............................................................................. 6

3. DELIVERY SET................................................................................... 6

4. OPERATING PRINCIPLE AND STRUCTURE..................................... 6

5. INSTALLATION................................................................................... 8

6. CALIBRATION.................................................................................... 8

7. MEASURING INSTRUMENTS ........................................................... 9

8. SAFETY MEASURES AND MAINTENANCE...................................... 9

9. TECHNICAL VERIFICATION .............................................................. 9

10. MARKING ........................................................................................ 10

11. OPERATION..................................................................................... 10

12. DAILY MAINTENANCE..................................................................... 11

13. TROUBLESHOOTING...................................................................... 11

14. PACKAGING .................................................................................... 11

15. TRANSPORTATION.......................................................................... 12

16. STORAGE ........................................................................................ 12

17. DISPOSAL......................................................................... 12

18. GUARANTEES AND LIABILITY ........................................... 12

19. INFORMATION FOR ORDER .............................................. 13

ANNEX ................................................................................... 14

DEZEGA CARBOFit-400

5

DESIGNATION

The Manual uses a series of symbols to draw the user’s attention to features, problems,

and dangerous situations as may be encountered in the course of the use and maintenance

of the device.

DANGER!

This symbol indicates an inevitable dangerous situation that, if not eliminated, can lead to a serious injury

or death of the user.

CAUTION!

This symbol indicates a dangerous situation that, if not eliminated, could result in equipment damage.

NOTE!

This symbol indicates additional information about the rules, methods, and recommendations

for correct use of the device.

CARBOFit-400 DEZEGA

6

INTRODUCTION

User manual (hereafter – manual) is intended to study CARBOFit-400, its operating principle and

the requirements for everyday carrying of positive pressure leak testing device for CARBO

self-contained self-rescuer and other types.

User manual includes information on designation, technical data, operating rules, possible

failures and their troubleshooting, safety measures, requirements on transportation and storage

conditions.

1. PURPOSE

CARBOFIt-400 is a device for leaktightness check of CARBO self-rescuer and other types by

positive pressure.

The CARBOFit-400 device is suitable for operation in rooms at an ambient temperature

from + 10 °C to + 40 °C and a relative humidity of not more than 80% at a temperature of + 25 °C.

2. TECHNICAL DATA

Name of parameter Value

Working pressure in the chamber, kPа (mbar) 5±0,2; (50±2)

Pressure measuring range, kPa (mbar) 0-6; (0-60)

