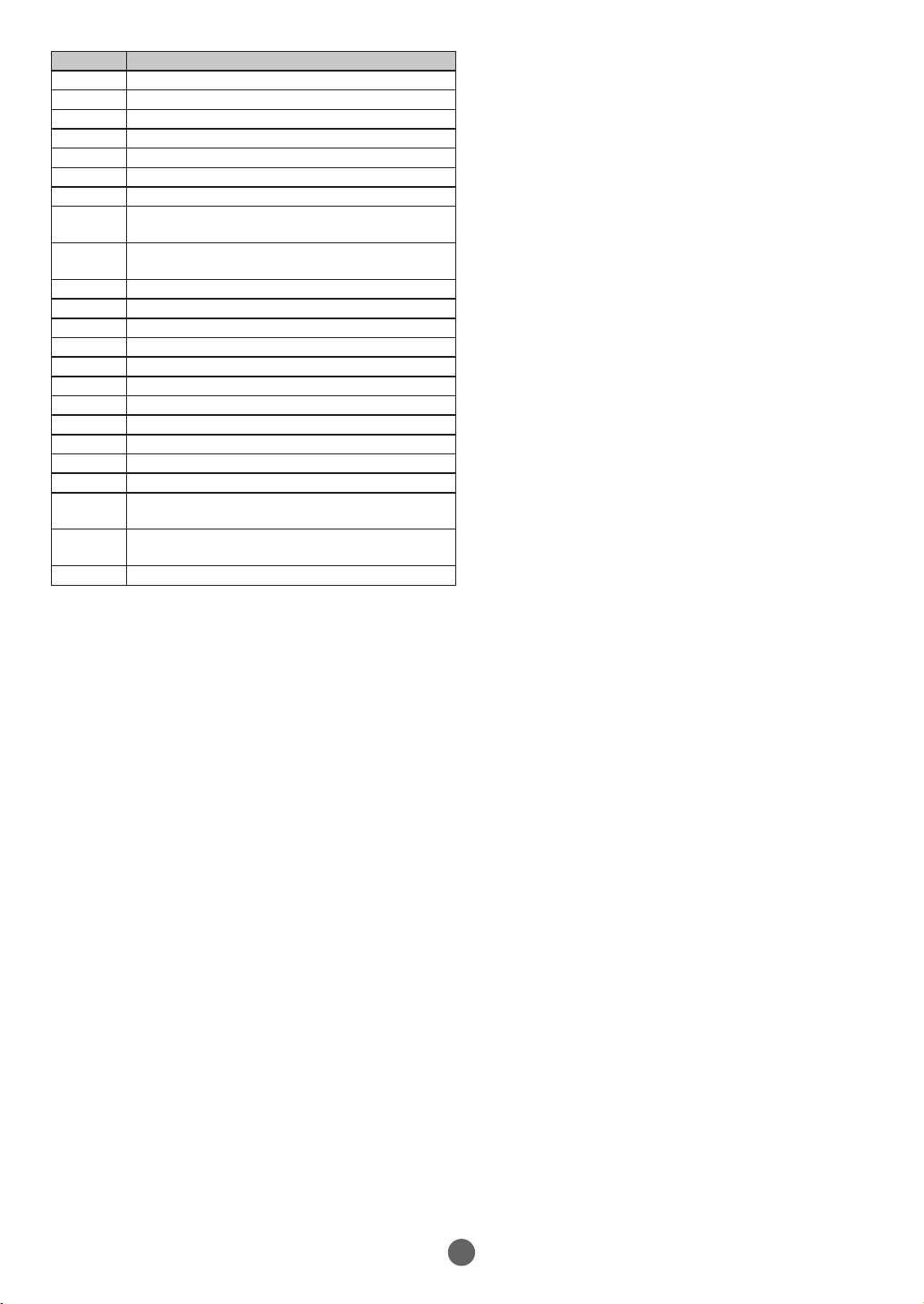

6

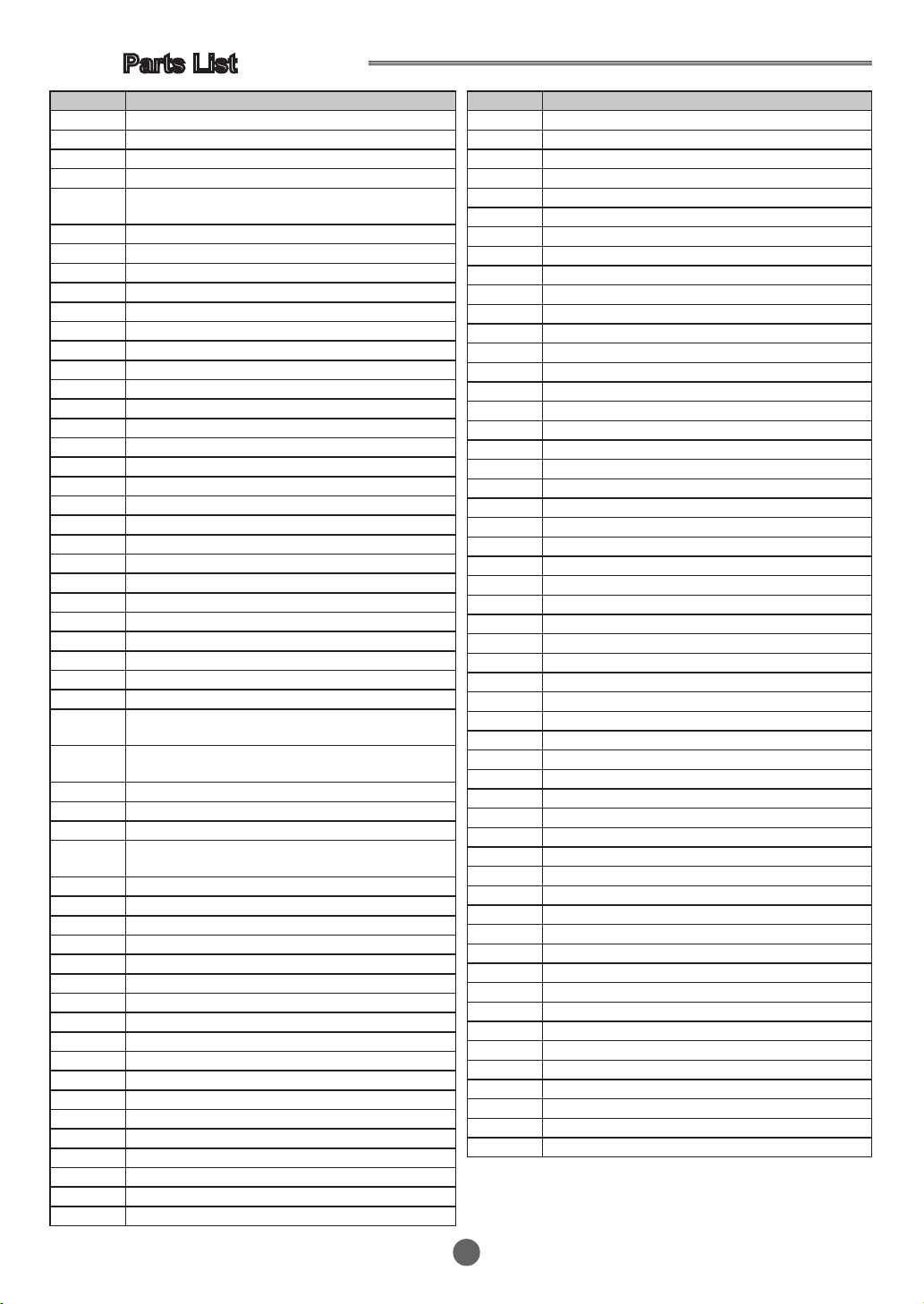

Parts List

Number Desc

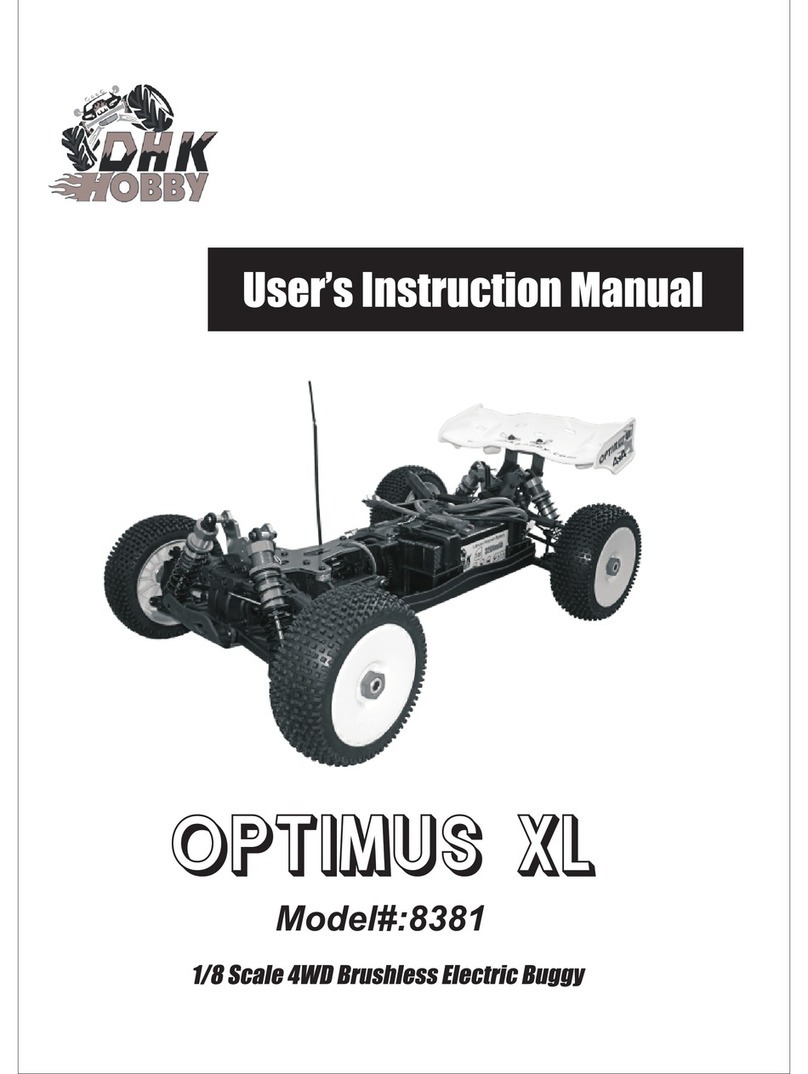

8381-100 Assembly of diff gear box

8381-101 Diff set

8381-102 Diff outdrive/pins (dia 2*10mm)

8381-103 Pins(dia 2*10mm) (16 pcs)

8381-104 Flathead screw-coarse thread(KB2.6*10mm) (16

pcs)

8381-105 Crown gear-41T (large)/pinion gear-11T (small)

8381-106 Diff case set/diff case cover/diff gasket

8381-107 Washer-A/washer-B (8 pcs each)

8381-108 Gear-18T (2 pcs)/gear-12T (4 pcs)

