DHOLLANDIA 6

5. IDENTIFICATION

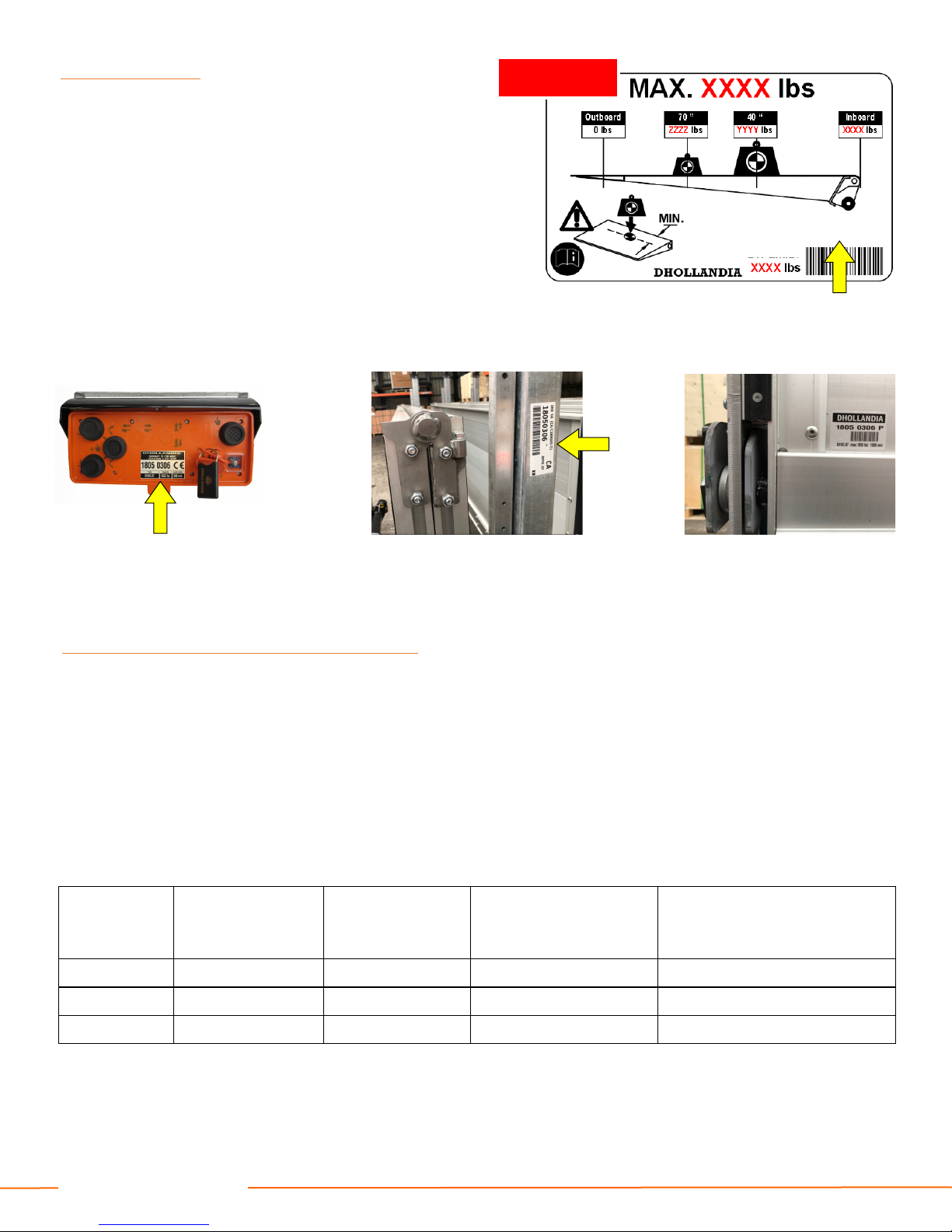

• Every HOLLAN IA liftgate is identified by and labelled with a

uniqu 8-digit s rial numb r (with or without a space

between the first and last 4 digits). Use this number for any

inquiry on a particular liftgate, or when ordering replacement

parts.