Accuracy class of manometer 1,6

Dimensions, mm

• height

• length

• width

325±2

520±2

400±2

Weight, kg, max 9,5

3. DELIVERY SET

Сhamber, pc. 1

Insert, UPG5.00.010, pcs. 2

Spare parts kit UPG5.07.000, pc. 1

User manual, pc. 1

Data sheet, pc. 1

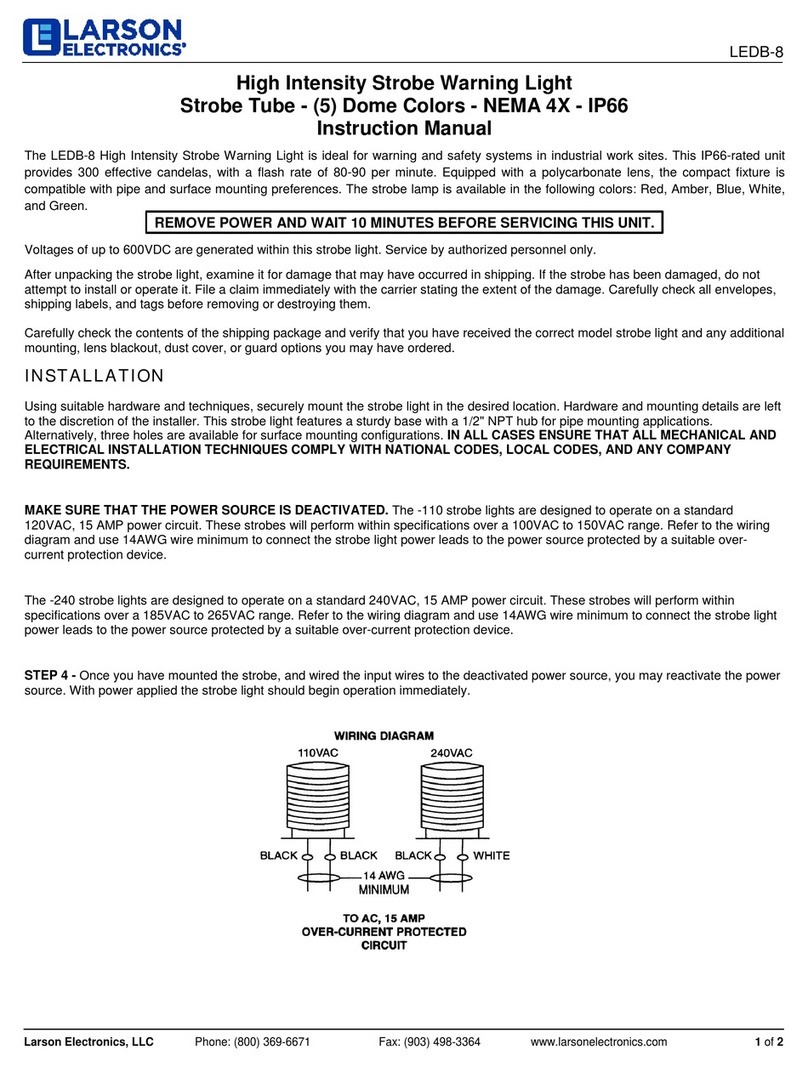

4. OPERATING PRINCIPLE AND STRUCTURE

CARBOFit-400 consists of a chamber and a manometer. After the self-rescuer has been placed

into the chamber, the manometer shows the pressure decrease inside the device indicating the

leaktightness of the self-rescuer.

The chamber consists of Cylinder 2 with the ellipsis cut (Picture 1). The elastic rubber Ring 4

is installed in Flange 3 at the upper part of the Cylinder 2. The Dampener 15 is placed

on the Bottom 1 of the Cylinder 2.

Locking device is installed on the upper side of the Cylinder 2 at the Bracket 5 and consists of

Lever 7 connected by Axis 6 with Bracket 5 and Lid 10. Eccentric lock consists of Eccentric 13

with Grip 14 connected with Lever 7 by Axis 11.

The Latch 8 is fixed on the Lid 10, which prevents it from turning around its axis.

DEZEGA CARBOFit-400

7

The chamber is airtight with the closed Lid 10 and its volume decreases when the elastic

Ring 4 is compressed. Excessive pressure is made inside the chamber. The Eccentric 13 is fixed

by Stopper 12 while the Lid 10 is closed. The Screw 9 connects the Lid 10 with the Lever 7.

The Screw 9 is fixed by adjusting Screw 16 (Picture 2).

There is a Bush 22 (Picture 3) on the Bottom 1, where the Nozzle 19 with the Screw 21 and the

Manometer 17 are inserted. Prior to the manometer a Dosing unit 20 is installed in the Nozzle 19,

which is used for limitation of pressure spikes. Dosing unit 20 reduces transmission of pressure

onto manometer sensing element.

The Nozzle 19 and the Manometer 17 are sealed by the Gasket 18. Thread connection should be

screwed up to the stop.

Device is supplied with inserts and Displacers 23. Its volume is equal to the volume

of the self-rescuer.

Picture 1. General view of CARBOFit-400

Picture 2. General view of CARBOFit-400 (from above)

CARBOFit-400 DEZEGA

8

5. INSTALLATION

CARBOFit-400 is supplied with the uninstalled Grip 14. Therefore, before using the device, it is

necessary to screw the Grip 14 into Eccentric 13.

6. CALIBRATION

Check leaktightness and adjust pressure in the system:

• Put the Inserts in the Chamber;

• Close the Lid 10 with the Eccentric Lock;

DANGER!

If the lid is not fixed, it can be suddenly opened and injured the user.

• Adjust the manometer with the Screws 9 if needed: loosen the Screw 16 and tighten

the Screw 9 if you need to increase pressure, loosen it to decrease pressure.

Fix the Screw 9 with the Adjusting Screw 16;

CAUTION!

Perform adjustment of pressure only when the Lid 10 is open.

• The Manometer should indicate pressure (5±0,2) kPa ((50±2) mbar)

CARBOFit-400 is leaktight if the manometer is stable for 2 minutes after exposure 10-15 seconds.

NOTE!

Check leaktightness of the CARBOFit-400 every time before its use.

Adjustment of CARBOFit-400 device for different types of self-rescuers is mentioned in the

ANNEX.

