DeZurik D10350 User manual

DeZURIK

D10350 © 2014 DeZURIK, Inc.

Instructions

These instructions provide information about Switch and Position Transmitters. They are for use by

personnel who are responsible for installation, operation and maintenance of Switch and Position

Transmitters.

Safety Messages

All safety messages in the instructions are flagged with an exclamation symbol and the word Caution,

Warning or Danger. These messages indicate procedures that must be followed exactly to avoid

equipment damage, personal injury or death. Safety label(s) on the product indicate hazards that can

cause equipment damage, personal injury or death. If a safety label becomes difficult to see or read, or

if a label has been removed, please contact DeZURIK for replacement label(s).

Personnel involved in the installation or maintenance of valves should be constantly

alert to potential emission of pipeline material and take appropriate safety precautions.

Always wear suitable protection when dealing with hazardous pipeline materials. Handle

valves, which have been removed from service with suitable protection for any potential

pipeline material in the valve.

Inspection

Your Switch and Position Transmitter has been packaged to provide protection during shipment,

however, it can be damaged in transport. Carefully inspect the unit for damage upon arrival and file a

claim with the carrier if damage is apparent.

Parts

Recommended spare parts are listed on the assembly drawing. These parts should be stocked to

minimize downtime.

Order parts from your DeZURIK sales representative, or directly from DeZURIK. When ordering parts,

please include the 7-digit part number and 4-digit revision number (example: 9999999R000) located on

the data plate attached to the valve assembly. Also include the part name, the assembly drawing

number, the balloon number and the quantity stated on the assembly drawing.

DeZURIK Service

DeZURIK service personnel are available to install, maintain and repair all DeZURIK products.

DeZURIK also offers customized training programs and consultation services.

For more information, contact your local DeZURIK sales representative or visit our website at

www.dezurik.com.

DeZURIK

May 2014 Page 3 D10350

Table of Contents

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Electrical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Mechanical Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Proximity Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5

Position Transmitter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

6

Indicator Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

7

Switch Mounting Kit used on PMV Positioner - - - - - - - - - - - - - - - - - - - - - - - - - - - -

8

DeZURIK

D10350 Page 4 May 2014

Description

This valve accessory provides electrical functions in response to the open, closed, and intermediate

positions of a 2-way valve or a 2-position 3-way valve. Electrical switching and variable current

functions are provided in selected combinations. The adjustable sensing devices are mechanically

linked to a valve, a valve actuator, or a positioner.

Components are located in a sealed and accessible aluminum enclosure, constructed to comply with

NEMA types 4, 4X, 7 and 9. The position of the valve is visibly displayed in two windows at 180°

viewing angles. Three basic options consisting of mechanical switches, proximity switches, and a

position transmitter are provided individually or in selected combinations. The three options are

described below.

Electrical Connections

Field wiring enters through ¾" and ½" NPT electrical connections to a prewired and labeled terminal

strip as described in the following sections. One ½" pipe plug is provided with the unit. If the ½"

connection is not used, install the pipe plug tightly in the connection. Do not use thread sealant.

Mechanical Switches

The two SPDT or four SPDT mechanical snap-acting switches each have a rating of:

Silver Contacts -10 Amps at 125/250 VAC, or 0.5 Amp at 125 VDC.