• In addition to the liftgate type and serial number, the various

serial number labels provide additional information, such as:

the maximum rated lift capacity and load chart, the bumper

certification number, the date of manufacture, etc...

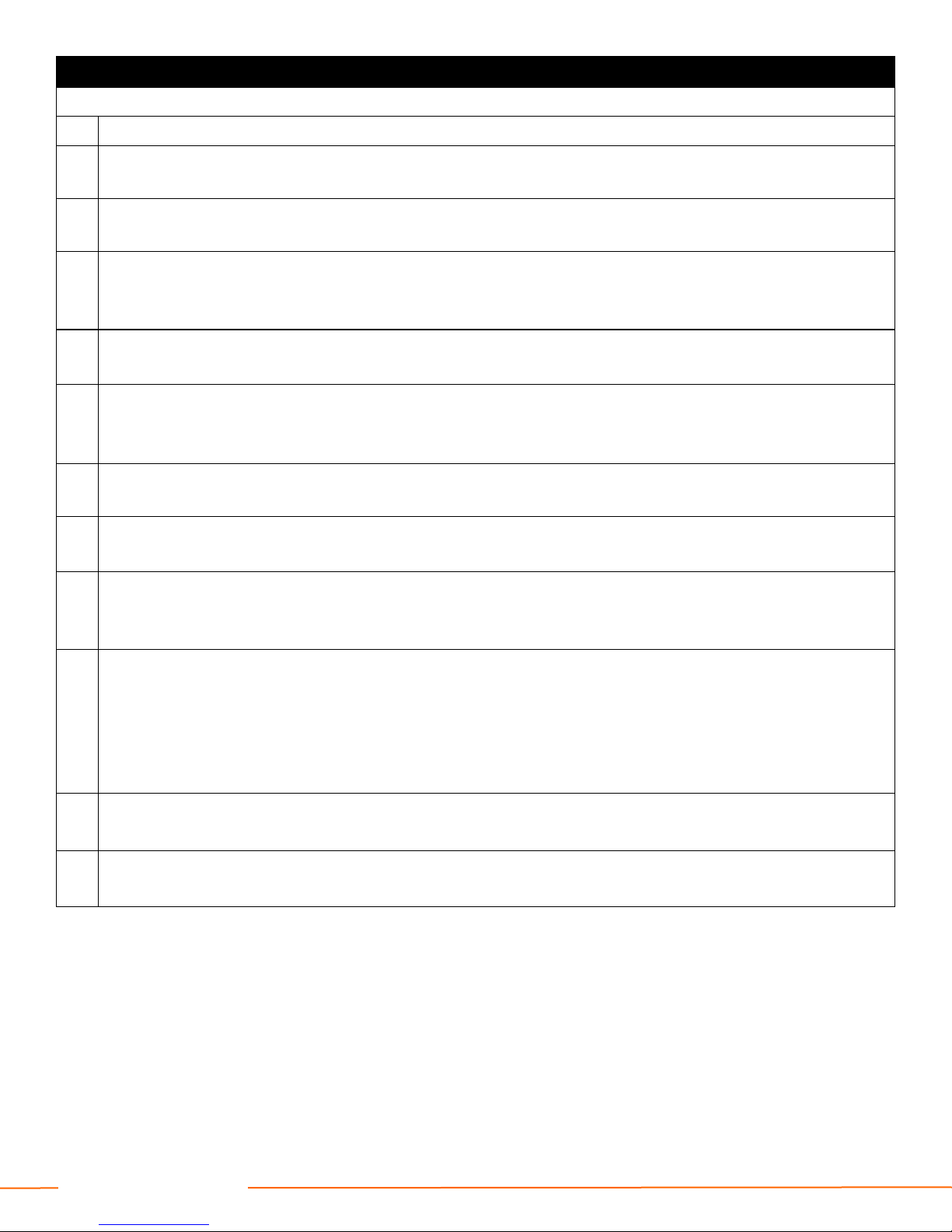

• These labels are usually affixed to the vehicle body and

various liftgate components, and can be found in following

locations (the yellow arrows point to the serial numbers):