Picture 3. Scheme of manometer mounting

DEZEGA CARBOFit-400

9

7. MEASURING INSTRUMENTS

For leaktightness tests of the self-contained self-rescuers mechanical timer should be used

together with CARBOFit-400 in accordance with the technical documentation.

NOTE!

It is allowed to use another measuring instrument with the similar parameters and characteristics.

8. SAFETY MEASURES AND MAINTENANCE

Lower the grip smoothly to the stop point while closing the lid as during intermediate fixation of

the grip, the lid can open abruptly due to the elastic forces of the compressed sealing ring and

injure the worker.

Keep the lid open between tests to extend lifetime of the elastic ring.

Do not expose to direct sunlight when testing the self-contained self-rescuers.

After usage wipe the chamber with clean cloth and put inserts inside.

9. TECHNICAL VERIFICATION

CARBOFit-400 device consists of the manometer type 611.10 «WIKA», which should be

periodically verified according to the local norms applied to the testing of measurement

instruments.

NOTE!

To carry out verification, the manometer must be disconnected from the chamber.

CAUTION!

When installing and dismounting the manometer, it is not allowed to turn it by the case.

The manometer should be unscrewed (twisted) with a suitable key beyond the edges on the

nozzle.

Hold the Nozzle 19 (Picture 3) with the key, unscrew manometer.

NOTE!

When installing a manometer, make sure that the gasket is not damaged and set the manometer to a

convenient reading position.

During verification, the following conditions must be met:

• the installation site of the instruments to be checked is selected so that observation of the

readings is not difficult;

• the temperature during calibration should be +20±5 °С, temperature fluctuations during

verification should not exceed 2 °C;

• the device is kept inoperative at an ambient temperature of at least two hours;

• the pressure adjustment must be smooth, without going beyond the verified value.

Prior to the verification, preparatory work must be carried out according to the chapter 5

«Installation».

Before carrying out verification, it is necessary to test the operation of the CARBOFit-400 device

according to the chapter 6 «Calibration».

CARBOFit-400 DEZEGA

10

During performing an external inspection, the device must meet the following requirements:

• the parts of the device must not have any flaws those worsen its appearance;

• metal parts of the device should have a protective coating, resistant against atmospheric

corrosion;

• the grip should rotate smoothly without rubbing;

• the marks, letters and numbers on the manometer scale should be clearly drawn.

NOTE!

The value of the working pressure created in the chamber of the CARBOFit-400 device is determined

during the leak test of the device according to the chapter 6 «Calibration».

10. MARKING

The Plate contains the following inscriptions:

• name or trademark of the plant;

• name of the device;

• serial number and manufacturing date;

• inscription «Made in Turkey» or «Made in Russia».

Marking of packaging for transportation of CARBOFit-400 includes:

• manipulation marks «Fragile. Caution»; «Top»; «Protect from heating»; «Protect from

moisture»;

• warning label «Do not throw»;

• basic inscriptions;

• additional inscriptions;

• information inscriptions.

11. OPERATION

During the test the examined self-contained self-rescuer should have the same temperature

as surrounding air and CARBOFit-400 itself. If the temperature differs, the self-contained

self-rescuer should be stored in the testing room at least for 2 hours before test.

Test the self-rescuers in the following order:

• disconnect the self-contained self-rescuers from the belt (if supplied);

• open the lid of CARBOFit-400;

• put a self-contained self-rescuer into the chamber and smoothly close the lid with eccentric

lock. The manometer should indicate (5±0,2) kPa ((50±2) mbar);

• wait for 5-10 seconds to let the pressure inside the chamber get stabilized;

• record the manometer indication. Observe the change in the readings of the manometer.

Pressure drop should not exceed the norms, specified in the manual to the tested

self-contained self-rescuer.

Leaktightness check of the CARBOFit-400 device must be done before testing each batch

of the self-rescuers.

NOTE!

Test a self-contained self-rescuer with CARBOFit-400 device only if the ambient temperature fluctuation

range is not more than ±2 °C during the test.

DEZEGA CARBOFit-400

11

12. DAILY MAINTENANCE

Wipe the CARBOFit-400 device chamber with a clean rag and put the inserts into it after use.

In the period between the checks of the self-contained self-rescuer, keep the lid open to avoid

premature failure of the elastic sealing ring.

NOTE!

Avoid direct sunlight on the CARBOFit-400 device when checking the self-contained self-rescuers

for leaktightness.