8381-109 O Ring(dia 8mm * dia 2mm) (16 pcs)

8381-110 Ball bearing(dia 10mm * dia 15*4mm) (2 pcs)

8381-111 Diff pins(dia 4*25.8mm) (4 pcs)

8381-112 Assembly of the pinion gear

8381-113 Flathead screw(KM2.6X6mm) (16 pcs)

8381-114 Ball bearing(dia 8mm * dia14*4mm) (2 pcs)

8381-115 Pins(dia 2*8mm) (16 pcs)

8381-116 Pinion gear outdrive/pins(dia 2*8mm)

8381-117 Ball bearing(dia 5 mm * dia 11*4mm) (2 pcs)

8381-118 Diff gear box-F/R

8381-119 B head screw-coarse thread(BB3*16mm) (16 pcs)

8381-200 Central diff gear box(complete)

8381-201 Central diff set

8381-202 Center diff pins/pins(dia 2*10mm)

8381-203 Spur gear-43T(plastic) (2 pcs)

8381-204 Lock nut (M4*4mm) (16 pcs)

8381-205 Center diff outdrive/lock nut(M4*4mm)

8381-206 Center diff gear box/center diff gear box plate

8381-207 B head screw-coarse thread(BB3*20mm) (16 pcs)

8381-300 Shock absorber complete (2 pcs)

8381-301 Shock cap (2 pcs)

8381-302 Shock connecting rod-upper/lower/O ring (dia

12mm * dia 2mm)

8381-303 Shock adjust ring /O ring (dia 18.5mm * dia 1.5mm)

(2 pcs)

