DHR DHR60 LED User manual

TECHNICAL MANUAL

DHR60 LED

MED2014/90/EU

46 CFR 111.75-17

Signalling Lights

Searchlights

Whistles

Den Haan Rotterdam

S

i

n

c

e

1

9

2

2

Navigation Lights

2Version 3.1 May 2018

Den Haan Rotterdam

DISCLAIMER

Despite constant care and attention DHR puts in its manuals it is still possible that information in this

manual is incomplete or incorrect.

We do not guarantee that the information in the manual is suitable for the purpose for which the

information was consulted. All information is offered in the state in which it actually is and without any

(implicit) guarantee or warranty regarding its validity or its suitability for a particular purpose or otherwise.

All illustrations are for illustrative purposes only. This manual is not intended to cover every possible detail

about the product.

We exclude all liability for any damages, direct or indirect, of any nature whatsoever, arising from or in any

way connected with the use of this manual. In addition we are not liable for damages, direct or indirect,

arising from the use of information obtained from this manual.

A user of this manual may not publish copyright protected works or other information from the manual

or in any way reproduce the information without our permission. This also includes the reproduction of

information or parts thereof by publication in an electronic (computer) network.

3Version 3.1 May 2018

Den Haan Rotterdam

TABLE OF CONTENTS

Technical data 4

Product photos 5

Dimensions 6

Available models 7

Exploded view 8

Repair kit 8

Electrical specification 9

Electrical spec. Manoeuvring light 10

Lifetime control 10

Positioning lights 11

Positioning all-round light 12

Mounting instructions 13

4Version 3.1 May 2018

Den Haan Rotterdam

TECHNICAL DATA

Application

• For all vessels used in (European) inland navigation

• For all seagoing vessels with a length less than 50 meters

• UL1104 (USA): for vessels of 65 feet or more in length

In compliance with:

• Directive 2014/90/EU

• Regulation (EU) 2017/306 Annex A.1/6.1

• US Code of Federal Regulations Title 46 CFR 111.75-17

Conform standards:

• COLREG Annex l/14

• IMO Resolution A.694 (17)

• IMO Resolution MSC.253 (83)

Materials:

• Housing: Seawater resistant aluminium, hard anodised, matt black

• LED driver: epoxy potted

• Screen: Seawater resistant aluminium, hard anodised

• Lens: Borosilicate glass

Min. visibility:

Sector lights All-round

Starboard - bright 2 NM White - bright 2 NM Green - bright 2 NM

Port - bright 2 NM Manoeuvring 5 NM Yellow - bright 2 NM

Masthead - bright 5 NM Red - bright 2 NM Blue - normal 1 NM

Stern - bright 2 NM Red & White 2 NM

Towing - bright 2 NM Red & Green 2 NM

Electrical insulation class: Power supply:

I, (grounded) / III 24VDC -20% +30%

Protection class: life time:

IP X6 50,000 Hours

Operation temperature: Mounting:

-30°C up to +55°C Base

Cable entry:

Two cable glands M20x1.5, for cable diameter 6-9mm

• EN 14744 (2005) + latest amendments

• IEC 60945 (2002) + latest amendments

• UL1104 (USA) + latest revisions

EC Type Approval

• Certificate No. : 34573/A (and latest revisions)

Quality System Approval

• Certificate No. : SMS.MED2.D/47678/B (and latest revisions)

Meets UL 1104 (United States of America)