13. TROUBLESHOOTING

Problem Possible reason Solution

System is

non leaktight

Sealing surfaces of rubber

ring and lid are dirty

Wipe the ring with a wet

cloth

Rubber tubes or rubber ring

are damaged

Replace rubber tubes

or ring

Insert is non leaktight

Detect the leakage and

eliminate it or replace the

inserts

Place the inserts in a

container with water heated

up to (45+5) оС. By forming

air bubbles the place of

leakage can be determined.

Wipe the inserts with a dry

rag and weld the marked

place.

Manometer is non leaktight Screw the manometer up to

the stop

The tightness of the sealing

nozzle bush is disrupted

Wrap the thread with FUM

tape

The pressure «jumps»

when closing the lid

The elastic properties of

sealing ring are disturbed Change the sealing ring

When opening the lid,

the manometer's needle

does not deflect

The opening of the dosing

unit is clogged

Remove the manometer,

unscrew and blow out the

dosing unit

14. PACKAGING

CARBOFit-400 is packed in the wooden box.

The inner surface of the box is lined with polyethylene film.

A set of spare parts and operational documentation are packed in polyethylene film bags.

CARBOFit-400 DEZEGA

12

15. TRANSPORTATION

Device packed in the wooden box can be transported in the closed and dry compartments of any

kind of transport at an ambient temperature from -40 °C up to +60 °C and up to 100% relative

humidity.

16. STORAGE

The device should be stored at an ambient temperature from +5 °C up to +40 °C and relative

humidity up to 80% at a temperature of +25 °C.

The device should be stored separately from the flammable and acid-base materials. An ambient

air should not contain aggressive steams or gases that cause the corrosion of materials.

17. DISPOSAL

Disposal of the CARBOFit-400 must be carried out in accordance with the rules and regulations

of the country in which it is operated. For this purpose, apply for clarifications to the relevant

government agencies.

The symbol above means that, in accordance with local laws and regulations,

products marked with this symbol must be disposed of separately from

household waste. When the product reaches its end of life, take it to a collection

point designated by your local authority.

Separate collection and recycling of your goods during disposal will help to

conserve natural resources and make sure that it is recycled safely for human

health and the environment.

18. GUARANTEES AND LIABILITY

The warranty period is indicated in the data sheet.

Assigned shelf and service life: 5 years.

The manufacturer guarantees the compliance of the CARBOFit-400 with the requirements of the

specifications and requirements set out in the contract documents subject to the consumer’s

compliance with the transportation, storage and operating conditions specified herein.

In case of violation of the requirements of this CARBOFit-400 user manual or any of its

transportation and storage conditions set forth in this manual, the user shall lose the right to

compensation and warranty service for the device.

Manufacturer will not be held liable for any damages related to the improper use or misuse

of the CARBOFit-400.

The responsibility for the use of the CARBOFit-400 is borne by the user.

The manufacturer shall have the right to introduce minor structural changes that do not affect the

work nor impair the performance of the CARBOFit-400 without prior notice to the users.

DEZEGA CARBOFit-400

13

19. INFORMATION FOR ORDER

Notation case example of positive pressure leak testing device CARBOFit-400 in the technical

documentation and when ordering:

AS-UPG-15-ENEU-5-1

Deciphering article:

Auxiliary equipment

Device type

Color of the device

Type of inserts

Documentation language

Market region

Assigned service life, years

Warranty period, years

Component ordering of CARBOFit-400 spare parts

Item Order name Quantity

Gasket UPG.00.005 1

Ring UPG.00.006 1

CARBOFit-400 DEZEGA

14

ANNEX

Adjustment of CARBOFit-400 for self-rescuers leaktightness check

№

Type

of

self-rescuer

Displacer

UPG5.00.007,

pcs.

Displacer

UPG5.00.008,

pcs.

Note

1 CARBO 1 - Displacer is positioned on the bottom of the chamber

2Ci-30 KS,

ROXY 40 3 - Displacers are positioned on the bottom of the chamber

3 ROXY 30 6 1 Displacers UPG5.00.007 6 pcs. are positioned on the bottom of the chamber and

Displacer UPG5.00.008 is positioned on the inner side surface of the chamber

Calibration of CARBOFit-400

Calibration is intended to check the leaktightness of the CARBOFit-400 and to preset the device for testing self-rescuers for leaktightness

(the final adjustment of the device is made with a screw on the lid).

