DFA 127 User manual

DFA 127

User manual

Translation of the original manual

Document identification

Article nr.: 102-127401806

Version: V1.0

Publication date: 01/02/2022

Subject to technical modifications

Copyright © agtatec ag

Table of contents

BAL_DFA_127_EN_1V0_OEM_102-127401806 3 / 28

Table of contents

Glossary ............................................................................................................................................................ 4

1 Safety................................................................................................................................................................. 5

1.1 Presentation of warning signs............................................................................................................... 5

1.2 Intended purpose of use ....................................................................................................................... 5

1.3 General hazards ................................................................................................................................... 5

1.4 State of technology ............................................................................................................................... 8

1.5 Spare parts and liability ........................................................................................................................ 8

2 General information ......................................................................................................................................... 9

2.1 Purpose and use of the instructions ..................................................................................................... 9

2.2 Copyright .............................................................................................................................................. 9

2.3 Product identification ............................................................................................................................ 9

2.4 Manufacturer agtatec ag....................................................................................................................... 9

2.5 Target groups ....................................................................................................................................... 10

2.6 Definition of terms................................................................................................................................. 10

3 Description........................................................................................................................................................ 11

3.1 Overview............................................................................................................................................... 11

3.2 Types of arm......................................................................................................................................... 12

3.3 Low energy drive (Low Energy) ............................................................................................................ 12

3.4 Functions .............................................................................................................................................. 12

3.5 Primary / secondary application............................................................................................................ 13

3.6 Control panel ........................................................................................................................................ 13

3.7 Battery pack (optional).......................................................................................................................... 14

4 Specifications ................................................................................................................................................... 15

4.1 Tecnical data ........................................................................................................................................ 15

5 Operation........................................................................................................................................................... 16

5.1 Toggle switch BDI................................................................................................................................. 16

5.1.1 Control elements and displays......................................................................................................... 16

5.2 Control panel BDE-D ............................................................................................................................ 16

5.2.1 Operation modes and button functions ............................................................................................ 16

5.2.2 Perform reset ................................................................................................................................... 18

5.2.3 Display system information .............................................................................................................. 19

5.2.4 Lock control panel............................................................................................................................ 19

5.2.5 Set parameters ................................................................................................................................ 20

5.2.6 Description of parameters................................................................................................................ 21

6 Malfunctions ..................................................................................................................................................... 23

6.1 Status displays...................................................................................................................................... 23

6.2 Troubleshooting .................................................................................................................................... 23

7 Maintenance and servicing.............................................................................................................................. 25

7.1 Test log book ........................................................................................................................................ 25

7.2 General remarks ................................................................................................................................... 25

7.3 Operator duties ..................................................................................................................................... 25

7.4 Spare parts and wearing parts.............................................................................................................. 26

Glossary

4 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

Glossary

BDE

Control panel

BDE-D

Bedienungseinheit mit Display

BDE-M

Control panel mechanical

BDI

Control unit with toggle switch

BDI-M

Print for mechanical control unit

NET

Power supply

SSK

Key pivot contact

STG

Control unit

Safety 1

BAL_DFA_127_EN_1V0_OEM_102-127401806 5 / 28

1 Safety

1.1 Presentation of warning signs

Various symbols are used in this guide for easier understanding:

NOTICE

Useful advice and information to ensure correct and efficient workflow of the system.

IMPORTANT

Specific details which are essential for trouble-free operation of the system.

IMPORTANT

Important details which must be read for proper function of the system.

CAUTION

Against a potential hazardous situation that can lead to minor personal injury and property

damage.

WARNING

Against a latent hazardous situation that can lead to severe injuries or death and cause sub-

stantial property damage.

DANGER

Against an imminent hazardous situation that can lead to severe injury or death.

DANGER

Against an imminent or latent hazardous situation that could lead to electric shock and cause

serious injury or death.

1.2 Intended purpose of use

The system is designed exclusively for use as a pedestrian passage. The installation must only occur

in dry areas. If there are deviations then proper waterproofing and water drains will be required on-

site.

Any other application or use beyond this purpose is not considered to be an intended purpose. The

manufacturer bears no liability for any resulting damage; the operator alone shall bear the associated

risk.

The intended purpose also includes observation of the operating conditions specified by the manufac-

turer, in addition to regular care, maintenance and repair.

Interventions in or alterations to the installation performed by non-authorized maintenance technicians

exclude the manufacturer's liability for consequential damages.

1.3 General hazards

The following section lists hazards that can be caused by the system even when used as intended.

To reduce the risk of malfunction, damage to property or injury to persons and to avoid dangerous

situations, the safety instructions listed here must be observed.

1Safety

6 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

The specific safety instructions in the other sections of this manual must also be observed.

IMPORTANT

The country-specific regulations must be observed and complied with!

IMPORTANT

To avoid malfunctions, moving objects such as flags or parts of plants must not be allowed to

enter the detection range of the sensors.

CAUTION

Risk of malfunctions, material damage or injury due to improper settings!

a) Improper settings can lead to malfunctions, material damage or personal injury.

ðDo not disconnect the system from the power supply overnight.

ðSettings should only be made by personnel qualified to do so.

ðDo not disassemble, put out of operation or manipulate safety devices.

ðHave faults rectified by specialist personnel or by personnel qualified to do so.

ðHave service and maintenance carried out according to locally applicable regulations or accord-

ing to a maintenance contract.

CAUTION

Risk of malfunctions, material damage or injuries due to insufficient or missing cleaning or

care!

a) Insufficient or inattentive cleaning or care of the system can lead to malfunctions, damage to

property or injury to persons.

ðCheck the sensors regularly for dirt and clean them if necessary.

ðRegularly remove dirt accumulations in the floor rail or under the floor mat.

ðKeep the system free from snow and ice.

ðDo not use aggressive or caustic cleaning agents.

ðUse road salt or loose chippings only conditionally.

ðLay the floor mat without folds and flush with the floor.

ðEquipment required for cleaning purposes such as ladders or similar must not be leaned on or at-

tached to the system.

CAUTION

Risk of material damage or injury due to unforeseen opening, closing or turning of the door!

a) The door can open, close or turn unexpectedly. This may result in damage to property or injury

to persons.

ðNo persons may be present in the opening area of the system.

ðEnsure that moving objects such as flags or parts of plants do not enter the detection range of

the sensors.

ðDo not make any settings on the control unit when the system is in use.

ðHave faults rectified immediately by specialist or personnel qualified to do so.

ðRemove objects from the opening area.

ðDo not disassemble, put out of operation or manipulate safety devices.

ðDo not rush through a closing system.

Safety 1

BAL_DFA_127_EN_1V0_OEM_102-127401806 7 / 28

CAUTION

Risk of bruising and severing of limbs!

a) If the system moves, careless behaviour can lead to serious injuries to limbs or severance of

limbs.

ðDo not reach in when parts of the system are moving.

ðKeep a distance when parts of the system move.

ðDo not bump into or touch the system when it is moving.

ðDo not open or remove protective covers during operation.

ðDo not permanently remove covers from the system.

ðOnly carry out inspection, service, maintenance and cleaning when the system is stationary and

switched off.

CAUTION

Danger of material damage or injury due to non-functioning safety devices!

a) If safety devices are not functioning, manipulated or put out of operation, there is a risk of dam-

age to property or injuries that can lead to death.

ðNever disable or manipulate safety devices.

ðHave inspection, service and maintenance of the safety devices carried out according to local

regulations or according to a maintenance contract.

CAUTION

Danger of malfunctions, damage to property or risk of injury if used by unauthorised persons!

a) If unauthorised persons use the system, there is a risk of malfunction, damage to property or in-

jury to persons.

ðChildren under 8 years of age may only use the system under supervision.

ðChildren must not play, clean or maintain the system.

ðPersons with limited physical, sensory or mental abilities as well as persons with insufficient

knowledge or experience may only use the system under supervision or must have received and

understood instructions to do so.

DANGER

Danger to life due to electric current!

a) In case of contact with live parts, there is an immediate danger to life due to electric shock.

Damage to or removal of the insulation or individual components can be life-threatening.

ðBefore starting work on active parts of electrical systems and equipment, ensure that all poles are

voltage free and that this is maintained for the duration of the work.

ðKeep moisture away from live parts. This can lead to a short circuit.

ðNever bridge fuses or put them out of operation.