• USCG accepted laboratory: ITL Boulder

• Report No.: ITL87872-REPORT OF CERTIFICATION-DHR60

• Date of Type-Test: 6th of April, 2018

INDEPENDENT TESTING LABORATORIES, INC

5Version 3.1 May 2018

Den Haan Rotterdam

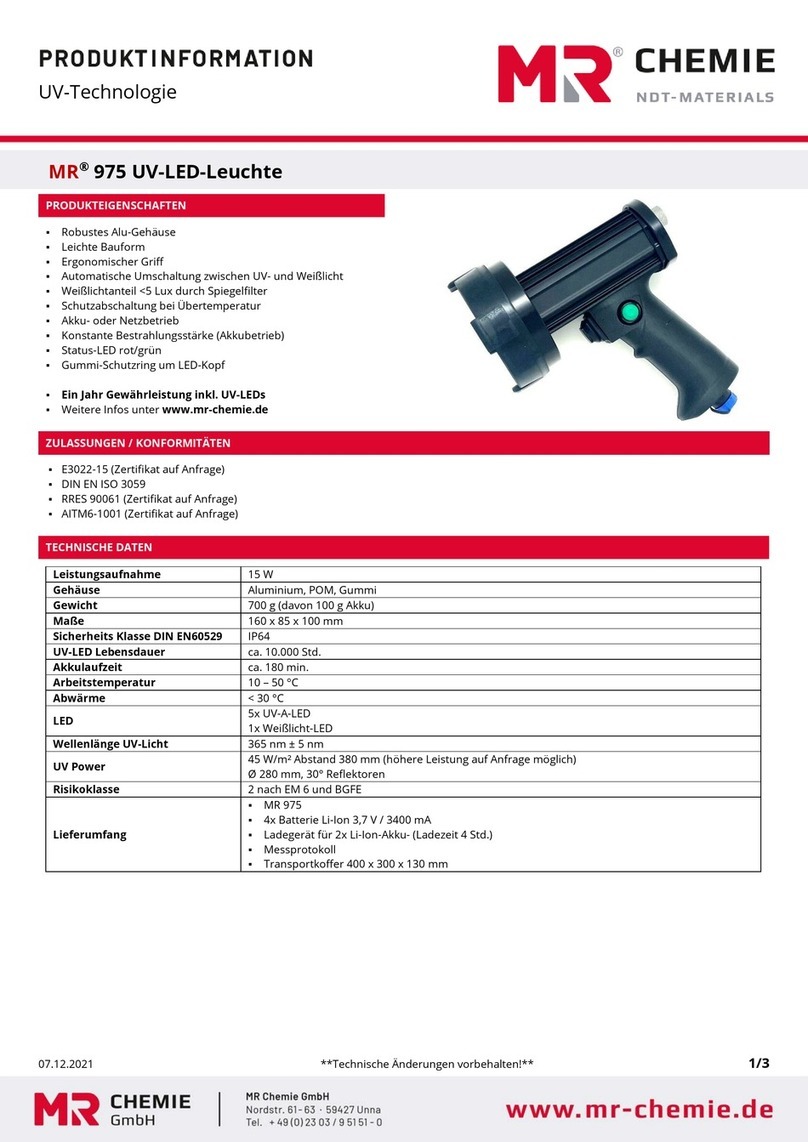

PRODUCT PHOTOS

6Version 3.1 May 2018

Den Haan Rotterdam

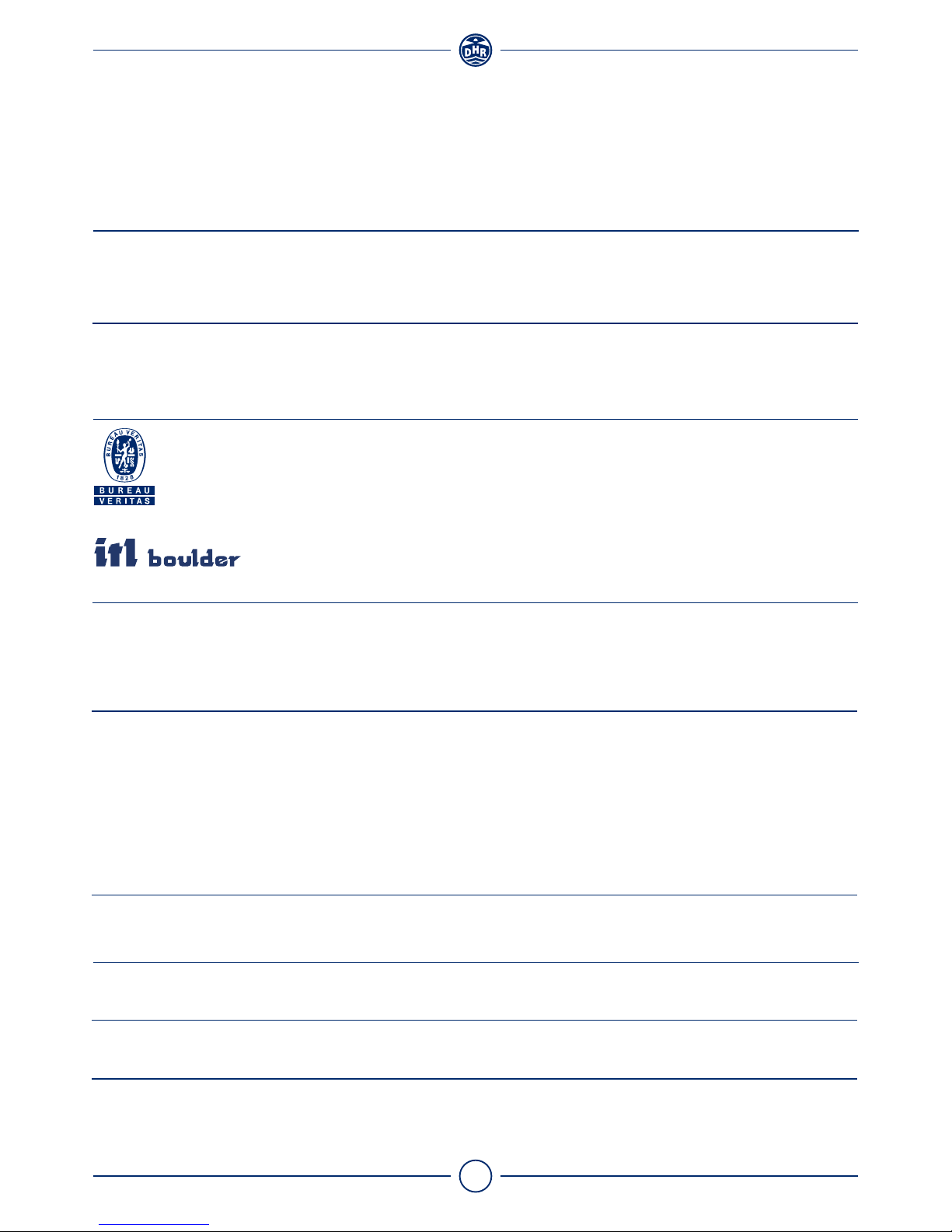

DIMENSIONS

All dimensions in mm.

