TABLE OF CONTENTS

1UNDERSTANDING SAFETY AND WARNING SIGNS..................................................................................................................2

2CONTACT INFORMATION AND DISCLAIMERS..........................................................................................................................3

3GENERAL INTRODUCTION .........................................................................................................................................................4

4INTENDED USE ............................................................................................................................................................................4

5IDENTIFICATION...........................................................................................................................................................................5

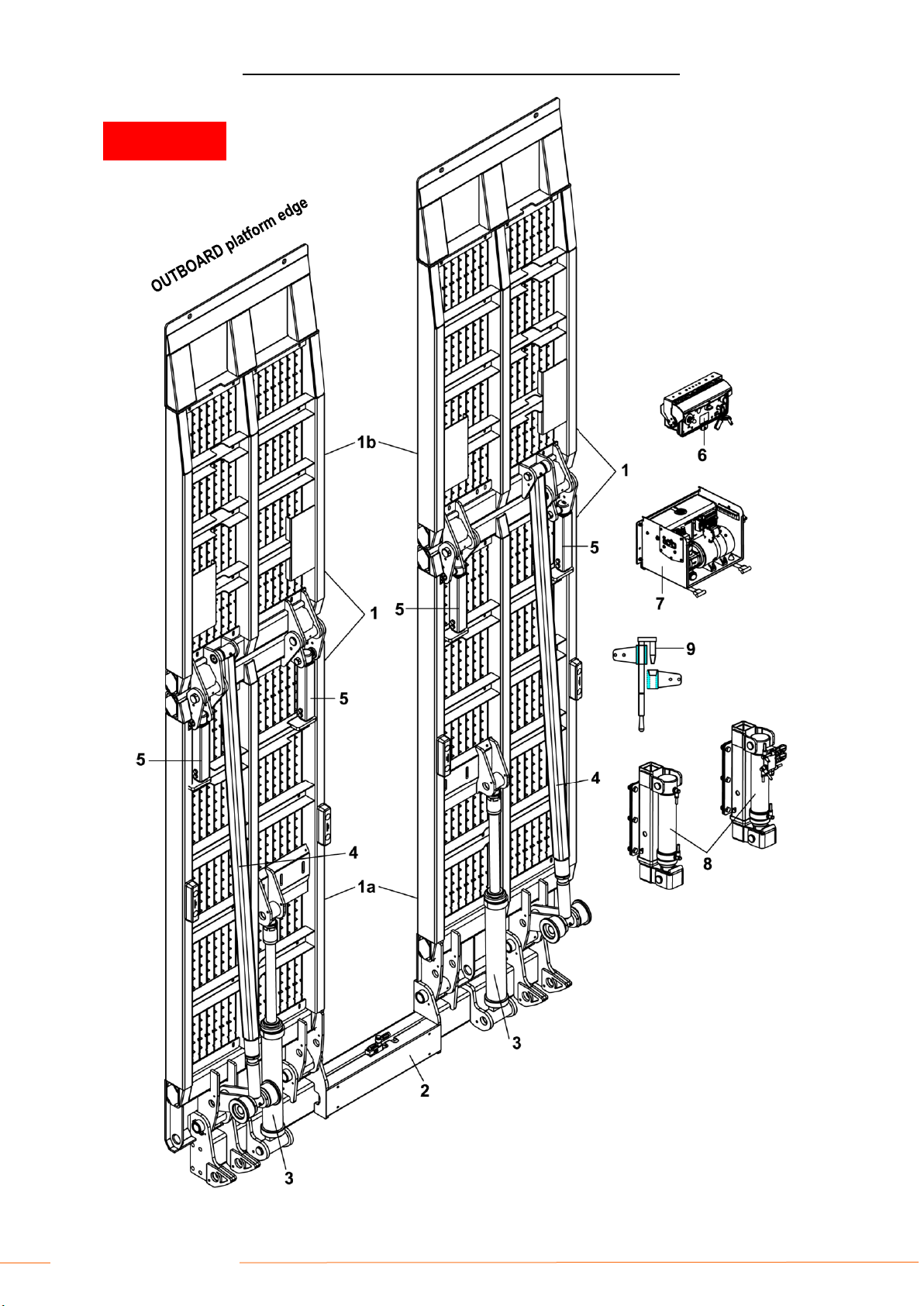

6DESCRIPTION AND HYDRAULIC RAMP TERMINOLOGY .........................................................................................................6

6.1 General .................................................................................................................................................................................6

6.2 Safety devices.....................................................................................................................................................................14

7SAFETY INSTRUCTIONS FOR USING THE HYDRAULIC RAMP .............................................................................................17

7.1 DO NOT use hydraulic ramp without adequate safety and operator training ......................................................................17

7.2 General safety instructions..................................................................................................................................................17

7.3 Danger zones, risk of crush and shear injury ......................................................................................................................21

7.4 Safe operator position .........................................................................................................................................................23

7.5 Recommended daily pre-trip inspection..............................................................................................................................24

7.6 Importance of preventative maintenance ............................................................................................................................25

8LOAD CHARTS AND CORRECT LOADING PROCEDURES.....................................................................................................26

8.1 General ...............................................................................................................................................................................26

8.2 Instructions for working at loading docks ............................................................................................................................27

9OPERATING INSTRUCTIONS - PRINCIPLES AND PROCEDURES.........................................................................................28

9.1 General ...............................................................................................................................................................................28

9.2 Switching the main power on / off .......................................................................................................................................28

9.3 Operating instructions for DH-AR1* ramps..........................................................................................................................29

9.4 Operating instructions for DH-AR2* ramps..........................................................................................................................32

9.5 Operating instructions for DH-AR3* / AR4* ramps .............................................................................................................35

9.6 The use of hydraulic side-shift [option OAH803] .................................................................................................................40

9.7 The use of hydraulic stabilising legs....................................................................................................................................41

10 DECALS.......................................................................................................................................................................................42

11 MEANING OF SAFETY AND WARNING SIGNS ........................................................................................................................43

12 END NOTE ..................................................................................................................................................................................45