ðDo not connect the power supply until all work has been completed.

ðHave work on the electrical system performed by qualified personnel only.

1Safety

8 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

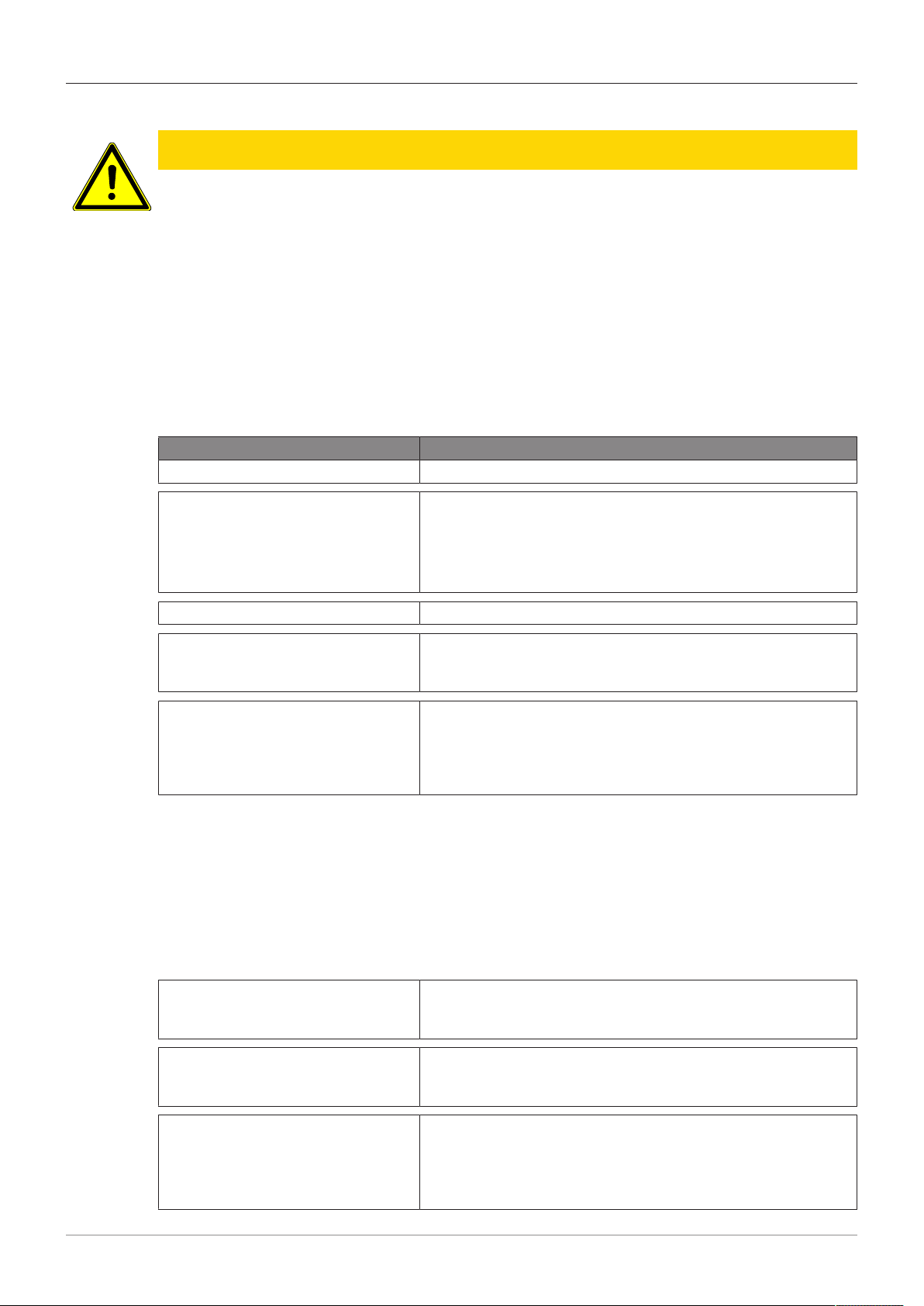

DANGER

Danger to life due to non-functioning safety devices of the fire protection system!

a) If safety devices of the fire protection system do not function properly, there is a risk of serious

or fatal injuries.

ðNever disconnect the fire protection system from the power supply overnight.

ðDo not disassemble, put out of operation or manipulate safety devices.

ðDo not remove safety instructions on the system.

ðNever block, hold open or otherwise prevent fire doors from closing.

ðHave inspection, service and maintenance of the fire protection system carried out in accordance

with locally applicable regulations or according to a maintenance contract.

ðHave the fire protection system checked and maintained according to the state of the art.

1.4 State of technology

This system was developed using state of the art technology and officially recognized technical safety

regulations. The system, depending on its options and diameter, comply with the requirements of the

Machine Guidelines 2006/42/EG as well as EN 16005 and DIN 18650 (D).

Nevertheless, danger may arise if not used as intended.

IMPORTANT

Installation, commissioning, inspection, maintenance and repair work may only be conducted

by qualified, trained and authorized technicians.

After commissioning or repair work, fill in the check list and give it to the customer for safe

keeping.

We recommend obtaining a service agreement.

1.5 Spare parts and liability

Reliable and trouble free operation of the door is only guaranteed when using parts that were recom-

mended by the manufacturer. The manufacturer declines any liability for damages resulting from un-

authorized modifications to the door or the use of parts that are not permitted.

General information 2

BAL_DFA_127_EN_1V0_OEM_102-127401806 9 / 28

2 General information

2.1 Purpose and use of the instructions

These instructions are an integral part of the system and enable efficient and safe handling of the sys-

tem. In order to ensure proper functioning, the instructions must be accessible at all times and kept in

the immediate area of the system.

Although only the male form has been chosen for reasons of better legibility, the information refers to

members of both sexes.

The operator must have read and understood the manual before starting any work. The basic require-

ment for safe working is to follow the safety instructions and the handling instructions. In addition, the

local regulations and safety rules apply.

The manual can be handed over in extracts to instructed personnel who are familiar with the opera-

tion of the system.

The illustrations are for basic understanding and may differ from the actual presentation. Specific rep-

resentations are contained in the drawings.

2.2 Copyright

The copyright for these instructions remains with:

agtatec ag

The instructions may not be reproduced, distributed, or used for the purpose of competition without

the written consent of agtatec ag.

Infringements shall result in the obligation to pay damages.

2.3 Product identification

For precise identification, please refer to the nameplate attached to the inside of the casing or to the

operator displaying the following information:

Example:

Type:

Serial number:

Year of construction:

Mains connection:

Power consumption:

Classification according to

18650-1:2005:

Marking:

2.4 Manufacturer agtatec ag

agtatec ag

Allmendstrasse 24

CH – 8320 Fehraltorf

Switzerland

Phone: +41 44 954 91 91

Fax: +41 44 954 92 00

2General information

10 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

2.5 Target groups

CAUTION

Risk of injury if personnel are insufficiently qualified!

If unqualified personnel work on the system or are in the danger zone of the system, dangers may

arise which can cause serious injuries and considerable damage to property.

a) All work must be carried out by qualified personnel only.

b) Keep unqualified personnel away from danger areas.

This operating manual is intended for the target groups listed below:

– Operating entity of the system:

the person who is responsible for the technical maintenance of this system

– Operator of the system:

the person who operates the system every day and has been suitably instructed

2.6 Definition of terms

Term: Explanation:

System The term is also used in these instructions as a synonym for

the product. Door operators, revolving doors, sliding doors,

etc. are referred to as a system.

If information in these instructions refers to a specific type, this

is shown accordingly in the text.

User Users are all persons who use the system.

System operator The respective owner is referred to as the system operator, re-

gardless of whether they operate the system as the owner or

pass it on to third parties.

Authorized representative The authorized representative takes over certain parts of the

manufacturer's obligations with regard to fulfilling the require-

ments of the Machinery Directive. In particular, the authorized

representative may also place the system on the market and/

or sign EC declarations of incorporation.

Qualified personnel are authorized and appropriately trained to perform the following work:

– Disassembly, Assembly, Commissioning, Operation, Audit, Maintenance, Troubleshooting, De-

commissioning

The qualified personnel have several years of professional experience in the technical field, e.g. as

mechanics or machine fitters.

The qualified personnel are aware of the residual risks arising from the installation site and, due to

their professional training, knowledge and experience, are able to carry out the work assigned to

them and to independently identify and avoid possible danger points.