120

120

Ø8,5

160

169

7Version 3.1 May 2018

Den Haan Rotterdam

AVAILABLE MODELS

Sector lights Min. Visibility Colour Nom. Power Art. Code

Starboard 2 NM Green 4,2 W 60.01.00.00

Port 2 NM Red 4,3 W 60.02.00.00

Masthead 5 NM White 11,7 W 60.03.00.00

Stern 2 NM White 4,1 W 60.04.00.00

Stern red (Suez) 2 NM Red 4,3 W 60.04.07.00

Towing 2 NM Yellow 4,3 W 60.04.09.00

Convoy light 1 NM Blue 4,1 W 60.04.10.00

All-round lights Min. Visibility Colour Nom. Power Art. Code

White 2 NM White 4,1 W 60.06.00.00

Manoeuvring 5 NM White 15,9 W 60.06.10.00

Red 2 NM Red 4,3 W 60.07.00.00

Red & White 2 NM Red/White 4,3 / 5,7 W 60.07.06.00

Red & Green 2 NM Red/Green 4,3 / 5,9 W 60.07.08.00

Green 2 NM Green 4,2 W 60.08.00.00

Yellow1) 2 NM Yellow 4,3 W 60.09.00.00

Blue 1 NM Blue 4,1 W 60.10.00.00

Screened lights2) Min. Visibility Colour Nom. Power Art. Code

White 180° 2 NM White 4,1 W 60.06.01.80

Red 180° 2 NM Red 4,3 W 60.07.01.80

Green 180° 2 NM Green 4,2 W 60.08.01.80

1. Yellow signal light to be used in conjunction with sound signal and only applicable for vessels navigating

the European Inland Waterways

2. - Screened navigation lights should NOT be considered as an official sectored navigation light, but as

two navigation lights with horizontal sectors that combined form a single all round light of 360°

- The interpretation of screened navigation lights are stipulated in IMO MSC.1/Circ.1260

