Energetiq LDLS EQ-1500 User manual

Model EQ-1500

LDLS™

Laser-Driven Light Source

Operation Manual

Revision 6 March 2013

Part Number DOC-4958

ii

Copyright © 2013 Energetiq Technology Inc. All rights reserved.

Energetiq products are covered by US and foreign patents. All technical information, including

drawings, schematics and specifications contained in this manual are the property of Energetiq

and shall not be reproduced in whole or in part without the written consent of Energetiq. The

content of this manual is subject to change without notice.

Energetiq Technology Inc.

7 Constitution Way, Woburn, MA 01801 USA

Tel. +1 (781) 939-0763

Fax +1 (781) 939-0769

E-mail: [email protected]

http://www.energetiq.com

i

ii

Declaration of Conformity

We, the manufacturers

Energetiq Technology Inc.

7 Constitution Way

Woburn, Massachusetts USA

hereby declare that the product

LDLS™ Laser-Driven Light Source

Model EQ-1500 Extreme High Brightness Broadband Light Source

is in conformity with the requirements of the following standards

EN61010-1 (2001) Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use: Part 1 –

General Requirements

CISPR 11:2003 Industrial, scientific and medical equipment - Radio-

frequency disturbance characteristics - Limits and methods

of measurement

IEC61000-3-2:2006 Harmonic Emissions

IEC61000-3-3:1995 Fluctuations and Flicker

+ A1:2001 + A2:2005

IEC61000-4-2:2001 Electrostatic Discharge Immunity

IEC61000-4-3:2002 Radiated Electromagnetic Field Immunity

IEC61000-4-4:2004 Electrical Fast Transient Burst Immunity

IEC61000-4-5:2001 Surge Immunity

IEC61000-4-6:2003 Radio Frequency Common Mode Immunity

IEC61000-4-8:1994 Power Frequency Magnetic Field Immunity

IEC61000-4-11:2004 Voltage Interrupts

EN61326-1:2006 Electrical equipment for measurement, control and

laboratory use. EMC requirements. General requirements

EN60825-1 (2007) Safety of laser products - Part 1: Equipment classification

and requirements

in accordance with the provisions of

2006/95/EC EU Low Voltage Directive

2004/108/EC EU Electromagnetic Compatability Directive.

Signed,

25 July 2011

Paul Blackborow, CEO Date

at Woburn, Massachusetts USA

i

v

v

TABLE OF CONTENTS

Chapter 1............................................................................................................................................... 1

General Information.................................................................................................................... 1

Safety........................................................................................................................................ 1

Chapter 2............................................................................................................................................... 9

Description .................................................................................................................................... 9

General.................................................................................................................................... 9

Specifications.......................................................................................................................... 9

Identification of Controls .................................................................................................. 11

Controller Unit .................................................................................................................... 11

Lamp House Unit ............................................................................................................... 15

Chapter 3............................................................................................................................................. 19

Installation ................................................................................................................................... 19

Unpacking............................................................................................................................. 19

Facilities Connections......................................................................................................... 19

Installation procedure......................................................................................................... 23

Chapter 4............................................................................................................................................. 27

Operation..................................................................................................................................... 27

Remote Mode ...................................................................................................................... 28

Chapter 5............................................................................................................................................. 31

Maintenance and Troubleshooting ......................................................................................... 31

Fiber Cleaning Process....................................................................................................... 31

Troubleshooting .................................................................................................................. 34

v

i

EQ-1500 Operation Manual Rev 6 1

Chapter 1

GENERAL INFORMATION

Safety

WARNING

CAUTION

The EQ-1500 emits dangerous levels of UV radiation. Even short

exposures to skin or eyes may cause burns. Ensure that only

authorized personnel are in the vicinity of source during operation.

Personnel in vicinity of operating source should wear protective

eyewear, clothing, and gloves. Lighted UV warning lights and signs

posted on doors to lab areas may help prevent accidental exposure.

This unit emits ultraviolet (UV) radiation that is harmful to humans.

Avoid exposure to the direct or reflected output beam. Make certain

that the appropriate output beam shields and optics are in place prior

to energizing the unit. All interlocks must be satisfied prior to

operation; failure to do so may lead to hazardous conditions.

EQ-1500 Operation Manual Rev 6

2

WARNING

General Precautions

The output beam from the EQ-1500 should be blocked when not in use with an electronic

shutter or other appropriate beam blocking device. Due to the absorption of the short

wavelength light and the possibility of ozone production, the beam should always be either

directly coupled to a fiber optic cable, or enclosed in an appropriate beam pipe, tube, or

enclosed space. We suggest purging any beam transport space with dry Nitrogen gas, as this is

also required for safe operation of the EQ-1500.

