Industrial LED Combination Exit/Emergency Light

DYNC C1D2 Series

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should

always be followed including the following.

READ AND FOLLOW ALL SAFETY

INSTRUCTIONS

1. Do not use outdoors (unless suitable for damp location)

2. Do not mount near gas or electric heaters

3. Equipment should be mounted in locations and at heights where it will not readily be

subject to tampering by unauthorized personnel.

4. The use of accessory equipment not authorized by the manufacturer may cause an

unsafe condition.

5. Do not use this equipment for other than its intended purpose.

6. Servicing of this equipment should be performed by qualified service personnel.

7. Test cycling: the Life Safety Code (NFPA 101) requires testing of emergency lighting

units once a month for a minimum of 30 seconds, and once a year for a minimum of

90 minutes.

INSTALLER:

•SEE UNIT LABEL FOR ADDITIONAL MODEL SPECIFICATIONS

•SAVE THESE INSTRUCTIONS FOR USE BY OWNER/OCCUPANT

RECYCLING INFORMATION

All steel, aluminum and thermoplastic parts are recyclable.

NOTICE: Emergency units contain rechargeable batteries which

must be recycled or disposed of properly.

Hubbell Lighting, Inc. Life Safety Products • www.dual-lite.com

Copyright©Hubbell Lighting, Inc., All Rights Reserved • Specifications subject to change without notice. • Printed in U.S.A.

93117090_A 10/19

Service / Maintenance

Maintenance

This emergency lighting unit should be tested and maintained in accordance with National Electrical Code and NFPA 101 Life Safety

Code requirements. It is recommended that emergency light xtures be tested for 30 seconds once a month and for 90 minutes

once a year.

Taking A Unit Out of Service

If a unit is to be deliberately taken out of service for an extended period, the battery lead connector should be disconnected from

the charger circuit board and insulated so that the battery will go into storage in a fully charged condition.

Replacing the Battery:

1. De-energize the AC power.

2. Remove the bottom electronic housing cover.

3. Disengage the battery and heater (if provided) harness from the charger PCB harness.

4. Disconnect the battery strap and remove battery pack.

5. Replace with new battery (see unit model label or battery label for correct p/n)

and repeat steps above in reverse.

Replacing LED Lamps

The LED lamps inside the exit and the lamp heads are not replaceable or eld servicable.

Troubleshooting

Emergency circuit does not work

• Batteries are shipped uncharged, please charge for 24 hours before testing.

• Make sure the switch pcb and the button/light pipe is correctly seated and aligned.

• Check wiring connections.