Manufacturer The manufacturer is whoever designs and/or builds machinery

or incomplete machinery under the scope of the Machinery

Directive.

Life phases All phases of the system's condition and use are referred to as

life phases. This applies from the time the system leaves the

factory until it is disposed of.

Personnel All persons who carry out activities on and with the system are

referred to as personnel. Personnel can be, for example, the

operator, the cleaning staff, or the security staff. The personnel

meet the personnel qualifications required by the manufac-

turer.

Description 3

BAL_DFA_127_EN_1V0_OEM_102-127401806 11 / 28

3 Description

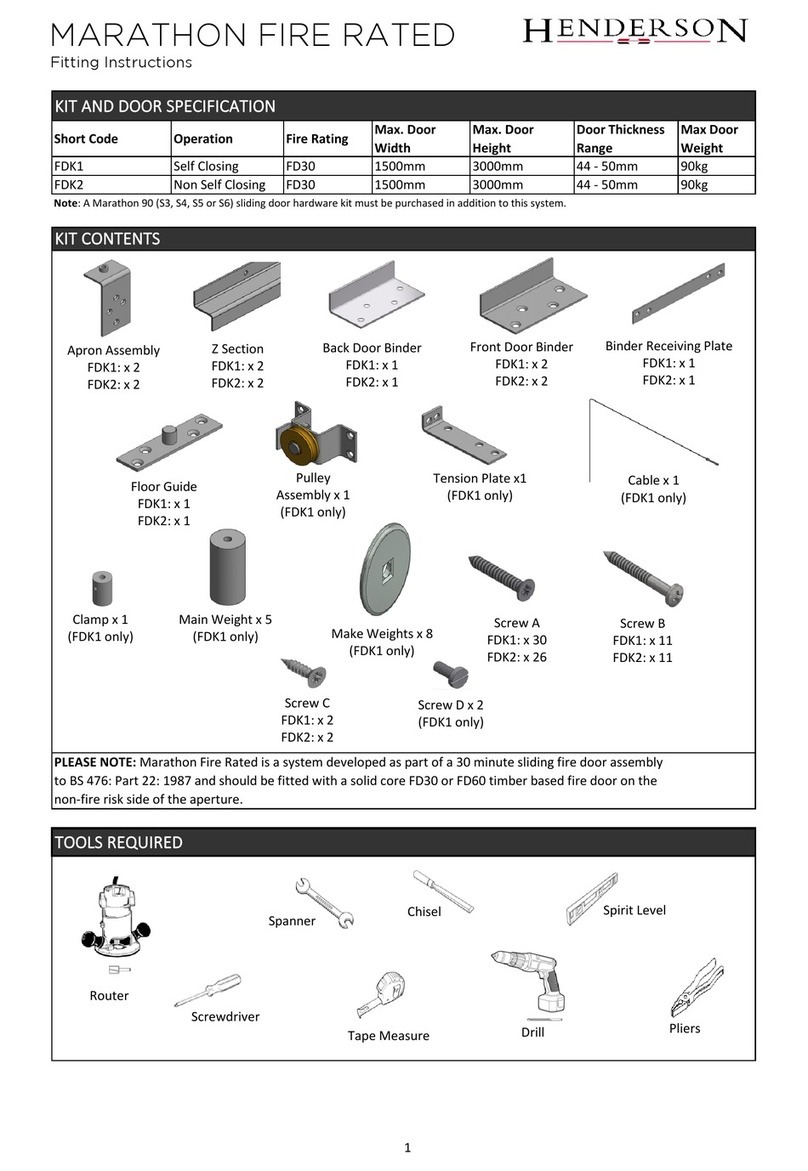

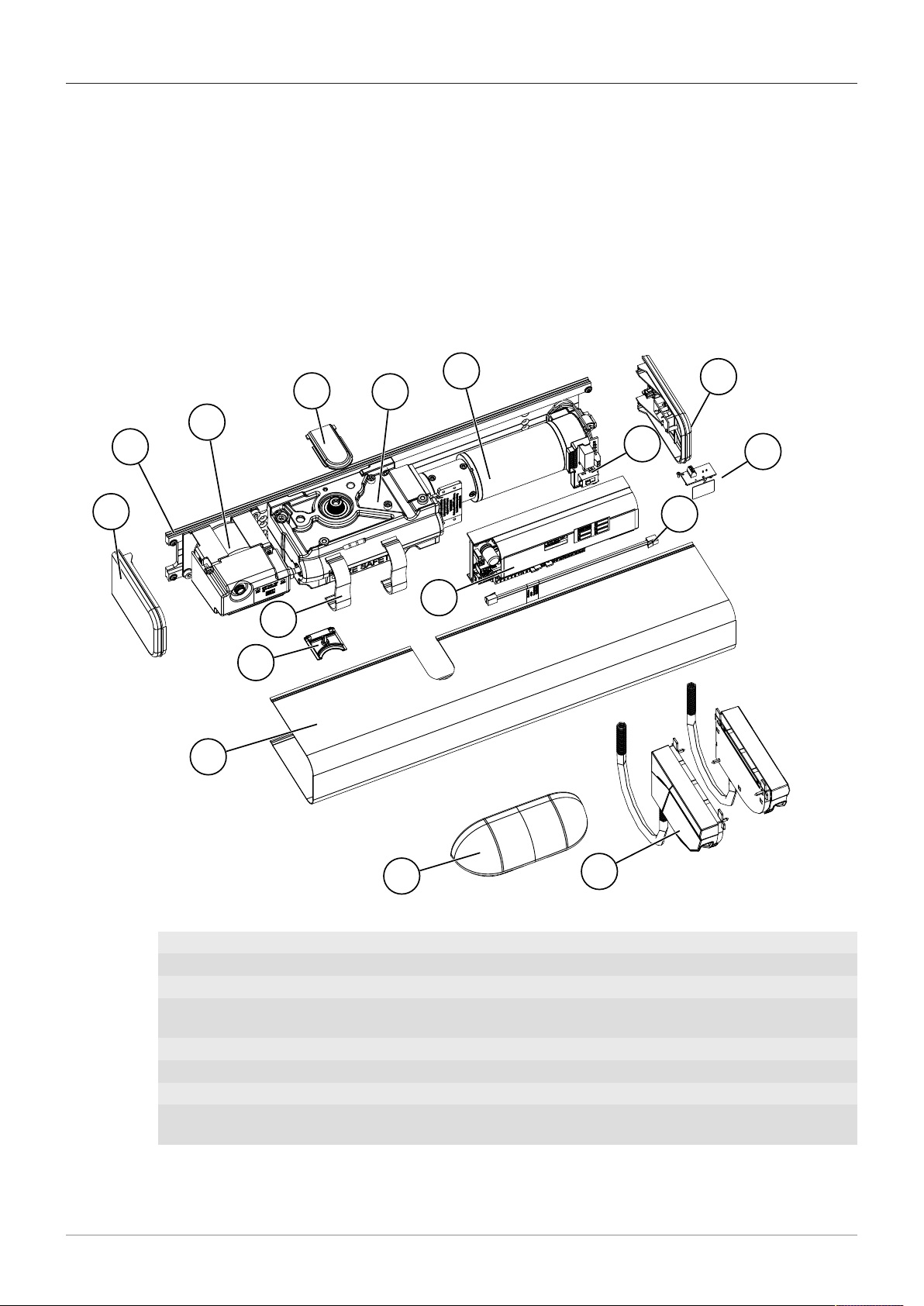

3.1 Overview

The swing door operator DFA 127 (hereinafter referred to as operator), is a self-monitored, micropro-

cessor-controlled swing door operator. It can be used in a multitude of ways thanks to its special and

additional functions.

The microprocessor analyzes the current door position, door speed, and target position and calcu-

lates the movement sequence. This means that there are no jerky braking movements or creep rate,

and end stops for the door are eliminated. The spring force must be adjusted depending on door leaf

width.