8Version 3.1 May 2018

Den Haan Rotterdam

EXPLODED VIEW

Item Part Material

1 Cover Seawater resistant aluminium,

hard anodized black

2 Gasket Ø91x4mm EPDM - shore 30

3 Screen Seawater resistant aluminium,

hard anodized black

4 Glass Tube Borosilicate glass

5 Heatsink Seawater resistant aluminium

6 LED PCB MC-PCB, aluminium 1.55 mm

7 Cable gland M20x15 Body: Polyamide

Seal: Neoprene

Gasket 28x20x1,5 PTFE

8 Housing Seawater resistant aluminium,

hard anodized black

9 LED driver Potting material: Polyurethane

10 Base plate gasket EPDM - shore 30

11 Base plate Seawater resistant aluminium,

hard anodized black

12 Insulation sleeve Ø8,5 Delrin - black

13 Membrane Vent Body: Silicone rubber

Membrane: ePTFE

14 Plug M20x1,5 Polyamide

Gasket 28x20x1,5 PTFE

1

2

8

14

3

4

56

2

79

10

11

13

12

REPAIR KIT

Gasket Ø91x4 (2x)LED-Driver LED MC-PCB

Item Navigation light Description Number

A Starboard Maintenance kit for: green 60.99.00.30

All-round green

B Port light Maintenance kit for: red 60.99.00.31

Stern Red

All-round red

C Masthead Maintenance kit for: white 5NM 60.99.00.32

D Stern Maintenance kit for: white 2NM 60.99.00.33

All-round white

E Towing light Maintenance kit for: yellow 60.99.00.34

All-round yellow

F All-round blue Maintenance kit for: Blue 1NM 60.99.00.35

G Manoeuvring light Maintenance kit for: Manoeuvring 60.99.00.36

H All-round Red & White Maintenance kit for: Red & white 60.99.00.37

I All-round Red & Green Maintenance kit for: Red & Green 60.99.00.38

Base plate gasket

9Version 3.1 May 2018

Den Haan Rotterdam

ELECTRICAL SPECIFICATION

Grounding (PE) is not required, but gives better ESD/EMI protection

Navigation light Power Nominal Typical Typical Error Inrush

supply voltage wattage* current* current current

Starboard 350 mA 4,2 W 174 mA

Port 500 mA 4,3 W 179 mA

Masthead 700 mA 11,7 W 489 mA

Stern 350 mA 4,1 W 169 mA

Stern red (Suez light) 500 mA 4,3 W 179 mA

Towing 500 mA 4,3 W 179 mA

Convoy light 350 mA 24 VDC 4,1 W 169 mA >40 mA <10 mA 20 A

All-round white 350 mA 4,1 W 169 mA

All-round green 350 mA 4,2 W 174 mA

All-round red 500 mA 4,3 W 179 mA

All-round red/White 500 mA 4,3/5,7W 179/235 mA

All-round red/Green 500 mA 4,3/5,9W 179/244 mA

All-round yellow 500 mA 4,3 W 179 mA

All-round blue 350 mA 4,1 W 169 mA

* Depends on temperature and LED production series

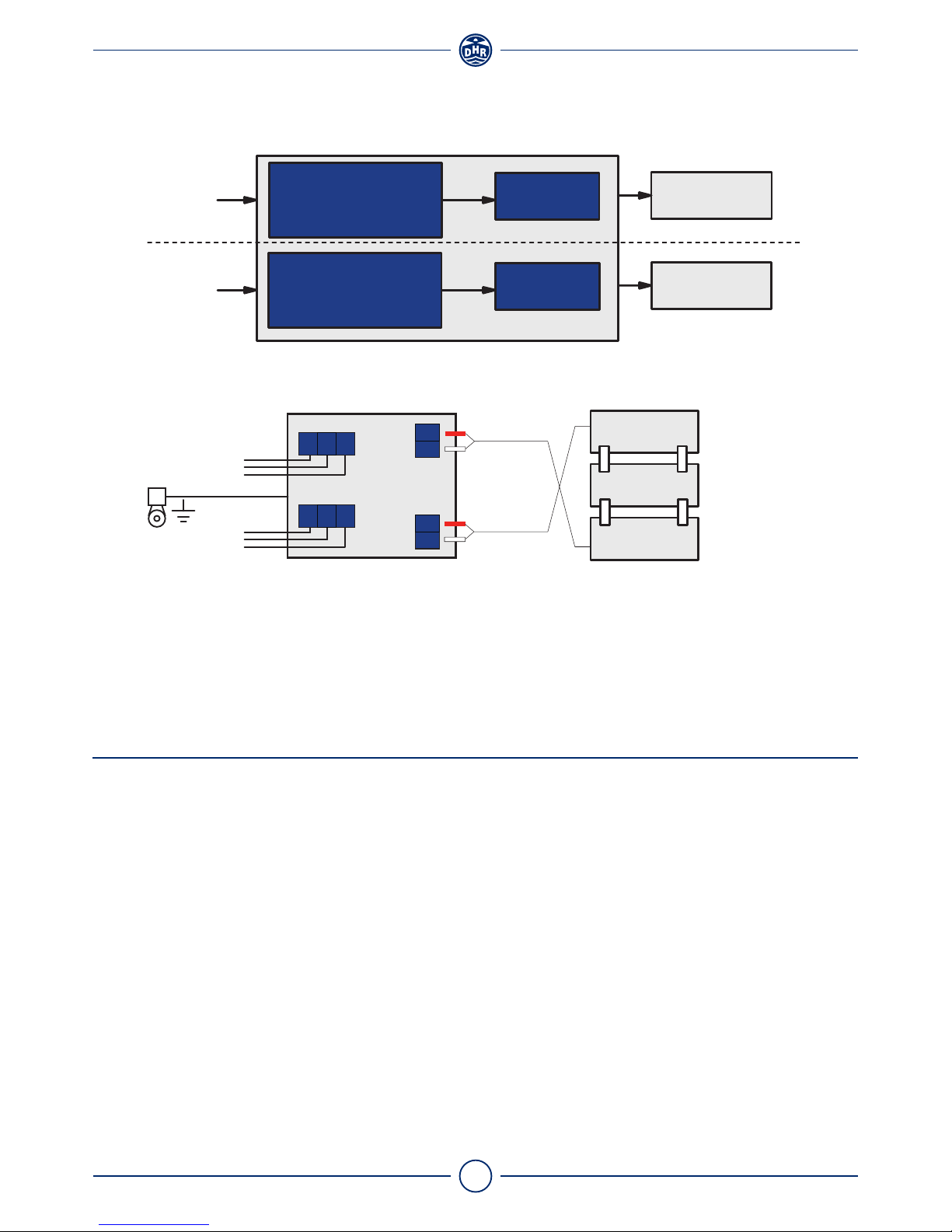

Power main

24VDC 3-5 LEDS

Output

LED DRIVER

LED driver LED PCB

Power spare

24VDC 3-5 LEDS

Output

LED DRIVER

Galvanic separation

(MAIN)

(SPARE)