Gold Contacts - 1 Amp at 125 VAC, or 0.5 Amp at 30 VDC

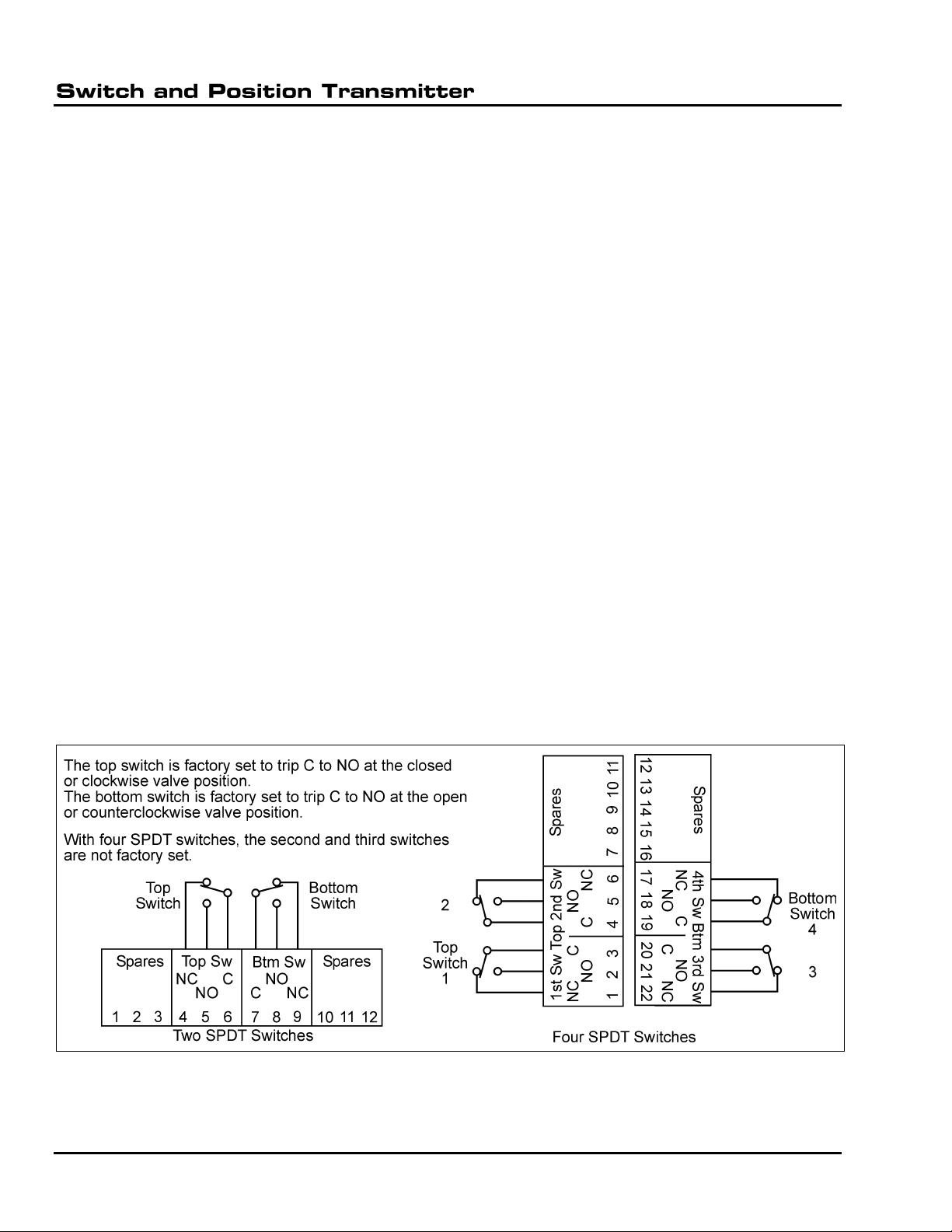

With two SPDT switches, the top switch is factory set to trip as the valve reaches the closed or

clockwise position, and the bottom switch is factory set to trip as the valve reaches the open or counter-

clockwise position. The internal wiring from the switches to the terminal strip is shown in Figure 1.

With four SPDT switches, the top (first) switch is factory set to trip as the valve reaches the closed or

clockwise position, and the bottom (fourth) switch is factory set to trip as the valve reaches the open or

counterclockwise position. The second and third switches are not factory set, but may be set in the

field. The internal wiring from the switches to the terminal strip is shown in Figure 2.

Figure 1—Mechanical Switches

DeZURIK

May 2014 Page 5 D10350

Mechanical Switches (Continued)

Each switch is actuated by a rotating cam. To adjust a top switch, push the top cam down, rotate it to

the desired position, and release the cam so it engages into the new position on the spline. To adjust a

bottom switch, repeat the process with the bottom cam, but lift the cam upwards to rotate it to the

desired position. Each cam may be further fine-tuned between spline positions by turning the set screw

on the cam with a 1/16" hex driver. The set screw is limited to adjustment of no more than one full turn.