Set parameters [}20]

Description of parameters [}21]

1

3

45

67

8

9

11

10

12

13

14

15 16

2

1 Side cover 2 Chassis

3 Power supply unit NET 4 Shaft cover

5 Drive group ATG 6 Motor MOT

7 Side cover with toggle switch 8 Print for mechanical control panel BDE-M

(option)

9 Cable SIP 220 mm 10 Motor print

11 Control device STG 12 Wedge

13 Cable clip 14 Casing

15 Sensor RAD 290 (option) 16 Sensor BEA Flatscan left and right (op-

tion)

3Description

12 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

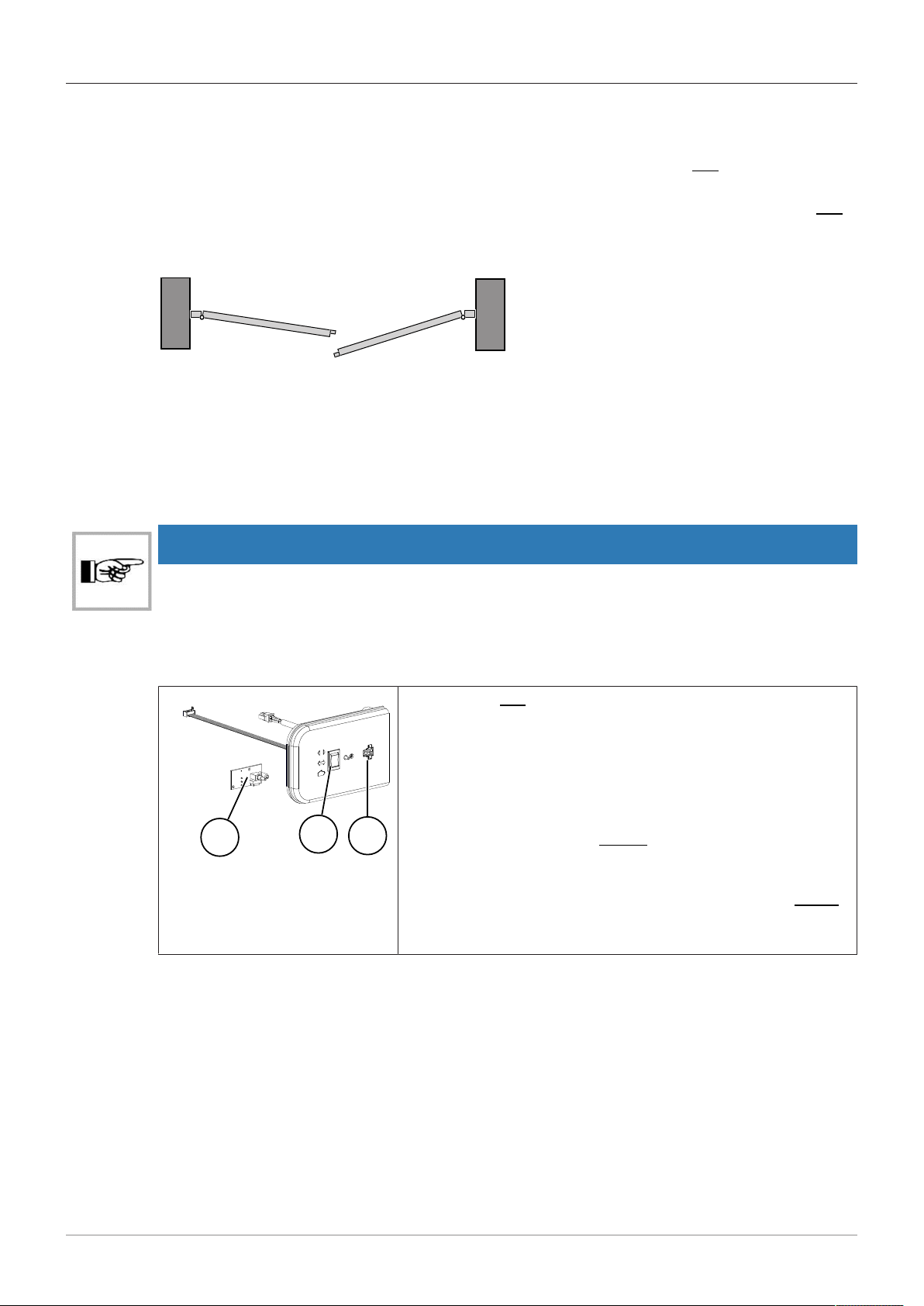

3.2 Types of arm

Power is transmitted from the operator to the door leaf by means of an arm. Depending on the install-

ation situation, a standard arm or a sliding arm may be suitable. Standard arms are available in vari-

ous lengths to adjust the recess depth. Varying over heights are adjusted with the lever sockets (shaft

extensions).

Standard arm SG

2

1

1 Lever socket 2 Adjusting screw length

Sliding arm GG

2

1

3

4

1 Stop plate with damper stop 2 Pin shaft

3 Slide shoe 4 Lever socket

3.3 Low energy drive (Low Energy)

Parameterization makes it possible to use the operator as a low-energy operator.

The door is closed with reduced spring force. The opening and closing speeds can be adjusted to a

limited extent and the operator reacts more sensitively in the event of a collision. To prevent acci-

dental or improper changes to the programming, access to the parameters is restricted for users.

Only qualified personnel may carry out the parameterization of the operator.

3.4 Functions

Obstacle detection: If the door hits an obstacle when opening, it stops immediately and saves the

position of the collision. During the hold open time, the operator briefly attempts to reach the open po-

sition. Once the hold open time has elapsed, the door closes and the obstacle position is passed over

more slowly the next time it opens. This prevents another hard impact.

Description 3

BAL_DFA_127_EN_1V0_OEM_102-127401806 13 / 28

Reversing: If the door hits an obstacle when closing, a reopening is initiated immediately (reversing).

The obstacle position is saved in the door operator and this position is approached gently the next

time the door is closed.

Operation: Three operation modes can be set using the built-in toggle switch BDIToggle switch BDI

[}16].

Primary / secondary: A primary / secondary system can only be operated via the toggle switch BDI

of the primary operator. This switch position also affects the secondary operator.

3.5 Primary / secondary application

Primary

Secondary

Active leafInactive leaf

With the primary / secondary application, the

opening and closing sequence of two-leaf doors is

controlled electronically.

For two-leaf fire doors, the mechanical door selector SFR 127 is additionally installed for the inactive

leaf and the active leaf.

The two operators communicate with each other via an interface so that the safety functions such as

reversing and obstacle detection remain in place.

The closing sequence control can only be used with operator height 108 mm.

NOTICE

The functions of the primary / secondary operator correspond to those of a standard operator.

3.6 Control panel

3

12

7

Toggle switch BDI (2) on the side cover of the operator with three

operation modes to choose from.

– Automatic

– Continuously open

– Manual operation

The connection for service (3) is found at the side cover.

If an electronic control panel BDE-D is connected, this has priority

for operation.

If a mechanical control panel BDE-M or an external activation is

used, the toggle switch BDI must be replaced with option BDI-M

(1).

Control elements and displays [}16]