PE

1

2

Spare 24VDC

Main 24VDC

1+

2 -

PE - +

1

2

1+

2 -

PE - +

Red cable ferrule

White cable ferrule

Red cable ferrule

White cable ferrule

Minimum

operating

current

10 Version 3.1 May 2018

Den Haan Rotterdam

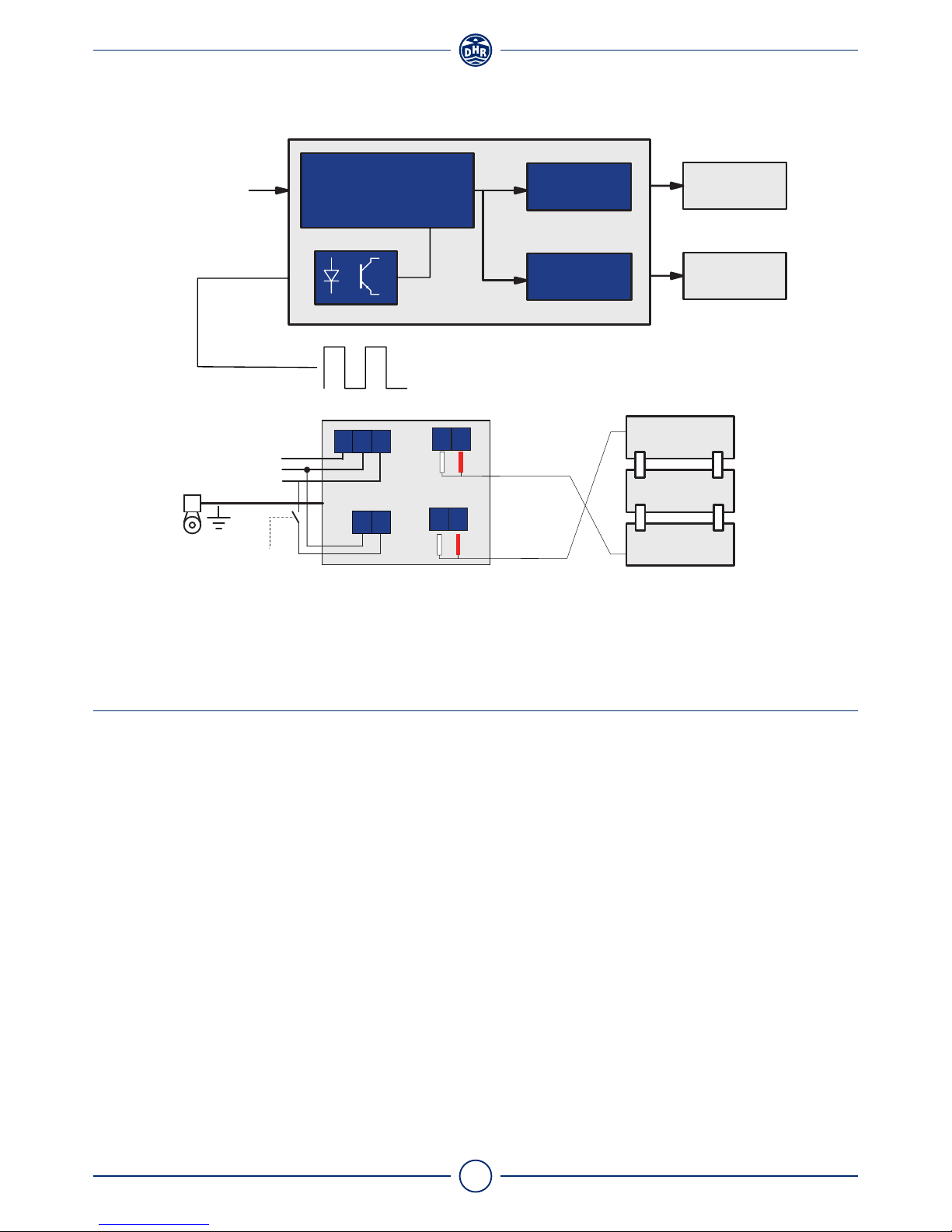

ELECTRICAL SPEC. MANOEUVRING LIGHT

Grounding (PE) is not required, but gives better ESD/EMI protection

Navigation light Power Nominal Typical Typical Error Inrush

supply voltage wattage* current* current current

Manoeuvring 700 mA 24 VDC 15,9 W 662 mA >40 mA <10 mA 40 A

* Depends on temperature and LED production series

Minimum

operating

current

LIFETIME CONTROL

Measurements of the navigation light and specifications retrieved from the OEM, show a conformity with the

minimum requirements of COLREG 72 at an operational lifetime of 50000 hrs. To guarantee a proper use of

the LED navigation lights, we as a manufacturer advise the following:

• Use the navigation light in combination with a DHR-specified control system, which monitors the status

and operational life time of each individual navigation light

• Each navigation light needs to undergo a quality check at least every 5 years of use to verify it still meets

the requirements of COLREG 72

Power 24VDC 3 LEDS

Output

LED DRIVER

LED driver LED PCB

3 LEDS

Output

PE - +

PE - +

Control

Signal

PE

+24VDC

OVDC

Control signal 24VDC

- +

- +

11 Version 3.1 May 2018

Den Haan Rotterdam

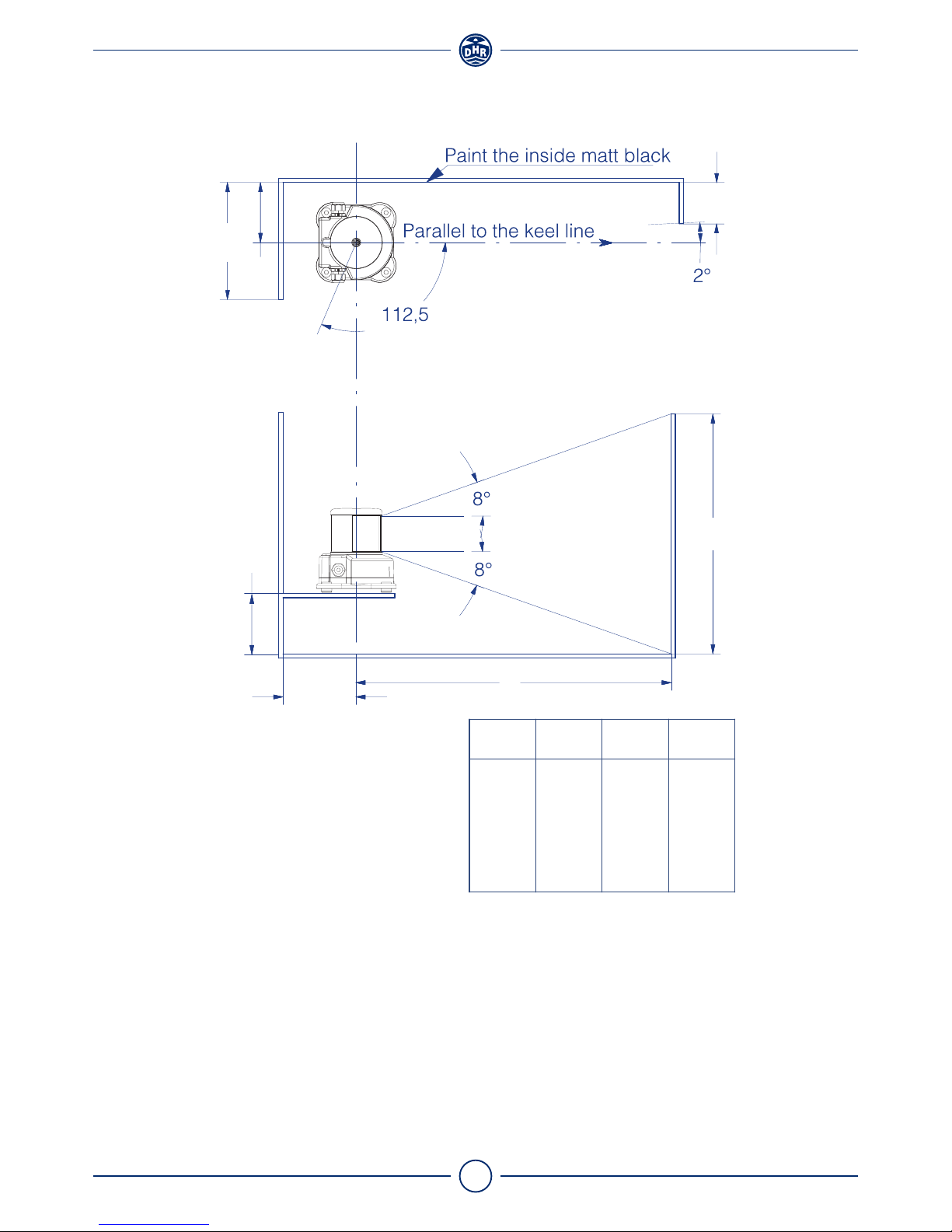

POSITIONING LIGHTS

Disclaimer:

• The minimum luminous intensity requirements in the forward direction are only guaranteed if the

sidelights are mounted in accordance with this drawing and table.

• This is an illustration to indicate the dimensions of the inboard screens, relative to the keel line of the

vessel. By no means may this image be used to determine the position of the sidelights on the vessel.

For positioning the lights at the vessel always check for compliance with COLREG 72 or local rules.

