A1000 5 53221004 - Rev.A

Translation of the original instructions ENGLISH

CONTENTS

EC Declaration of conformity of a machine.................................... 3

EC Declaration of conformity.................................................................. 3

Declaration of incorporation of partly completed machinery4

Declaration of incorporation for partly completed machinery

4

1. INTRODUCTION TO THE MANUAL........................................................ 7

1.1 Safety recommendations ........................................................................... 7

Safety of the installer/maintenance technician........................... 7

Workplace safety ........................................................................................... 7

User safety......................................................................................................... 7

1.2 Meaning of the symbols used.................................................................. 8

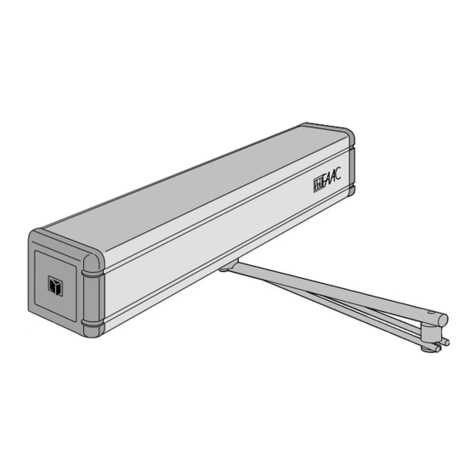

2. AUTOMATION A1000 .................................................................................. 10

2.1 Intended use....................................................................................................10

Limitations for use......................................................................................10

2.2 Unauthorised use..........................................................................................10

2.3 Identification plate.......................................................................................11

2.4 Technical specifications A1000..............................................................12

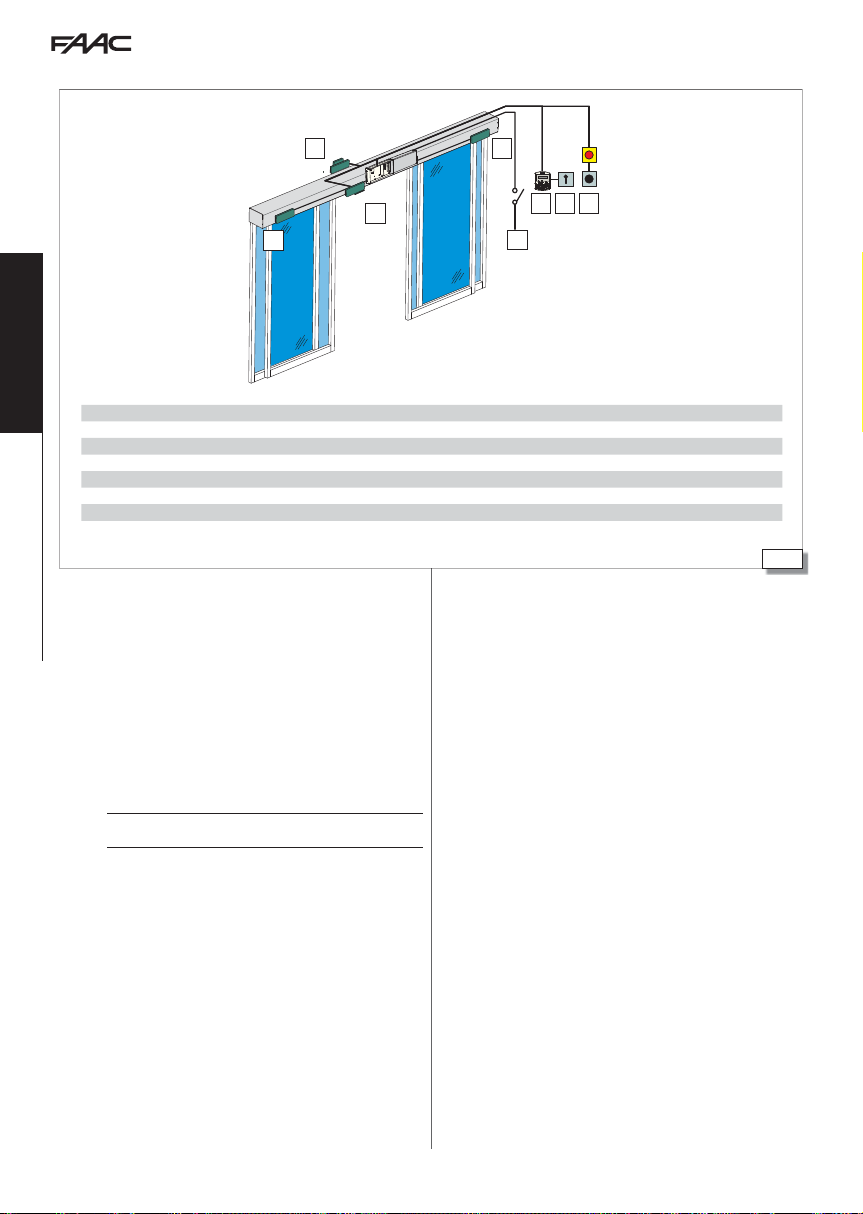

2.5 Types of system supplied..........................................................................13

Installation according to the type of system supplied...........13

A1000 Automation components........................................................14