№

Type

of

self-rescuer

Displacer

UPG5.00.007,

pcs.

Displacer

UPG5.00.008,

pcs.

Inserts,

pcs. Position of the displacers

Before leaktightness check of

self-rescuer, remove from the

chamber:

1 CARBO 1 - 2 Displacer is positioned on the bottom of

the chamber

Remove inserts 2 pcs. and

displacers 2 pcs.

2Ci-30 KS,

ROXY 40 3 - 2 Displacers are positioned on the bottom

of the chamber

Remove inserts 2 pcs. and add

displacer UPG5.00.007 1 pc.

3 ROXY 30 6 1 1

Displacer UPG5.00.008 is positioned on

the inner side surface of the chamber.

Displacers UPG5.00.007 7 pcs. are

positioned near the insert

Remove insert

Remove displacer UPG5.00.007

1 pc.

DEZEGA CARBOFit-400

15

DEZEGA SP GÜVENLİK ÜRÜNLERİ SANAYİ VE TİCARET ANONİM

ŞİRKETİ EGE SERBEST BÖLGESİ ZAFER SB MAH. NİLÜFER SK.NO:30

GAZİEMİR, İZMİR

Tel.: +90 232 251 0 394

Fax: +90 232 252 0 394

www.dezega.com

South Ural Respiratory Protective Equipment LLC

13 Orskoe Avenue

Gaj, Orenburg region, Russia, 462631

Tel.: +7 (353-62) 4-70-42

Fax: +7 (353-62) 4-19-95

www.dezega.ru

РУКОВОДСТВО

по эксплуатации

RU

CARBOFit-400

УСТРОЙСТВО ДЛЯ КОНТРОЛЯ

ГЕРМЕТИЧНОСТИ САМОСПАСАТЕЛЕЙ

CARBO

CI-30 KS

ROXY 40

ROXY 30

СОДЕРЖАНИЕ

ОБОЗНАЧЕНИЕ .................................................................................... 19

ВВЕДЕНИЕ ............................................................................................ 20

1. НАЗНАЧЕНИЕ................................................................................. 20

2. ТЕХНИЧЕСКИЕ ДАННЫЕ .............................................................. 20

3. КОМПЛЕКТНОСТЬ......................................................................... 20

4. УСТРОЙСТВО И РАБОТА............................................................... 20

5. УСТАНОВКА.................................................................................... 22

6. КАЛИБРОВКА................................................................................. 23

7. СРЕДСТВА ИЗМЕРЕНИЯ .............................................................. 23

8. МЕРЫ БЕЗОПАСНОСТИ ............................................................... 23

9. ТЕХНИЧЕСКОЕ ОСВИДЕТЕЛЬСТВОВАНИЕ................................ 24

10. МАРКИРОВКА................................................................................ 25

11. ИСПОЛЬЗОВАНИЕ ........................................................................ 25

12. ОБСЛУЖИВАНИЕ .......................................................................... 25

13. ПЕРЕЧЕНЬ ВОЗМОЖНЫХ НЕИСПРАВНОСТЕЙ ........................ 26

14. УПАКОВКА...................................................................................... 26

15. ТРАНСПОРТИРОВАНИЕ................................................................ 26

16. ХРАНЕНИЕ ...................................................................................... 26

17. УТИЛИЗАЦИЯ................................................................................. 27

18. ГАРАНТИИ И ОТВЕТСТВЕННОСТЬ............................................... 27

19. ИНФОРМАЦИЯ ДЛЯ ЗАКАЗА ....................................................... 27

ПРИЛОЖЕНИЕ...................................................................................... 28

DEZEGA CARBOFit-400

1919

ОБОЗНАЧЕНИЕ

В инструкции использован ряд символов для того, чтобы привлечь внимание пользователя

к особенностям, проблемам и опасным ситуациям, с которыми он может столкнуться при

использовании устройства.

ОПАСНО!

Указывает на неизбежную опасную ситуацию, которая, если ее не устранить, может привести к

серьезной травме или гибели пользователя.

ВНИМАНИЕ!

Указывает на угрозу опасной ситуации, которая, если ее не устранить, может привести к

повреждению оборудования.

ПРИМЕЧАНИЕ!

Содержит дополнительную информацию о правилах, приемах и рекомендациях по корректной

работе с устройством.