Proximity Switches

The two SPDT proximity switches each has a rating of 0.3 amp at 120 VAC, or 0.2 amp at 30 VDC. The

switch contacts are sealed for low-energy switching of solid-state signal circuits.

The top switch is factory set to trip as the valve reaches the closed or clockwise position, and the

bottom switch is factory set to trip as the valve reaches the open or counterclockwise position. The

internal wiring from the switches to the terminal strip is shown in Figure 2.

Each switch is actuated as the white stripe on its rotating cam aligns with the white stripe on the switch.

To adjust the top switch, push the top cam down, rotate it to the desired position, and release the cam

so it slides into the new position on the spline. To adjust the bottom switch, repeat the process with the

bottom cam, but lift the cam upwards to rotate it to the desired position.

Figure 2—Proximity Switches

DeZURIK

D10350 Page 6 May 2014

Position Transmitter

The position transmitter provides a 4 to 20 mA output signal with the plus and minus terminals

connected in series with an external 24 VDC power supply. Voltage variations from 10 VDC to 40 VDC

do not affect the current signal. The maximum load is 700 ohms at 24 VDC. The unit is calibrated as

shown in the following steps. Refer to Figure 3 for component identification.

1. Plug the 3-pin potentiometer connector into the appropriate 3 pins on the 5-pin block as

described in Figure 3. The 5-pin block is located next to the span adjustment.

2. Place the valve in the position desired for 4 mA output. Do not connect power until step 4. If the

valve is in the closed or clockwise position, connect an ohmmeter to terminals 2 and 3 of the

potentiometer; if the valve is in the open or counterclockwise position, connect an ohmmeter to

terminals 1 and 2 of the potentiometer.

3. Loosen the coupling that drives the potentiometer shaft, and rotate the potentiometer so that the

ohmmeter reads 500 ± 100 ohms. Then tighten the coupling, and disconnect the ohmmeter from

the potentiometer.

4. Connect a 20 mA ammeter and a 24 VDC power supply to terminals + and –as shown in Figure

3.

5. Adjust the zero trimpot so that the ammeter reads 4 ± 0.1 mA.

6. Place the valve in the position desired for 20 mA output. Adjust the span trimpot so that the

ammeter reads 20 ± 0.1 mA. The zero and span adjustments are not interactive.