The source must be purged with dry nitrogen gas via the nitrogen input connector on the lamp

head. The unit must be purged for a minimum of 10 minutes prior to operation in order to

ensure that no ozone is created by residual oxygen inside the unit. It is recommended that any

beam transport be purged for a similar amount of time.

The EQ-1500 controller must be connected to an appropriate closed-loop water chiller

system. The water system must be capable of maintaining 0.5gpm at 22°C with a minimum of

200W cooling capacity

The EQ-1500 source must also be cabled correctly and connected to a socket with a protective

earth ground prior to operation. Failure to do so may result in an electrical shock hazard.

Refer to the Installation section of this manual (Chapter 3) for details of the facilities

connections.

The EQ-1500 utilizes an internal Class 4 IR laser

capable of causing severe injury to eyes or skin. Do

not open or attempt to service this unit. Contact

Energetiq regarding any problems with the unit.

EQ-1500 Operation Manual Rev 6 3

There are no user-serviceable parts inside the EQ-1500. For any problems encountered during

operation, please refer to the Troubleshooting section of this user manual. If there is a

component failure, do not attempt to open the chassis of the EQ-1500.

The EQ-1500 utilizes a quartz lamp containing a high-pressure gas fill. Explosion of the lamp

and possible injury from flying fragments can occur if the lamp is mishandled. Never attempt

to remove or replace the lamp. If there is a failure of the lamp, the unit must be shipped

back to the factory for refurbishment.

Do not open the chassis of either the lamp unit or the power supply unit. Dangerous

invisible infrared laser beams and hazardous voltages exist inside the units. Opening

the chassis both voids the warranty and exposes the user to dangerous radiation and hazardous

voltages.

CAUTION

CAUTION

The EQ-1500 must be operated for its intended use and as

described in this operating manual. Operation in an un-intended

manner may result in dangerous conditions.

Use of controls or adjustments or executing procedures other

than those specified herein may result in hazardous radiation

exposure.

EQ-1500 Operation Manual Rev 6

4

Laser Information

The EQ-1500 uses a patented (U.S. Patent #7,435,982, others pending) laser drive system to

excite a plasma that radiates in the UV as well as the visible bands. Since the lamp unit

contains an embedded laser, the EQ-1500 is defined as a Laser Product. However, the drive

laser does not exit the system.

The parameters of the non-accessible internal laser are given below in Table 1.

Wavelength 975 nm

Emission Type CW

Laser Power for classification <40 mW via 7mm measurement

aperture

Beam Diameter ~25 mm at aperture

Divergence >100 mRad

Transverse Beam Mode Highly irregular, diffuse

Table 1: Embedded Laser Parameters

No regular service or maintenance is required. Any service to the system must be performed

only by factory authorized and trained technicians. To avoid eye injury, under no

circumstances should the user open or modify the lamp unit.

The unit must not be operated if the covers are removed or it is defective in any way. Contact

Energetiq if any problems with the equipment are suspected.

Labels and Safety Notification

The following safety labels appear on the product. Figure 1 shows the location of each label

on the EQ-1500 lamp unit.

UV Hazard warning label – indicates hazardous levels of UV

light are present.

EQ-1500 Operation Manual Rev 6 5

Manufacturer’s identification label – gives the manufacturer’s

name and address, and the model, serial number, and date of

manufacture of the equipment.

Explanatory label – states the classification of the laser product.

Class 1 is the lowest hazard level classification.

Certification label – states that the equipment has been tested

and verified to meet the standards indicated.

Interlocked housing label – notifies of a potential hazard when

covers are removed and interlocks failed or defeated.

Protective Ground (Functional Earth) symbol

EQ-1500 Operation Manual Rev 6

6

Figure 1: Safety label locations

Cover Interlocks

The EQ-1500 is equipped with cover interlock switches to prevent operation of the source

without the lamp unit and controller covers in place. Since no user service is permitted, these

switches are intended for the protection of factory service personnel.

External Interlock

An external interlock connector is provided for the customer’s use. Any suitable

normally-open contact can operate the interlock circuit. The unit is shipped with a shorted

connector which may be used to connect to the user’s interlock circuitry. The interlock circuit

must not be grounded.

Interlocked

Housing Label Explanatory

Label

Interlocked

Housing Label

UV Warning

Label Manufacturer’s ID

Label

Certification

Label

Functional

Earth Symbol

EQ-1500 Operation Manual Rev 6 7

The interlock circuit must be connected to enable the operation of the unit. Should the

interlock connection open during operation or standby, the source is immediately disabled, and

all light output from the aperture ceases. The source is then latched off and will not restart

until the interlock is restored and the lamp manually restarted.