CARBOFit-400 DEZEGA

2020

ВВЕДЕНИЕ

Руководство по эксплуатации (далее – руководство) CARBOfit-400 предназначено для

изучения конструкции и принципа работы устройства для контроля герметичности

самоспасателей типа CARBO и самоспасателей других типов.

В руководстве приведены сведения о назначении, технических характеристиках,

возможных неисправностях и методах их устранения, о мерах безопасности, правилах

хранения и транспортирования.

1. НАЗНАЧЕНИЕ

Устройство для контроля герметичности самоспасателей (далее – устройство

CARBOFit-400) предназначено для контроля герметичности изолирующих

самоспасателей типа CARBO и других типов, проводимой в соответствии с руководством по

эксплуатации самоспасателей.

Устройство CARBOFit-400 пригодно для эксплуатации в помещениях при температуре

окружающей среды от плюс 10 оС до плюс 40 оС и относительной влажности не более 80%

при температуре плюс 25 оС.

2. ТЕХНИЧЕСКИЕ ДАННЫЕ

Наименование показателя Величина

Рабочее давление, создаваемое в камере, кПа (мбар) 5±0,2 (50±2)

Диапазон измерения давления, кПа (мбар) 0-6; (0-60)

Класс точности манометра 1,6

Габаритные размеры, мм

• высота

• длина

• ширина

325±2

520±2

400±2

Вес устройства, не более, кг 9,5

3. КОМПЛЕКТ ПОСТАВКИ

Устройство, шт. 1

Вкладыш UPG5.00.010, шт. 2

Комплект запасных частей UPG5.07.000, шт. 1

Руководство по эксплуатации, экз. 1

Паспорт, экз. 1

4. УСТРОЙСТВО И РАБОТА

Устройство CARBOFit-400 состоит из камеры и манометра. Камера служит для размещения

в ней проверяемого самоспасателя, а манометр - для измерения давления в камере и

наблюдения за изменением избыточного давления в ней.

Камера (Рисунок 1) представляет собой Стакан 2 эллипсного сечения. В верхней части

Стакана 2 имеется Фланец 3, на который устанавливается эластичное уплотнительное

Кольцо 4. На Дно 1 Стакана 2 уложена амортизирующая Подкладка 15.

This manual suits for next models

3

Table of contents

Languages:

Other DEZEGA Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Mini Gadgets

Mini Gadgets BB2ElectricalBox user manual

ASO Safety Solutions

ASO Safety Solutions Sentir Safety Contact Bumper instruction manual

Tractel

Tractel mobifor Installation, operating and maintenance manual

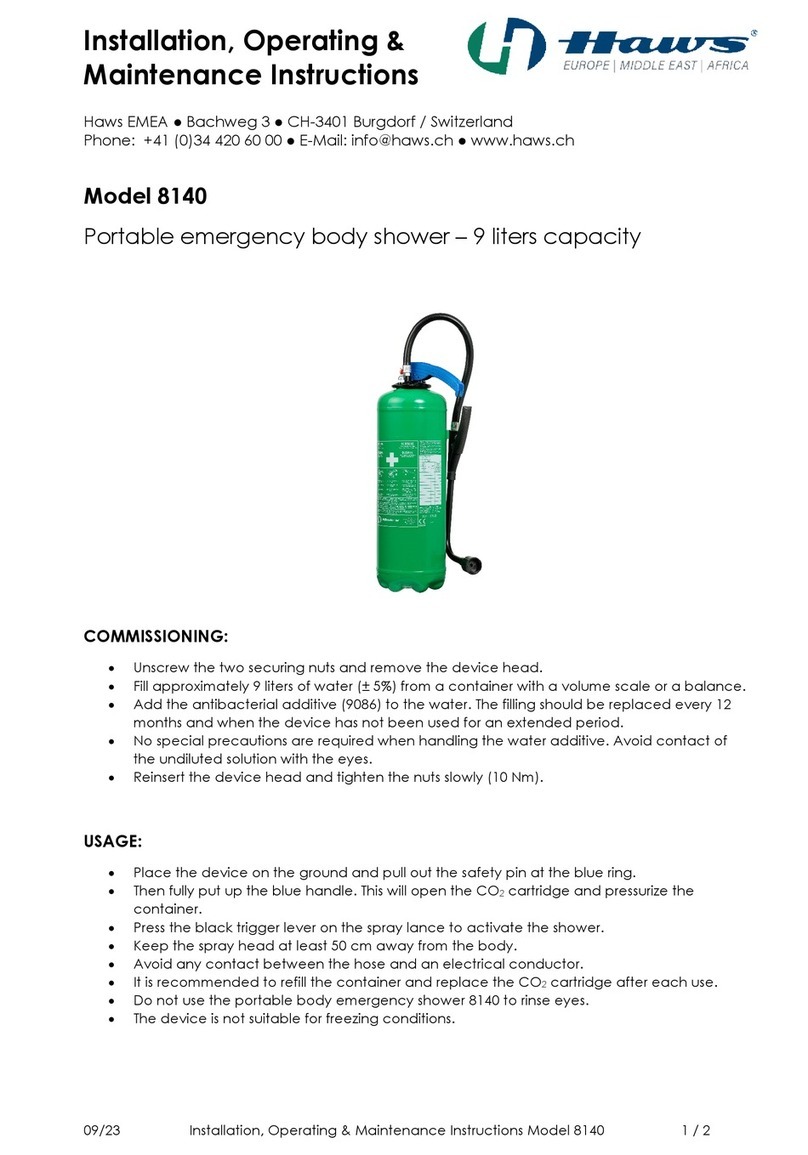

Haws

Haws 8140 Installation, operating, & maintenance instructions

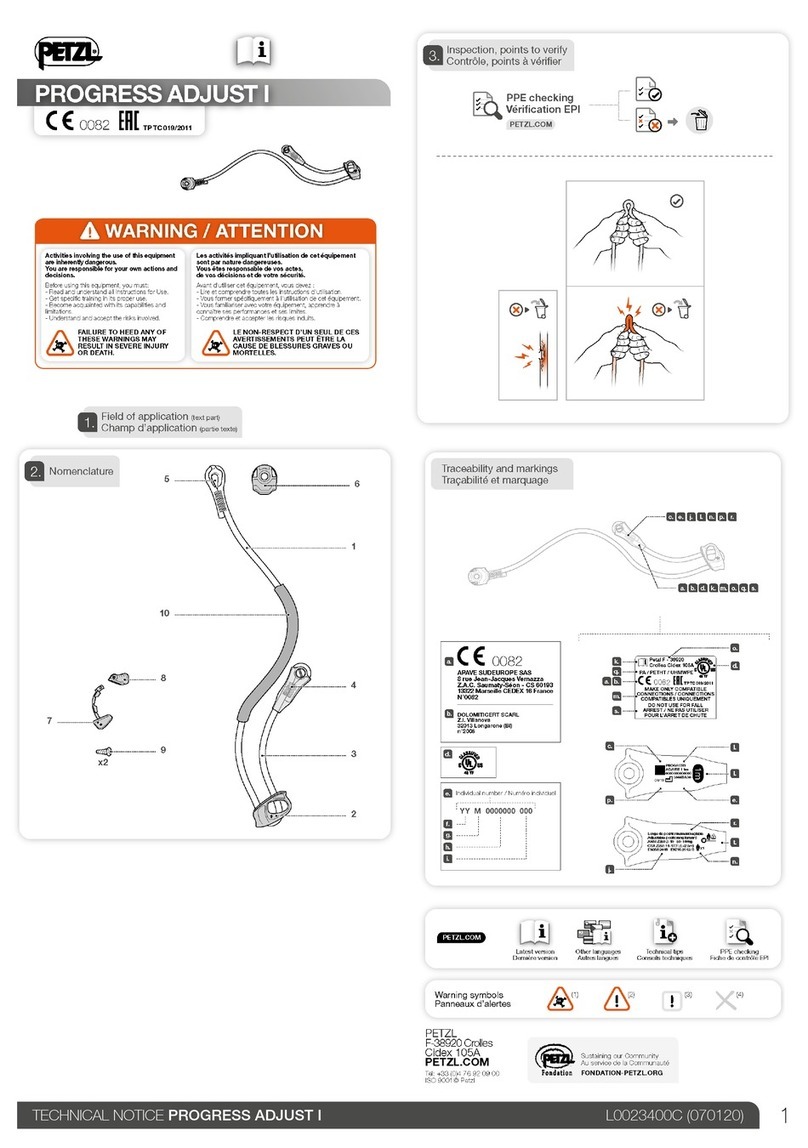

Petzl

Petzl PROGRESS ADJUST I TECHNICAL NOTICE

KStrong

KStrong UFL201701 User instruction manual