8381-304 Shock body (2 pcs)

8381-305 Shock ball (8 pcs)

8381-306 M3 nylon nut (8 pcs)

8381-307 Lower shock mount/piston/O ring(dia 13mm * dia

1.5mm)

8381-308 O ring (16 pcs)

8381-309 Shock shaft (4 pcs)

8381-310 Shock spring (4 pcs)

8381-400 Anti-roll bar assembly

8381-40L Assembly of anti-roll bar linkage-Left

8381-40R Assembly of anti-roll bar linkage-Right

8381-401 Anti-roll bar rod end (8 pcs)

8381-402 Anti-roll bar linkage (4 pcs)

8381-403 Anti-roll bar pivot ball-upper/lower (4 sets)

8381-404 Lock nut(M3*3mm) (8 pcs)

8381-405 Anti-roll bar(dia 2.2mm) (2 pcs)

8381-50L Assembly of upper sus.arm-Left

8381-50R Assembly of upper sus.arm-Right

8381-501 Upper sus.arm ball (4 pcs)

8381-502 Upper sus.arm/rod end (2 sets)

8381-503 Upper sus.arm linkage (2 pcs)

8383-600 Assembly of buffer set

8381-601 Brass washer (4 pcs)

Number Desc

8381-602 Buffer bushing/adiustment ring

8381-603 Buffer spring (4 pcs)

8381-604 Buffer sus.arm-upper/lower/steering sus.arm

8381-605 B head screw-coarse thread(BB3*12mm) (16 pcs)

8381-606 Screw bushing (16 pcs)

8381-601 Steering plate

8381-608 Shaft (2 pcs)

8381-6Z0 Assembly of steering linkage (2 pcs)

8381-6Z1 Steering linkage (2 pcs)

8381-6Z2 Plastic rod end (8 pcs)

8381-6Z3 Double way ball end (8 pcs)

8381-701 Upper sus.arm mount-rear/suspension mount

8381-702 B head screw-coarse thread(BB3*14mm) (16 pcs)

8381-703 B head screw-coarse thread(BB3*10mm) (16 pcs)

8381-704 Sus.arm long axle/short axle (2 sets)

8381-705 E-Clip(dia 2*0.4mm) (16 pcs)

8381-706 Lower sus.arm-front (2 pcs)

8381-707 Drive shaft set/revolving shaft (2 sets)

8381-708 Wheel axle (2 pcs)

8381-709 Steering arm (2 pcs)

8381-710 Ball bearing(dia 5mm * dia 10*4mm) (2 pcs)

8381-711 Hex adapter/nut-M12

8381-712 Pins(dia 2*16mm) (16 pcs)

8381-713 B head screw(BM3*12mm) (16 pcs)

8381-714 C-hub (2 pcs)

8381-715 B head screw(BM3*20mm) (16 pcs)

8381-716 Lock nut(M4*10mm) (16 pcs)

8381-717 Brace (2 pcs)

8381-718 Pivot ball mount (4 pcs)

8381-719 Upper sus.arm shaft (4 pcs)

8381-720 Front bumper/upper sus.arm mount-front

8381-721 Lower sus.arm plate-front

8381-726 B head screw-coares thread(BB3*18mm) (16 pcs)

8383-001 Tire complete (black rims) (2 pcs)

8381-801 Lower sus.arm-rear (2 pcs)

8381-802 Rear hub-L/F

8381-803 B head screw(BM3*18mm) (16 pcs)

8381-804 Wing mount/wing brace-L/R

8381-805 B head screw(BM3*10mm) (16 pcs)

8381-806 Rear wing rod-long/short

8381-807 Pin-A(dia 1.5mm) (16 pcs)

8383-002 Rear wing (black)

8381-9M1 Motor mount-Upper/Lower

8381-9M2 Motor gear-15T/Lock nut(M4*4)

8381-9S0 Assembly of 9kgs servo (with servo horns)

8381-9S1 Servo mount

8381-9S2 Servo steering plate (2 pcs)

8381-9S3 B head screw(BM3*6mm) (16 pcs)

8381-9Z0 Assembly of steering tie rod

8381-9Z1 Steering tie rod (2 pcs)

8383-003 Chassis

8381-002 Side guard-L/R

8382-003 Battery mount-A/B

8381-004 Upper deck mount-F/R