Figure 3—Position Transmitter

DeZURIK

May 2014 Page 7 D10350

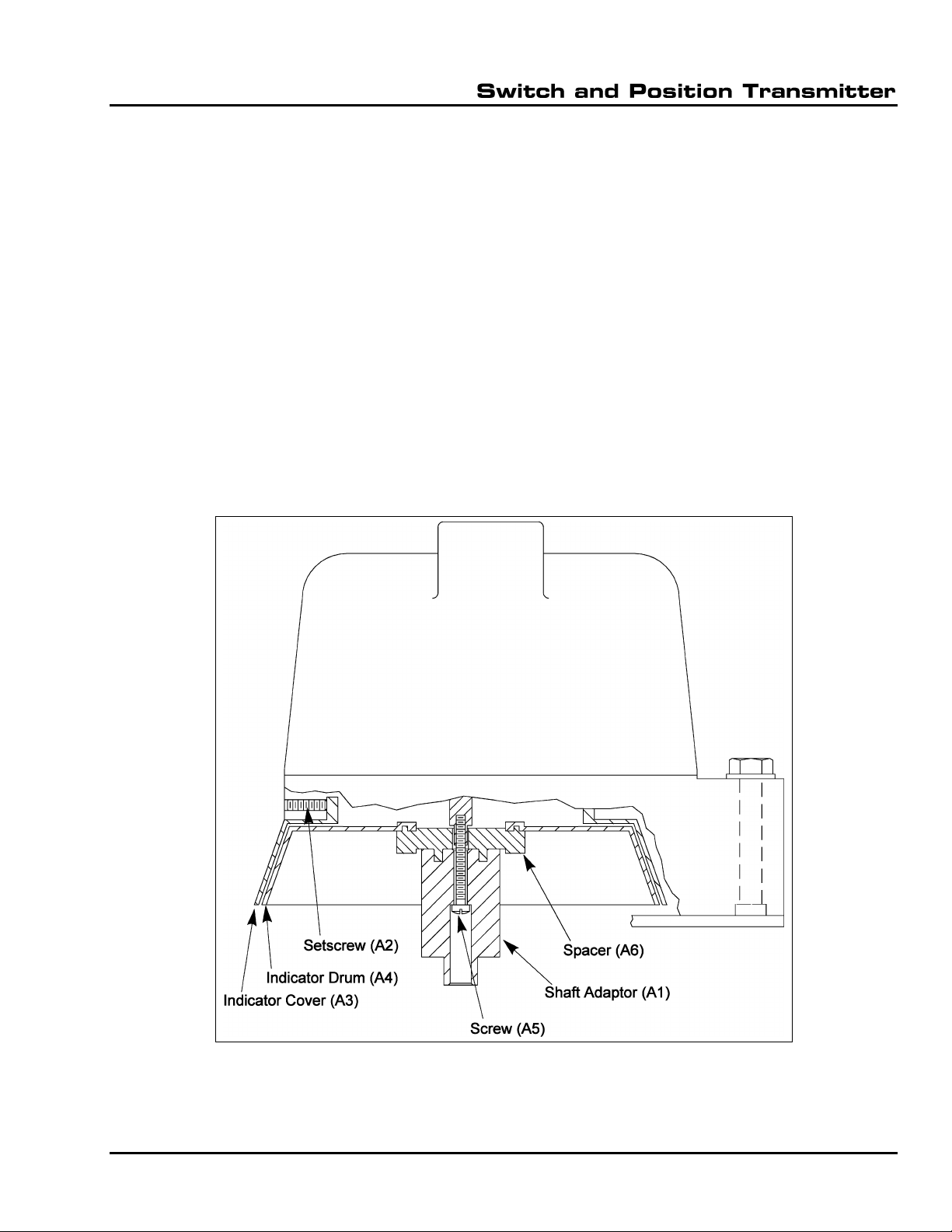

Indicator Adjustment

The open-closed indicator on all units, shown in Figure 4 as indicator drum (A4), may be re-indexed on

the input shaft as follows:

1. Remove the two mounting screws and washers near the conduit connection, and lift the unit

from position so that the bottom of the unit is accessible.

2. Loosen the screw (A5) about 3 turns.

3. Pull out the spacer (A6) and shaft adaptor (A1) so that the spacer pins are disengaged from the

timing holes in the indicator drum (A4). (The shaft adaptor may be a different size and/or shape

than shown in Figure 3.)

4. Rotate the indicator drum (A4) to the desired position, and push the shaft adaptor (A1) and

spacer (A6) towards the indicator drum (A4) to engage the spacer pins with the nearest timing

holes in the indicator drum. Tighten the screw (A5) to 8 ± 2 inch pounds.

5. Replace the unit in the same mounting position with the two screws and washers, and tighten

the screws to 80 ± 5 inch pounds.

6. To fine-tune the position of the indicator cover (A3), loosen the set screw (A2), and rotate the

indicator cover to the desired position. Tighten the set screw.

Figure 4 - Indicator Adjustment Components

DeZURIK

D10350 Page 8 May 2014

Switch Mounting Kit used on PMV Positioner

Figure 5 –Switch Mounting Kit used on PMV Positioner

Limited Warranty

DeZURIK, Inc. (“Seller”) manufactured products, auxiliaries and parts for a period of twenty-four (24) months from date of shipment from

Seller’s factory, are warranted to the original purchaser only against defective workmanship and material, but only if properly stored, installed,

operated, and serviced in accordance with Seller’s recommendations and instructions.

For items proven to be defective within the warranty period, your exclusive remedy under this limited warranty is repair or replacement of

the defective item, at Seller’s option, FCA Incoterms 2020 Seller’s facility with removal, transportation, and installation at your cost.

Products or parts manufactured by others but furnished by Seller are not covered by this limited warranty. Seller will provide repair or

replacement for other’s products or parts only to the extent provided in and honored by the original manufacturer’s warranty to Seller, in

each case subject to the limitations contained in the original manufacturer’s warranty.

No claim for transportation, labor, or special or consequential damages or any other loss, cost or damage is being provided in this limited

warranty. You shall be solely responsible for determining suitability for use and in no event shall Seller be liable in this respect.