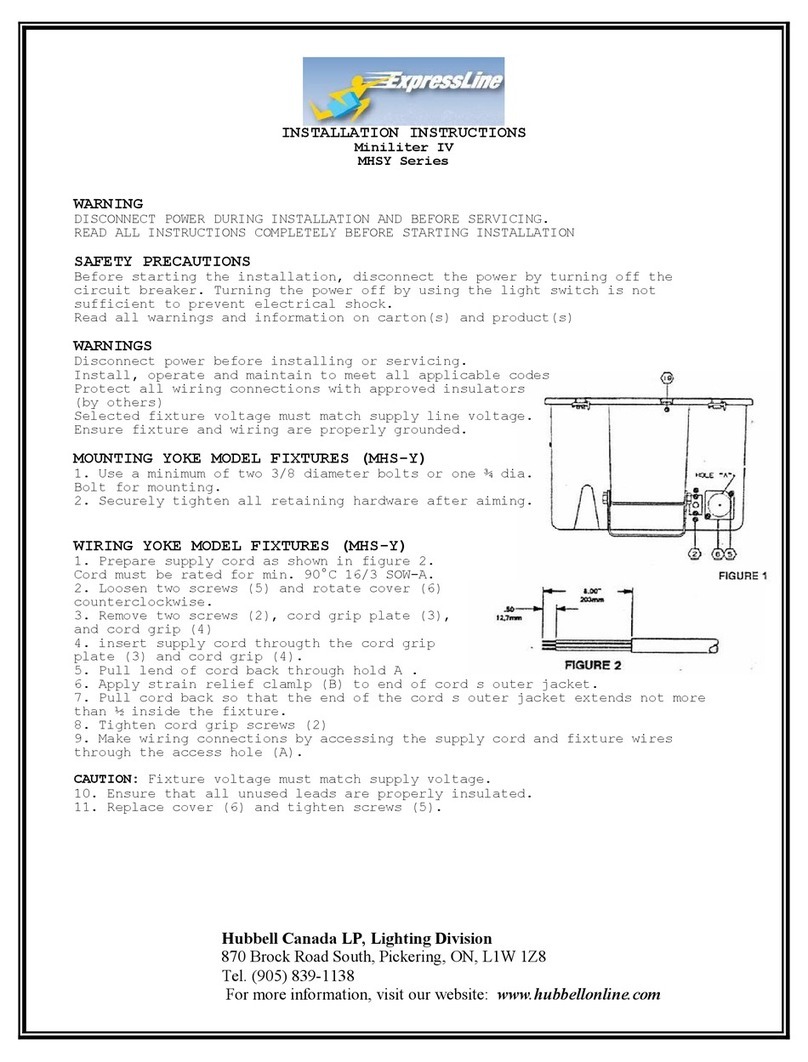

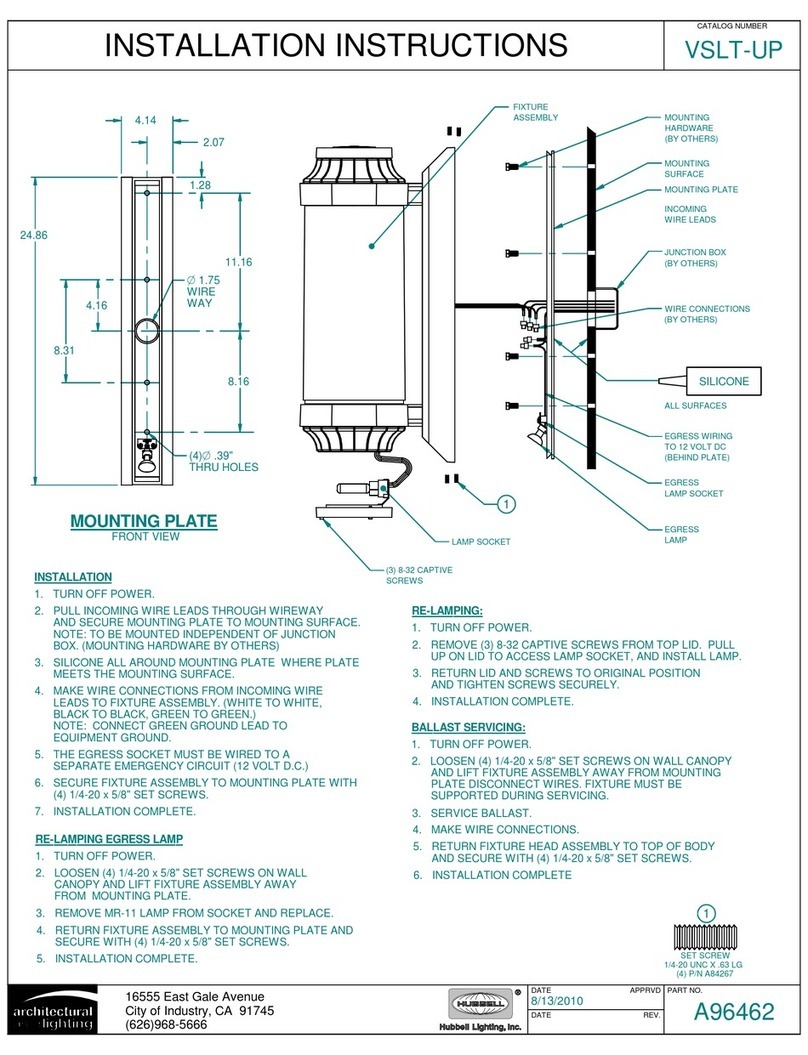

INSTALLATION

This Industrial Unit is designed to be mounted on a wall, ceiling or end mount. Provide standard units with a single unswitched

power supply from a 120/277VAC branch circuit used for normal lighting in the areas to be protected.

The DYNC Industrial exit combo is equipped with intelligent wiring. Connect the black wire from unit to the building hot wire

(120 or 277VAC) and the white wire to the building com wire.