ACCESSORIES ................................................................................................15

3. INSPECTION AND PREPARATION....................................................... 16

3.1 Preliminary inspection..............................................................................16

3.2 Arrangement of electrical cables........................................................16

4. TRANSPORT AND RECEIPT OF THE GOODS................................ 17

Handle packages .........................................................................................17

Unpack and Handle....................................................................................17

5. CUTTING THE PROFILES ........................................................................... 18

6. ASSEMBLING THE HEAD SECTION.................................................... 19

6.1 Assembling the components .................................................................20

Mechanical stops.........................................................................................20

Electronics module.....................................................................................21

Safety cables and spacers.......................................................................22

Motor..................................................................................................................22

Return PULLEY..............................................................................................22

Motor release monitor..............................................................................23

Internal release.............................................................................................23

XB LOCK Motor block operation test................................................23

Cover drilling..................................................................................................24

Closed door monitor sensor..................................................................24

Emergency battery kit .............................................................................24

7. ASSEMBLING THE A1000 CS FRAME................................................ 25

7.1 Entry with TK50 profiles............................................................................25

Preliminary operations.............................................................................25

Assembling the frame ..............................................................................25

Fastening the fixed leaves ......................................................................26

Fixed leaves may be: .................................................................................26

Mounting mobile leaves ........................................................................26

Glazing installation.....................................................................................26

Assembly of the head section to the upper profile..................26

7.2 Entry door with TK20 profiles.................................................................26

Preliminary operations.............................................................................26

Assembling the frame ..............................................................................27

Mounting MOBILE LEAVES ....................................................................27

Assembly of the head section to the upper profile..................27

8. INSTALLING THE HEAD SECTION.......................................................28

8.1 Preliminary operations ..............................................................................28

8.2 Fastening to the wall...................................................................................28

9. INSTALLING THE LEAVES .........................................................................29

9.1 Mounting the lower shoes.......................................................................29

Shoe with TK50 bracket ...........................................................................29

TK50 Swivel shoe.........................................................................................29

Shoe with TK20 bracket ...........................................................................29

9.2 Mount profiles on the leaves..................................................................30

9.3 Mount the lower sweeper........................................................................30

Glass leaves.....................................................................................................30

9.4 Installing the leaves.....................................................................................30

9.5 Adjusting the leaves and carriages.....................................................31

Height of the leaves...................................................................................31

Depth of the leaves....................................................................................31

Counter wheel...............................................................................................31

10. INSTALLING THE GLASS LEAVES.....................................................32

10.1 Mounting the brushes.............................................................................34

11. ASSEMBLE THE BELT, CASING AND ACCESSORIES............. 35

11.1 Mounting the belt......................................................................................35

Adjusting the belt .......................................................................................37

11.2 Belt tensioning ............................................................................................38

11.3 Adjusting the mechanical stops.........................................................39

Stops on opening........................................................................................39

Single leaf closing stops..........................................................................39

Double leaf closing stops........................................................................39

11.4 Mounting the side profiles....................................................................40

11.5 Installing the casing brackets..............................................................40

11.6 Fitting the cover..........................................................................................41

11.7 Installing the XB LOCK Motor block.................................................42

11.8 Adjusting the XB LOCK Motor block ................................................42

11.9 Mounting the cable gland guides.....................................................43

12. ELECTRONICS INSTALLATION E1SL .............................................. 44

12.1 E1SL Electronic module.........................................................................44

E1SL Electronic board ...............................................................................44