EQ-1500 Operation Manual Rev 6

8

EQ-1500 Operation Manual Rev 6 9

Chapter 2

DESCRIPTION

General

The EQ-1500 is a DUV lamp system for a wide variety of applications. The lamp features

high brightness, broad-band light from DUV wavelengths through visible and beyond. The

output is very stable, and has a long lifetime before any service is required. The interface is

quite simple, but robust enough for any lab or industrial environment.

The EQ-1500 system consists of a Controller unit, Lamp House unit, interconnecting

signal/power cable, and interconnecting laser fiber optic cable. Connections to AC power,

cooling water, and purge gas are required for operation.

The Controller unit contains the IR laser, laser power supply, laser cooling, a permanently

attached laser fiber optic cable, and control electronics.

The Lamp House unit contains the lamp, igniter, laser focusing optics, and interlocks.

Specifications

DUV Performance

Typical output spectrum: see Figure 2.

oUpper, Blue line: typical EQ-1500 output

oLower, Red line: typical D2 lamp output

EQ-1500 Operation Manual Rev 6

10

Figure 2: Typical output spectrum

Physical Specifications

System Dimensions (H x W x D), Weight

Lamp House 175 x 142 x 218 mm (6.9 x 5.6 x 8.6 in)

Controller 142 x 254 x 419 mm (5.6 x 10.0 x 16.5 in)

Weight

Lamp House 5 kg (11 lbs)

Controller 6.5 kg (14.3 lbs)

Utility Requirements

Electrical 100–120/200–240 VAC ±10%, 50/60Hz, 300VA max.

Fuse: 250VAC, 8A Fast

Cooling Water 0.03–0.07 MPa (5–10 psi) differential, 1.9–3.8 lpm (0.5–1 gpm),

22°C inlet temperature, controlled within ± 1.0°C

Purge Gas: Dry nitrogen, grade 6 preferred, 0.14 MPa (20 psig), 1 slpm, filtered to

5um

0.001

0.01

0.1

1

10

100

180 280 380 480 580 680 780

Wavelength (nm)

Spectral Radiance (mW/mm^2/nm/sr)

EQ-1500 Operation Manual Rev 6 11

Environmental Requirements

Operating

Temperature: 5–40°C

Relative Humidity: non-condensing, 80% max. for temperatures up to 31°C,

decreasing linearly to 50% max. at 40°C

Altitude: 2000 m (6562 ft) max.

Pollution Degree 2 (normally only non-conductive pollution; occasional,

temporary condensation possible)

Installation Category II

Indoor use only

Transport

Temperature: -5–95°C

Relative Humidity: non-condensing, 95% max.

Identification of Controls

The following sections show the location of controls and other features, and give an overview

of their functions. Refer to the “Installation” section of this manual (Chapter 3) for more

detailed information.

Controller Unit

Figure 3: Controller front panel

Operation

Selector Switch

Status Indicator

LEDs

EQ-1500 Operation Manual Rev 6

12

Operation Selector Switch

Momentary switch used to start or stop UV light output, or to clear a Fault condition.

Status Indicator LEDs

Lamp controller Status

LEDs

LED

Color

Functional Description

Power Green AC power is applied and power switch is on

Controller Interlock OK Green All interlocks in the Lamp Controller are

satisfied

Lamp House Interlock OK Green All interlocks in the Lamp House are

satisfied

External Interlock OK Green External interlock is satisfied

Remote Control Green Remote Control has been activated via

connector J6. Local Control via the front

panel Operation Selector Switch is disabled.

Laser On Green Laser current is on (Lamp on command has

been asserted)

Lamp On Green Plasma has ignited and is operating

Lamp House Overtemp Red Bulb housing temperature has exceeded 90C

(cooling failure)

Lamp Controller Overtemp Red Safety interlock for cold plate temperature

has exceeded 70C (cooling failure)

Laser Overtemp Red Unit has shut off due because laser

temperature has exceeded 40 degC. Cooling

water flow or temperature for Lamp

Controller is insufficient.

Excess Laser Current Red Laser current has exceeded 9A (does not

stop operation)

Laser Fault Red Indicates that the laser has been disabled

due to a fault. The Controller has requested

laser power, but an IR sensor in Lamp

House did not detect laser power.

Prior to Ignition:

1. The unit has shut down due to a

separate interlock fault

2. The plasma has failed to ignite.

3. A failure has occurred in the laser

fiber.

After Ignition:

1. A failure has occurred in the laser

fiber or laser delivery optics.