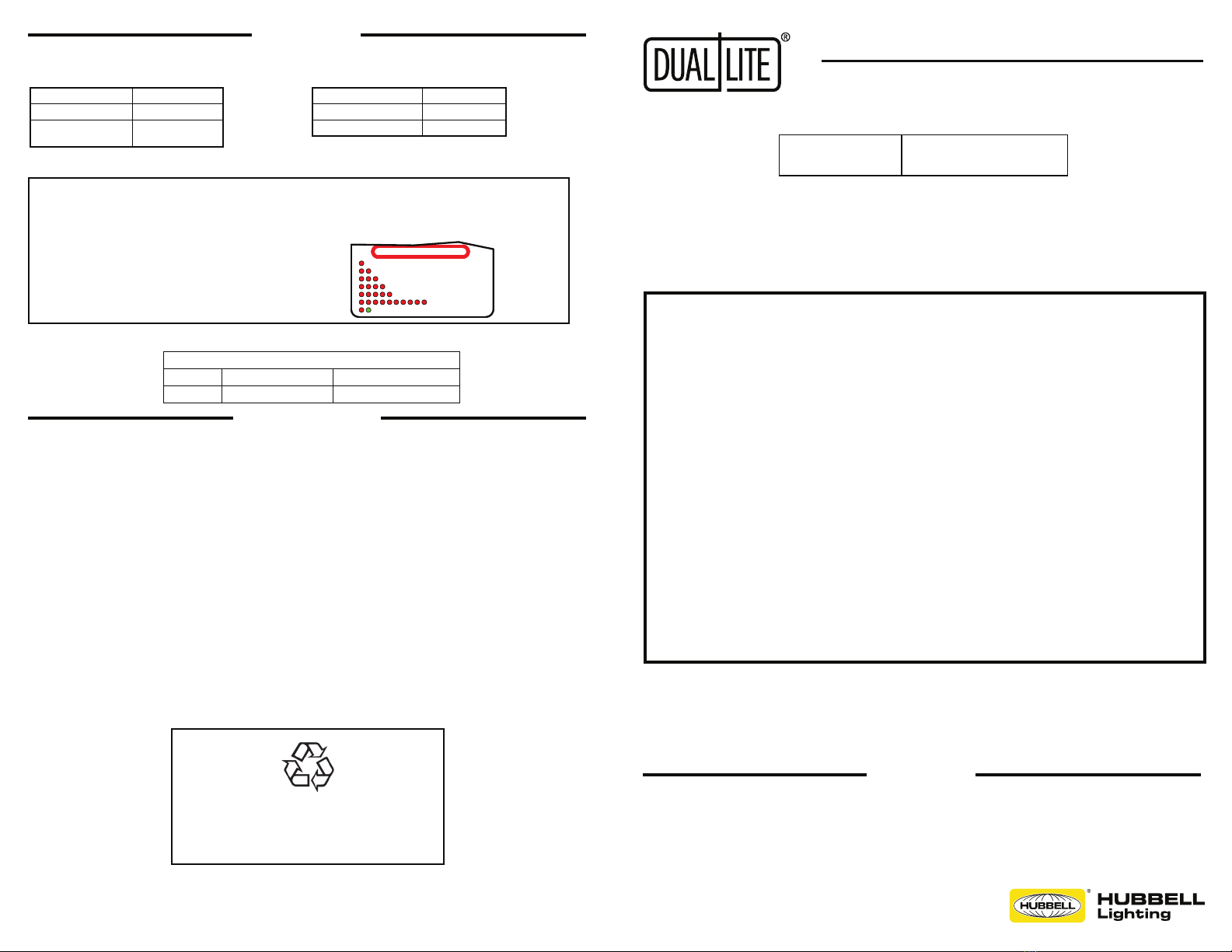

Automatic Tests

The unit will automatically initiate a self-test/self-diagnostic cycle

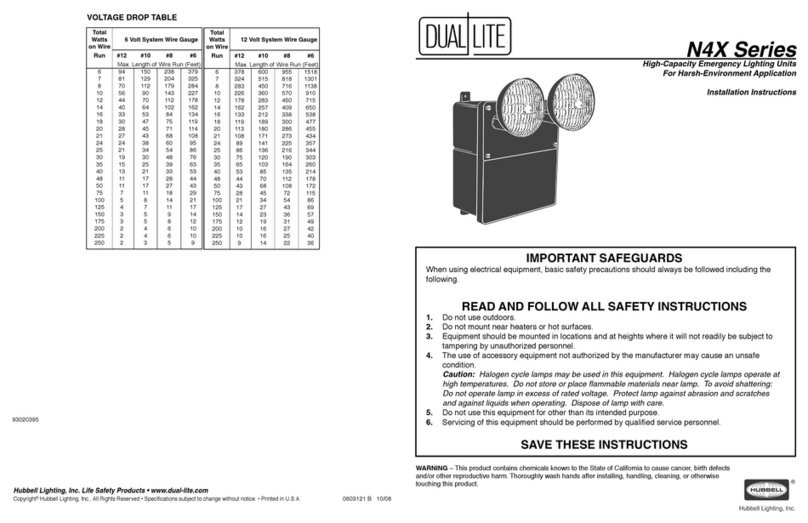

based on the following table:

Testing Period Duration of Test

Once a month 1 minute

Once every 6 months Alternating:

30 or 60 minutes

Manual Tests

Using the unit test switch, users can initiate different duration test

cycles based on the following table:

Initiating Action Test Cycle

Press test switch once 1 minute

Press test switch twice 90 minutes

Pressing the test switch any time after a 90 minute test cycle has

begun cancels the remainder of the 90 minute test and returns

the unit to normal operation.