12.2 Terminal boards and connectors .......................................................46

J1 J4 - INPUTS S1-S2...................................................................................46

J7 - INPUTS E1 -E2........................................................................................46

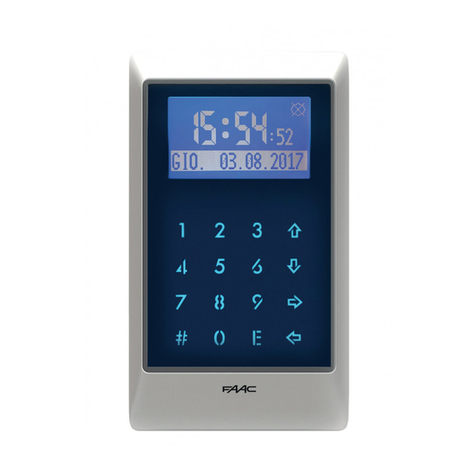

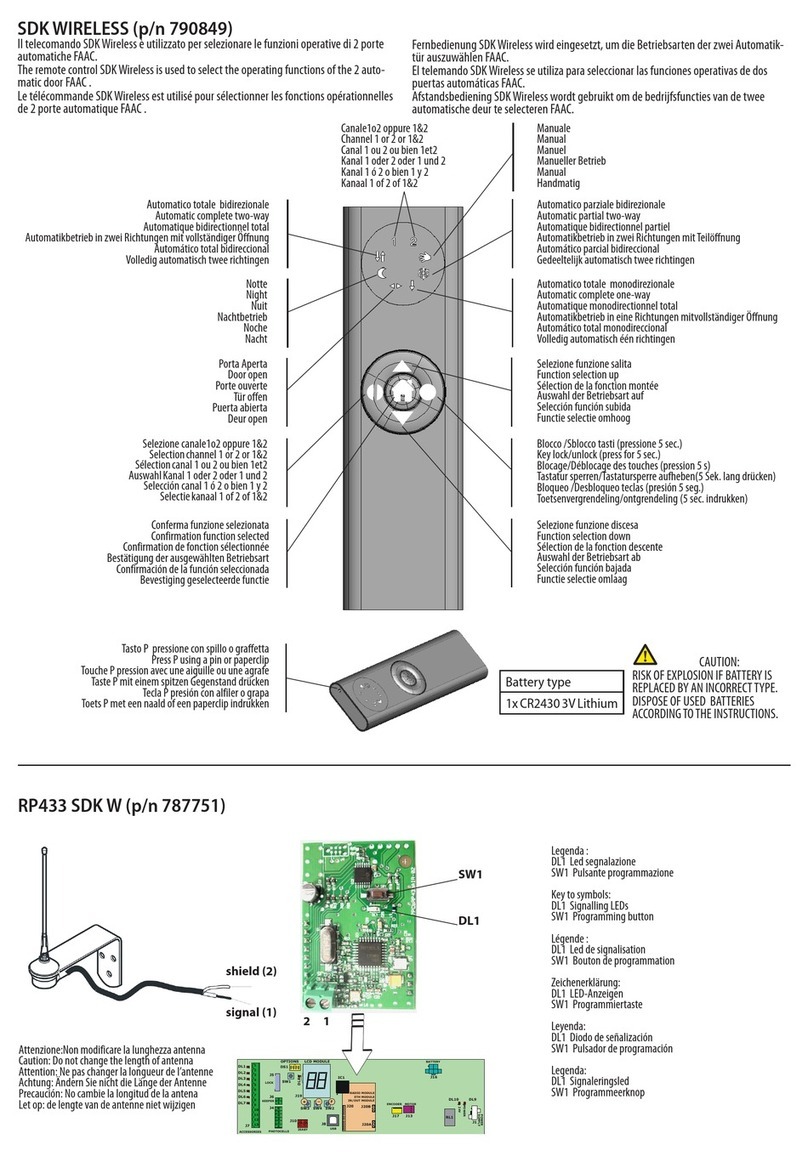

J8 - SDK EVO - LK EVO - KS EVO............................................................46

J9 - XFA button photocells .....................................................................46

J10 - Main power supply 36V - 4A......................................................46

J11 - Motor......................................................................................................47

J12 - Motor Encoder...................................................................................47

J13 - XB XM LOCKOCK/ 47 Motor block and monitoring

(OPTIONAL).....................................................................................................47

J14 - Emergency battery .........................................................................47

J17 - USB Port ................................................................................................47

J18 - INTERCOM............................................................................................47

J21 - Inputs i1-i2-i3-i4 .............................................................................47

J22 - Configurable outputs ...................................................................47

J23 J24 J25 - Optional modules...........................................................47

12.3 Motor and encoder ...................................................................................48

12.4 XB LOCK motor block and monitoring (OPTIONAL)...............48

12.5 XV1-XDT1 EXIT and entry detectors ................................................49

12.6 2 XDT1 Exit detectors and 2 XDT1 ENTRY detectors ...............50

12.7 XBFA Detectors for safety in OPENING ..........................................51

12.8 J9 - XFA button photocells....................................................................52

12.9 J7

- INPUTS E1 -E2

.....................................................................................

.....................................................................................

52

12.10 J22 - Configurable outputs.................................................................52

13. STARTUP............................................................................................................53

Preliminary checks prior to commissioning.................................53

13.1 Switching on and system SETUP .......................................................53

Checks following SETUP..........................................................................53

Saving the Configuration........................................................................53

13.2 Basic / advanced programming.........................................................54