3Description

14 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

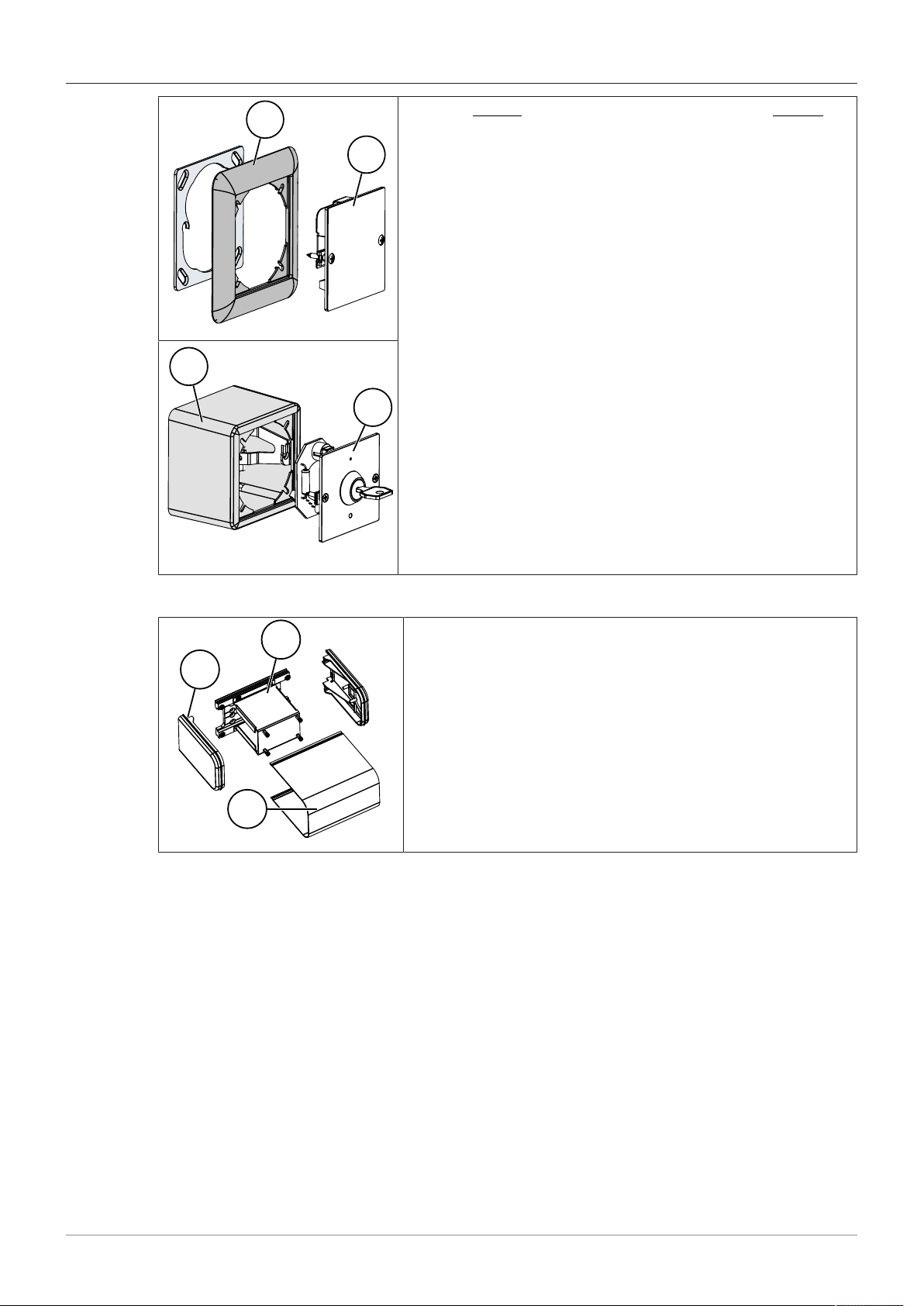

1

2

4 5 6 7 8910

Electronic BDE-D (2) and/or mechanical control panel BDE-M (4).

The electronic control panel can be used to choose between five

operation modes and set selected door parameters.

– Automatic

– Continuously open

– One-way

– Manual operation

– Locked

The control panels can be installed with corresponding attach-

ments as a flush-mounted (1) or surface-mounted (3) version.

Control panel BDE-D [}16]

3

4

5 6 7 8910

3.7 Battery pack (optional)

1

3

2

The battery pack supplies power to the operator in the event of a

power failure. It is installed on the side of the operator and con-

sists of a side cover (1), battery kit (2), and casing (3).

If space allows, the battery kit (2) can be installed in the operator

housing.

Specifications 4

BAL_DFA_127_EN_1V0_OEM_102-127401806 15 / 28

4 Specifications

4.1 Tecnical data

Operating voltage: 230VAC, 50/60 Hz

Power consumption: Standby 13 W, rated power 67 W

Max. torque: 50 Nm

Max. Mass inertia door leaf: 65 kgm2

Opening angle: 70° - 115°

Hold open time 0 to 60 seconds (40 steps)

Opening speed: 3 to 20 seconds (40 steps)

Closing speed: 5 to 20 seconds (40 steps)

Noise generation: < 45 dB

Degree of protection: IP20

Temperature range: From -15 to +50° C

Humidity range: Up to 85% rel. humidity, not condensing

5Operation

16 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

5 Operation

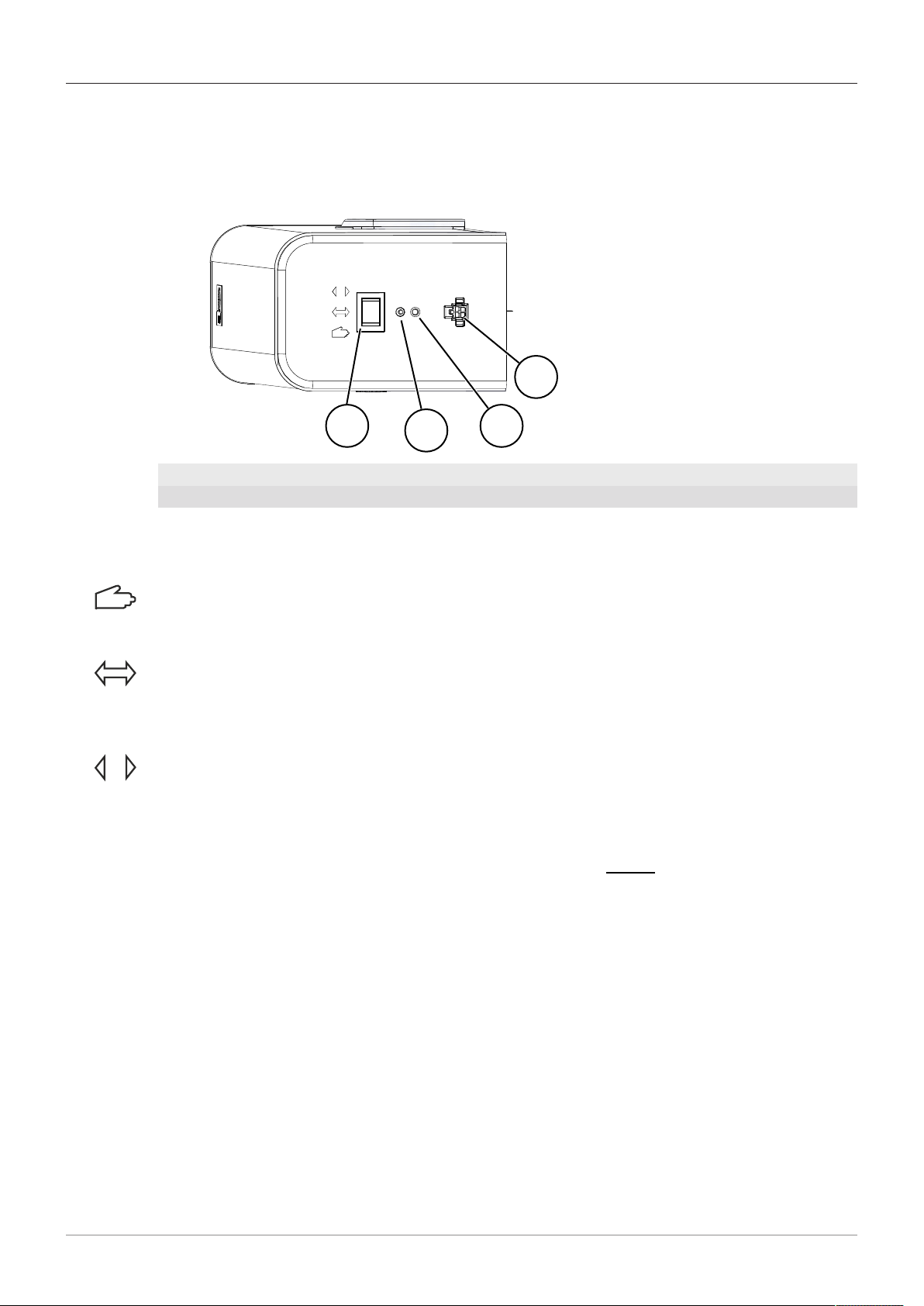

5.1 Toggle switch BDI

5.1.1 Control elements and displays

123

4

1 Toggle switch BDI 2 Reset button

3 Status display LED 4 Connection for configuration tool

Toggle switch BDI

Three operation modes can be selected using the toggle switch:

Manual operation:

The operator works like a door closer. It can be opened manually and closes independently. The

connected sensors are disabled.

Automatic:

In the "Automatic" operation mode, the door opens with the aid of a trigger device/sensor or when

pushed when the touch control is activated. The door closes after the hold open time has elapsed,

unless a new opening impulse is given.

Continuously open:

The door remains open.

If the door encounters an obstacle when opening, the operator attempts to open the door. If the

obstacle does not move, the current position is recognized as continuously open.