LED Status Indicator:

A green/red LED is provided on the control pane

of all models equipped with the Spectron option.

Green Operating Status LED:

The green Operating Status LED serves as both an AC pow-

er and self-test indicator. During normal operation, the green

Operating Status LED will be illuminated, indicating the

presence of AC power. During all automatic or manual self-

test cycles, the green Operating Status LED will blink “twice”

per second for the 30 / 60 / 90 minute test.

Red Service Alert LED:

Under normal operating conditions, the red Service Alert

LED indicator will remain off. If the Spectron controller

detects a malfunction, the red Service Alert LED will blink

in the pattern listed on the label around the test button.

OPERATION

= LAMP FAULT

= LED DRIVER FAULT

= CHARGER FAULT

= BATTERY FAULT

SERVICE ALERT CODES

= BATTERY DISCONNECTED

= LOAD LEARN FAILURE

ALTERNATING = LOAD LEARN IN PROGRESS

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

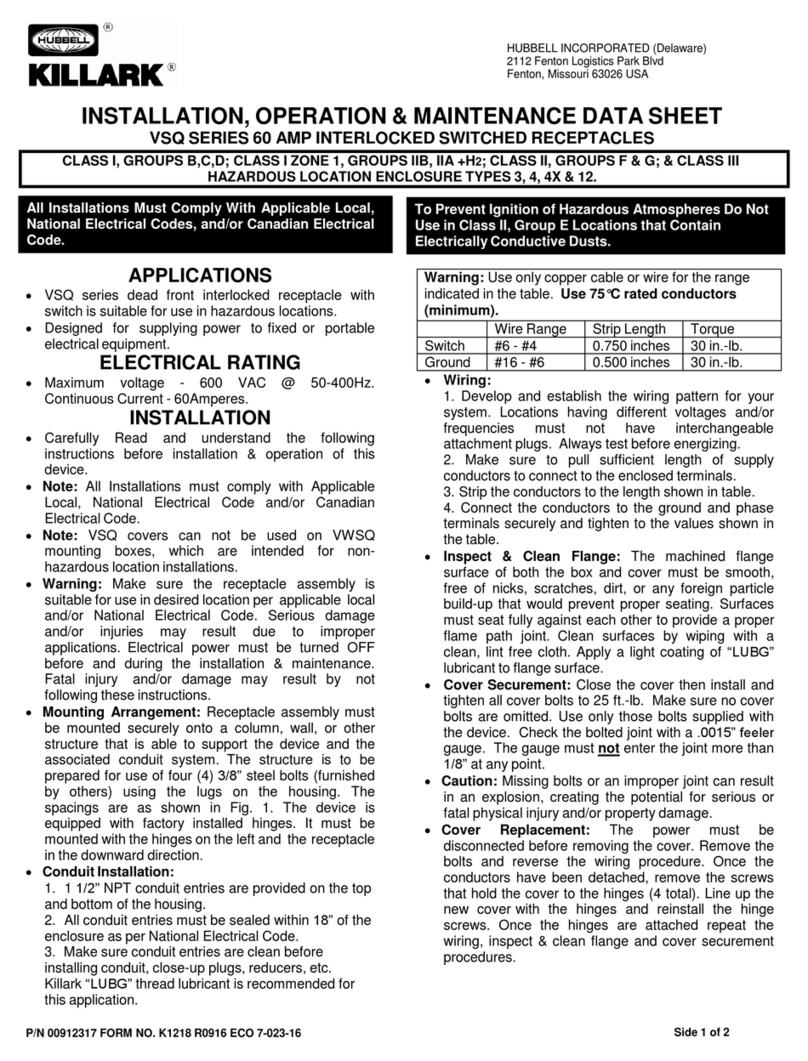

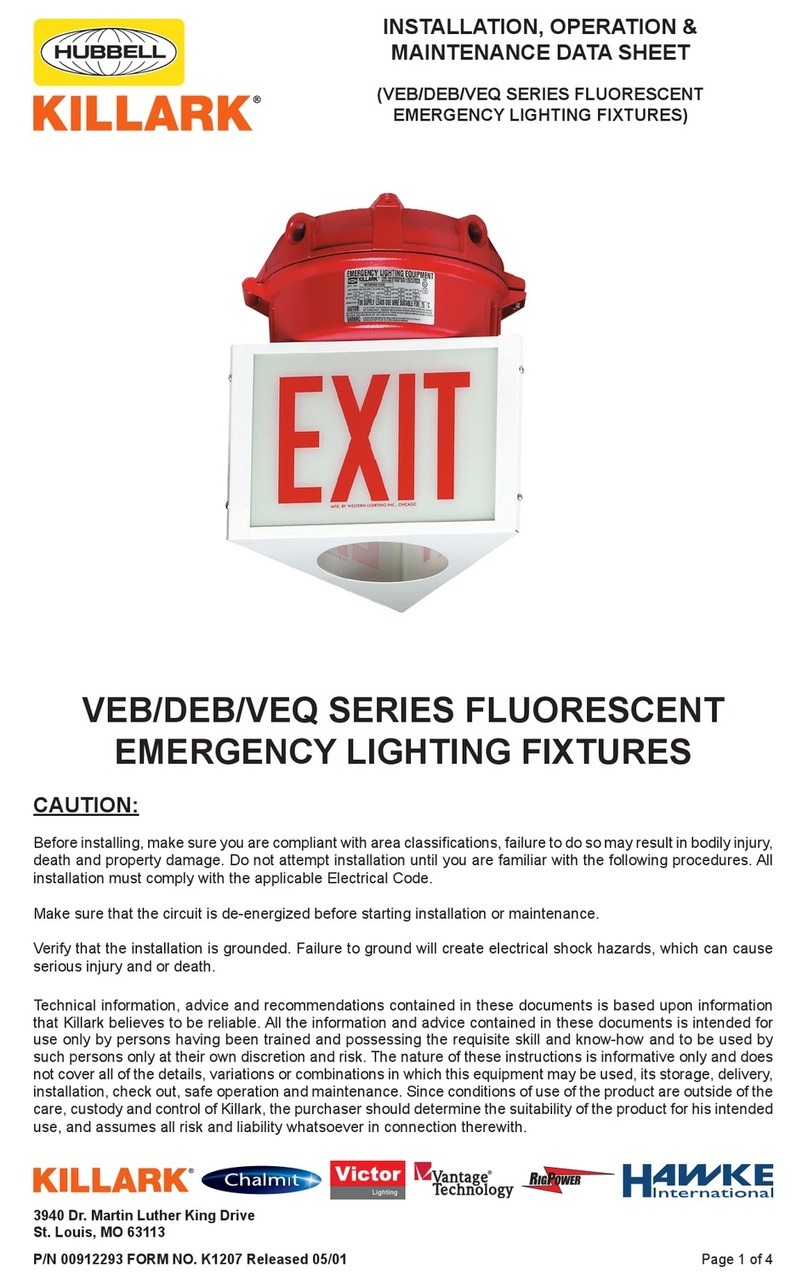

Class1, Division 2

Groups A,B,C,D

Class 1, Zone2

Groups IIA, IIB, IIB+H2, IIC

%HIRUHLQVWDOODWLRQHQVXUHWKDWXQLWVFRPSO\ZLWKKD]DUGRXVDUHDFODVVLÀFDWLRQ)DLOXUHWRGRVRPD\UHVXOWLQERGLO\

injury and/or property damage. To prevent ignition of hazardous atmospheres, area must be free of hazarous vapors

EHIRUHRSHQLQJHQFORVXUHRUVHUYLFLQJÀ[WXUHV7RUHGXFHWKHSRVVLELOLW\RIVWDWLFVSDUNLQJGRQRWDWWDFKPHWDOOLFSDUWV

to the outside of unit (i.e., metallic screws, tags decals etc.)

DO NOT ATTEMPT INSTALLATION UNTIL YOU ARE FAMILIAR WITH THEFOLLOWING PRECAUTIONS AND PROCEDURES.

CAUTION: SERVICE BY QUALIFIED PERSONNEL ONLY.

DE-ENERGIZE BEFORE OPENING.

Temperature Codes and Maximum Temperature Ratings

Operating Temperature In Cº

Ambient Cº CLASS 1 DIV. 2 A,B,C,D Supply Wire Temp. C º Min.

50 T3C; TYPE4X 75