Ÿ It is important for all authorized persons and users to refer to the applicable ANSI Standards and to the regulations

governing occupational safety.

Ÿ Always check for obstructions below the work area to make sure that the potential fall path is clear.

Ÿ All the synthetic material of fall protection equipment must be protected from slag, hot sparks, open flames or

other heat sources. It is recommended that heat resistance materials are used in such applications.

Ÿ It is important to inspect the equipment according to the manufacturer's instructions before each use.

Ÿ DO NOT REMOVE product labels which include important warnings and information for the authorized person.

Ÿ It is important to allow adequate fall clearance below the work surface.

Ÿ Always have a Rescue Plan ready and at hand when using this equipment.

"Authorized Person" is a person who is exposed to fall hazards during the course of their work. This individual

requires formal training in the use of personal fall protection equipment and systems. The term "Authorized Person"

may be used interchangeably with "User" and "End-User".

WARNING !!

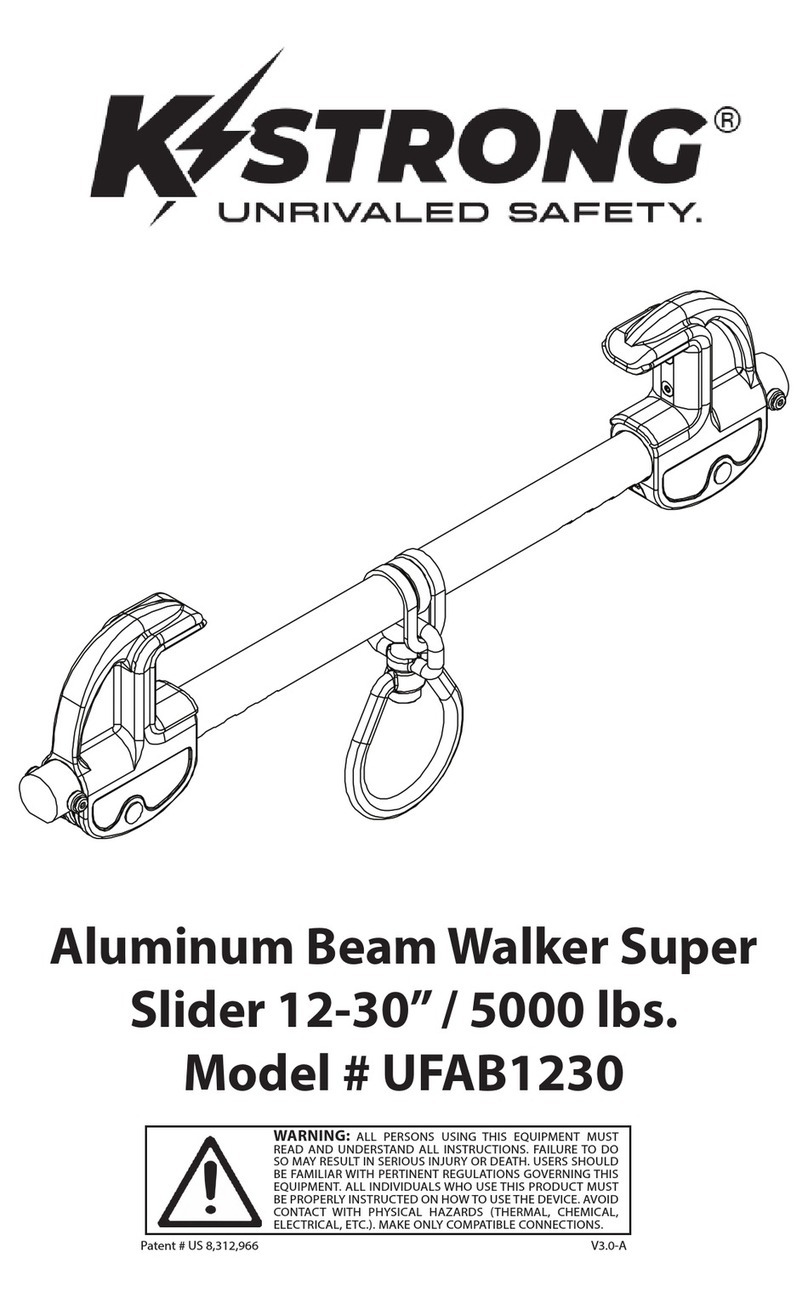

To ensure the compatibility of the connectors with their connecting element, it is important to safeguard that the sizes

and shapes of the connectors and the connecting elements do not allow their gate mechanisms to open inadvertently

notwithstanding their orientation with each other. All hooks, carabiners, D-rings and other such connectors, must be

capable of supporting a min. force of 5000 lbs. (23 kN). All connectors must be compatible with all system components

like anchorages, etc. Never use equipment that is not compatible as this may cause the connectors to disengage

unintentionally. All connectors must be compatible in shape and size. As per ANSI Z359.12 and OSHA, only self-locking

snap hooks and carabiners may be used.

Ÿ A competent person must ensure compatibility of the system to minimize any potential for accidental disengagement.

Ÿ DO NOT ALTER the equipment in any way.

Ÿ Keep the equipment away from anything that could damage it such as sharp edges, rough or abrasive surfaces,

high temperature surfaces, heat and welding sources, moving machinery, electrical hazards, etc.

Ÿ It is important to keep in mind environmental hazards when selecting fall protection equipment.

IMPORTANT INFORMATION

Ÿ DO NOT expose the equipment to chemicals, highly corrosive or caustic environments, or to direct sunlight and

UV radiation, which may cause UV degradation.

Ÿ Always send the equipment back to the manufacturer, or to persons or entities authorized in writing by the

manufacturer, for any repairs if required.

Ÿ Authorized persons, or users, shall be trained on all warnings and instructions provided in this manual.

Ÿ Never use any natural material like manila, cotton, etc. as part of a Fall Protection System.

Ÿ Immediately remove from service any equipment that has been subjected to a fall.

COMPONENT COMPATIBILITY

COMPATIBILITY OF CONNECTORS

Component compatibility with KStrong manufactured fall protection equipment is ensured by strictly following the

instructions for each type of equipment used. However, if the fall protection equipment utilizes combinations of

components or sub systems that are manufactured by others, only a “qualified” or “competent” person (as defined in

OSHA) can ensure the compatibility. If substitutions or replacements are made with non-approved components or sub

systems, then this may severely affect the compatibility of the equipment, making the complete system unsafe for use.

Ÿ Inspection of equipment should be conducted on a regular basis by a qualified person, and the results must be

recorded in the inspection log.

Ÿ Immediately discard any product which is exhibiting unusual wear, deformity or deterioration.

Ÿ This equipment should never be used for towing and hoisting or for any other purpose than its intended use.

Ÿ Fall protection equipment should only be used for the purpose for which it has been designed.

Ÿ Take proper precautions to remove any debris, material, obstructions, etc., from the work area which could cause

injury, or otherwise interfere with the functioning of the system.

Ÿ Such harmful environments requires a more frequent inspection and servicing program of the fall protection

equipment to maintain the integrity and safety of the equipment. Contact KStrong if in doubt.

02