Table 2: Front Panel LED functions

EQ-1500 Operation Manual Rev 6 13

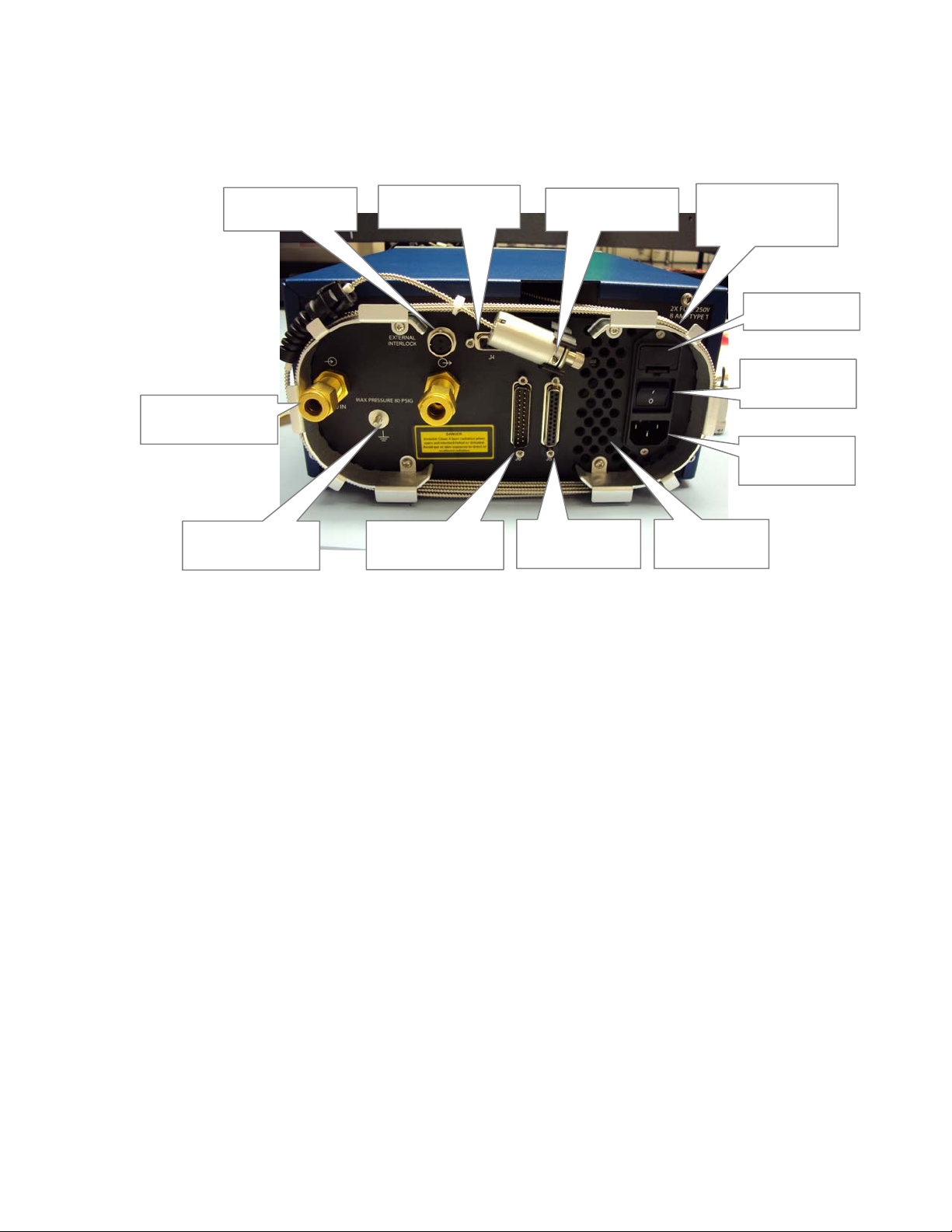

Figure 4: Controller rear panel

Interlock Connector

Connection point for a user-supplied external interlock contact. Contact must be closed or

connector jumpered to enable operation. We recommend that any door or enclosure switches

in the user’s system be wired in series with this interlock connection.

Laser Connection to Lamp House

Connects to the Lamp House to supply laser energy to the lamp via the fiber cable.

J4 Remote Sensor Connector

Connection point for a user-supplied photosensor, when using remote control/remote sensing

mode.