220

110

K

L

J

110

H

200

216

245

273

301

330

98

96

92

89

86

82

345

400

500

600

700

800

0

8

22

36

50

64

H

LKJ

[mm]

12 Version 3.1 May 2018

Den Haan Rotterdam

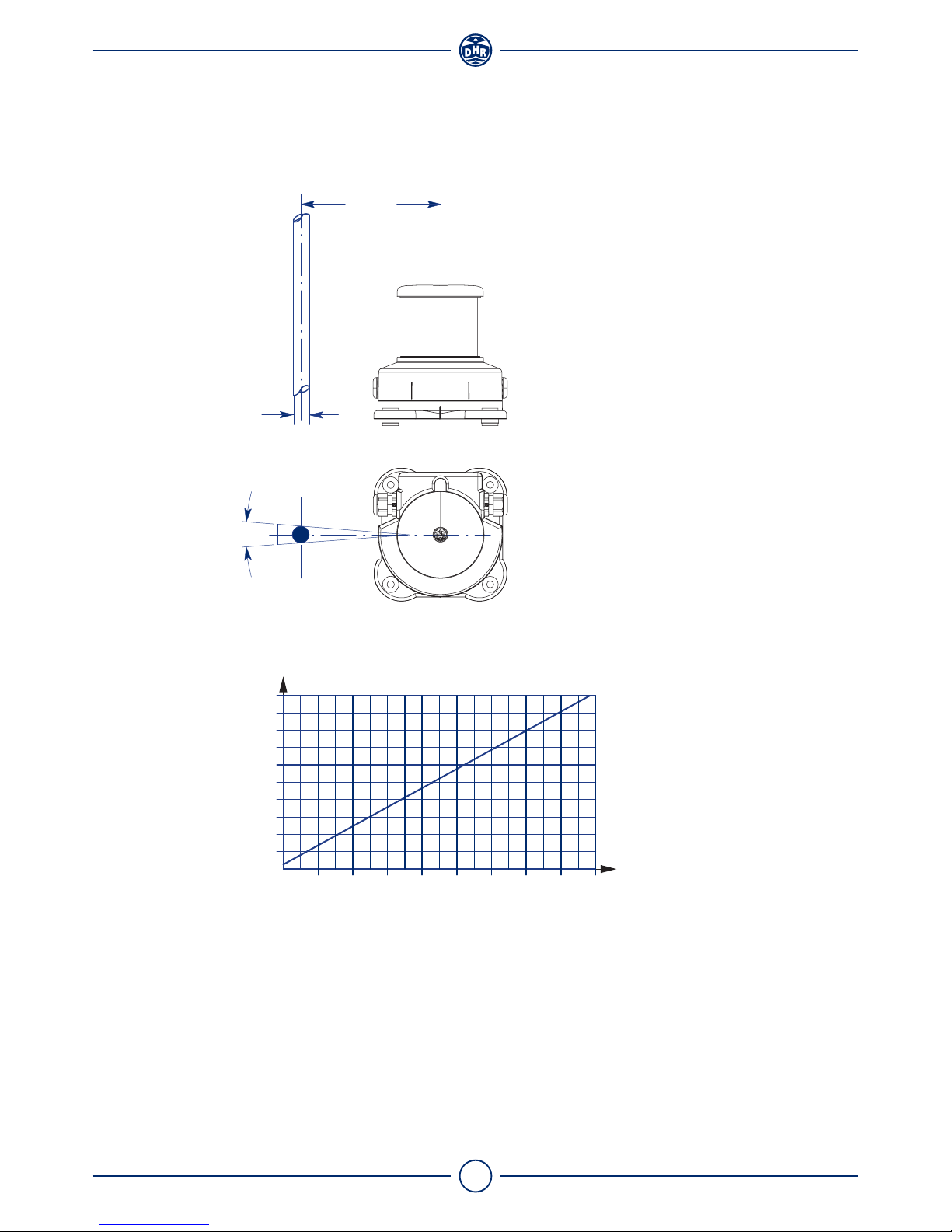

POSITIONING ALL-ROUND LIGHT

Disclaimer:

This is an illustration to indicate the position of the all-round light so not to be obscured by mast, topmasts

or structures within the angular sector of more than 6 degrees. By no means may this image be used to

determine the position of the all-round lights on the vessel. For positioning the lights on the vessel always

check for compliance with COLREG 72 or local rules.

D

1000

180

1600

100 S

160

140

120

200

14001200 1800

Diagram for choosing the minimum distance between

obstacle and mounting plate.

S[mm]

D[mm]