The toggle switch is always active. If an electronic control panel BDE-D is connected, the operation

mode is determined by this.

Reset button

When pressed for 5 seconds, this button resets the control device.

Status display LED

– When LED is off the operator is ready to use.

– Flashes when an error occurs during operation.

5.2 Control panel BDE-D

5.2.1 Operation modes and button functions

The buttons on the control panel BDE-D are used to set the door system operation modes in the main

menu. The parameters of the door system are set in the sub menu.

The button functions are divided into main menu and sub menu.

Operation 5

BAL_DFA_127_EN_1V0_OEM_102-127401806 17 / 28

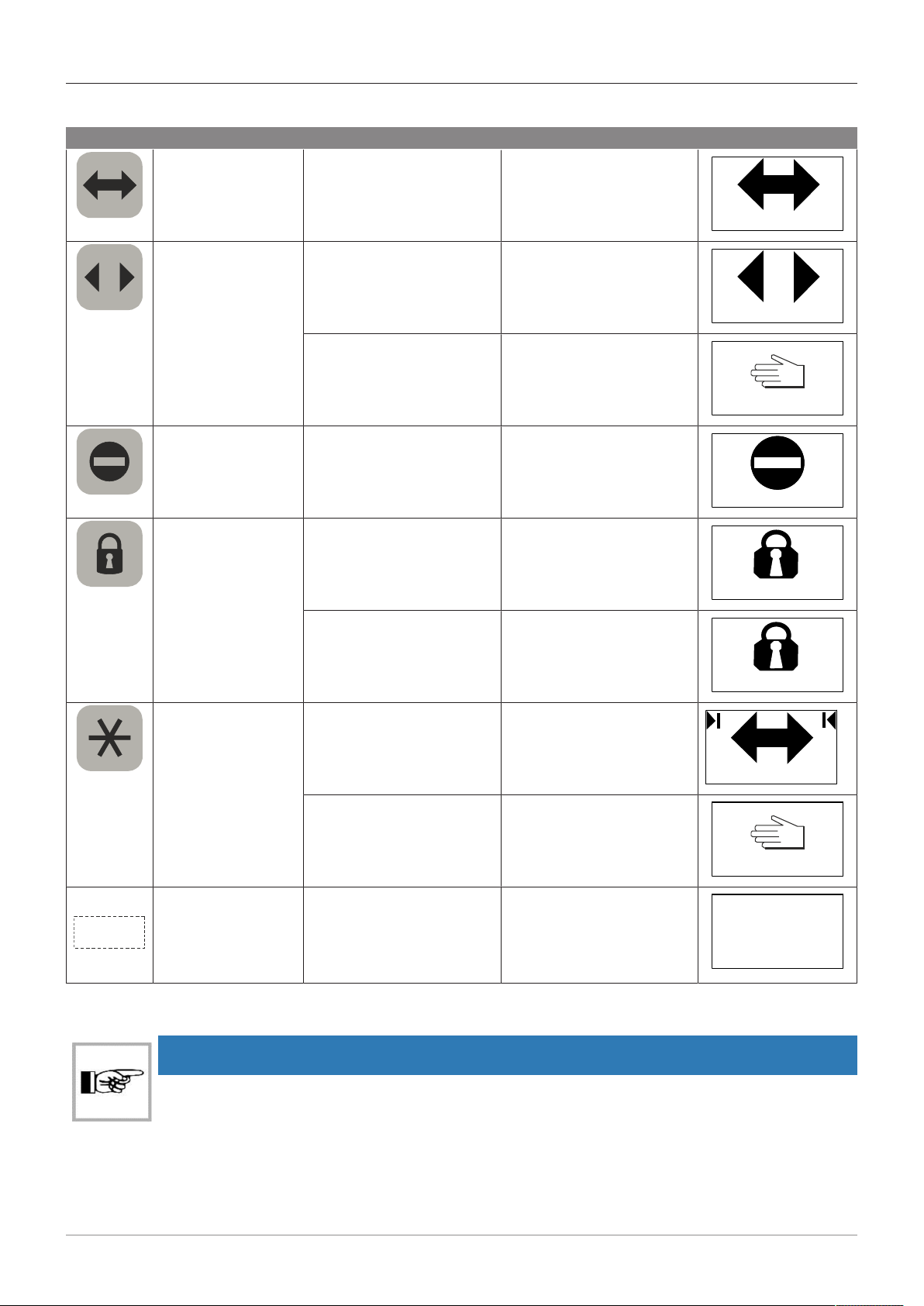

Main menu

Button Name Operation Function Display on LCD

Automatic button Press button 1 x Automatic operation via

sensors

Automatic

Continuously open

button

Press button 1 x For sliding door operator

and swing door operator:

continuously open, sensors

disabled

Continuously open

Press button 2 x or hold it

down for 2 seconds

For sliding door operator:

manual operation

Manual

One-way button Press button 1 x Passage only possible from

one direction

One-way

Locking button Press button 1 x Door closed, sensors dis-

abled

Locked

Press button again The door opens again,

closes, and locks again.

Can be opened with a key

(optional).

Locked

Star button Press button 1 x For sliding door operator:

Reduced open width

Automatic

Press button 1 x For swing door operator:

manual operation

Manual

E

Menu button Restart control device:

press button for 5 seconds

Restart hardware BDE-D:

press button for 12 seconds

Access to parameter menu

Enable control lock

Restart control device

Restart hardware BDE-D

Sub menu

NOTICE

The main menu is returned to automatically 3 minutes after the last entry.

5Operation

18 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

Button Name Operation Function Display on LCD

E

Enter button Press button 1 x to go to

the next sub menu.

Select menu item, confirm

entry

Opening speed

0 10 20 30 40

+

Plus button Press button 1 x to go

down.

Navigate downwards in the

menu

Parameter

Driving cycle

Time delay open

Operator

Press button 1 x to increase

the value.

Move the slide control to

the right to increase the

value

Closing speed

0 10 20 30 40

-

Minus button Press button 1 x to go up. Navigate upwards in the

menu

Parameter

Driving cycle

Time delay open

Operator

Press button 1 x to reduce

the value.

Move the slide control to

the left to reduce the value

Closing speed

0 10 20 30 40

C

Clear button Press button 1 x to go to

the previous menu.

Leave the menu item

without saving.