Interlock

Connector

J5 Lamp House

Connector

Power Entry

Connector

Power On/Off

Switch

Fuse Drawer

Cooling Fan

Exhaust

J6 Remote

Control Connector

J4 Remote Sensor

Connecto

r

Armored Laser

Fiber (coiled for

storage)

Cooling Water

Connections

Functional Earth

Terminal

Laser Connection

to Lam

p

House

EQ-1500 Operation Manual Rev 6

14

Armored Laser Fiber

Transmits laser energy from the Controller to the Lamp House. Handle the fiber gently and

avoid creating sharp bends or kinks in the cable. Minimum bend radius for the cable is 30 mm

(1.2 in). See instructions in Chapter 3 under “Installation Procedure” for details on inspecting,

cleaning and installing the fiber.

Fuse Drawer

Two AC line fuses are installed in this fuse holder. The fuse type is 250V, 8A, Fast, 5 x 20mm

Power On/Off Switch

This switch is used as a main AC power switch. It can also be used as an emergency off

switch.

Power Entry Connector

The power input connection to the EQ-1500 is made via a standard IEC 3-pin power entry

module. A power cable is included with the system, but any standard cable can be used.

Cooling Fan Exhaust

The internal laser power supply is air cooled. To avoid overheating, do not obstruct this fan

exhaust.

J5 Lamp House Connector

Provides power and control signals to the Lamp House. No connector or cable may be used

with the EQ-1500 other than the one supplied.

J6 Remote Control Connector

Provides access to control and status signals when operating the EQ-1500 in remote control

mode.

Cooling water connections

Standard Swagelok® connectors for cooling water supply and return, providing cooling for the

internal diode laser.

Table of contents

Other Energetiq Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

ALPHA LITE

ALPHA LITE DS-PAD User manual book

ML Accessories

ML Accessories NH023AW Installation & maintenance manual

Cooper

Cooper Metalux CGTS NUV instructions

Heitronic

Heitronic 39689 installation instructions

Linergy

Linergy PRODIGY PR08F10EBR Installation and use instructions

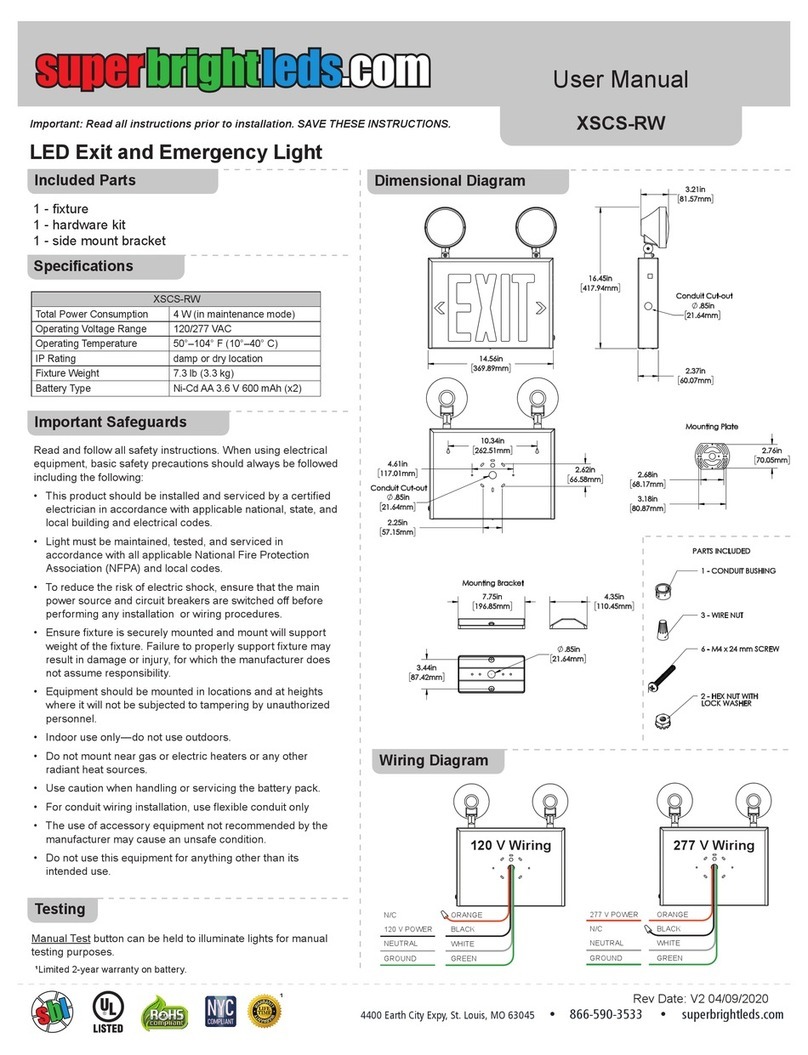

superbrightleds

superbrightleds XSCS-RW user manual