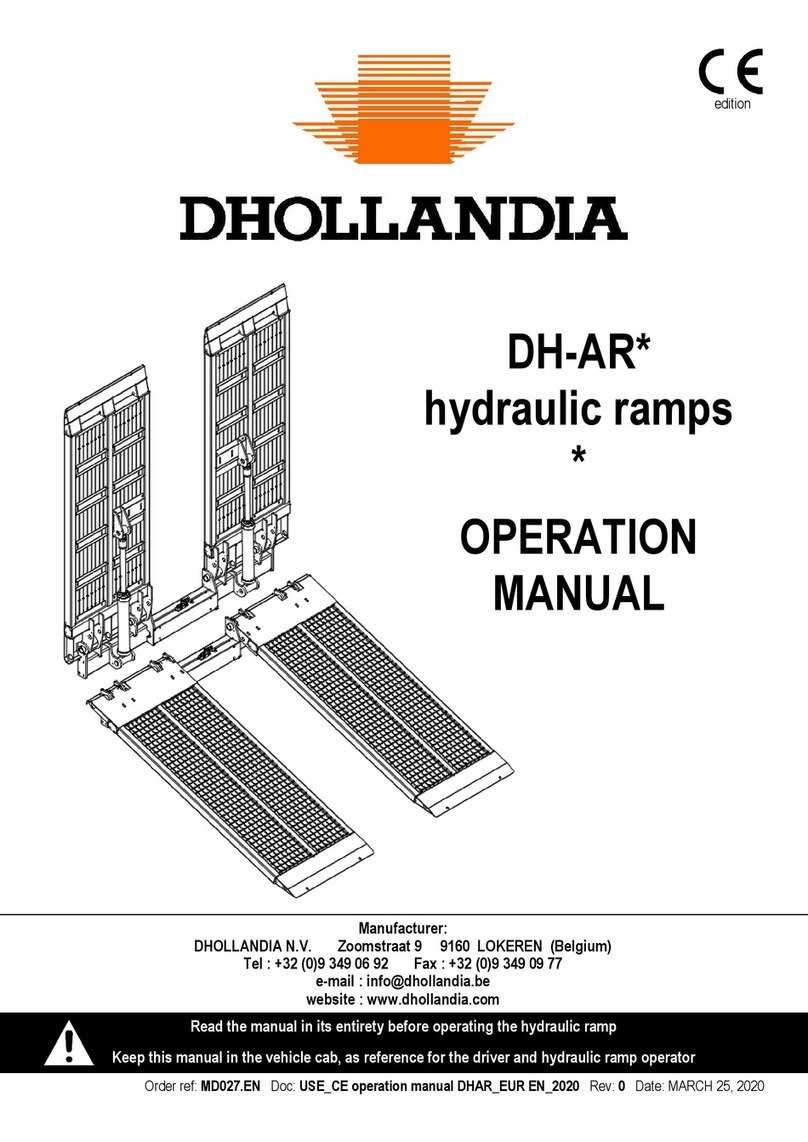

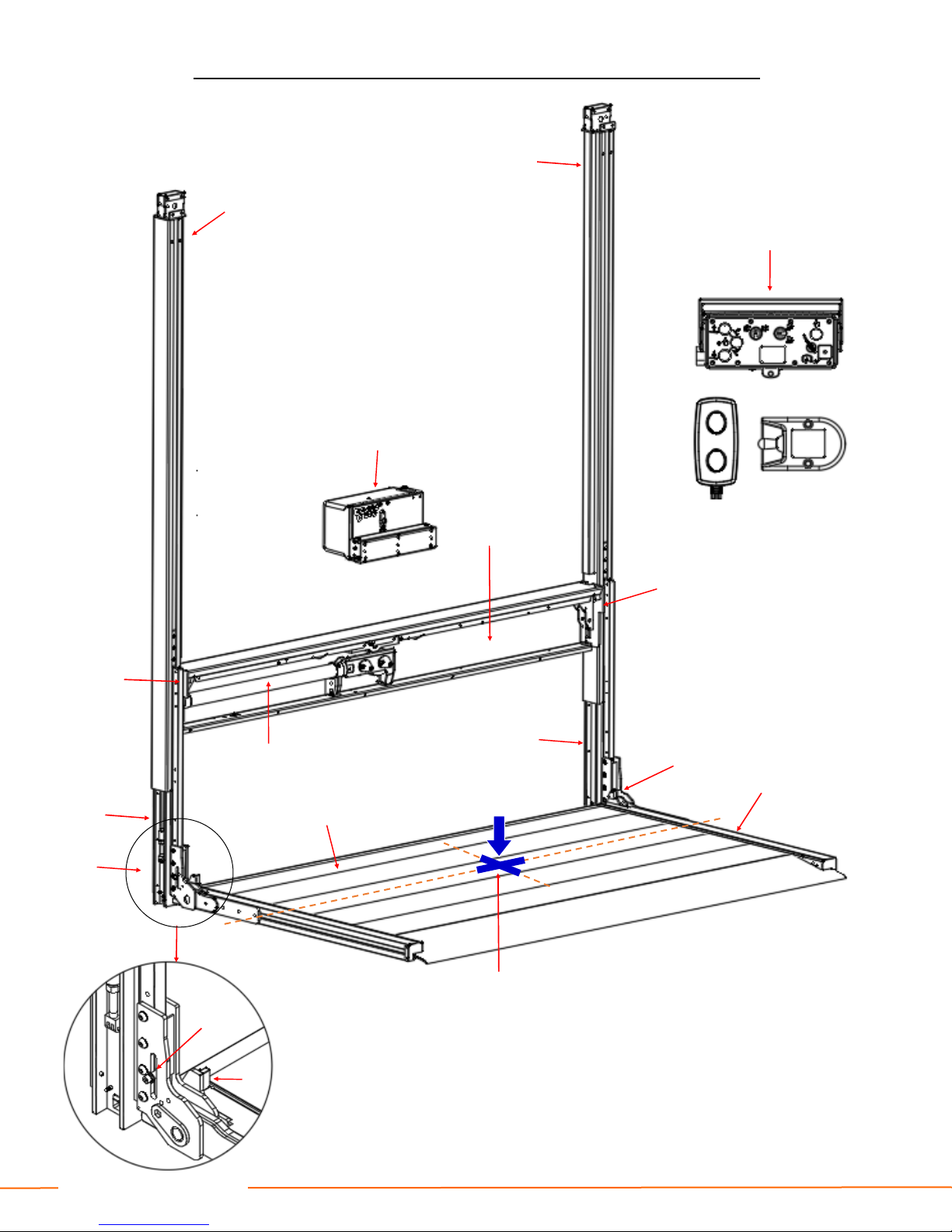

6. DESCRIPTION AND LIFTGATE TERMINOLOGY

• HOLLAN IA liftgates are developed and manufactured using state-of-the-art technology, high quality materials and components,

and highly skilled workmanship.

• The H-VO.07.K9, H-VO.15.K9 and H-VO.20.K9 comprise of a range of column liftgates, designed for a wide variety of trucks,

trailers and semi-trailers, and is available with lift capacities ranging from 1,000 to 4,400 lbs.

• In its travel position, the platform of the column liftgate is stowed vertically behind the vehicle body. Before use, the platform is

lowered approx. 7 “, then tilted open 90 degrees from the vertical travel position, to a horizontal work position.

• epending on liftgate model and options chosen, the opening and closing of the platform can be manual, or driven by 1 or 2

hydraulic tilt cylinders. See table below:

EXAMPLE

Affixed to the side of the vehicle body, or on the platform

On the lift frame On the platform

On the main external control box

Typ Lift capacity Manual closur Hydraulic closur 0-90°

OVH004

Hydraulic closur with adjustabl

platform pitch

OVH011

H-VO.07.K9 1,100 - 1,650 lbs standard not available not available

H-VO.15.K9 2,200 - 3,300 lbs standard optional optional

H-VO.20.K9 3,300 - 4,400 lbs standard optional optional

18050306

DH-VO.07