Slimdrive SL NT product family

2

Contents

1 Introduction...............................................................................................................................................................3

1.1 Symbols and illustrations...............................................................................................................................................................................3

1.2 Revisions and validity......................................................................................................................................................................................3

1.3 Product liability .................................................................................................................................................................................................3

1.4 Reference documents.....................................................................................................................................................................................3

2 Fundamental safety precautions .......................................................................................................................4

2.1 Intended use.......................................................................................................................................................................................................4

2.2 Safety instructions ...........................................................................................................................................................................................4

2.3 Safety-conscious working.............................................................................................................................................................................5

2.4 Environmentally conscious working .........................................................................................................................................................5

2.5 Safety instructions related to transportation and storage ...............................................................................................................5

2.6 Qualication .......................................................................................................................................................................................................5

3 About this document.............................................................................................................................................6

3.1 Overview..............................................................................................................................................................................................................6

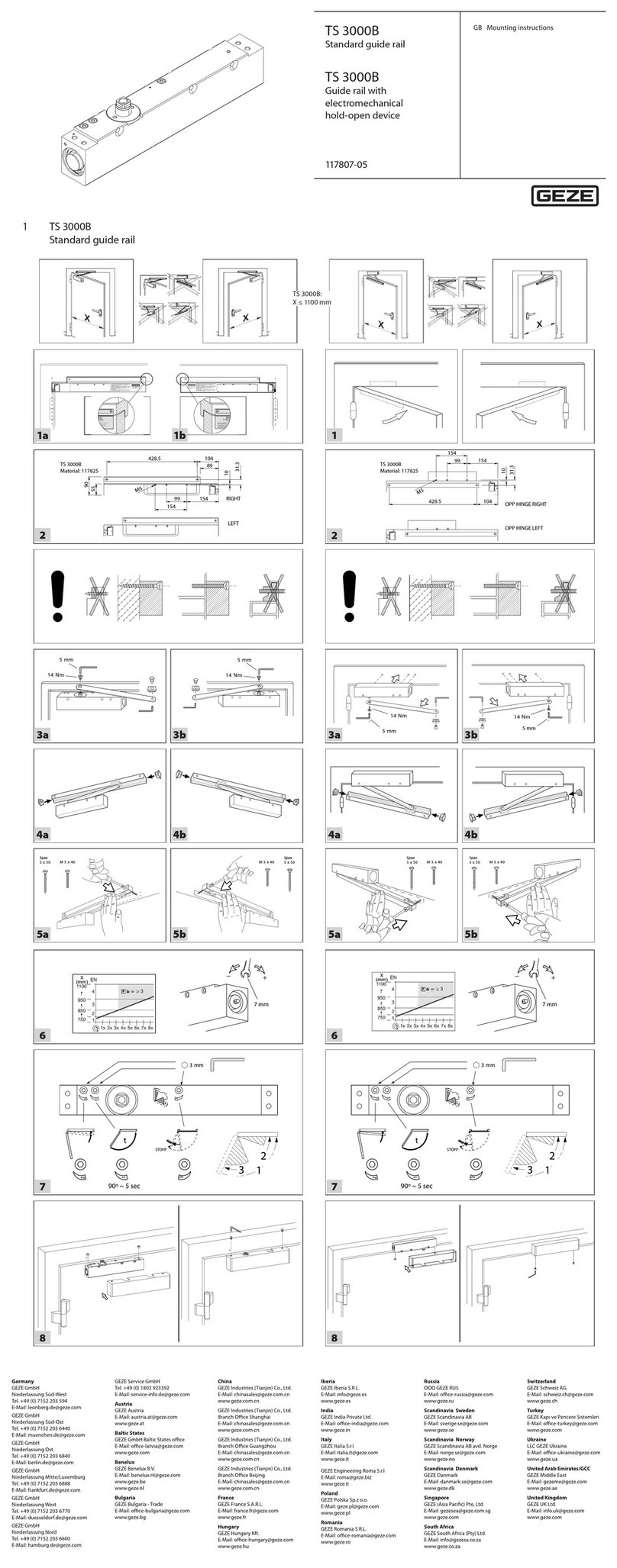

4 Overview.....................................................................................................................................................................7

4.1 Diagrams..............................................................................................................................................................................................................7

4.2 Tools and aids.....................................................................................................................................................................................................8

4.3 Torques.................................................................................................................................................................................................................8

4.4 Components and assembly groups...........................................................................................................................................................8

5 Installation..................................................................................................................................................................8

5.1 Preparations to be made on-site ................................................................................................................................................................8

5.2 Preparing the track ..........................................................................................................................................................................................8

5.3 Mounting the track ..........................................................................................................................................................................................9

5.4 Mounting the oor guide........................................................................................................................................................................... 10

5.5 Installing the moving leaf............................................................................................................................................................................11

5.6 Installing the drive components...............................................................................................................................................................17

5.7 Connecting earthing.................................................................................................................................................................................... 22

6 Production test and commissioning.............................................................................................................. 23

6.1 Connecting the drive ................................................................................................................................................................................... 23

6.2 Mounting the cover...................................................................................................................................................................................... 24

6.3 Mounting the safety devices..................................................................................................................................................................... 27

6.4 Installing operating elements/switches/push buttons................................................................................................................... 27

6.5 Commissioning the door system............................................................................................................................................................. 27

6.6 Dismantling...................................................................................................................................................................................................... 28

7 Service and maintenance .................................................................................................................................. 29

7.1 Mechanical service........................................................................................................................................................................................ 29

7.2 Maintenance.................................................................................................................................................................................................... 29

8 Troubleshooting.................................................................................................................................................... 30

8.1 Mechanical faults........................................................................................................................................................................................... 30

8.2 Replacing roller carriage..............................................................................................................................................................................31

8.3 Replace brushes on the roller carriage...................................................................................................................................................31

8.4 Electrical faults................................................................................................................................................................................................ 32

9 Drive identication plate ................................................................................................................................... 33

10 Inspection of the installed door system....................................................................................................... 34

10.1 Protective measures to prevent and protect from hazardous areas.......................................................................................... 34

10.2 Installation checklist Slimdrive SL NT..................................................................................................................................................... 34