Parameter

Driving cycle

Time delay open

Operator

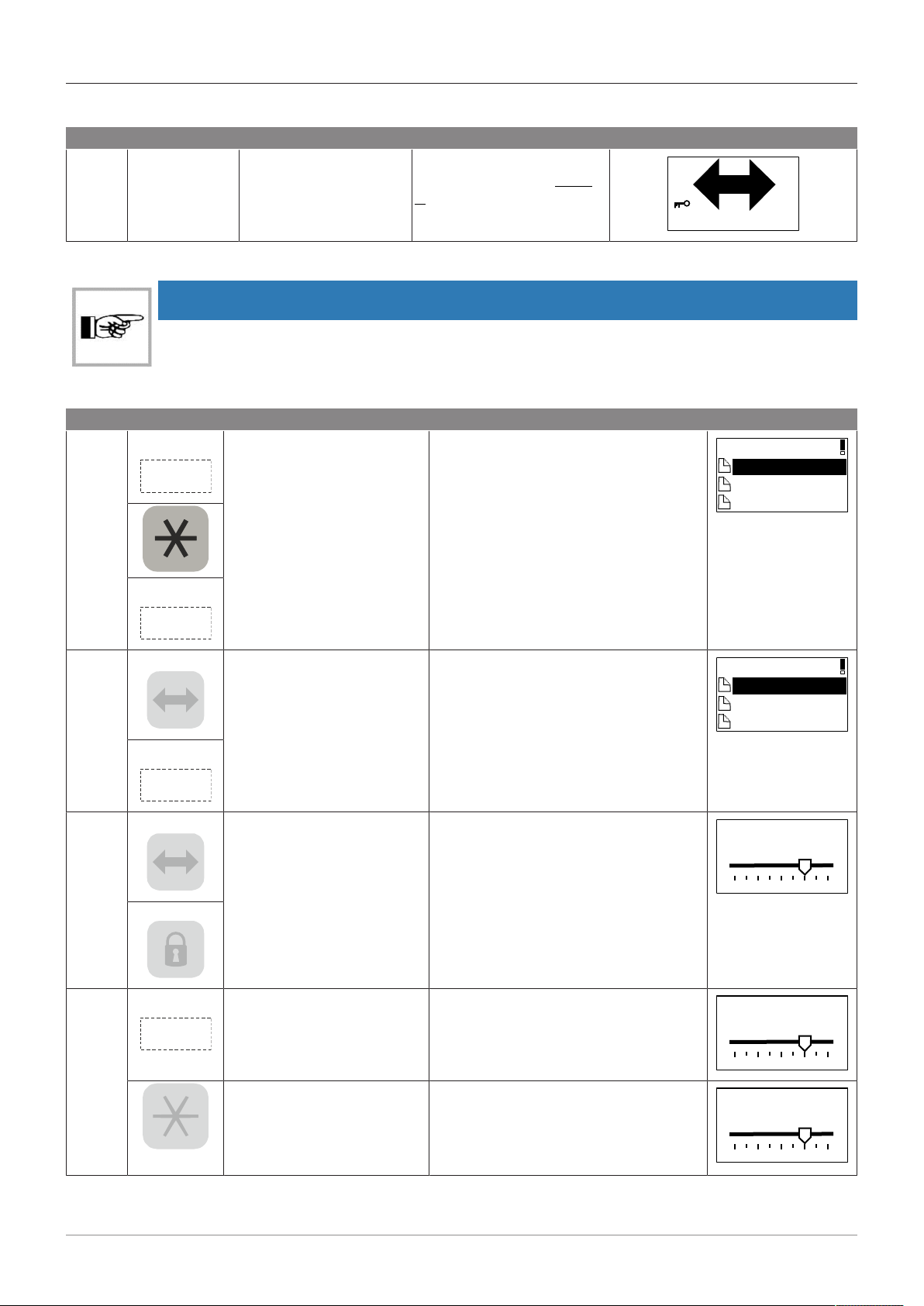

5.2.2 Perform reset

Reset controller

Step Button Operation Function Display on LCD

1.

E

Press button for 5 seconds Perform controller reset

No

Reset controller?

Yes

2.

C

Press button 1 x Cancel reset

E

Press button 1 x Perform reset

Reset control panel

Step Button Operation Function Display on LCD

1.

E

Press button for 12 seconds Perform control panel reset

Operation 5

BAL_DFA_127_EN_1V0_OEM_102-127401806 19 / 28

Step Button Operation Function Display on LCD

2.

3. The connection has been established

DFA 127 V2.21

Basic operator

5.2.3 Display system information

Information about the door system, such as software version, door type, or servicing status, can be

shown on the display.

NOTICE

The main view is returned to by scrolling or automatically after 20 seconds.

Step Button Operation Function

1.

E

Press button for approx.

2 seconds

Software information

is displayed

STA20 V2.0

BDE-D V2.05 1

Software

2.

E

Press button 1 x Scroll through the in-

formation and/or re-

turn to main view

STA20 V2.0

BDE-D V2.05 1

Software

3.

E

Press button 1 x Scroll through the in-

formation and/or re-

turn to main view

Servicing

0 50 100

5.2.4 Lock control panel

Enable control lock on the keyboard

Step Button Operation Function Display on LCD

1.

E

Press the button se-

quence as shown

To disable, press the

button sequence again

No settings can be made

on the control panel BDE-

D.

Automatic

5Operation

20 / 28 BAL_DFA_127_EN_1V0_OEM_102-127401806

Enable control lock with key

Step Requirement Operation Function Display on LCD

1. The desired

operation

mode is set.

Enable/disable the con-

trol lock with the key

No settings can be made

on the control panel BDE-

D.

Automatic

5.2.5 Set parameters

IMPORTANT

With the type "low energy", the parameters can only be changed by qualified personnel.

The following example of the closing speed explains how to set the parameters of the door.

Step Button Operation Function Display on LCD

1.

E

Press the buttons in the or-

der shown

Access to the parameters in the sub

menu

Parameter

Driving cycle

Time delay open

Operator

E

2.

+

Press the buttons in the or-

der shown

In the sub menu, access the parameter

closing speed

Driving cycle

Closing speed

Opening speed

Acceleration

E

3.

+

Set the closing speed with

the buttons shown.

Hold down the button to

move continuously

Increase speed

0 = minimum speed

40 = maximum speed

Closing speed

0 10 20 30 40

-

6.