6°

13 Version 3.1 May 2018

Den Haan Rotterdam

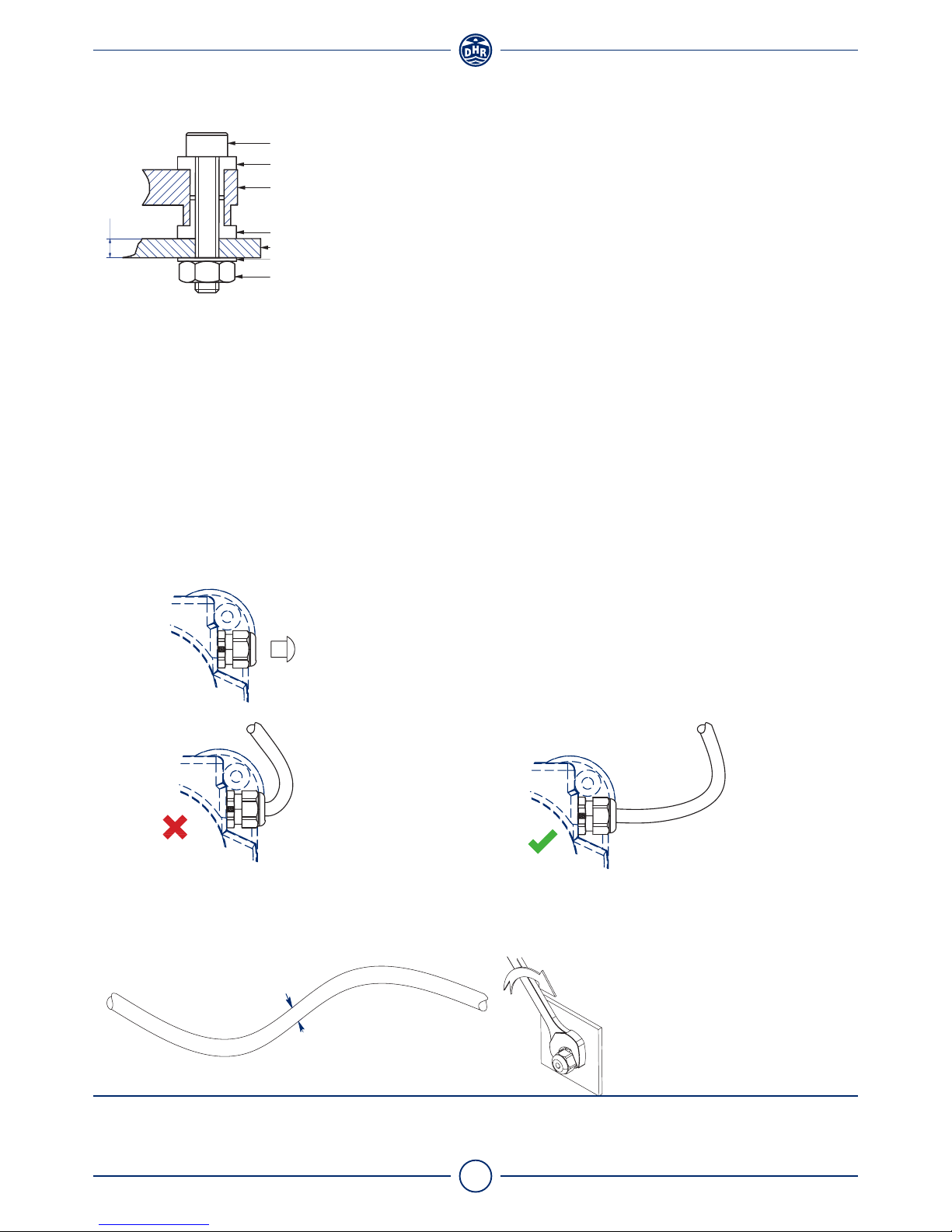

MOUNTING INSTRUCTIONS

Mounting plate

The mounting plate for navigation lights should be at least 3 mm thick and should not exceed a parallelism

of // 00,5.

Fasteners

• The permissible torque should be 6 Nm

• Use only A4-grade stainless steel

Caution!

Even though the housing is made of corrosion resistant materials, galvanic corrosion may still occur.

To prevent galvanic corrosion use the insulation sleeves to isolate the aluminium housing from other

metal parts.

Cable glands

Important

Do not paint or use any other chemical for the lanterns, clean only with fresh water.

Bolt M8 x (35 + M)

Insulation sleeve

Lantern base

Insulation sleeve

Washer M8

Mounting plate Min. 3 mm

Nut M8

M

All dimensions in mm

ØD

Preferred cable diameter D is 6 - 9 mm

Cable too tight!

This gives unwanted stress at the sealing of the

cable gland and water ingress will occur.

Include cable slack at the entering

point of the cable gland

Replacing cable gland

• Use gasket between housing

and cable gland

• Tighten firmly (6Nm) with

wrench

Remove the plug before placing the cable.

If no cable is connected leave the plug in place!

14 Version 3.1 May 2018

Den Haan Rotterdam

Wiring recommendations

EU:

• Neoprene cable H07 RN3x1.5

• Cable diameter 6 - 9 mm

USA:

• Type SJ or equivalent and comply with UL 62 and IEEE 45- 83

• Wire gauge16 AWG

• No. of conductors 3

• Cable diameter 6 - 9 mm

15 Version 3.1 May 2018

Den Haan Rotterdam

S

I

N

C

E

1

9

2

2

ADVANCED MARITIME

SIGNALLING SOLUTIONS

Den Haan Rotterdam

Fascinatio Boulevard 1182

2909 VA Capelle a/d IJssel

The Netherlands

T+31 (0) 10 413 07 55

Esales@dhr.nl

www.dhr.nl

Table of contents

Other DHR Lighting Equipment manuals