This limited warranty does not warrant that any Seller product or part is resistant to corrosion, erosion, abrasion or other sources of failure,

nor does Seller warrant a minimum length of service.

Your failure to give written notice to us of any alleged defect under this warranty within twenty (20) days of its discovery, or attempts by

someone other than Seller or its authorized representatives to remedy the alleged defects therein, or failure to return product or parts for

repair or replacement as herein provided, or failure to store, install, or operate said products and parts according to the recommendations

and instructions furnished by Seller shall be a waiver by you of all rights under this limited warranty.

This limited warranty is voided by any misuse, modification, abuse or alteration of Seller’s product, accident, fire, flood or other Act of God,

or your failure to pay entire contract price when due.

The foregoing limited warranty shall be null and void if, after shipment from our factory, the item is modified in any way or a component of

another manufacturer, such as but not limited to, an actuator is attached to the item by anyone other than a Seller factory authorized service

personnel.

All orders accepted shall be deemed accepted subject to this limited warranty, which shall be exclusive of any other or previous Warranty,

and this shall be the only effective guarantee or warranty binding on Seller, despite anything to the contrary contained in the purchase order

or represented by any agent or employee of Seller in writing or otherwise, notwithstanding, including but not limited to implied warranties.

THE FOREGOING REPAIR AND REPLACEMENT LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, OBLIGATIONS AND

LIABILITIES, INCLUDING ALL WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR OF MERCHANTABILITY OR

OTHERWISE, EXPRESSED OR IMPLIED IN FACT OR BY LAW, AND STATE SELLER’S ENTIRE AND EXCLUSIVE LIABILITY AND YOUR

EXCLUSIVE REMEDY FOR ANY CLAIM IN CONNECTION WITH THE SALE AND FURNISHING OF SERVICES, GOODS OR PARTS,

THEIR DESIGN, SUITABILITY FOR USE, INSTALLATION OR OPERATIONS.

Disclaimer

Metric fasteners should not be used with ASME Class 150/300 bolt holes and flange bolt patterns. If you use metric fasteners with ASME

Class 150/300 bolt holes and flange bolt patterns, it may lead to product failure, injury, and loss of life. DeZURIK Inc. disclaims all liability

associated with the use of metric fasteners with ASME Class 150/300 bolt holes and flange patterns, including but not limited to personal

injury, loss of life, loss of product, production time, equipment, property damage, lost profits, consequential damages of any kind and

environment damage and/or cleanup. Use of metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns is a misuse that

voids all warranties and contractual assurances. If you use metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns,

you do so at your sole risk and any liability associated with such use shall not be the responsibility of DeZURIK, Inc. In addition to the

foregoing, DeZURIK’s Manufacturer’s Conditions apply.

Limitation of Liability

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES

WHATSOEVER, AND SELLER’S LIABILITY, UNDER NO CIRCUMSTANCES, WILL EXCEED THE CONTRACT PRICE FOR THE GOODS

AND/OR SERVICES FOR WHICH LIABILITY IS CLAIMED. ANY ACTION FOR BREACH OF CONTRACT BY YOU, OTHER THAN RIGHTS

RESPECTING OUR LIMITED WARRANTY DESCRIBED ABOVE, MUST BE COMMENCED WITHIN 12 MONTHS AFTER THE DATE OF

SALE. Sales and Service

For information about our worldwide locations, approvals, certifications and local representative:

250 Riverside Ave. N., Sartell, MN 56377 ● Phone: 320-259-2000 ● Fax: 320-259-2227

DeZURIK, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this manual, are provided for your information only

and should not be relied upon unless confirmed in writing by DeZURIK, Inc. Certified drawings are available upon request.

Printed in U.S.A.

October 2021

Table of contents

Popular Transmitter manuals by other brands

Honeywell

Honeywell 5802mn2 - Ademco Wireless Panic user manual

Shure

Shure UR1M quick start guide

rojaflex

rojaflex WSR-15 Original assembly and operating instructions

Emerson

Emerson Rosemount 5402 Reference manual

Levil Aviation

Levil Aviation Beacon 978 Series Installation and Pilot's Guide

Steren

Steren MP3-050 instruction manual