E

Press button 1 x Save value

Closing speed

0 10 20 30 40

C

Press button 1 x Leave without saving

Closing speed

0 10 20 30 40

Table of contents

Popular Door Opening System manuals by other brands

Dormakaba

Dormakaba PT 22 Installation instruction

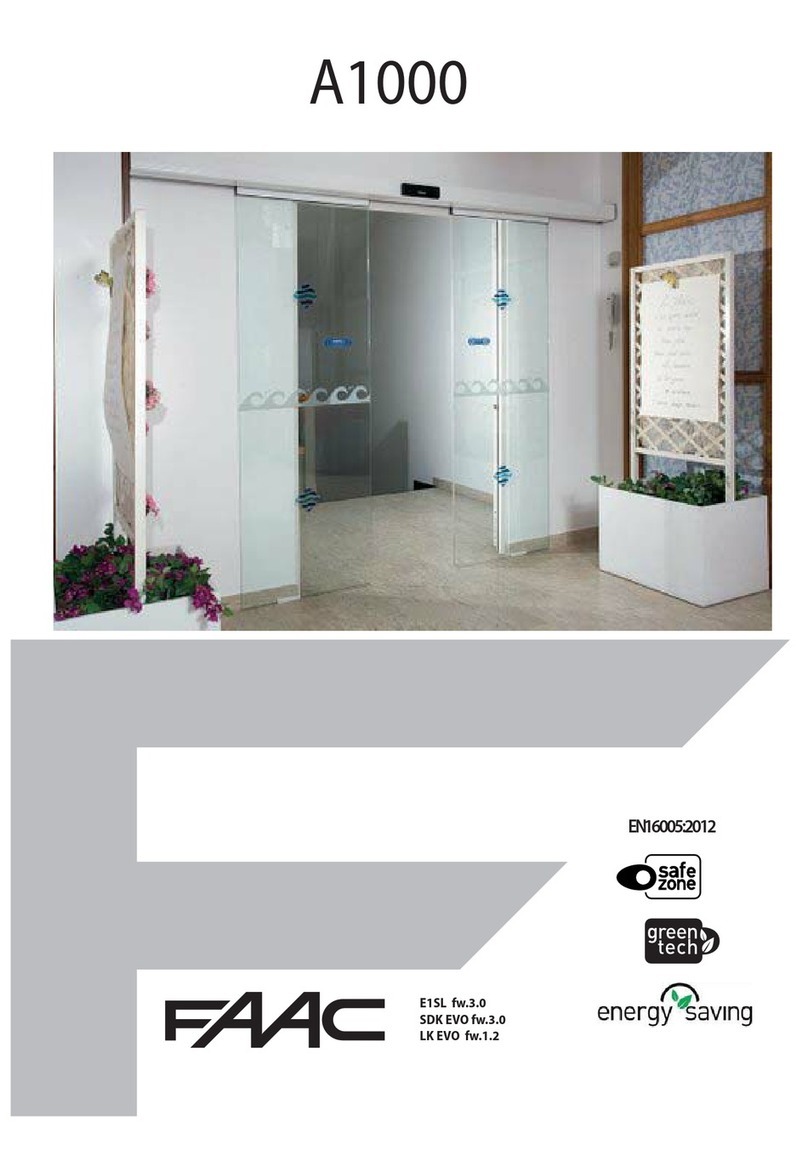

FAAC

FAAC A1000 user manual

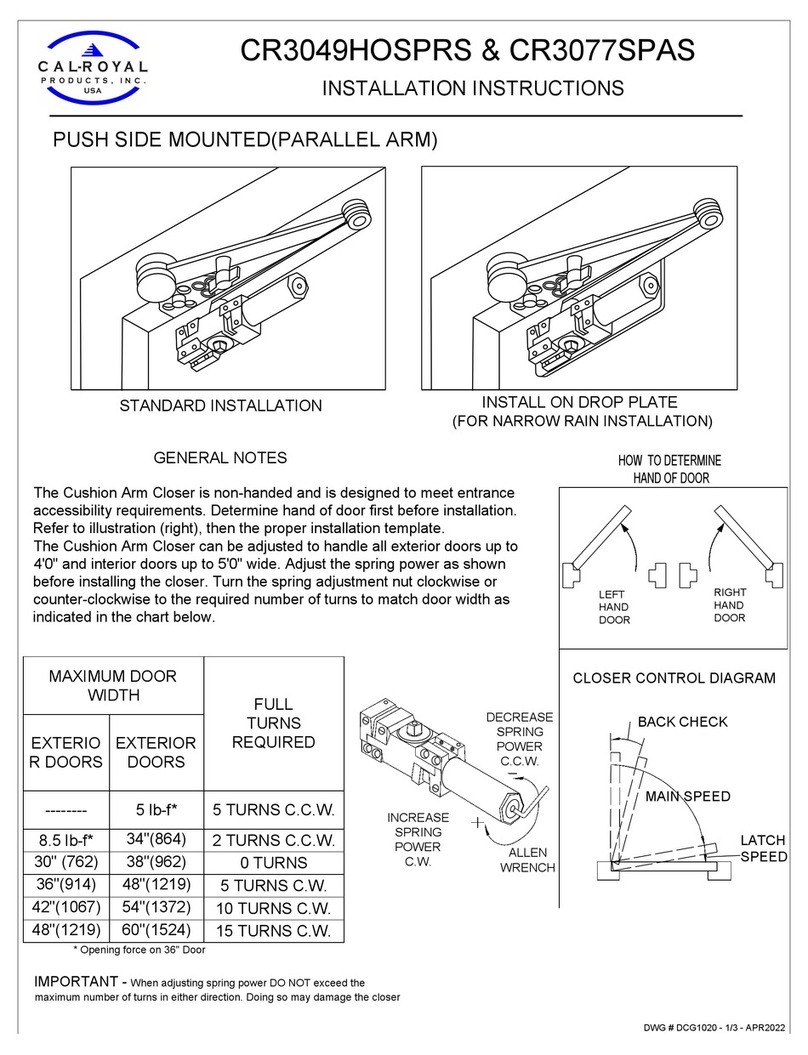

Cal-Royal

Cal-Royal CR3049HOSPRS installation instructions

Lamp

Lamp AZ-GD231 installation instructions

GEZE

GEZE Slimdrive SL NT Installation and service instructions

Assa Abloy

Assa Abloy Corbin Russwin ED4000 Series installation instructions

hager

hager 5200 Series installation instructions

CornellCookson

CornellCookson FS-36EP Series Installation instructions and operation manual

Dormakaba

Dormakaba RTS Series installation instructions

Automatic Technology

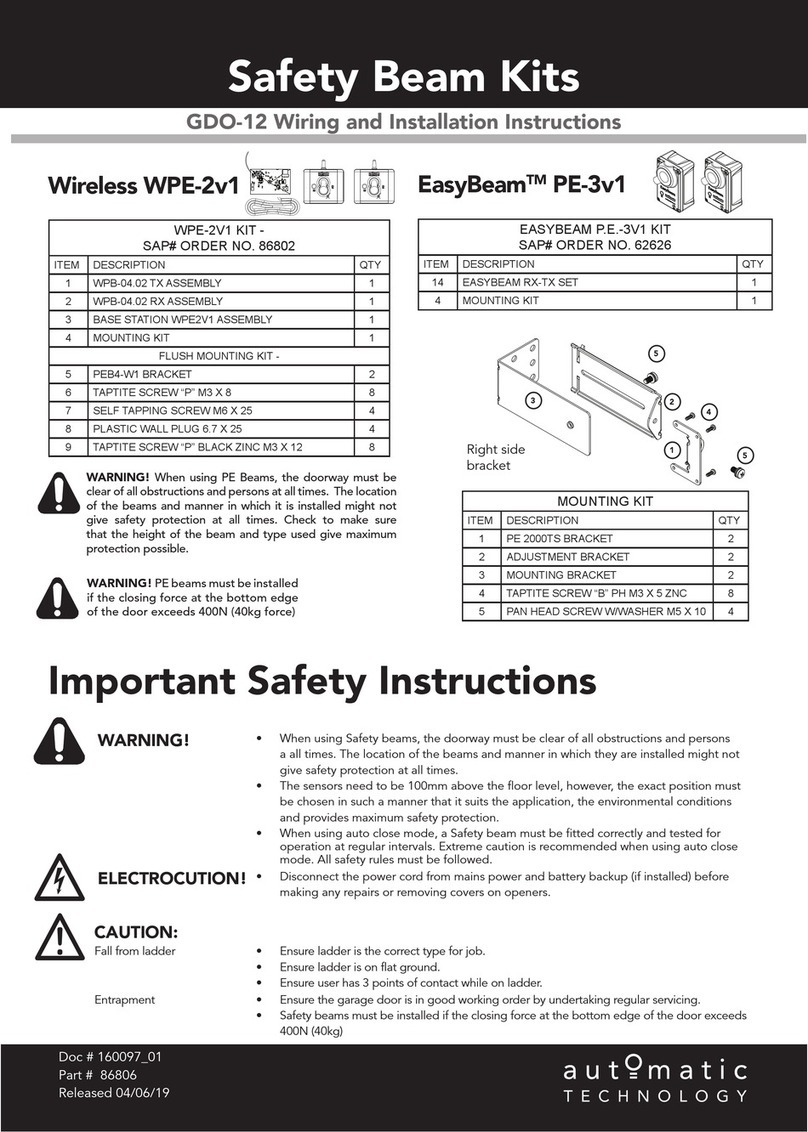

Automatic Technology HiRO GDO-12 Wiring and Installation Instructions

Command access

Command access MLRK1 Series instructions

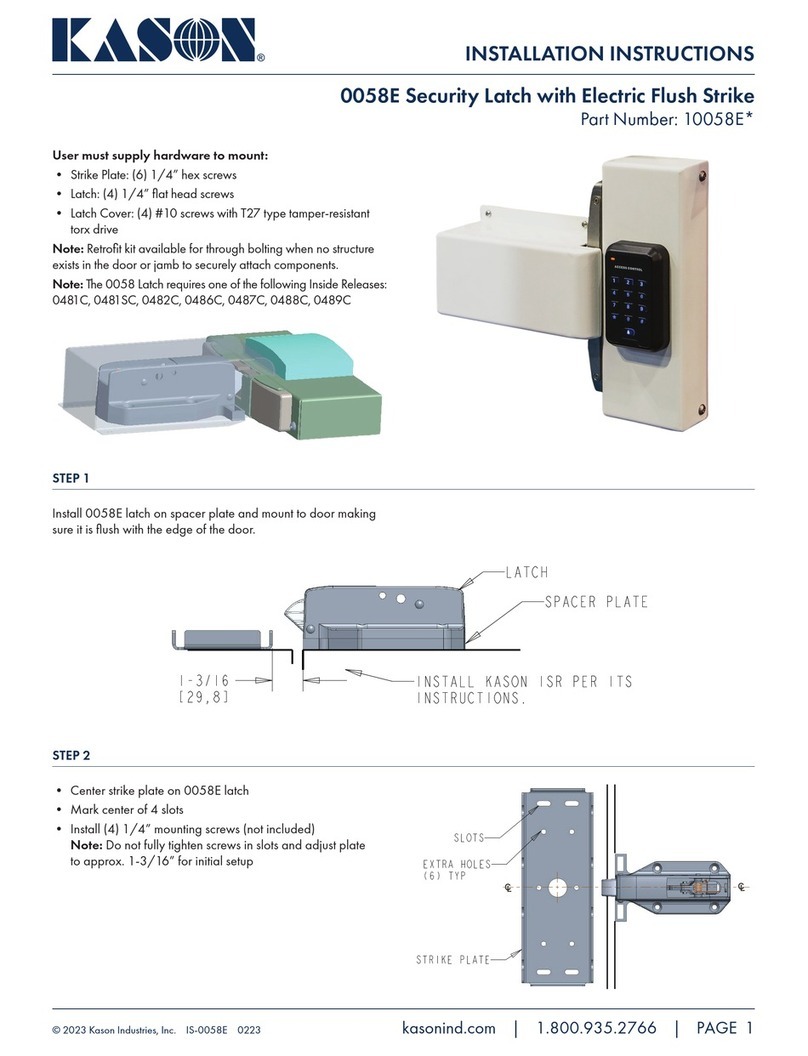

Kason

Kason 10058E Series installation instructions